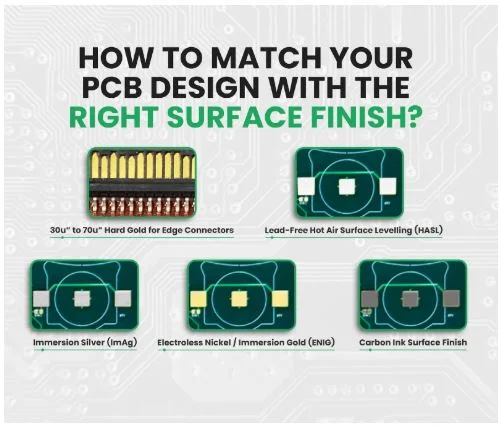

Choosing the right surface finish affects the overall quality, functionality, and reliability of printed circuit boards. The finish is intended to be a protective coating to prevent soldering and contact pads from becoming oxidized or sullied. Quite simply put, copper surfaces that are not covered are prone to oxidizing, rendering them useless for the efficient soldering of components or reliable electrical contacts.

This article covers various types of PCB surface finishes, their selection processes, and, of course, which designs are right for which surfaces. The wrong decision regarding the surface finish could create assembly problems or cause them later in the PCB’s life, so making an informed choice is essential for your PCB’s success.

Key Information You Need

A number of considerations, including design, application, and environment, must be taken into account when deciding on the PCB surface finish. Commonly used finishes are listed below, along with guidelines for PCB Circuit Board Manufacturers on their use:

Lead-Free Hot Air Surface Levelling (HASL)

-

- Best for: General-purpose applications, especially when solderability and cost are priorities.

- Advantages:

- Good solderability

- Affordable and robust for multi-step assembly

- Excellent for larger board surfaces

- Drawbacks:

- Extra thermal load due to the submersion in liquid solder

- Less flat compared to other finishes

- Not ideal for fine-pitch components

Electroless Nickel/Immersion Gold (ENIG)

- Best for: Designs requiring flat surfaces, long shelf life, or applications like keypads and wire bonding.

- Advantages:

- Excellent flatness and solderability

- Suitable for fine-pitch and sensitive components

- Drawbacks:

- Higher cost

- It can be brittle under stress or vibration

Immersion Silver (ImAg)

- Best for: Prototypes and short production runs where flatness and solderability are needed.

- Advantages:

- Flat and smooth surface

- Good solderability

- Drawbacks:

- Susceptible to tarnishing in sulfur-rich environments

- Shelf life can be limited depending on storage conditions

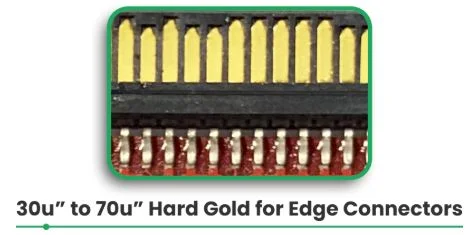

30u” to 70u” Hard Gold for Edge Connectors

-

- Best for: Edge connectors that need to withstand wear and tear.

- Advantages:

- Durable and resistant to abrasion

- High-quality electrical contact

- Drawbacks:

- Only applied to specific areas (edge connectors)

- Higher cost and limited application

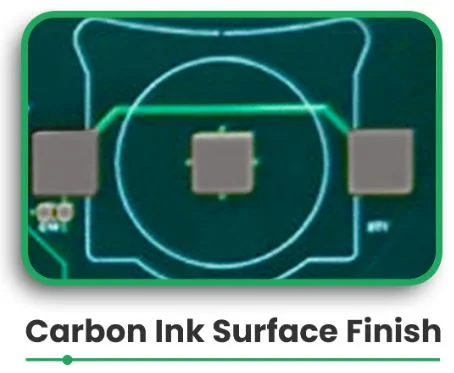

Carbon Ink Surface Finish

-

- Best for: Switch contacts, foil keyboards, and cross-over conductors.

