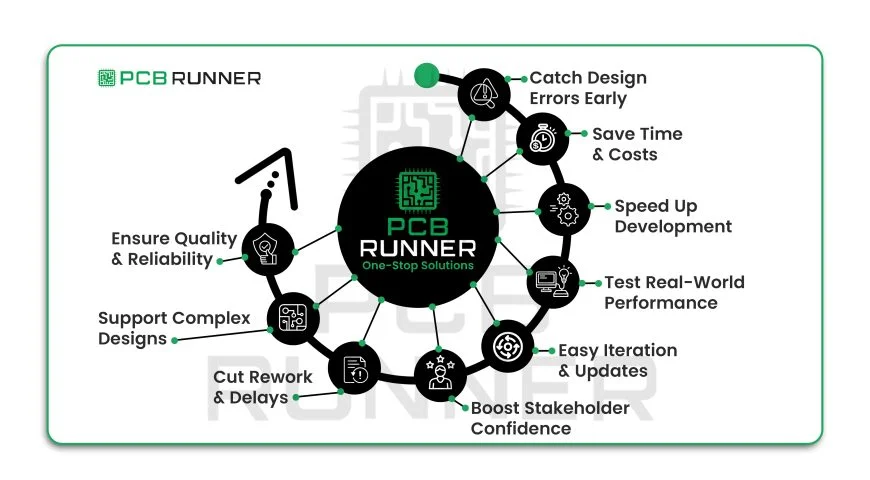

When you flip a switch and your LED lamp glows, you probably don’t think about the tiny circuit board inside. But for engineers and makers, the journey from idea to a working LED light PCB board is full of questions and challenges. How do you know your design will work? What if something goes wrong? This is where prototyping comes in. Building a PCB prototype can save you time, money, and stress, especially for projects like an LED PCB board or any new electronic device.

Let’s walk through the top reasons why using prototyping in PCB design is not just smart, but essential. Whether you’re working with PCB manufacturing companies or building your own LED PCB, these insights will help you get it right the first time.

What Is PCB Prototyping?

A PCB prototype is a test version of your circuit board. It’s not the final product, but a working sample you can touch, test, and tweak. Think of it as a rough draft for your electronics project. For tasks like designing LED light circuit boards or developing new gadgets, prototyping helps you identify problems before they become major headaches.

1. Catching Design Mistakes Early

No one gets it perfect on the first try. Even the best engineers make mistakes. By creating a PCB prototype, you can:

- Test your design in real life

- Find wiring errors or missing parts

- Check if your LED lights PCB board glows as expected

Catching mistakes early means you avoid costly problems later. Imagine building 1,000 LED PCB boards, only to find out they don’t work. Prototyping saves you from that nightmare.

2. Saving Money in the Long Run

Some people think skipping prototyping will save money. But it’s the opposite. Fixing problems after mass production is expensive. With a PCB prototype, you:

- Spend a little now to save a lot later

- Avoid wasting materials on faulty boards

- Make changes before you commit to a big order

PCB manufacturing companies know that a small investment in prototyping can prevent huge losses down the road.

3. Speeding Up Your Design Process

It might seem like prototyping adds extra steps. In reality, it speeds up the entire process. Here’s why:

- You test and fix problems as you go

- You don’t waste time waiting for a big batch to arrive

- You can show your team or customers a real, working board

For LED PCB manufacturer teams, quick feedback means quicker progress. You can move from idea to finished product much faster.

