The foundation of every electronics today is printer circuit boards (PCBs) as they are used in everything from consumer gadgets to complex industrial systems. As PCB production in Europe and worldwide has evolved, so have the methods of ensuring precision, reliability, and repeatability in manufacturing.Among the key design features that make this possible are fiducials. These small copper markers may seem insignificant, but they play a crucial role in ensuring accuracy during PCB printed circuit board assembly

In this blog, we’ll explore fiducial in PCB, the different types available, fiducial placement on PCB guidelines, and why these elements have become indispensable for modern electronics manufacturing.

The Role of Fiducials in Modern PCB Manufacturing

What Is Fiducial in PCB?

A fiducial in PCB is a small, accurately placed copper marker on the circuit board surface. It acts as a reference point for automated optical systems, allowing machines to recognize board orientation and position components with high accuracy. Without fiducials, high-speed assembly equipment would struggle to place in tiny SMD components correctly.

Historical Evolution: From Manual to Automated Assembly

In earlier decades, PCB assembly was mostly manual, and alignment was guided by human operators. With the rise of surface-mount technology (SMT) and automation, fiducials became essential. By providing a universal visual reference, fiducials allowed assembly machines to align boards consistently and minimize placement errors, revolutionizing PCB production in Europe and across global markets.

At PCBRunner, our advanced PCB printed circuit board assembly processes are designed with precise fiducial recognition systems, ensuring accuracy even for high-density, complex boards. This level of precision helps our clients reduce defects and achieve faster time-to-market

Types of Fiducial in PCB Designs

Fiducials come in different types, each serving a specific purpose depending on the complexity of the board design.

