You choose the finest components. You adhere to the guidelines. But if you skip the final coat of paint, the car will rust and fade. That’s akin to what a PCB (printed circuit board) can undergo if you omit the final protective layer, which is a surface finish.

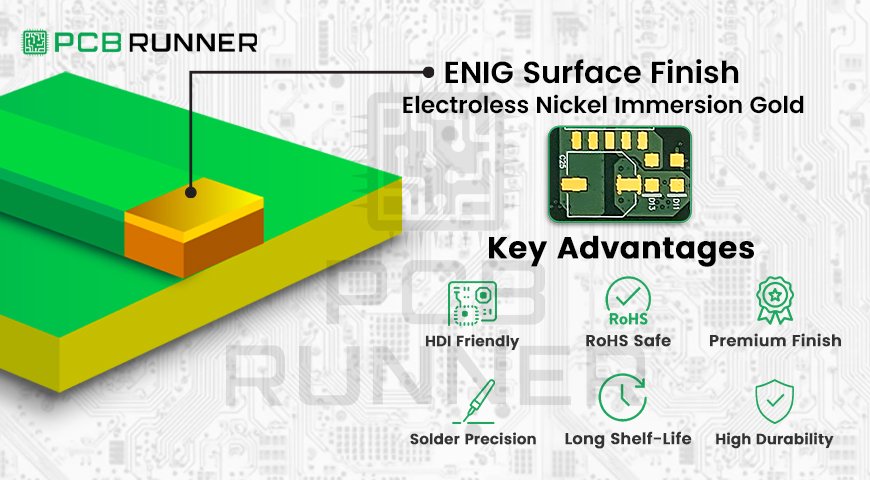

In electronics, surface finishing adds value by protecting, joining, and increasing functionality; it integrates more advanced features. From many alternatives, ENIG surface finish is recommended for new designs as well as on dependable circuits. ENIG stands for Electroless Nickel Immersion Gold.

Let’s see what features encourage engineers and makers, as well as the finest HD IC PCB suppliers, to choose ENIG.

