Think about how your phone, laptop, or car’s control system works. Each one depends on a printed circuit board (PCB) inside it. These boards keep electronic components connected and working correctly. But one hidden factor makes all the difference in how durable a PCB is, the material’s Tg value.

The term Tg refers to the glass transition temperature in PCB manufacturing. Tg is the temperature where the PCB’s resin system changes from rigid to soft , not a heat-resistance limit, but a key indicator of thermal stability. Understanding Tg helps engineers design more reliable circuit boards. PCB Runner highlights the importance of picking the right Tg value for both core and pre-preg materials so every board can handle real-world heat and stress.

At PCB Runner, a leader in PCB production in the UK, we emphasize selecting the right Tg for both core and pre-preg materials to ensure superior performance, longevity, and manufacturing precision.

What Is Tg and Why Does It Matter in PCBs

Definition of Tg

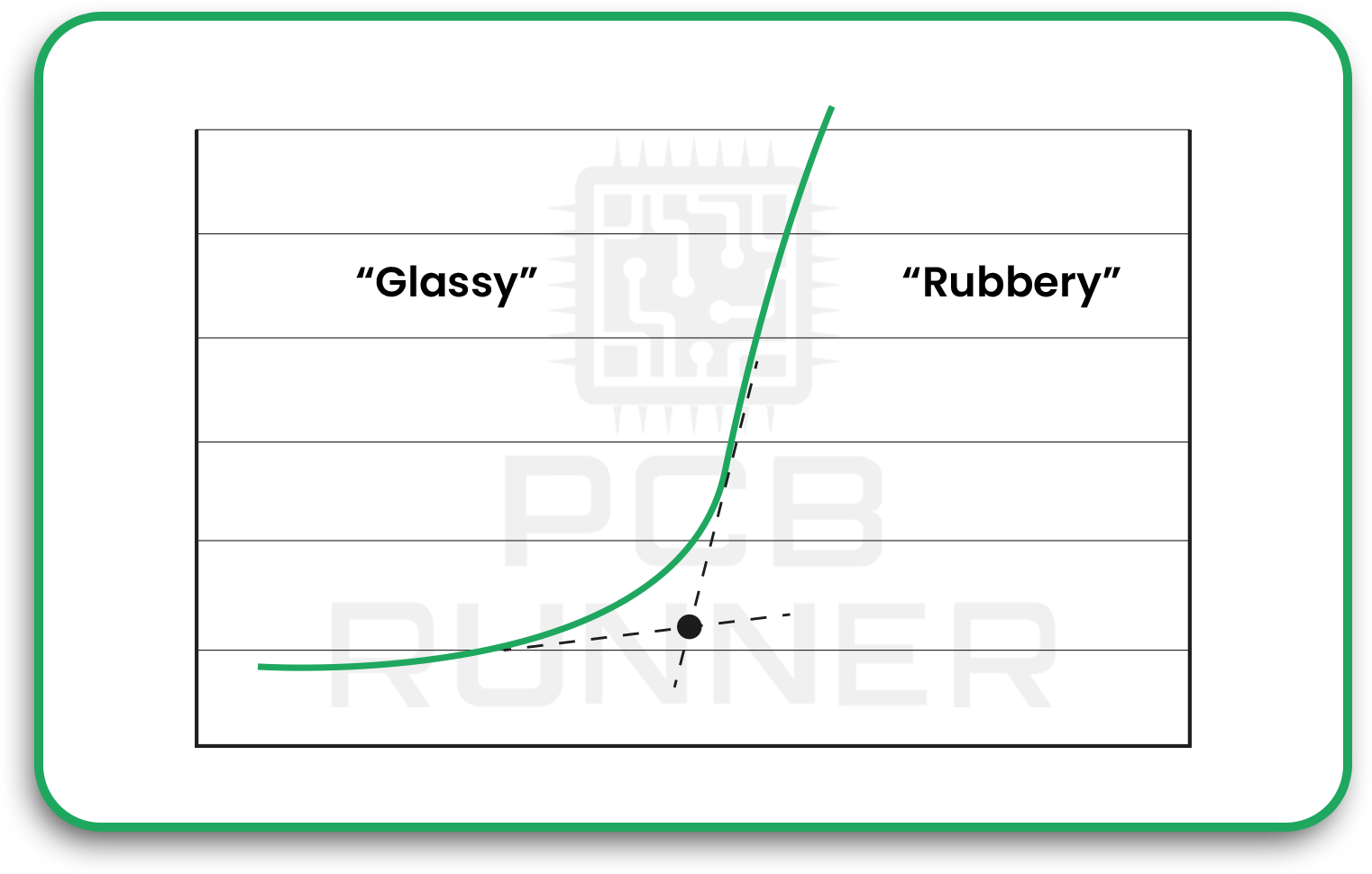

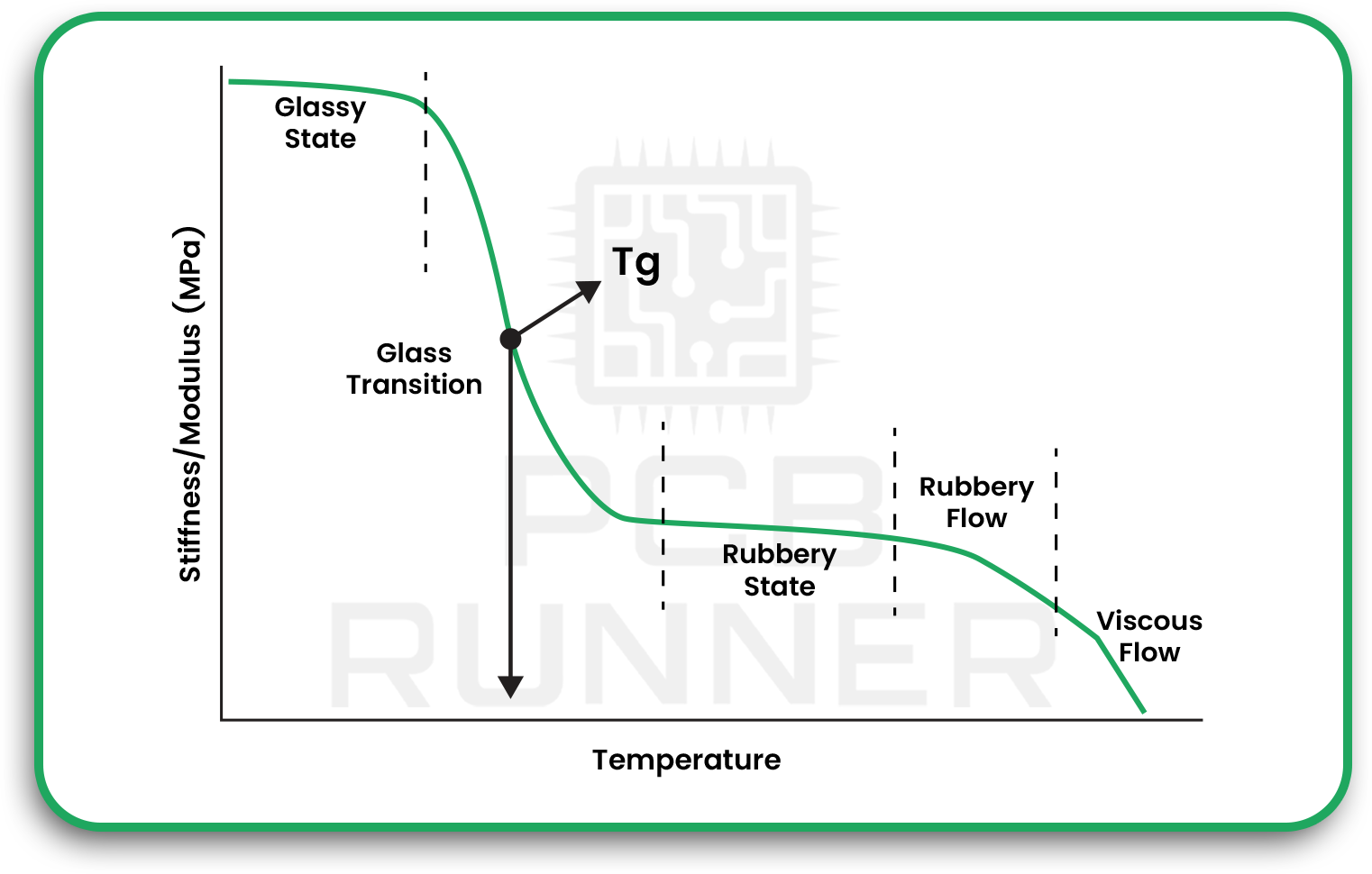

Tg is the temperature at which the PCB’s resin system , not the glass fibre itself , changes from a rigid to a rubbery state. Below Tg, your board stays firm and stable. Once the heat rises above that level, the material becomes flexible and loses its shape.

During PCB manufacturing, the board faces high heat when components are soldered or when the layers are laminated together. So, selecting a proper Tg value helps the board stay stable and strong throughout the entire process.