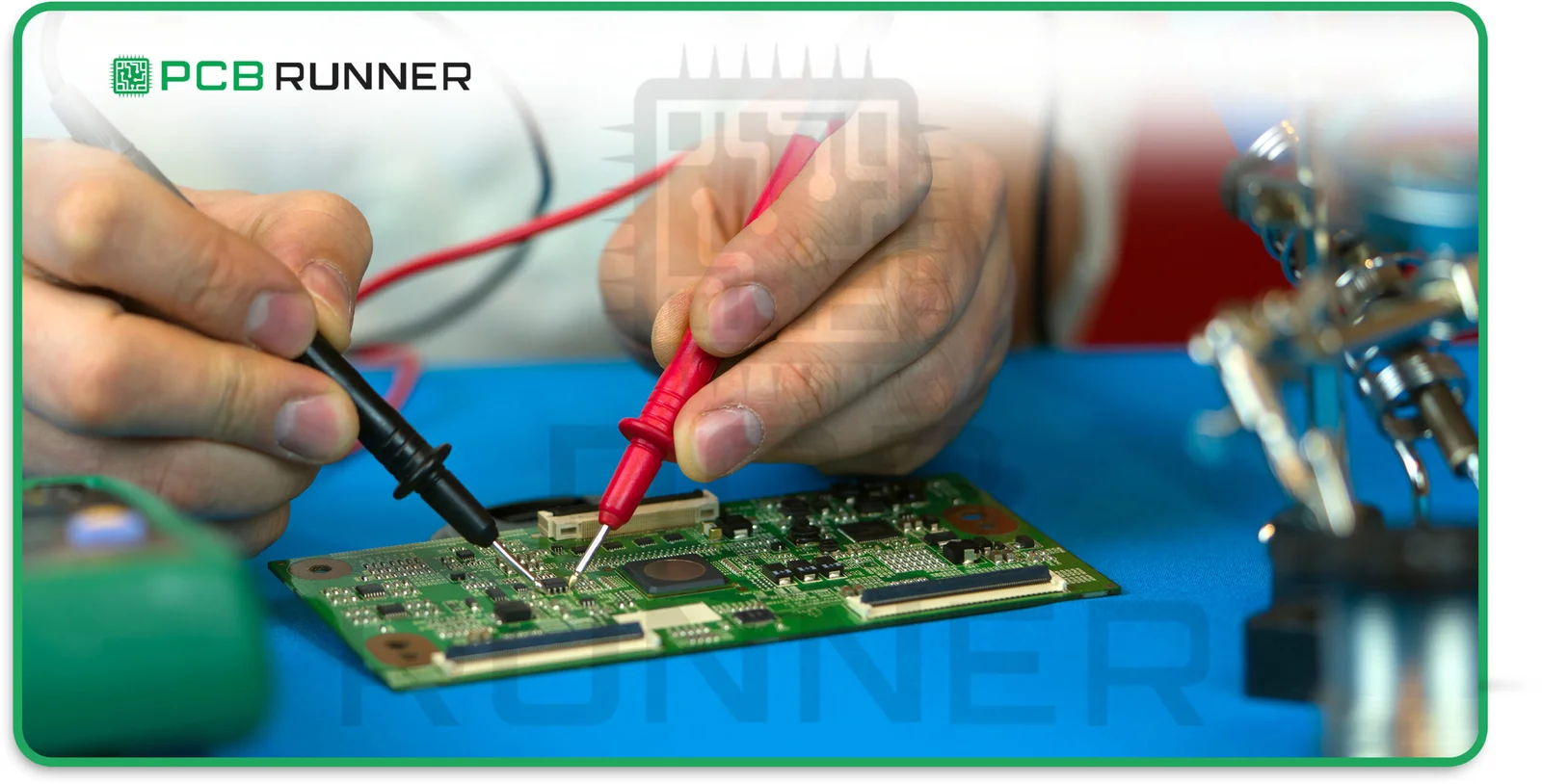

4. Testing Real-World Performance

A design that looks good on paper might fail in real life. With a PCB prototype, you can:

- Check if your LED PCB gets too hot

- See how it handles power surges or drops

- Test the brightness and colour of your LED lights

This is especially important for LED PCB assembly. You want to ensure your board works properly in its final application, whether that’s a lamp, sign, or gadget.

5. Making Changes and Improvements

Prototyping gives you freedom to experiment. You can:

- Try different layouts for your LED light circuit board design

- Swap out components to see what works best

- Adjust the size or shape of your board

Each new prototype brings you closer to the perfect design. You’re not locked in, you can keep improving until you’re happy with the result.

6. Building Confidence with Stakeholders

If you’re working with a team, boss, or customer, showing a real LED PCB board build helps establish trust. A prototype isn’t just a drawing or idea, it’s something you can hold and test. This helps:

- Get feedback from others

- Show investors or clients your progress

- Prove your design works before spending more money

A working prototype is often the key to getting approval for full production.

7. Reducing Rework and Delays

Mistakes found late in the process can cause significant delays. By using a PCB prototype:

- You spot and fix issues early

- You avoid having to redo large batches

- Your project stays on schedule

For PCB manufacturing companies, this means happier customers and fewer complaints.

8. Supporting Custom and Complex Designs

Some projects, such as custom LED displays or smart gadgets, require specialised layouts. Prototyping lets you:

- Test unique shapes or sizes

- Try out new features or sensors

- Make sure your LED PCB fits perfectly in your product

This is much easier (and cheaper) to do with a prototype than with a full production run.

9. Improving Quality and Reliability

Every product should be safe and reliable. With prototyping, you can:

- Test for overheating or short circuits

- Check if your LED PCB assembly meets safety standards

- Make sure your board lasts as long as it should

Quality matters, especially if your product will be used every day or in harsh conditions.

10. One-Stop Solutions from PCB Manufacturing Companies

Many PCB manufacturing companies now offer fast prototyping services. This means you can:

- Get your prototype made quickly

- Work with experts who know the latest trends

- Use high-quality materials and tools

A reputable LED PCB manufacturer can guide you through the entire process, from the initial idea to the finished board.

Tips for Prototyping Success

- Start simple: Don’t try to do everything at once. Test basic functions first.

- Take notes: Write down what works and what doesn’t.

- Ask for help: Good LED PCB manufacturer teams are happy to answer questions.

- Test in real conditions: Use your prototype the way it will be used in real life.

- Keep improving: Don’t stop at the first working board. Look for ways to make it even better.

Final Thoughts

Prototyping isn’t just for big companies or fancy gadgets. It’s a smart step for anyone designing a new LED PCB board, lamp, or electronic device. By building and testing a PCB prototype, you save money, avoid mistakes, and end up with a better product.

So next time you have an idea for a new LED light or gadget, remember: start with a prototype. It’s your best tool for turning ideas into reality, one board at a time.

Prototyping is the secret ingredient behind every great LED project. It helps you learn, improve, and succeed, no matter how big or small your idea is.