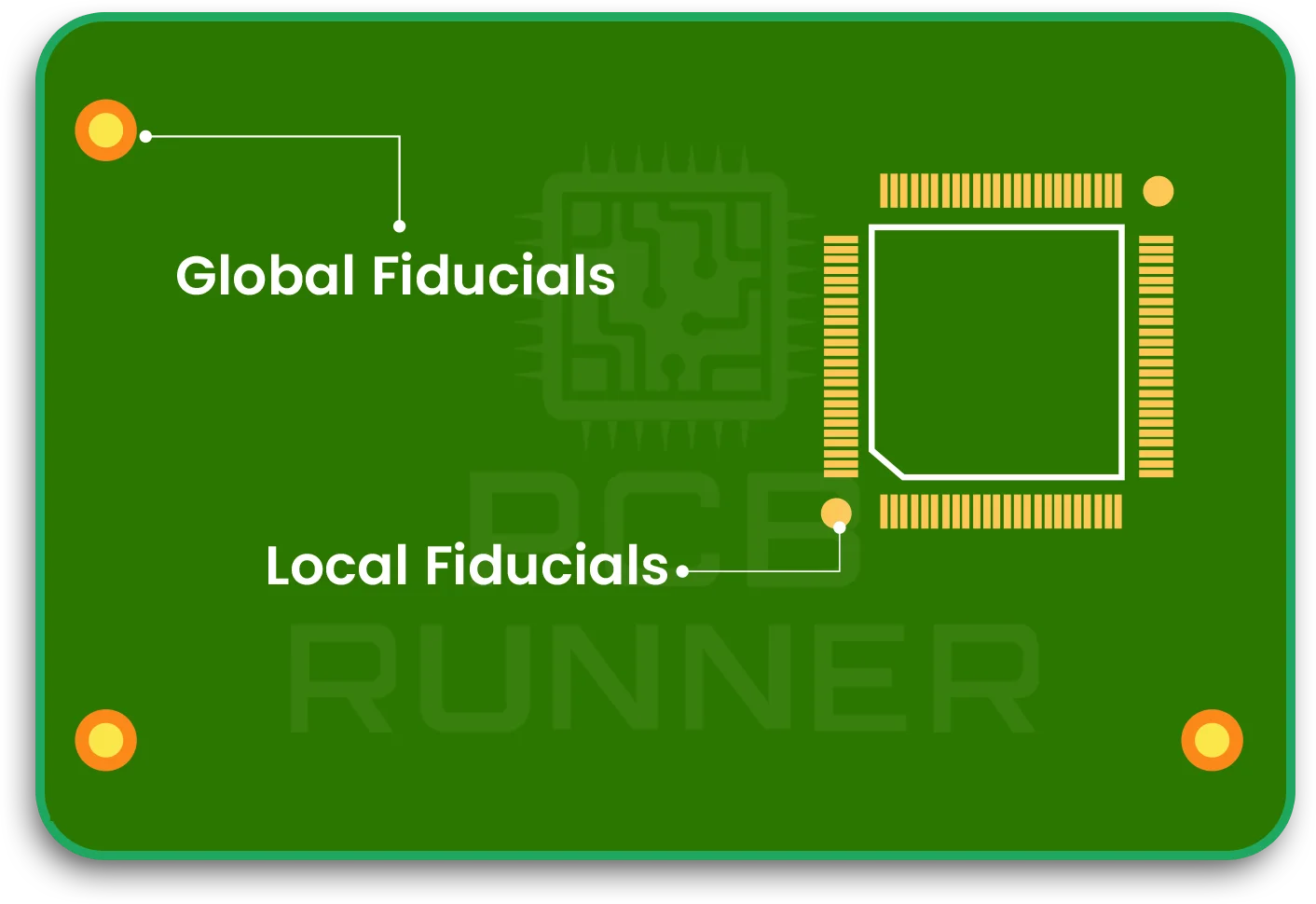

Global Fiducials

Global fiducials are placed at the corners or edges of the board. They help machines detect the PCB’s orientation as a whole and are critical in ensuring the entire layout is aligned correctly before component placement begins.

Local Fiducials

Local fiducials are smaller markers positioned near complex components, such as BGAs (ball grid arrays) or fine-pitch ICs. They allow machines to fine-tune alignment for a specific area, ensuring even the smallest leads or solder balls are placed accurately.

Other Fiducial Types

In some cases, PCB designers may use custom fiducials, such as cross or hash patterns. While less common, they can help when unique geometries or extremely tight tolerances are required.

By understanding the types of fiducial in PCB, designers can apply the right strategy for both simple and complex assemblies.

Fiducial Placement PCB – Best Practices & Guidelines

The success of PCB fiducials depends heavily on where and how they are placed. Following industry-standard fiducial guidelines ensures manufacturability and minimizes errors during production.

