Every electronic gadget contains a printed circuit board (PCB) at its core. However, a PCB in isolation has no utility value. It needs to be interfaced with other boards, wires, or systems. In these scenarios, PCB connectors are of help. These connectors facilitate the transfer of power, signals, and data among different components of the device. If you are looking for PCB production in the UK, collaborating with printed circuit board suppliers, or simply want to know how various devices are integrated, this blog is for you.

In this article, we will cover the fundamental concepts of PCB connection systems, their various types, and provide crucial information to help you select the most suitable connector for your project.

Importance of PCB Connectors

Like bridges for your circuit boards, connectors enable you to:

- Join the respampling of two or more PCBs

- Link cables or wires to the board

- Facilitate the connection of external devices such as sensors or USBs

- Enhance the ease of maintenance, repair, or device upgrade.

In the absence of an appropriate connector, one runs the risk of damaging the device or rendering it useless. High-quality connectors, on the other hand, contribute to increased durability and optimisation of the device’s efficiency.

Main Categories of PCB Connectors

While there are various shapes and designs of PCB connectors, they can be categorised into a few basic types. Here is an informative overview of the kinds of PCB connectors that are more prevalent:

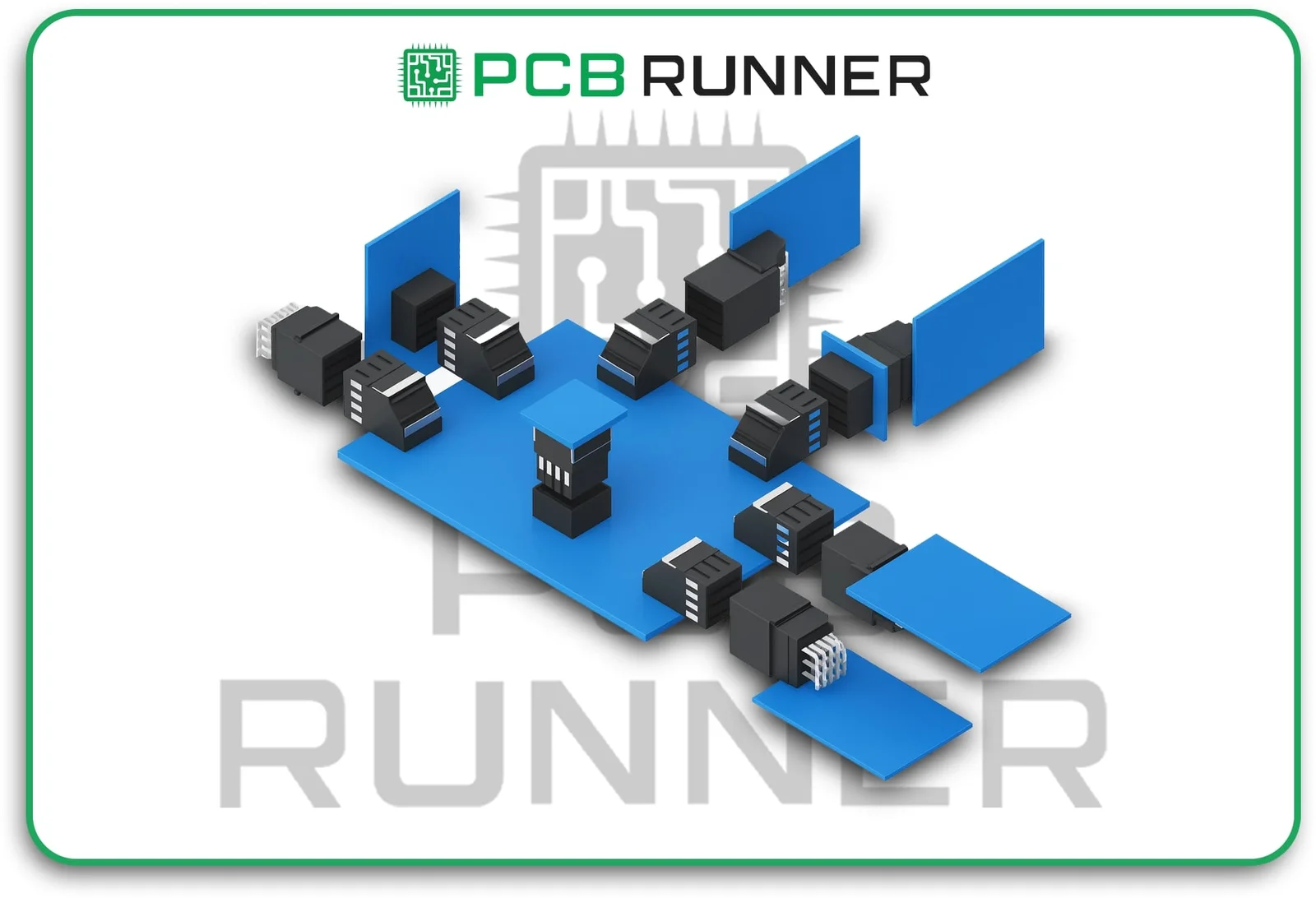

1. Inter-Board Connectors

They connect two or more PCBs without the use of wires. They are helpful for designs that require compactness and for stacking boards.