What is ENIG Surface Finish

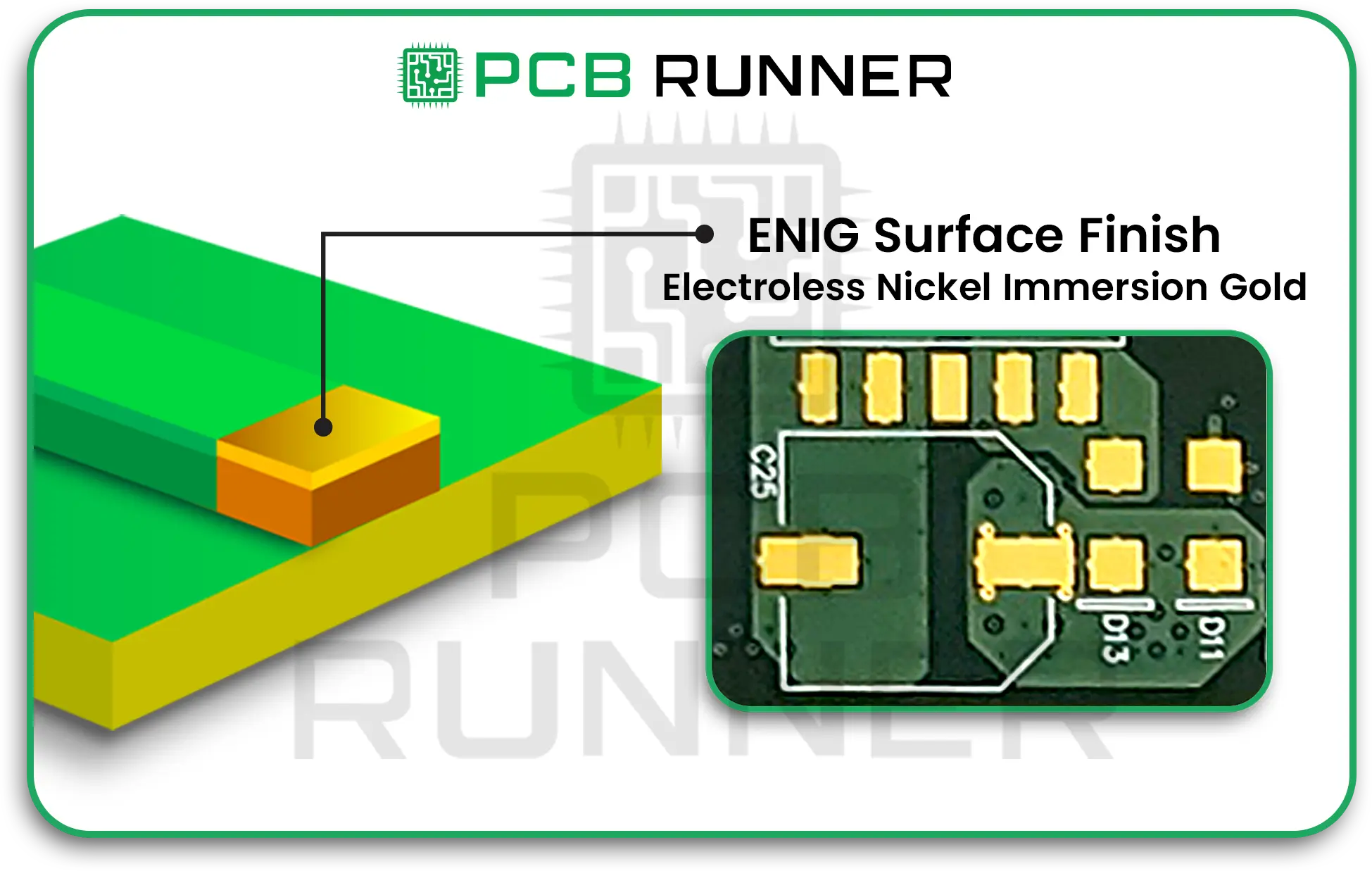

A PCB surface finish ENIG is two thin layers of a bottom layer of nickel as a base, and a thinner overlay of gold as a thin layer on the PCB gold finish. All layers of copper pads in every PCB are plated with nickel to protect the copper. Gold will keep the Nickel and enhance the surface finish. This helps to maintain the longevity, function, and preservation of the board throughout usage, exposure, and environmental conditions.

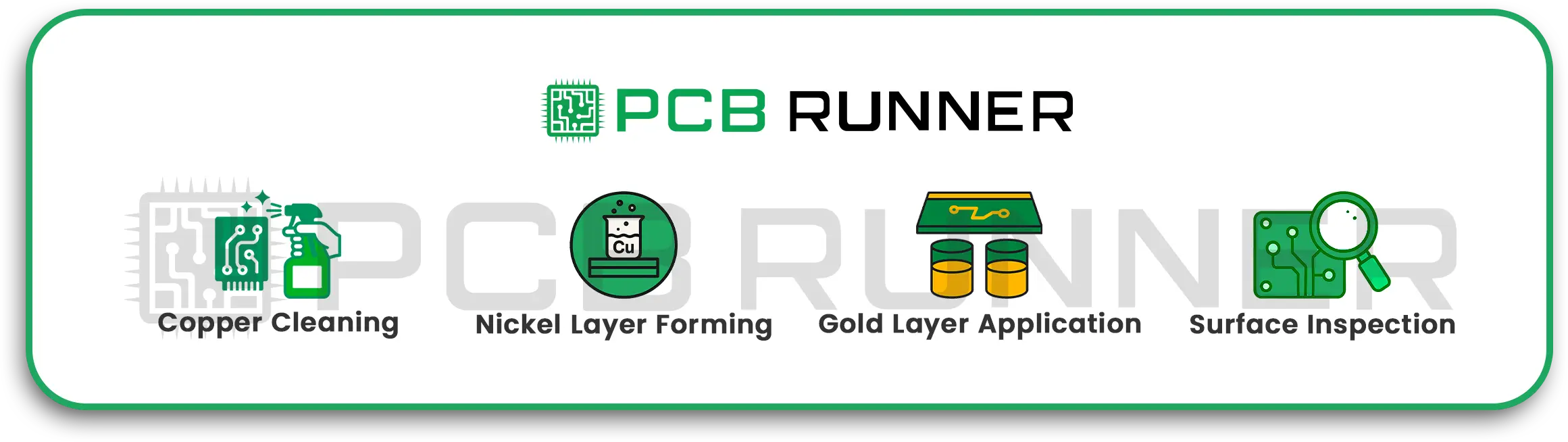

ENIG Surface Finish: The Working Steps:

Step 1: Copper Cleaning

Wash the copper surface of the board to remove dust and oily materials.

Step 2: Nickel Layer Forming

The board is immersed in a nickel layer-forming solution, where a layer of nickel is deposited, protecting the copper.

Step 3: Gold Layer Application

Roll the board to gold bath 2, where gold is deposited as a thin layer on the surface.

Step 4: Surface Inspection

Every step is verified. The result is a surface enduring a flat and durable finish of high quality, which is ready for assembling the board.

Why ENIG? The Key Advantages

1. Amazing for Fine Pitch and High Density (HDI PCBs)

If you are passionate about compact and innovative technology like smartphones, tablets, and wearables, you are familiar with the need for densely packed components on PCBs. ENIG surface finish is perfect for these dense, tiny components and ensures HDI PCBs are equally complex and compact.