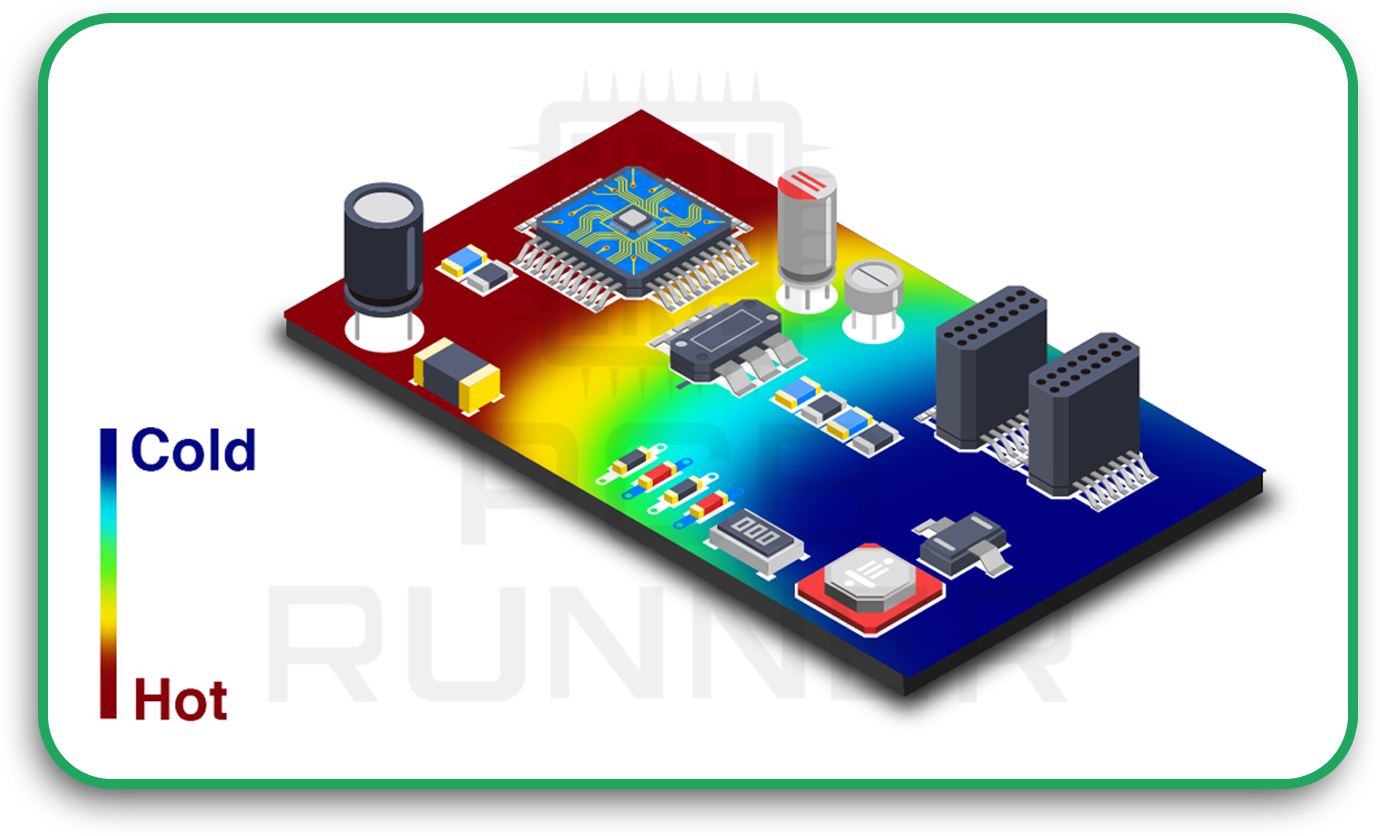

Relationship Between Tg, Heat, and Reliability

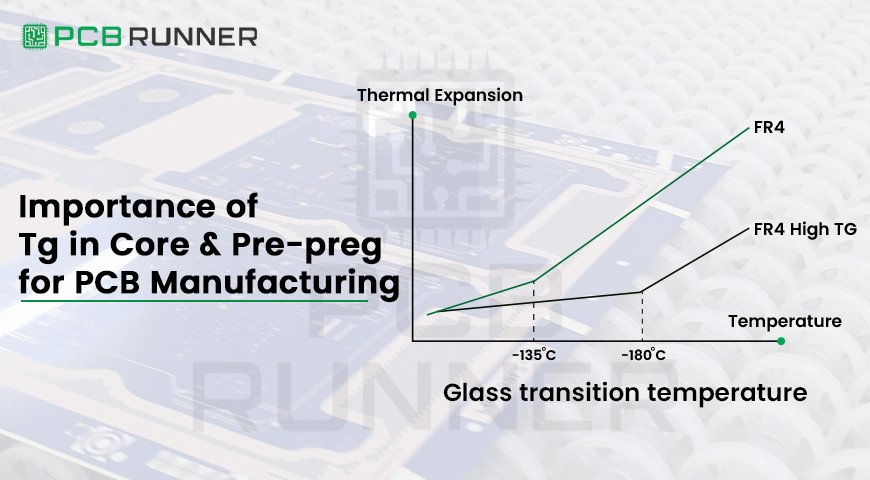

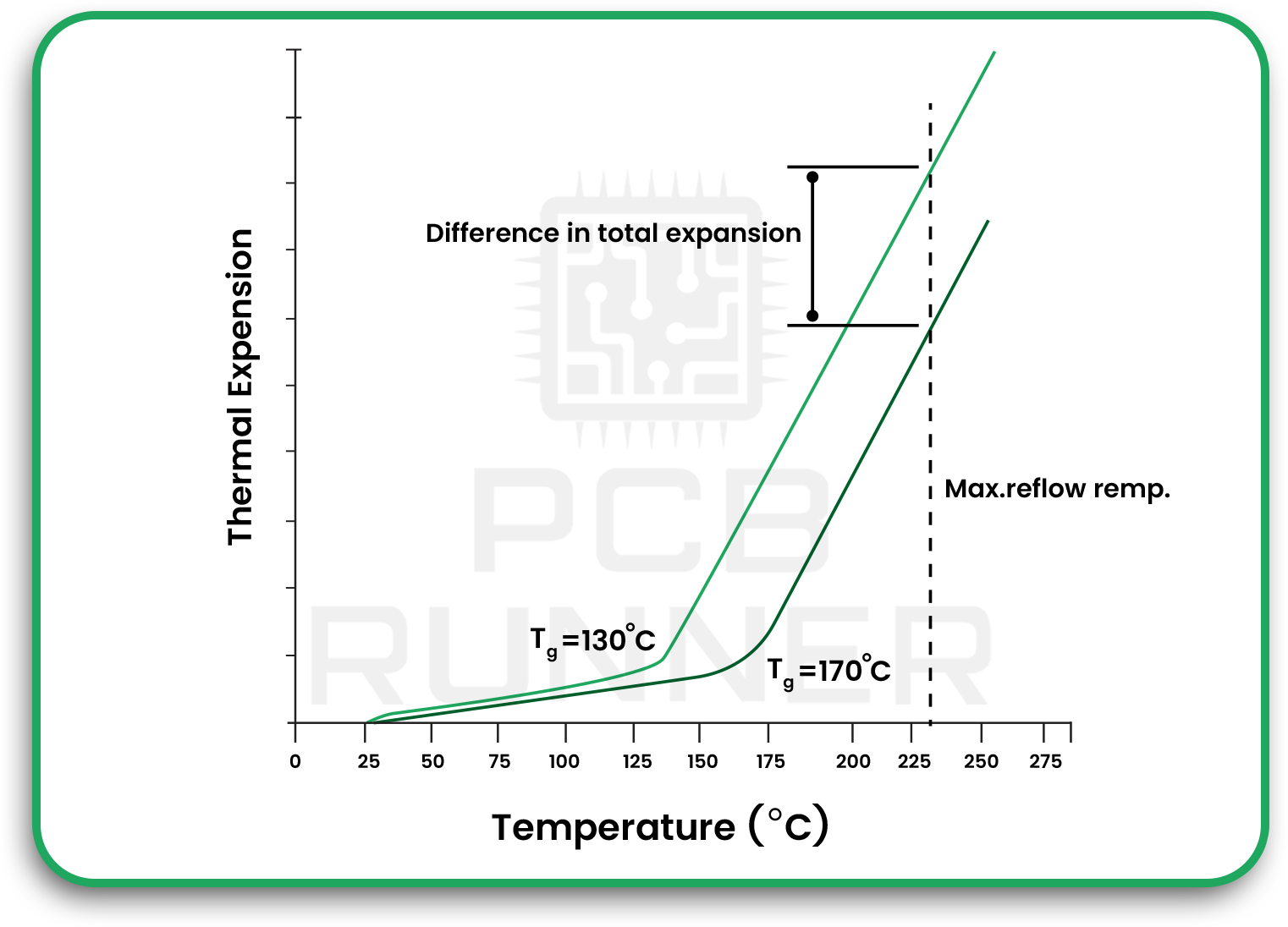

When a board heats during assembly or operation, it expands; when cooled, it contracts. If Tg is too low, it cannot handle this change. Cracks, warping, and broken connections can follow. Boards with a higher Tg can survive repeated heating cycles, keeping your circuit reliable for years.