- Mezzanine connectors: They stack boards vertically close to each other or spaced apart.

- Orthogonal connectors: These connect boards at right angles to each other. They serve a compact layout purpose.

- Backplane connectors: Serve larger systems, such as servers, to connect multiple boards to a central board.

Types of board-to-board connectors allow the construction of advanced devices while saving space. They are essential components in computers and various types of communication equipment.

2. Wire-to-Board Connectors

These connectors link a wire or cable to your PCB. Almost every device contains these connectors.

- Crimp connectors: A wire is crimped to metal contacts and later plugged into a socket on the board.

- Insulation displacement connectors (IDC): Wires are inserted into a connector without stripping their insulation.

- Headers and sockets: A pin on the board is connected to a socket on the wire.

They serve functions such as powering the device, as well as powering sensors, buttons, and displays.

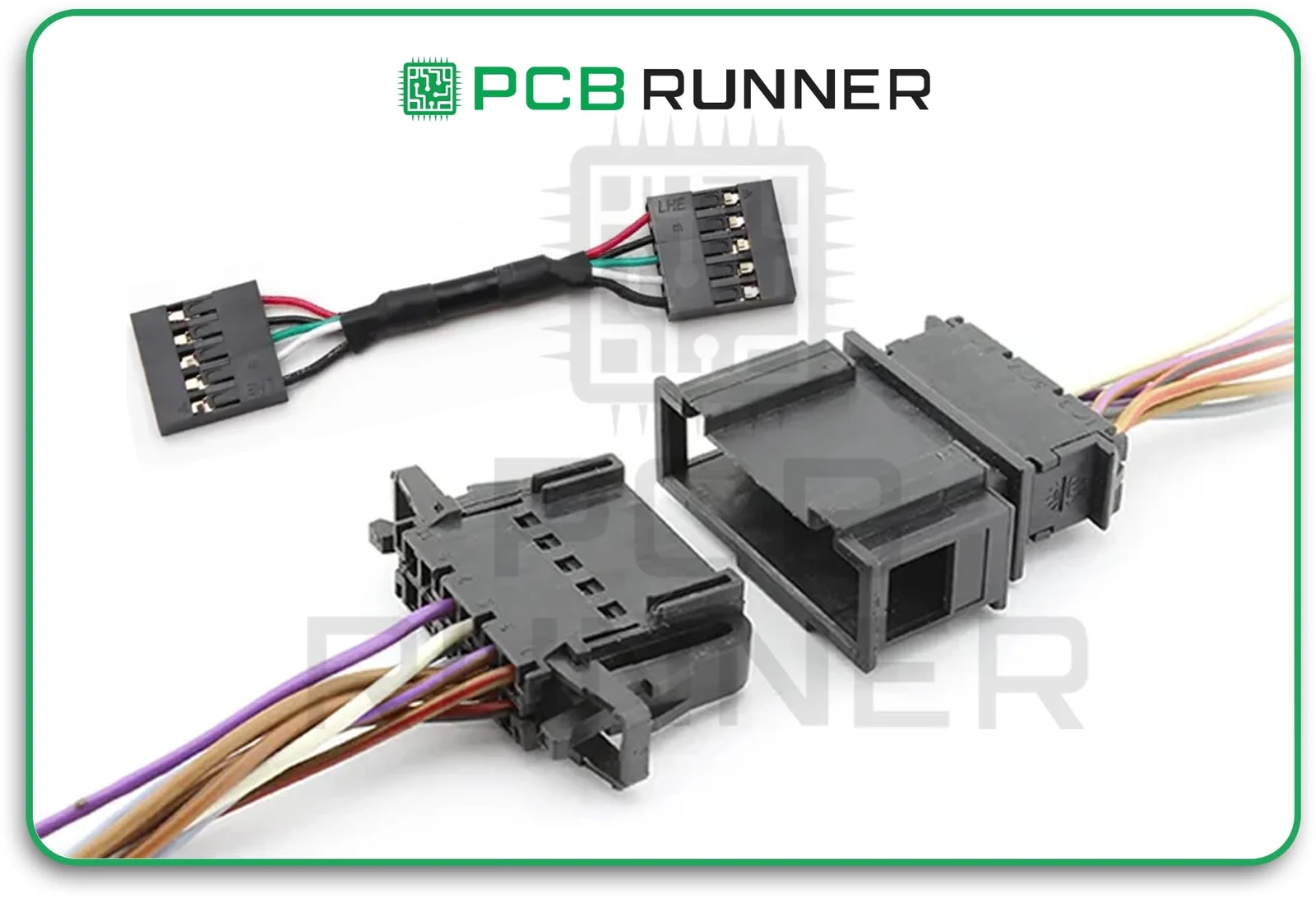

3. Wire-to-Wire (Cable-to-Cable) Connectors

These connectors join two cables together. They are helpful in connecting subsystems as well as for troubleshooting and repairs.