PCB Fiducial Guidelines

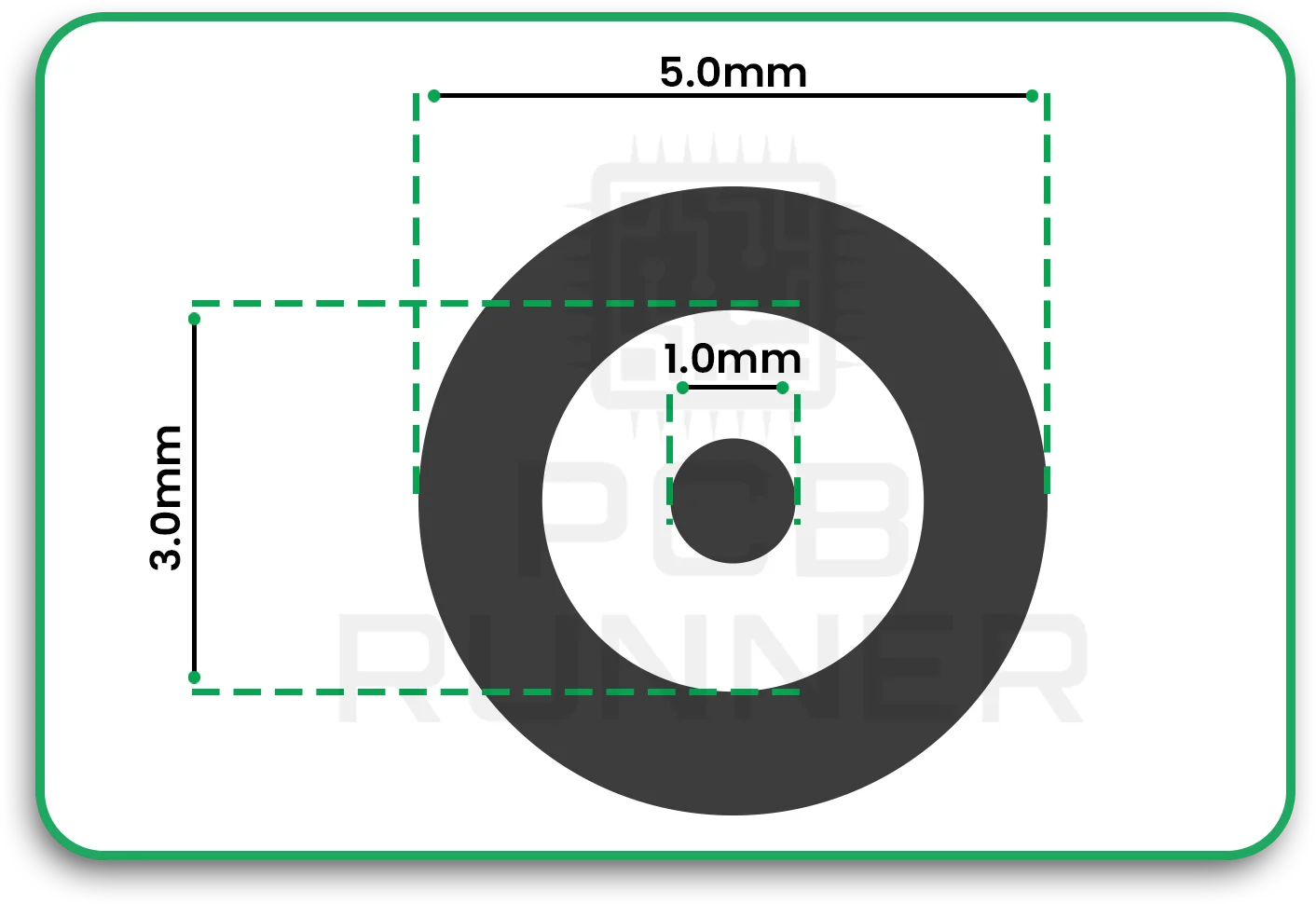

- Shape and size: Fiducials are usually circular, 1–3 mm in diameter, with no solder mask covering them.