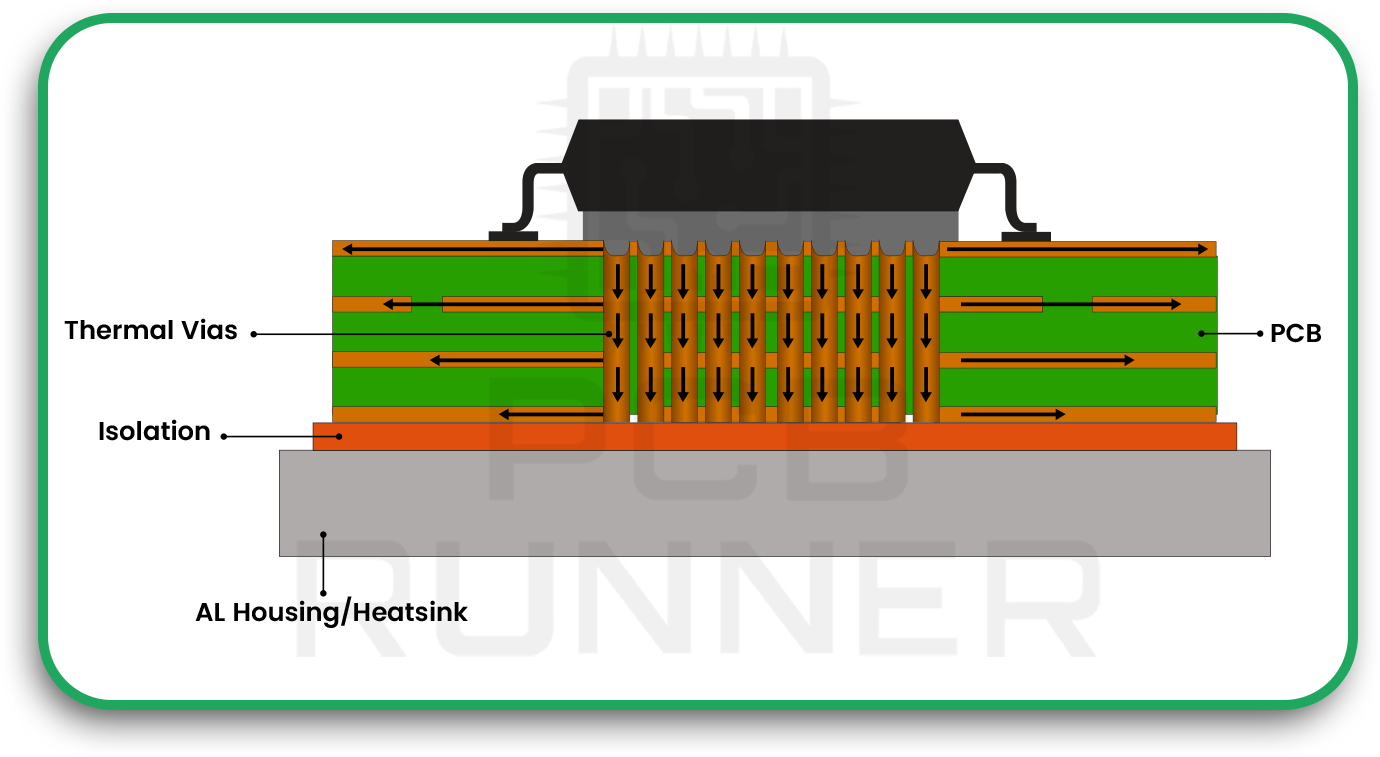

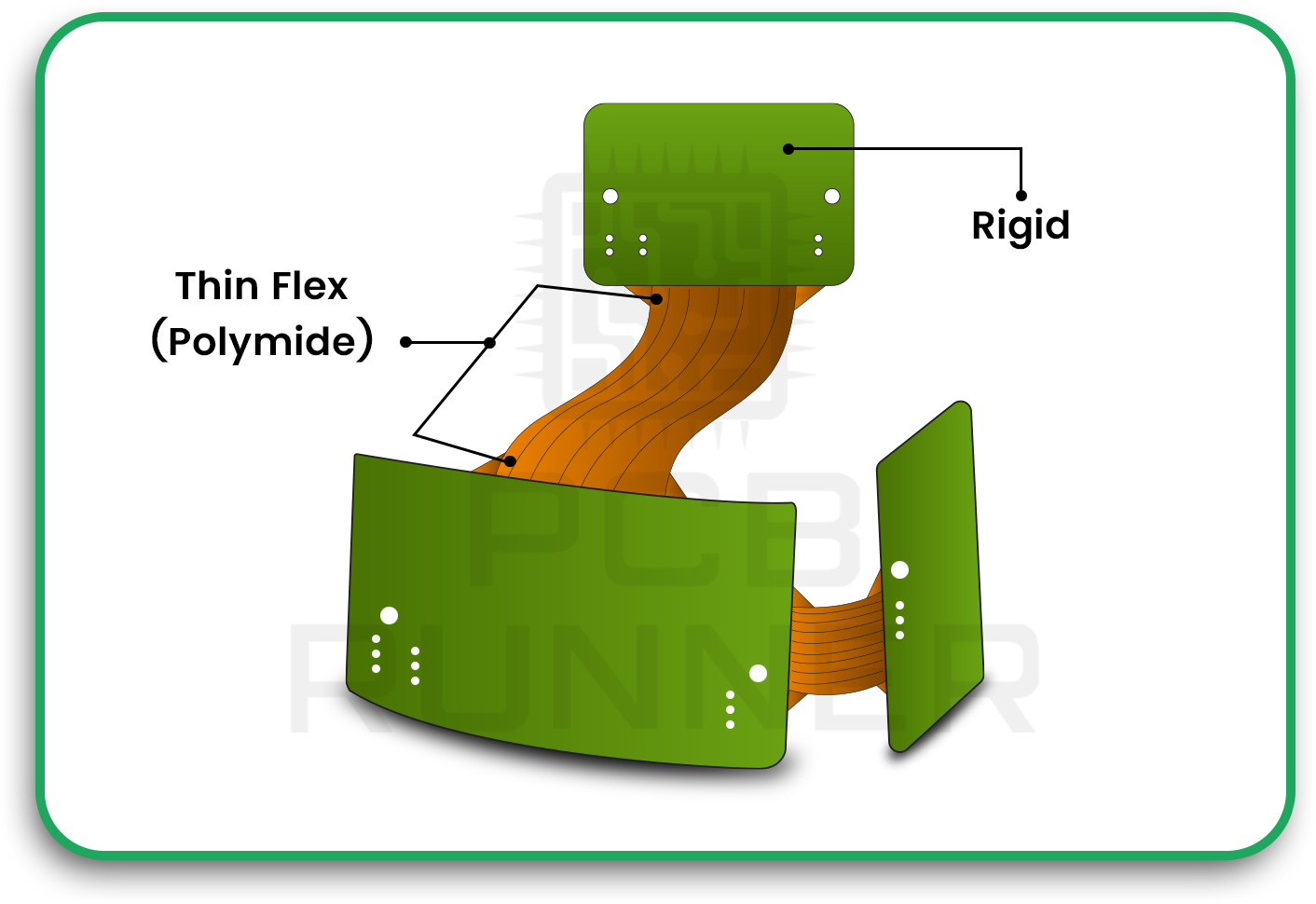

Core and Pre-preg Materials – The Building Blocks of a PCB

What Are Core and Pre-preg Layers

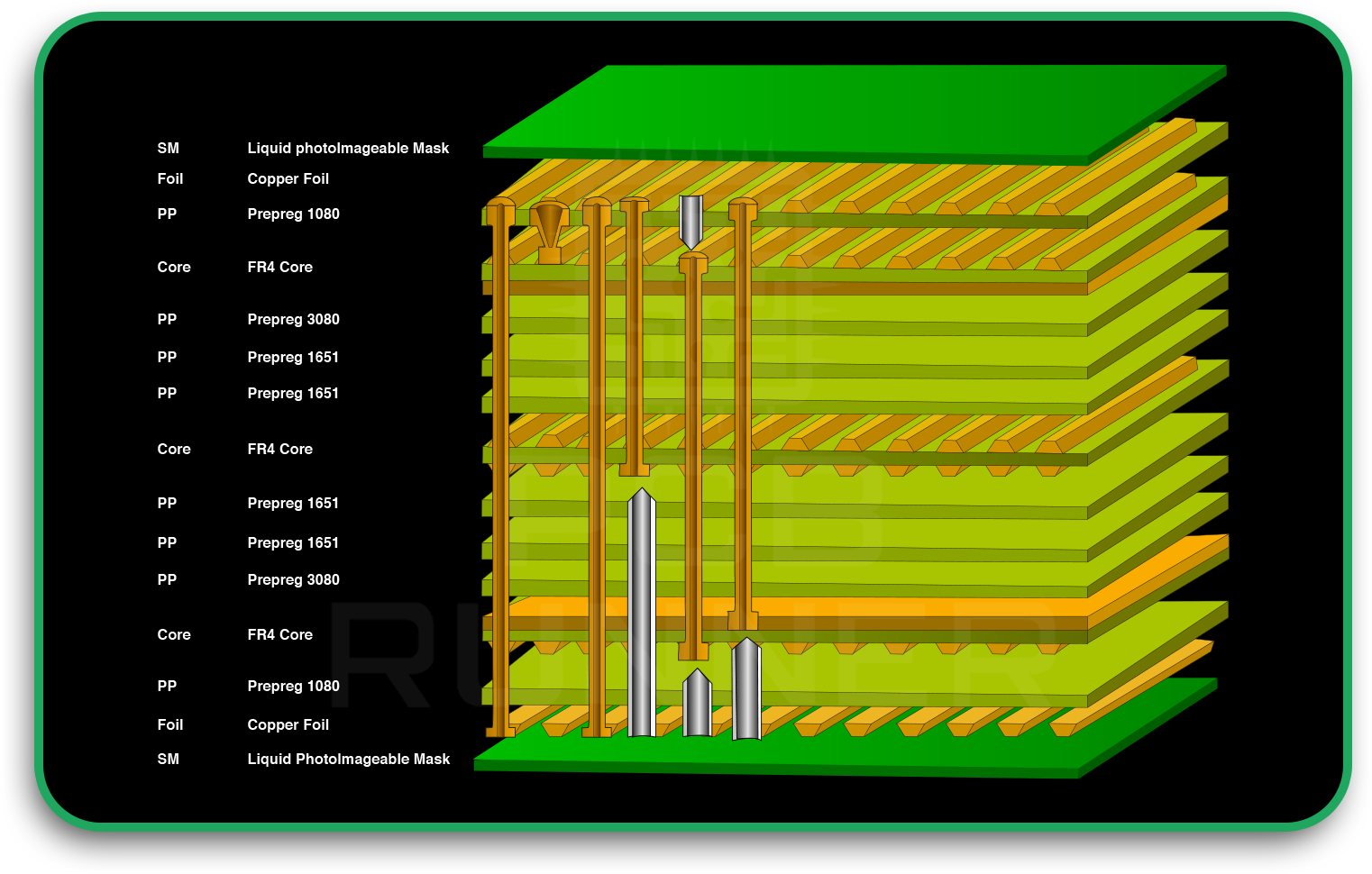

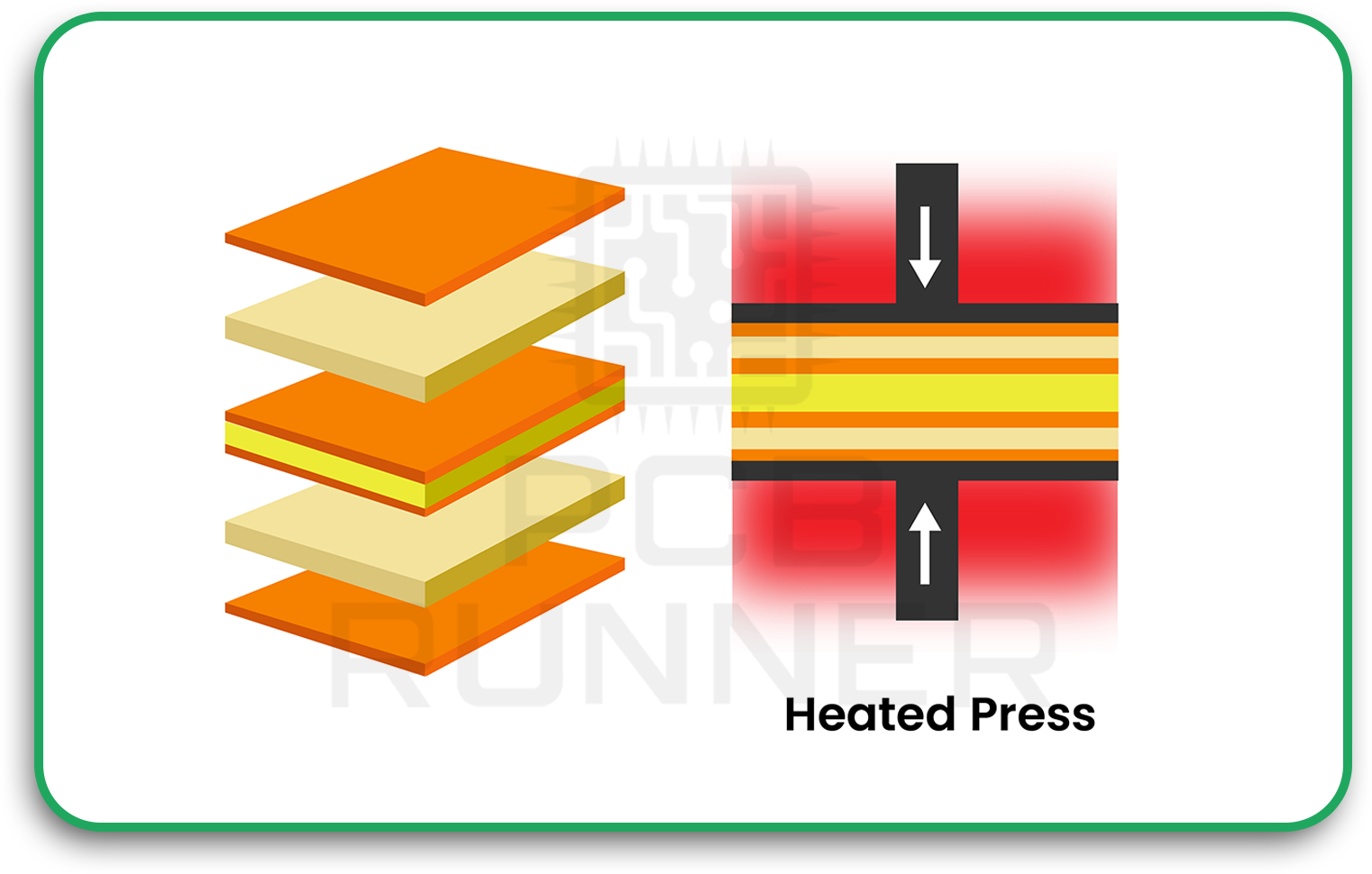

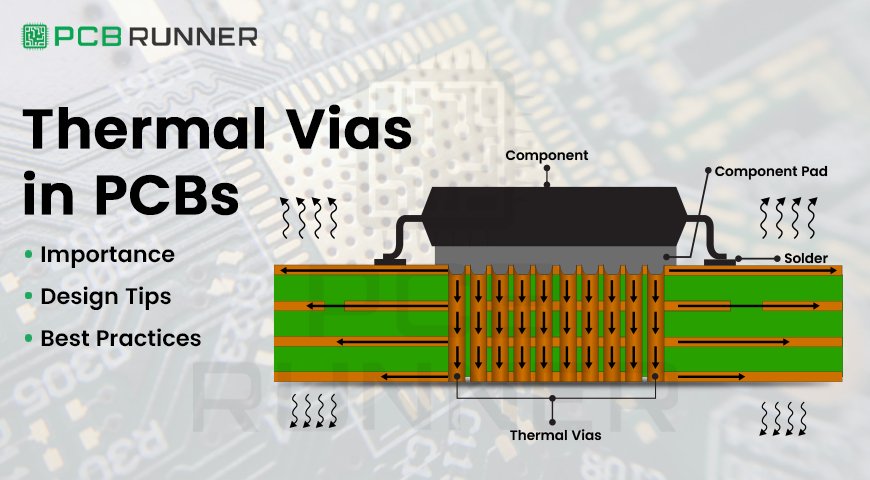

A PCB is made of multiple layers joined together. The core is a stiff sheet made of fibreglass and resin. The pre-preg is a layer of fibreglass cloth coated with partially cured resin. When both are heated, they bond to form one strong, solid unit.

These layers decide how thick your PCB will be and how well it can handle heat and mechanical stress.

How Tg Affects Core and Pre-preg Performance

The Tg of the resin directly affects mechanical strength, dimensional stability, and bonding quality during lamination. Low-Tg pre-pregs can soften or warp when heated during lamination. Layers might become unevenly bonded as a result. The board will maintain its shape, resist delamination, and handle thermal stress with a high Tg core and pre-preg material.

Types of Tg Materials Used in PCB Manufacturing

Standard Tg Materials (≤130°C)

These are fine for simple consumer electronics like toys or basic gadgets. They are cheaper but not built to handle high temperatures for long periods.

Mid-Tg Materials (130–170°C)

These materials work well in industrial or automotive products where boards face moderate heat. They strike a balance between cost and durability.

High-Tg Materials (>= 170 °C)

High-Tg materials are commonly used in defence, aerospace, and high-performance computing applications. They can handle multiple soldering cycles as well as high-speed signals and mechanical strain with no problem. A majority of manufacturers of printed circuit boards in Europe use high-Tg laminates to ensure longevity and reliability.