- Plug and socket: Each cable has a connector that snaps together with the corresponding socket.

- Quick disconnect: Easily pull apart for repair and change.

These are commonly found in industrial devices, but are particularly prevalent in power supplies and extension cables.

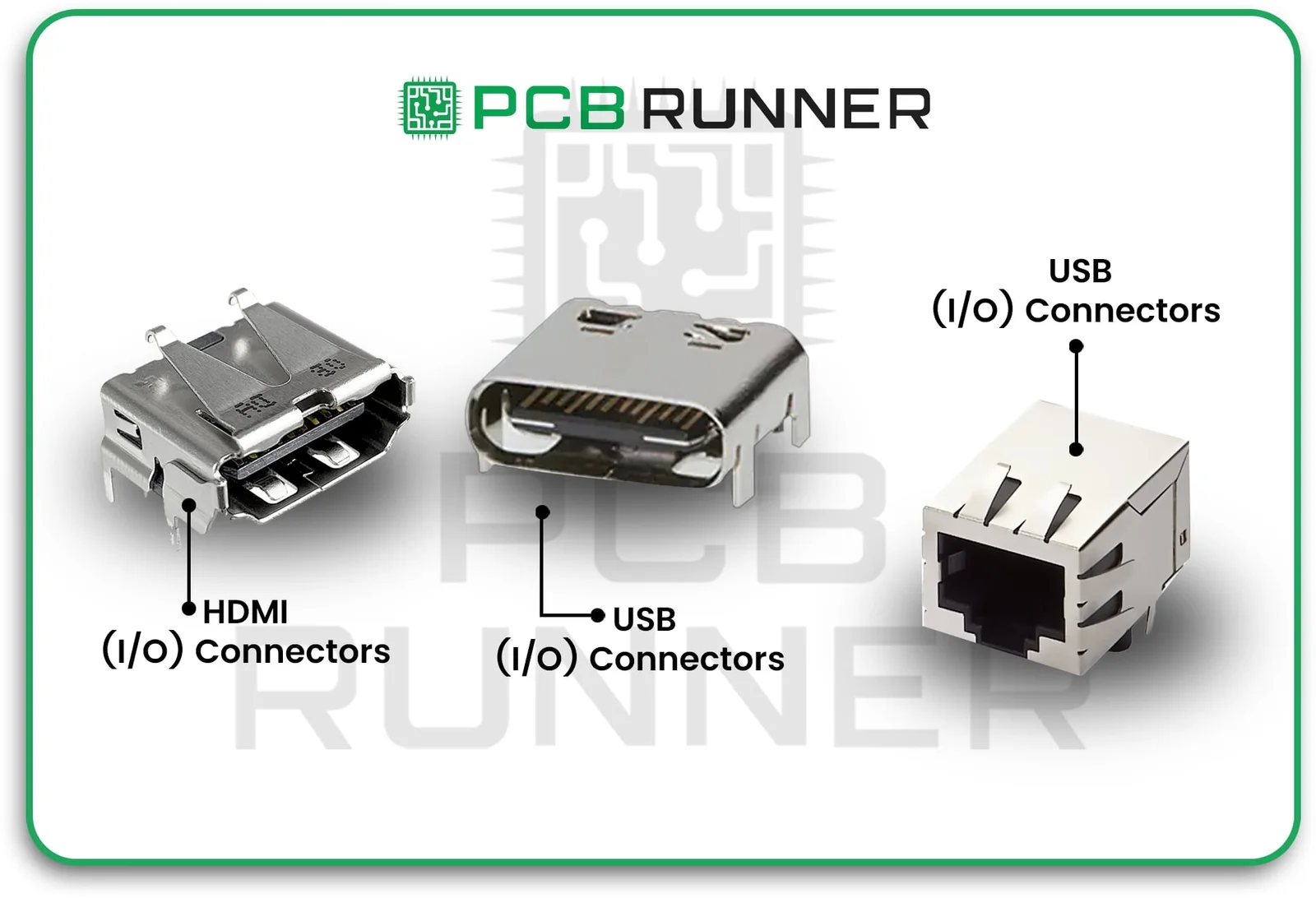

5. Input/Output (I/O) Connectors

These connectors enable communication between peripherals and the circuit board.