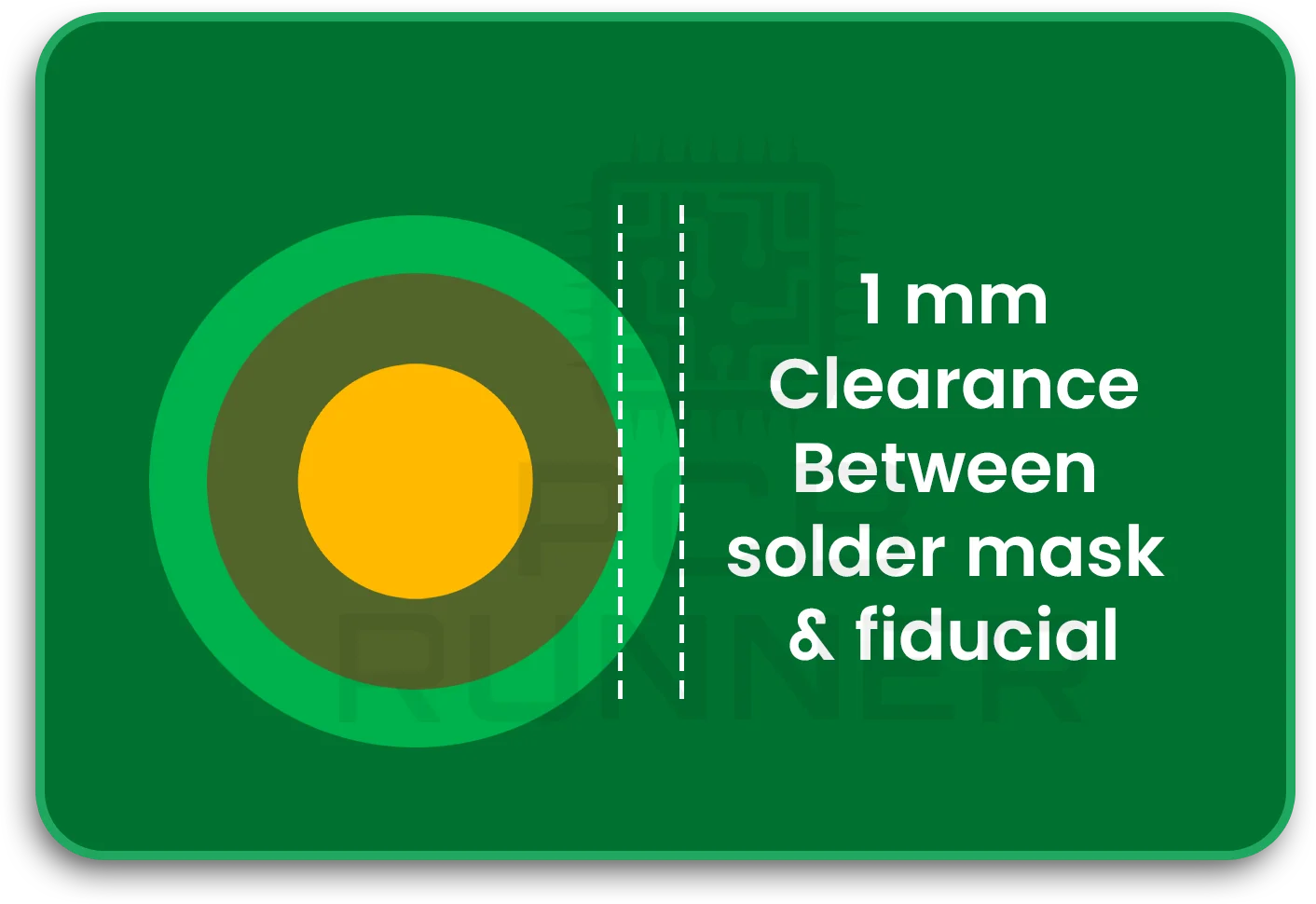

- Clearance: A solder mask clearance of at least 1 mm around the fiducial ensures that automated cameras can easily detect it.

