PCBs are made up of two main components: printed wires (the copper traces) and a substrate, or the board.

Substrates that divide the different layers are needed for multi-layer boards. The substrate acts as both an electrical insulator between conductive portions and a structural support for the printed wires and circuit components.

PCB substrates are incapable of conducting electric currents. They act as a layered electrical insulator between electronics for this reason. A material that does not conduct when subjected to an electrical current is known as an electrical insulator because its internal electric charge does not flow freely. As a result, plated through holes are used to connect traces on opposing levels in every layer of the circuitry.

Purpose of PCB Substrate

A printed circuit board is constructed using substrate as a base. A PCB’s electrical, thermal, and physical characteristics are determined by its substrate. Typically, substrates are dielectric composite structures made of epoxy resin combined with one or both sides connected with copper foil. The copper layer is then covered with a solder mask to shield it from other elements that can damage the copper traces.

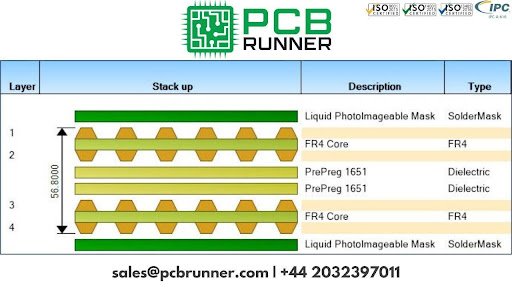

In multi-layer PCB, the laminate core is press between the substrate and all of the layers are bonded together with prepregs by applying high pressure and high temperature.

A PCB’s hard substrate enhances its strength and durability, whereas flexible substrates enable the construction of flexible circuits that may be bent and twisted without impairing signal flow. A PCB’s substrate determines its physical qualities.

Types of Multilayer Rigid PCBs Substrates

There are five different types of multilayer rigid PCBs substrates, each with special qualities for use in particular applications.

FR-2

This lower-grade substrate is composed of easily machined impregnated paper, sometimes known as phenolic, over a fiberglass substrate. Flame Resistant is what the name “FR” stands for. Typically, less priced consumer gadgets use this kind of substrate.

FR-4

Fiberglass substrates consist of a flame-resistant substance that has been impregnated into woven fiberglass. Although the material is stiff and can be drilled, cut, or machined, tungsten carbide tools are required since the fiberglass is abrasive. In comparison to a FR-2, a FR-4 substrate is stronger and more resistant to breaking or shattering and are typically found in more expensive devices.

RF (High frequency)

RF substrates are used in printed circuit boards for high power radio frequency applications. They are made of low dielectric polymers. The substrate exhibits remarkable electrical performance properties despite its weak mechanical attributes.

A dielectric is inserted between a copper layer and a sub-composite that has already undergone lamination as part of the sequential lamination process.

Sequential lamination can be used to incorporate buried and blind vias into a PCB. A PCB with buried vias is produced by first creating a layer with blind vias (as though it were a two-sided PCB) and then consecutively laminating this layer with an inner layer.

HDI boards go through this process more than once when varying via structure types and layer combinations are required.

PCB runner has the capability of following material for multilayer PCB substrates:

|

PCB Material/Substrate |

||

| Description | Standard | Advanced |

| Regular TG | FR4 140TG | |

| High TG | NANYA NP175, ITEQ IT180TC, IT180A | |

| High Speed | ISOLA 370HR, FR408HR, I-Speed, PANASONIC M6, M7, ARLON 85N (PI) | |

| RF & Microwaves | ROGERS 4350B, 4003C, 4450F , ROGERS 4835 | |

| Aluminum Substrate | VENTEC 4A2H – 2.2W/mK, MOT 105℃ ARLON 92ML – 2.0W/mK, MOT 90℃ |

|

| Halogen Free | NANYA NPG series (151, 170D, 186) | |

Thermal Benefits of PCB substrates

The electrical and thermal properties of PCB substrates:

A printed circuit board’s electrical and thermal conductivity are also determined by its substrate.

Important Thermal Characteristics:

The temperature at which a substrate material changes from a stiff to a soft state—or, to put it another way, melts—is known as the glass transition temperature (Tg). PCB boards should never run over the substrate’s glass transition temperature.

The temperature at which the PCB substrate material undergoes chemical breakdown is known as the decomposition temperature (Td).

Coefficient of Thermal Expansion (CTE):

CTE is a measurement of how quickly a material expands in the presence of heat. The enlargement will result in a size rise that could potentially cause internal stress and harm. To find out more about CTE, go here.

The rate at which a material conducts heat is determined by its thermal conductivity or k.