The Effects of Tg’s on PCB Properties

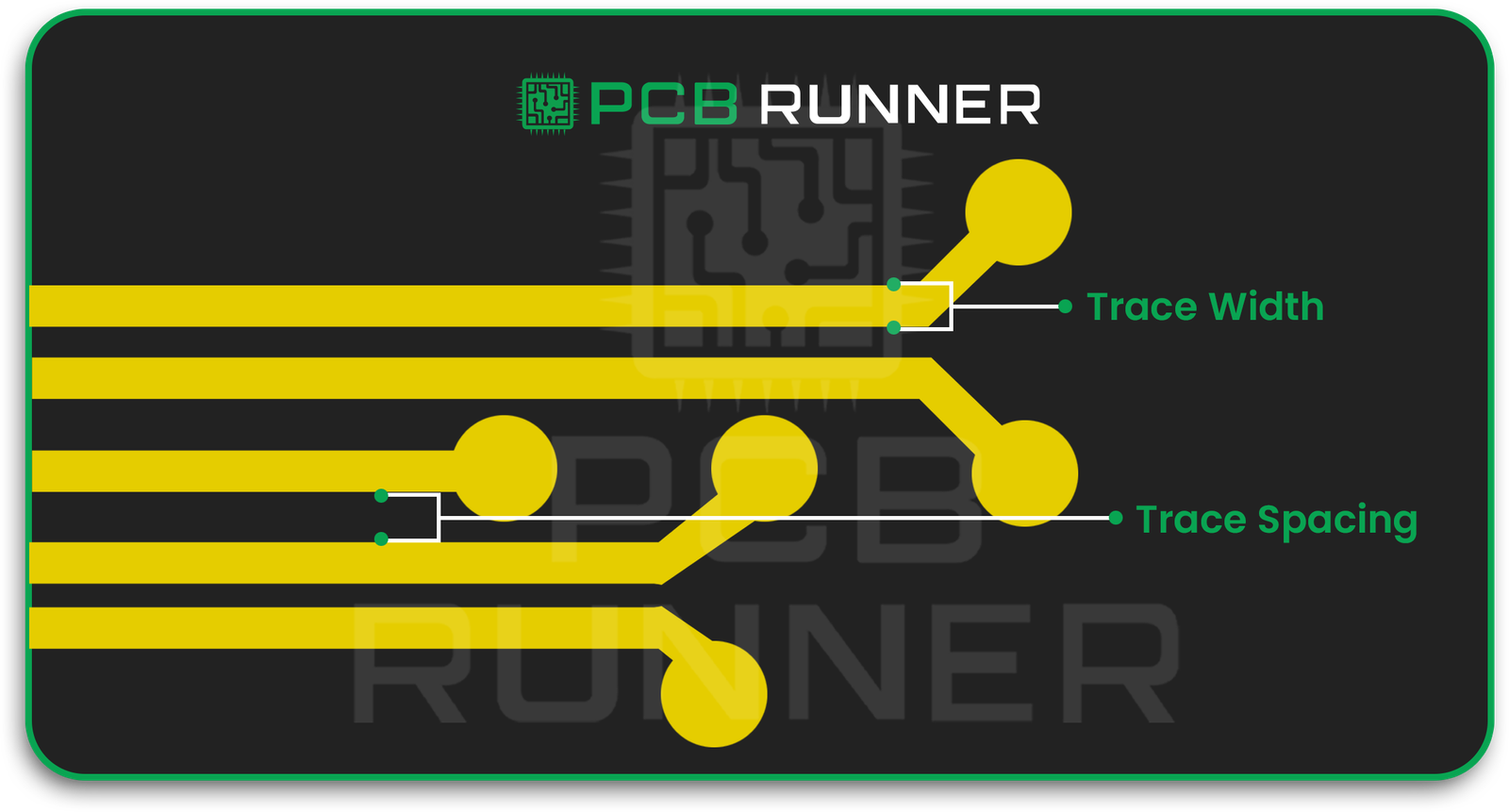

Dimensional Stability

A higher Tg material maintains dimensional stability at elevated temperatures. This stops copper traces or connections from shifting or bending off-centre.

