Look around you, and you will see a number of devices that rely on technology. The smartphone you use in the morning. The laptop you use for studies. The TV that shows you your favourite shows. The most crucial piece of technology that all of these devices use is a printed circuit board, or a PCB. A PCB needs to be robust and reliable for a gadget to work optimally. Furthermore, selecting the right printed circuit board manufacturers is critical, especially if you are searching for a circuit board supplier UK or a quality PCB production UK.

What is a PCB and Why Is It Important?

A printed circuit board PCB is essential in today’s world. It is like the nervous system for gadgets and makes sure that all the functions work well together. Top gadgets and devices won’t be possible without the right printed circuit board. This is precisely why engineers, electronic hobbyists and companies need a reliable printed circuit board manufacturer that can do PCB assembly and production for them.

Why the Right PCB Manufacturing Company Makes All the Difference

Consider building a robot or a medical device. Now think about how frustrating it would be to realise the device is non-functional due to a poorly made circuit board. All that effort, money, and time wasted! The wrong supplier often leads to mistakes like these. This is the very reason why a lot of companies trust PCB Runner. They count on them for their circuit boards, whether it be for one prototype or hundreds for a new product launch.

What Sets A Supplier Out Differently From The Rest

Choosing a supplier often revolves around pricing. But here is additional information that you should never ignore.

- Quality Control: They need to be diligent. Double and triple-checking every board should be standard.

- Fast Turnaround: Quick delivery means that your work schedule won’t be thrown out of order.

- All Sizes Supported: The supplier should be flexible and assist you, whether you need one board or one hundred.

- Problem Solving: What good is the supplier if the only information provided is through an automated service? Real people need to be answering your inquiries and resolving them.

Some suppliers pass your work to someone else. For this reason, they disregard communication, support, and even the review portion of the work. At PCB Runner, everything is done in-house, including design, review, and manufacturing. This brings you total peace of mind throughout the process.

What Are The Main Steps Of The PCB Manufacturing Process

Let’s discuss what to expect by breaking it down step by step.

1. Finalising the Design

It begins with you. You or your engineer will devise a design and generate Gerber files, which will serve as the detailed blueprints for the PCB.