2. Soldering Accuracy Improvement

Think of glue that works so effectively, it can be unreliable at times. ENIG entirely smooth surfaces that give u even finishes allow for soldering ( the installation of chips and wires on boards) to be done with precision. Every hinge and turn can now be done with precision.

3.Durability and Resistance

Devices that decide to malfunction and ‘quit’ early are something we can all agree on. ENIG surface finish protects boards much like a military grade armour plating. It works effectively at preventing rust and all forms of corrosion. When combined with harsh conditions, such as humid or coastal climates, the outer layer of gold nickel is like the shields of your devices, helping them function for a long longer.

4. ENIG is RoHS Compliant

More and more restrictions are being put in place for the harmful components that can be added to finishes. ENIG gold surface finishes are now marked as being non-toxic and safe for the environment.

5. Extended Storage Availability

Have your plans fallen behind schedule? ENIG is able to keep your boards “fresh” longer. Boards using ENIG finish can often be kept for months or even years without any significant performance degradation or extensive cleaning prior to assembly.

6. Surface Finish Quality

Performance also improves with ENIG, as its aesthetics are a significant consideration. This finish gives each PCB a mirror-like surface, which makes it possible to print fantastic traces onto the PCBs. Smooth assembly is also without any rough patches or bumps to ruin those tiny traces.

Real-World Example: ENIG and Modern Electronics

Have you ever had a look inside a smartwatch or a fitness tracker? They often contain a very compact gold-plated PCB, which is a hallmark of ENIG and its ability to keep these devices reliable and small, protecting them from sweaty wrists and bathroom splashes.

ENIG is the choice for automotive, aerospace, medical devices, and even smart home devices when the stakes are high and the space is at a premium.

ENIG Surface Finish vs. Other Surface Finishes

| Feature | ENIG Surface Finish | HASL Surface Finish | OSP/Other Types |

| Surface Flatness | Excellent | Not great for small parts | Varies |

| Solderability | High | Moderate | Moderate |

| Durability | High | Can crack/wear | Lower |

| Lead-Free | Yes | Often no (if leaded) | Yes or No |

| Lifespan | Long | Shorter | Short/Medium |

| HDI/Prototype Use | Ideal | Not preferred | Sometimes |

Where ENIG Excels: Product Highlights

- HDI PCB Applications: Ultra-small sizes, high complexity.

- PCB Prototype Runs: Perfect for testing new ideas where reliability matters.

- General PCB Printing: When you want predictable results and easy assembly.

- Sensitive Devices: Medical, aerospace, and defence use ENIG for maximum safety.

Suggestions to Consider for Various Project Types

ENIG is ideal for those working with HDI or congested areas. No tombstoning or chip-out “falling-out” is possible.

Best long-term durability performance? ENIG-prepped boards will not degrade over time.

Have to pass strict compliance? ENIG is lead-free and a widely accepted global standards which aid in passing compliance for numerous countries.

Trying out new concepts? ENIG’s ability for fast-turn prototyping takes the hassle out of turning ideas into reality.

The Human side: Build your ideas more effectively.

Imagine baking cookies: rushing the bake and not using non-stick leads to cookies baked and burnt, stuck to the pan. PCB finishing is the same. No cooking electronics “finishes” means electrons will “glue” to unwanted areas, causing critical device failures.

Struggling with chargers for devices? Everyone wants functioning devices and does not want to deal with devices turning into non-functioning bricks. ENIG’s finishing takes the worry out with reliability behind using getting connected without mystery breakdowns.

Addressing the Most Frequently Asked Questions:

Q. Is the cost of ENIG high?

A.It sure can be more expensive when compared to simpler finishes like HASL. However, it pays off in the long run by lowering defects, increasing yield, and enabling new designs.

Q. Is ENIG suitable for my prototype?

A. Yes. Many prototype shops, ENIG, which makes testing quick and dependable.

What about health and environmental standards? ENIG processes are lead-free, making them more supportive of eco-friendly policies.

Expert Insight: The Future of Surface Finishing

With the continuing miniaturisation and intelligence of electronic devices, finishes like ENIG will become increasingly common. The high demand for surface finish quality and ENIG’s consistent reliability and adaptability make it a perfect fit for advancing technology. To understand more about ENIG and its many benefits, read this guide.

Final Thoughts: ENIG and PCB Runner

In short, ENIG provides distinct value for builders, testers, or purchasers of complex PCBs. For professionals and hobbyists alike, ENIG’s smooth and robust finish makes it easy to anticipate future needs.

If you’re focused on maintaining rigorously high standards for boards, particularly for contemporary HDI designs and rapid prototypes, ENIG merits your consideration. For outstanding work, one can rely on PCB Runner, which offers unparalleled trust and top-grade surface finishing PCB fabrication for every project without compromise.

In the background, delivering the best for your electronics, enhancing safety, and preparing them for the future, ENIG and PCB Runner work hand in hand where innovation meets trust.