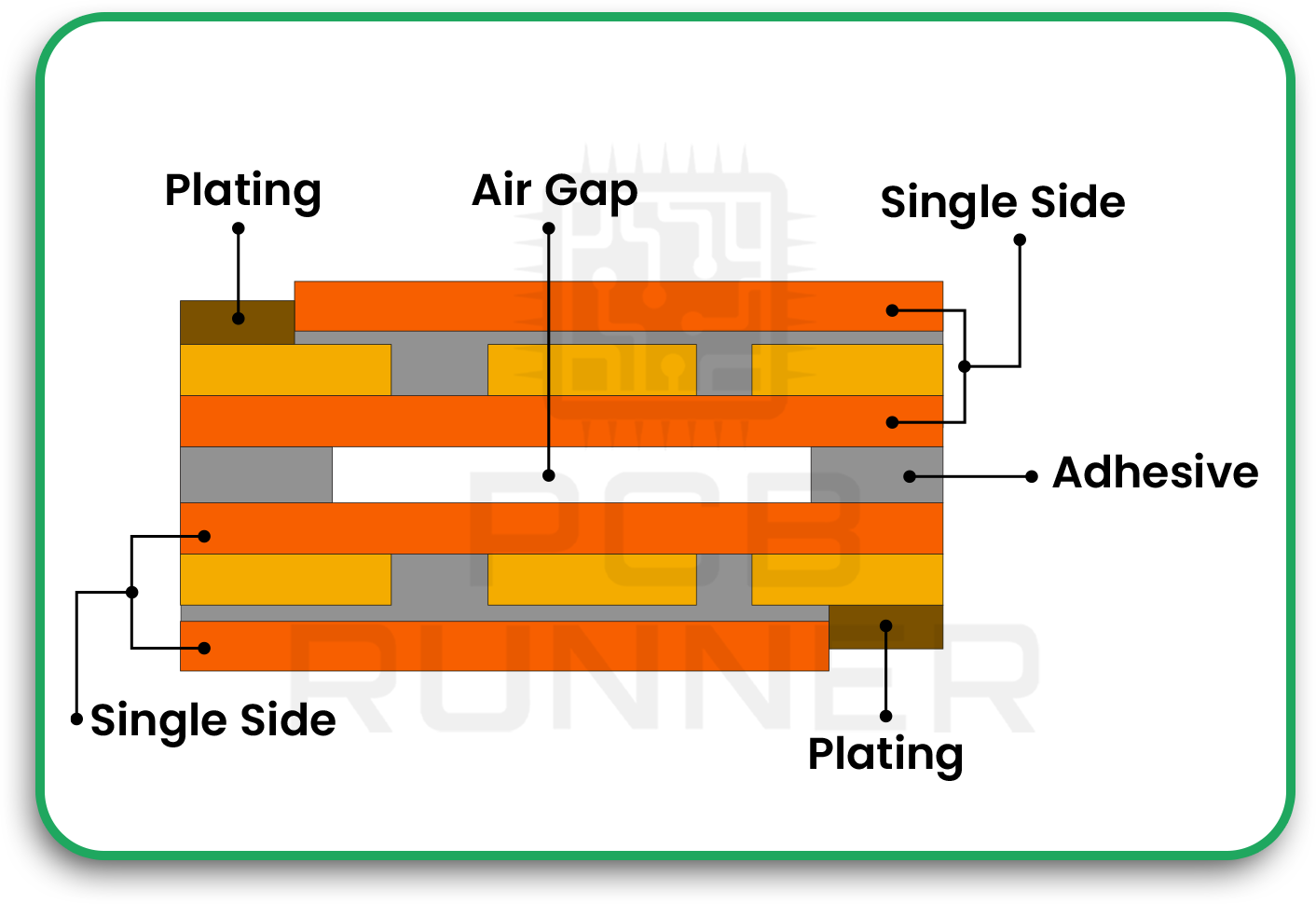

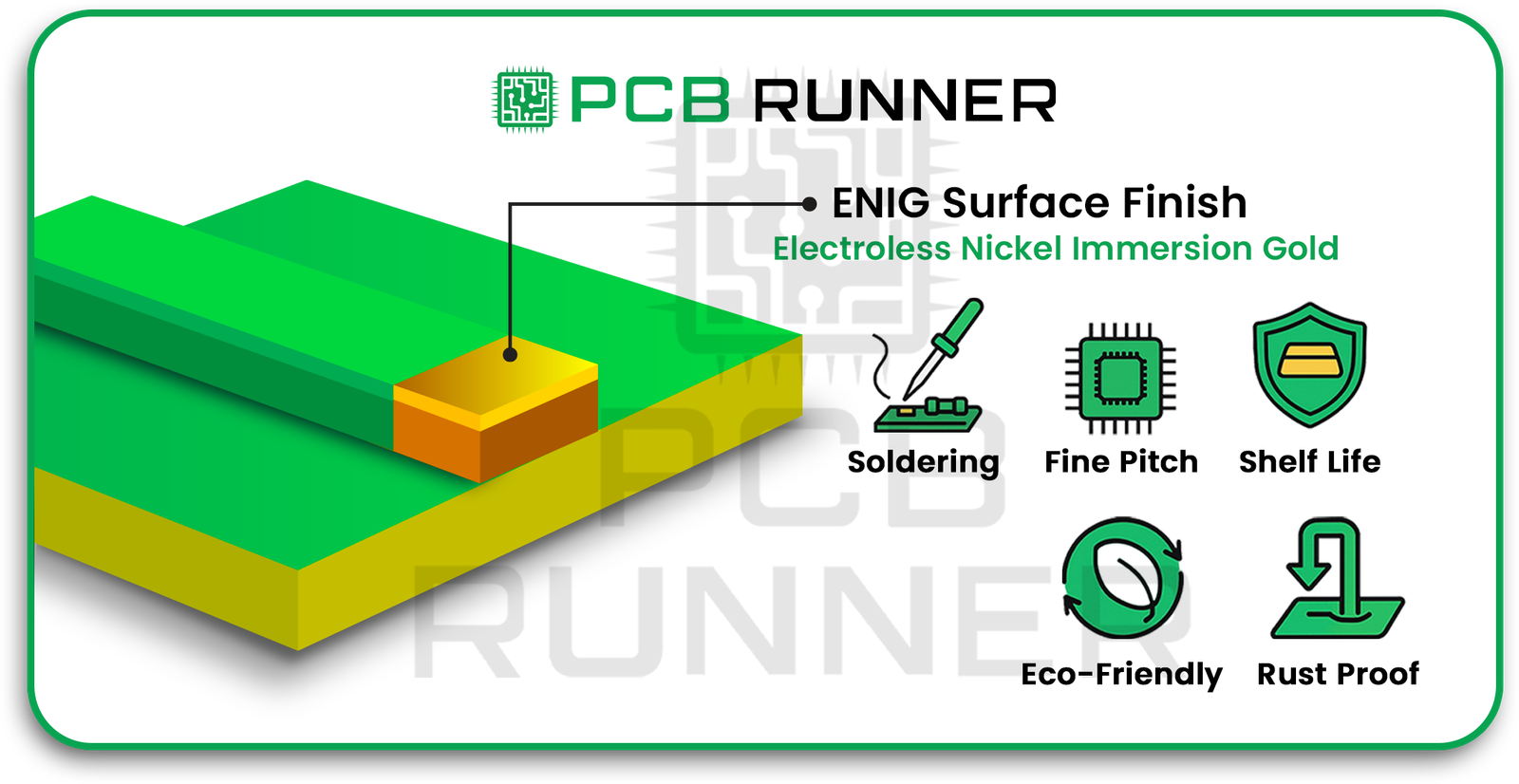

Lamination Quality and Delamination

Low-Tg materials may delaminate during soldering or lamination due to resin softening. Good Tg guarantees a solid bond between the layers, and also prevents the entrapment of air or gaps.

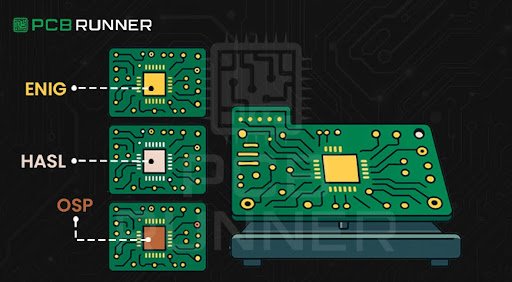

Soldering and Assembly Tolerance

If components have soldered on, the heat generated can cause boards with low Tg to crack. This issue, also known as the tombstone defect in PCB assembly, occurs when one end of a surface-mount component lifts during soldering. Low-Tg materials can worsen the tombstone soldering defect by allowing minor warping under reflow heat. High-Tg boards help prevent these issues.

Electrical Performance

Higher-Tg materials tend to maintain stable dielectric properties under heat, supporting consistent signal integrity. It can help prevent signals from being lost as well as short circuits and leakage currents, particularly in high-frequency or high-density circuits.

Tg. CTE and Thermal Expansion – How Do They Connect

What is CTE? ( Coefficient of Thermal Expansion)

CTE is the measure of how much a substance increases when it is heated. Different PCB materials expand at different rates when heated, which creates mechanical stress between layers.

The reason why matching CTE is Important

When the thickness of the layer and its CTE don’t align, the laminates could slide away from one another in the course of cooling and heating. Choosing materials whose CTE values are well-matched minimises expansion mismatch and reduces the risk of layer separation. This means fewer cracks and more reliability of your circuits.