- USB connectors Are Used for both data transmission and charging.

- Audio jacks: For headphones or speakers.

- Ethernet, HDMI, and others: For networking, video and more.

- I/O connectors have become so ubiquitous that they are found in nearly every electronic device, including computers, phones, and TVs.

- How Are PCB Connectors Mounted?

- There are two primary methods for attaching connectors to a PCB.

- Through-Hole Mounting

- Connector pins pass through holes in the board and are soldered on the opposite side.

- Very robust and reliable for connectors that receive significant pulling and pushing forces.

- Typically found in industrial equipment, automotive, and other heavy-duty devices.

- Slower assembly and occupies more space on the board.

- Surface Mount Technology (SMT)

- The connector sits on top of the board and is soldered onto pads.

- This method preserves real estate on the board and is more efficient for small and lightweight connectors.

- This method is more affordable for mass production. Retains flexibility and speed.

- In mobile phones, laptops, and portable gadgets.

- The selection of a specific mounting method should be made based on the device’s specific requirements and its intended use.

This article is a concise guide for PCB board-to-board connectors.

Your options when connecting two or more boards are as follows:.

- Parallel or Mezzanine: This involves stacking the boards in a flat arrangement. This is particularly beneficial in spaces with limited room.

- Right Angle or Orthogonal: This refers to the angle at which boards connect, typically at a ninety-degree angle. Ideal for L-shaped arrangements.

- Stacking connectors: These allow simple addition or removal of board(s).

- Backplane connectors are commonly found in large racks or servers, where numerous boards are connected to a single primary board.

When selecting board-to-board connectors, it is advisable to consider the following factors.

- Your total area

- Number of connections

- Data or current traffic

Frequency of connecting and disconnecting the boards

Advanced types of connectors of PCB require special attention as listed below:

- FFC connectors: Bendable circuits used in phones and wearable devices.

- Circular connectors are used in extreme conditions, such as those found in aerospace and defence applications.

- D-Sub connectors: Suitable for harsh environments, featuring strong D-shaped connectors.

These connectors manage a large amount of data and power in extensive systems as backplane connectors.

Choosing the Right Connector for Your Project

Choosing the best connector will either enhance or ruin your design. Here are the factors to consider:

- Mechanical strength: Is the connector likely to get yanked or bumped?

- Size and space: How much real estate do you have on your board?

- Current and voltage: Ensure the connector is compatible with your required power levels.

- Signal speed: For quick data transfer, use high-speed connectors.

- Assembly method: Will it be through-hole or SMT?

- Cost: Some connectors are inexpensive, while others are costly but more durable.

If you are in doubt, consult your printed circuit board manufacturers or PCB assembly services provider. They are in a position to recommend the right connector suitable for your application.

Real World Examples

- Laptops: Incorporate board-to-board connectors to interconnect the keyboard, screen, and motherboard.

- Smartphones: Use FFC connectors for the screens and cameras.

- Servers: Use backplane connectors to connect multiple boards in a rack.

- Cars: These use robust through-hole connectors for the sensors and controls.

Tips for Better PCB Connector Design

- Follow the datasheets: Always adhere to the land patterns provided by the connector manufacturers.

- Leave space: Ensure that there is adequate space around the connector for engagement and disengagement.

- Plan for service: Use connectors that are simple to replace if needed.

- Test Your Design: Create a prototype to evaluate fit and function.

- Collaborate with Professionals: Your PCB assembly services provider can assist you with the most challenging designs.

The Role of UK Suppliers of PCB Production and Their Vendors

If you are located in the UK, numerous options for PCB production and connector vendors are available. Local vendors are strategically positioned to supply you with components efficiently, guide your PCB through the fabrication process, and provide comprehensive project support. They know how to assist UK companies.

Conclusion

The connection systems in printed circuit boards are fundamental for all modern electronics. Selecting appropriate ones increases functionality and reliability across the entire device. Smaller and more complex devices are increasing the demand for intelligent connector selection.

The reliability of board connections, advanced assembly capabilities, and numerous connector options make PCB Runner a leading UK PCB production company. They work with you to ensure that the best connectors are selected and utilised for your design. With their experienced team, you can navigate the design and assembly phases with confidence, knowing that your boards and connectors will function as required, regardless of system complexity.

Using the services of PCB Runner means that you gain a partner who will assist you in achieving your project goals while also helping you to avoid common pitfalls and delivering the highest quality products. Earning your trust is crucial in building better systems and products, which significantly aids in the development of effective products.