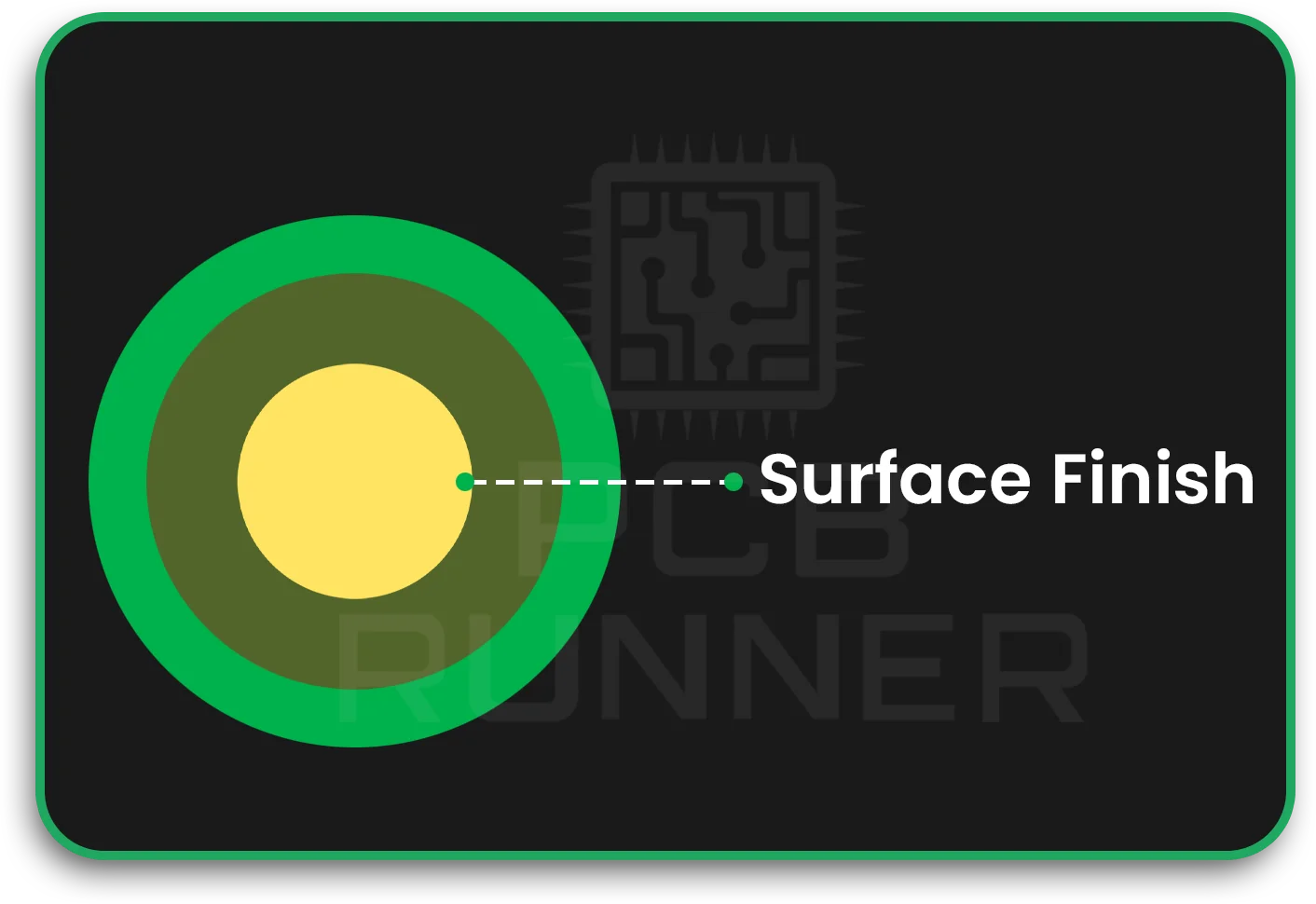

- Surface finish: Fiducials should match the PCB’s surface finish (e.g., ENIG or HASL) to maintain visibility.

When and Where to Place Fiducials

- Global placement: At least two, preferably three, fiducials should be placed on opposite corners of the PCB.

- Local placement: Components with fine pitch should have at least two local fiducials nearby.

- Symmetry: Avoid placing fiducials in random positions; symmetric placement enhances machine recognition.

By following these fiducial placement PCB practices, manufacturers improve the efficiency and reliability of PCB printed circuit board assembly.

At PCBRunner, our engineering team applies IPC-compliant fiducial placement standards across every build, from prototypes to full-scale production. This ensures flawless compatibility with SMT automation, helping businesses reduce costly placement errors and maximize manufacturing efficiency.

How Fiducials Enable Reliable PCB Assembly & Production in Europe

Automation has made PCB manufacturing faster and more precise, but it relies on fiducials for consistency.

Integration with Pick & Place Machines

Modern pick & place machines use high-resolution cameras to align boards. Fiducials act like “anchors” for these machines, allowing them to calculate the exact positioning of each component. Without fiducials, machine vision systems could misinterpret copper pads, vias, or traces, leading to misalignment.

Error Reduction and Efficiency Gains

By providing a universal reference point, fiducials drastically reduce placement errors, improve throughput, and minimize costly rework. For PCB production Europe manufacturers who face high demand for precision and quality, fiducials are non-negotiable.

Challenges, Common Mistakes & Troubleshooting in Using Fiducials

Even though fiducials are simple, mistakes in design can cause problems during manufacturing.

Overcrowding and Masking Issues

If fiducials are too close to other copper features, or if solder mask partially covers them, machine vision may fail to detect them.

Mismatch with Assembly House Requirements

Different PCB assembly providers may have specific fiducial requirements. Designers who overlook these guidelines risk delays, rejections, or added costs. For European production houses, adhering to IPC standards ensures compatibility across multiple assembly lines.

Summary & Future Trends in PCB Fiducials for European Production

Fiducials might be small, but they play a vital role in the success of PCB printed circuit board assembly. By serving as precise reference markers, they enable machine vision systems to align components, reduce errors, and keep European PCB manufacturers competitive.

As PCB technology moves toward greater miniaturization and higher component densities, fiducials will continue to adapt. Future trends may include micro-fiducials designed for ultra-small components and advanced machine learning systems capable of reading boards with fewer fiducials.

In conclusion, fiducials are not just small copper dots they are the backbone of accuracy in pcb production and beyond.