Selecting the Right Tg for Your PCB

Factors That Affect Tg Choice

The best Tg will depend on a couple of essential elements:

- The maximum temperature your device can reach during its time of operation

- The number of thermal cycles the board will experience

- Design and thickness of the board complexity

- Environmental factors like vibration, humidity, as well as contact with the elements

When to Select High-Tg Materials

Make use of high-Tg materials for PCBs that undergo lead-free soldering that requires greater temperature reflow. Also, opt for it if your device is over a long period of time or has a variety of fine-pitch parts.

UK PCB manufacturers for automotive and industrial sectors typically use high-Tg materials due to the consistent heat loads and lengthy operating times.

At PCB Runner, our sales engineers are there to help you select the ideal Tg materials for your application by balancing cost, performance, and manufacturability at sales@pcbrunner.com.

Test and Measurement of Tg PCB Materials

How Tg Is Measured

Engineers employ tests such as Differential Scanning Calorimetry (DSC) and Thermomechanical Analysis (TMA) to determine the Tg. These tests gradually heat the material and monitor its physical or dimensional changes to identify the glass transition point.

Why Consistency Matters Between Suppliers

Two different suppliers might list the same Tg in their products; however, slight variations could still be present. A difference of 5-10 degrees Celsius could affect the reliability of the board. Make sure you check the Tg value prior to mass production to prevent surprises in the future.