- Advantages:

- High mechanical strength

- Good electrical conductivity

- Drawbacks:

- Less common and not suitable for general-purpose applications

Benefits and Application

Choosing the right surface finish for your PCB ensures that your design can handle the demands of both the manufacturing process and the operational environment.

Here are some practical benefits:

- Enhanced Reliability: A proper finish can protect gold from oxidation and contamination. It also ensures that soldering and electrical connections are permanent.

- Improved Assembly: Flatness is essential for placing fine-pitched components. Some finishes help, like ENIG, which is used for soldering gold, while HAL is best for bigger components.

- Cost-Effective: A surface finish that is not too expensive but can withstand the conditions is perfect for non-specific applications like HAL.

- Long-Term Wear: Hard gold-plated surface finishes protect edge connectors from excessive physical abuse and provide durability.

These considerations, coupled with the type of components, environment, and projected shelf life, make it possible to increase the efficiency and durability of PCBs.

Expert Insights

The ionic contamination of printed circuit boards (PCBs) with different surface finishes was systematically evaluated using ionograph testing at room temperature. The study examined three PCB surface finishes applied to copper substrates: (i) hot air solder leveling (HASL LF), (ii) electroless nickel immersion gold (ENIG), and (iii) organic surface protectant (OSP), in combination with two flux types, EF2202 and RF800.

Among the PCBs without soldered components, the ENIG finish with an 18 µm thickness exhibited the lowest average contamination level, measured at 0.01 µg NaCl/cm². Conversely, PCBs with soldered components showed higher contamination levels, reaching 0.29 µg NaCl/cm² for the HASL LF finish of the same thickness. The introduction of fluxing agents resulted in the highest contamination values across all surface finishes.

The study further investigated the impact of phosphorus content in the Ni-P layer of the ENIG finish on ionic contamination. Among PCBs with gold coatings, the lowest surface contamination level (0.32 µg NaCl/cm²) was observed for the Ni-2-5%P layer, while higher contamination levels were recorded for Ni-11%P (0.47 µg NaCl/cm²) and Ni-8%P (0.81 µg NaCl/cm²).

In contrast, PCBs without gold coatings exhibited their lowest contamination levels (0.48 µg NaCl/cm²) at 11% phosphorus content, whereas increased contamination levels were observed for lower phosphorus contents, with values rising to 1.98 µg NaCl/cm² at 8% phosphorus content. The findings suggest that PCBs with an Au finish generally exhibit lower contamination levels compared to their non-Au counterparts, contributing to enhanced reliability of electronic assemblies by mitigating the risk of failures associated with current leakage and corrosion caused by surface contaminants.

FAQs

What is the most suitable surface finish for surface mount components of low pitch?

ENIG (Electroless Nickel/Immersion Gold) is best for supplementing fine-pitch components with flat surfaces and easy solderability.

What do I do to keep Immersion Silver from tarnishing?

PCBs should be stored in sulfur-free environments to prevent tarnishing, and protective finishes can benefit from hermetically sealed packaging.

Why is Hard Gold used for edge connectors?

Because edge connectors endure frequent contact, Hard Gold is the most favorable option because it has a high wear rate.

What is the shelf life of ENIG?

Compared to other surface finishes, ENIG has a longer shelf life; therefore, it is better suited for long-term storage or designs that are not immediately assembled.

Is it possible to use more than one finish on a single PCB?

Yes, a variety of finishes may be applied to several areas of the PCB, such as Hard Gold on edge connectors and HAL on the remainder of the board.

Conclusion

Selecting an appropriate surface finish for your PCB is crucial for its performance during and after assembly. For long-term reliability, ENIG, HAL, ImAg, or Hard Gold can all be selected, but the option you select should depend on your design requirements and the environment it will be subjected to.

Are you unsure which surface finish to use on your PCB? Do not hesitate to contact us. We at PCB Runners will guide you so that you achieve your project objectives.