2. Selecting the Materials

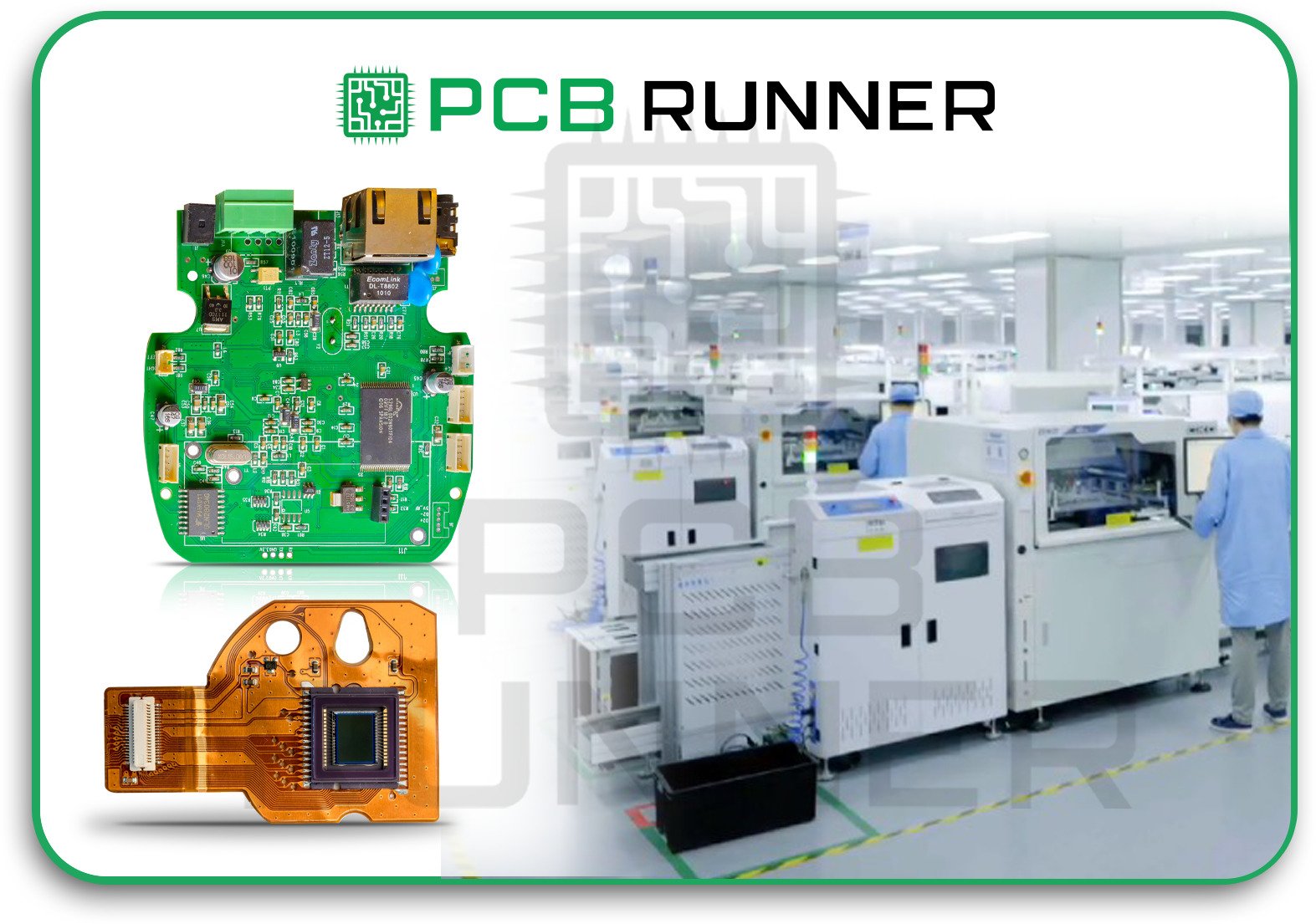

Some PCBs need to be robust. Some must be flexible. PCB Runner offers a full range, from the traditional rigid boards to the latest flex and hybrid ones.

3. Board Printing and Etching

Your artwork is printed on copper plates, from which excess copper is etched away, leaving the desired circuit.

4. Drilling and Vias

Small holes for the “vias” connections are drilled. This is where the components will be soldered on later.

5. Solder Mask and Finishing

The board is covered with a protective finish (usually green), and the board is applied an exceptional finish is applied to protect from oxidation.

6. Rigorous Testing

Here is where the most focus is put on quality. Each board is tested electrically to ensure functionality prior to assembly.

7. Assembly (If Required)

If you place an order for complete PCB assembly, skilled workers and machines will place all chips, connectors and components on the board. Each procedure is performed error-free.

8. Order Fulfilment and Transport

Your PCBs or assemblies are sent to you, ready to be built or sold. They are carefully packed to ensure no damage occurs during shipping.

Why PCB Runner’s Method is Good for You

It doesn’t come from nowhere that PCB Runner is not simply classified as one of the PCB production UK shops. Why is that?

- Human assistance is available at any time of the day, every day of the week.

- Charges can be viewed instantly, and the files can be uploaded in minutes.

- Your design is checked thoroughly by the team as part of a complimentary design review.

- Solutions are implemented immediately instead of being stalled by drawn-out email exchanges.

You have complete transparency in the order processes.

Features Offered by PCB Runner’s Technology and Services

- Complex HDI as well as flex and rigid flex boards, as well as simple single-layer PCBs, can all be found in one place.

- Certification granted for military, medical, and aerospace work includes ISO9001 and IPC Class 2, 3, 3A.

- Fulfilment is excellent for large orders as well as tiny batches.

- After-sales assistance: Calls are answered by our technical team even after delivery.

- Want to explore modern PCB trends in the UK? Check this expert article on modern PCB trends.

Maximising PCB and Assembly Services: A How-To Guide

- Ensure the files are the best and most detailed possible. Errors at this stage are costly in time.

- If you are doing something new, talk to your supplier. Companies like PCB Runner thrive on complex projects, so don’t be afraid to reach out.

- Save time by selecting a supplier that offers a design review. It can prevent costly errors well before they are made.

- Find out about after-sales services. Dependable firms offer strategic advice even after boards are delivered.

Conclusion

Selecting your PCB manufacturing company is an important decision. The best partners do not simply manufacture your boards. They enable you to design, assist in problem resolution, and facilitate your growth. Runner PCB differentiates itself from the competition with excellent industry knowledge, positive reviews, and superb customer service. With every order, you are guaranteed thorough inspections, prompt responses, and a dedicated team for your project.

For dependable circuit board suppliers UK, leading PCB production UK, and complete PCB manufacturing and assembly services, trust PCB Runner. They are known for circuit board fabrication and PCB assembly services in the UK. Begin your next project with a partner who prioritises your requirements and can help with innovations.

FAQs

Q: What advantages are there in using a UK PCB supplier?

A: For most people, local suppliers mean faster turnaround, straightforward shipping, easy shipping and better communication, especially in your time zone.

Q: How can I ensure that my boards are of high quality?

A: Choose companies that showcase their certifications, such as ISO9001, as well as those that test each board before shipping.

Q: Is it possible to order both single units and large quantities at the same time?

A: Absolutely! Proficient suppliers manage both prototype and volume production. For example, PCB Runner is prepared for both.

Q: What if my design contains an issue?

A: Companies such as PCB Runner will provide free engineering consultations and suggested revisions. They give recommended changes before the production phase.

Q: Is it easy to change suppliers?

A: Not really, but if you are attempting to change partners, send complete documents and request a test order.