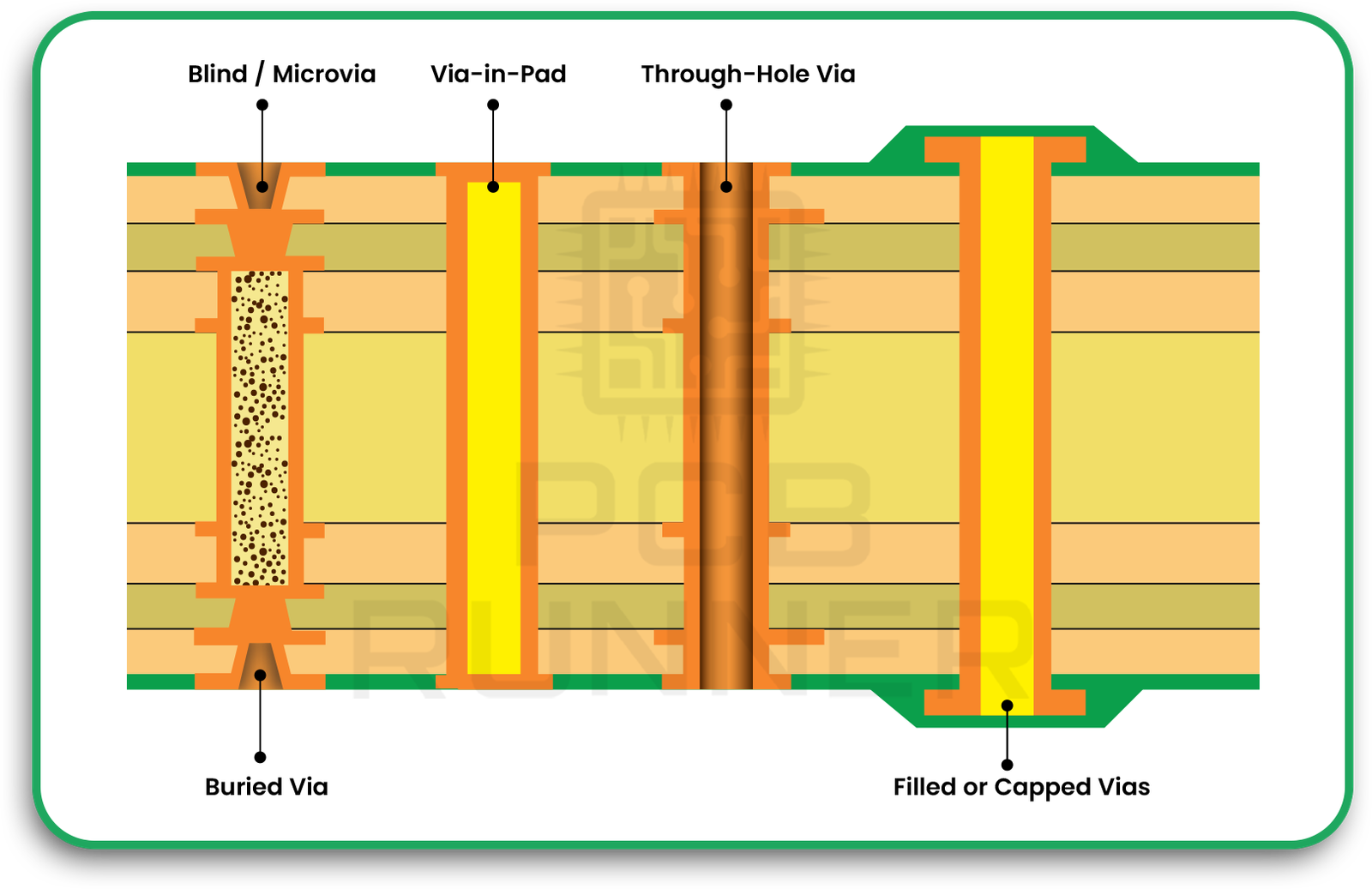

Common Issues from Wrong Tg Selection

Using materials with the wrong Tg can cause serious manufacturing issues:

- Tombstone issue and soldering problems

- Layer separation or delamination

- Cracked vias due to uneven expansion

- Reduced reliability under high temperatures

However, using materials with improper Tg can indirectly increase the likelihood of the tombstone defect by altering how heat distributes across the board. Inconsistent reflow profiles or laminate stress can amplify the tombstone effect PCB during assembly.

How to Ensure Proper Tg Handling During PCB Manufacture

Connect with Tg Requirements for Fabricator

Be sure that the fabricator is aware of your desired Tg requirements when you are designing the layout. This allows them to select the correct materials and profiles for lamination.

Control Lamination Temperature and Duration Carefully

Rapid heating or cooling can create internal stresses that weaken the resin bond. The controlled temperature keeps Tg values in check throughout the bonding process.

Do not use multiple thermal cycles.

Reduce the number of times the board gets heated during the process of manufacturing. Fewer cycles means greater Tg retention and better layer stability.

Utilise trusted material suppliers

Choose trusted suppliers that test and validate their products. Companies such as PCB Runner confirm the quality of the laminates they employ to ensure accurate and consistent Tg ratings during production.

Technology and Emerging PCB Technologies

As electronics develop, PCBs must be able to handle higher power and have faster speeds. High-Tg materials are increasingly essential in electric vehicles, renewable energy systems, and 5G electronics.

Certain new materials contain the advantages of high Tg along with low dielectric losses to help design engineers process signals more quickly and with less heat accumulation. Europe’s PCB manufacturing industry is continuing to develop new materials to meet the increasing technical requirements.

Conclusion

The term “tg” may look like another technical word, but it plays a significant role in the performance of your PCB. It determines how well your board handles heat and soldering throughout its lifetime. A PCB made with the right Tg materials maintains its shape, bonding strength, and electrical performance under demanding conditions.

For designers, engineers, and production teams from Europe, knowing Tg can mean lower defects, more streamlined assemblies, and greater reliability. Collaboration with trusted partners like PCB Runner ensures each stage of the PCB manufacturing procedure is executed using the correct materials and a carefully controlled temperature.

By managing heat distribution, choosing appropriate Tg materials, and controlling reflow profiles, manufacturers can minimize common soldering issues such as the tombstone defect and tombstone soldering defect. Awareness of how Tg interacts with soldering temperature helps prevent the tombstone defect in PCB assemblies and improves yield across production.

FAQs

Q1: What is Tg in PCB manufacturing, and why do printed circuit board manufacturers care about it?

Tg is the temperature at which the PCB base material changes from solid to soft. Printed circuit board manufacturers consider Tg essential because it guides how well the board will handle heat during production and use.

Q2: How does low Tg lead to the tombstone defect in PCB assembly?

Low Tg materials may warp during reflow soldering, causing parts to lift or shift. This leads to the tombstone soldering defect, where one side of a small component stands up instead of sitting flat. Engineers also refer to this as the tombstone defect in PCB assembly or tombstone effect PCB, both describing the same lifting issue caused by uneven heating.

Q3: How is Tg tested during PCB production in the UK?

In PCB production in the UK, Tg is tested using heating analysis tools that show how the material reacts to temperature changes. The readings ensure consistency and reliability before boards go into assembly.

Q4: What happens when a PCB’s Tg is too low for its application?

A board with low Tg can suffer from delamination, warping, cracking, and poor soldering results. It can also experience the tombstone defect during assembly if heating isn’t well-controlled.

Q5: Why do European printed circuit board manufacturers prefer high-Tg materials?

High-Tg boards are durable, dimensionally stable, and can handle demanding environments. This is why European printed circuit board manufacturers use them in automotive, aerospace, and power systems.