How Thermal Conductivity Affects PCB Temperature?

One of the many crucial elements of PCB design is selecting a substrate with an appropriate thermal conductivity. Smaller boards with fast-switching active components are more likely to require thermal management in PCBs, as are boards carrying high currents because resistive losses in a trace cause heat to be generated, which then transfers into the substrate.

It can be necessary to select a substrate with increased thermal conductivity if there is a likelihood that the board will produce a lot of heat while operating or if it will be used in a hot environment. Maintaining the temperature of crucial components within their acceptable operating range may also require the use of passive cooling, active cooling, or both.

Evaluating Other Material Properties and Thermal Conductivity

Strong heat conductivity PCB substrate materials are known to have strong electrical conductivity as well. This does not imply that the substrate’s actual part of the dielectric constant will likewise increase in value. Instead, it indicates that higher thermal conductivity substrates typically have larger conductive losses in their substance.

This indicates that heat at the trace’s surface and leakage between the transmission line and its reference conductor will cause losses along a transmission line in a PCB to grow.

Volumetric expansion of Multilayer rigid PCBs substrates

The volumetric expansion of PCB substrate is another thermal factor to consider. While not all materials have a thermal conductivity that increases with volumetric expansion coefficient, it is still preferable to choose a substrate with a higher thermal conductivity since it transfers heat away from heated components and results in a more even temperature distribution across the board. This inhibits the creation of hotspots and localized volumetric expansion around active components or high-current traces.

If these traces have an extremely high current, they can be dangerous.

PCB Thermal Management for Various Applications

Higher thermal conductivity substrates help with thermal management and passive cooling, which lowers board temperatures in industrial electronics, automobile applications, cellphones, and other applications. This makes it possible for heat to dissipates more frequently over the PCB, resulting in a temperature distribution that is more uniform. To control the temperature rise, various other basic passive cooling techniques or active cooling parts can be employed, such as thermal pads (Epoxy fileed, copper paste filled or copper coin filled), heatsinks on critical components, cooling fans, arranging multiple planes in inner layers, and by choosing good thermal insulation material (HITG).

Materials for Ceramic PCB Substrates

Ceramics have far better heat conductivity than FR4, PTFE, and polyimide, but at the expense of higher manufacturing costs. Multilayer manufacturing is challenging due to the difficulty of drilling these mechanically robust substrates, both mechanically and with lasers. Since the nanoparticles of these materials will sinter at the same temperatures as ceramic PCB substrates, ceramic PCB substrates can likewise be utilized with sintered gold or silver conductors with ease.

For heatsinks, thermal paste vs. thermal pads

Heatsinks serve as a big reservoir to trap heat and transmit it to the surrounding environment. There are two ways to attach heatsinks to active components: thermal paste and thermal pads. A heatsink needs to be mechanically fastened to its component, or it can be bonded with thermal paste or a thermal pad. While thermal paste will outlast any thermal pad in terms of wear and tear, different pastes offer varying degrees of heat dissipation. These materials also allow for the combination of a heatsink and fan to provide powerful cooling directly to active components, such as CPUs, GPUs, FPGAs, and other components that switch quickly.

Dynamic Power Regulation

This technique, which is commonly used in mobile devices too small for active cooling, involves actively turning various functional blocks on and off as needed, as well as putting components like microcontrollers into sleep mode to conserve power and get rid of a heat source in the system. When combined with some special substrate material or metal core PCB, one can make up for the low thermal conductivity of standard PCB substrates.

Two fundamental types of boards with only one or two layers of conductive materials over the substrate are single-layer and double-layer PCBs. Multi-layer printed circuit boards are well-suited to satisfy requirements for increased routing space or signal integrity. Multilayer PCBs, as opposed to single- and double-layer PCBs, stack several layers of conductive and insulating material to produce an intricate web of connections. Prepreg, substrates, cores, and copper layers are usually included in the stack-up. In PCBs, there are two different kinds of insulating or dielectric materials: prepreg and core.

Conclusion

After reading about PCB substrate, you may be unsure about where to make your purchase. A PCB substrate may not always need to be purchased separately. You can discuss your needs with a PCB manufacturer, like PCB Runner, by getting in touch with them. In order to jointly determine which Multilayer rigid PCBs substrates best suits your needs, you can have a discussion. In this sense, PCB Runner will be beneficial. There is an abundance of possibilities available to you due to the various varieties of PCB substrate. You may be confident that the FR-4 substrate will allow you to create a variety of circuit boards. If none of the possibilities on this list appeal to you, you may always ask us for suggestions.