Are you struggling with dropped calls, slow data, or unreliable telecom equipment? If you work in telecom equipment manufacturing, you know how these issues can damage your reputation and limit your market reach. Many telecom companies face the same pain points: keeping up with rapid technology changes, meeting strict quality standards, and delivering reliable products that stand out in a crowded market. The solution often starts with one thing, PCB excellence.

Let’s explore how advances in custom printed circuit board design, flexible printed circuit manufacturers, and state-of-the-art PCB production in the UK are transforming telecom PCB assembly, raising industry standards, and helping telecom businesses expand their reach.

Why PCB Excellence Matters in Telecom

Telecom networks are the backbone of modern life. From mobile phones and broadband to 5G and IoT, every connection relies on high-performance PCBs. These boards are the heart of telecom equipment, routing signals, managing power, and ensuring devices work seamlessly together.

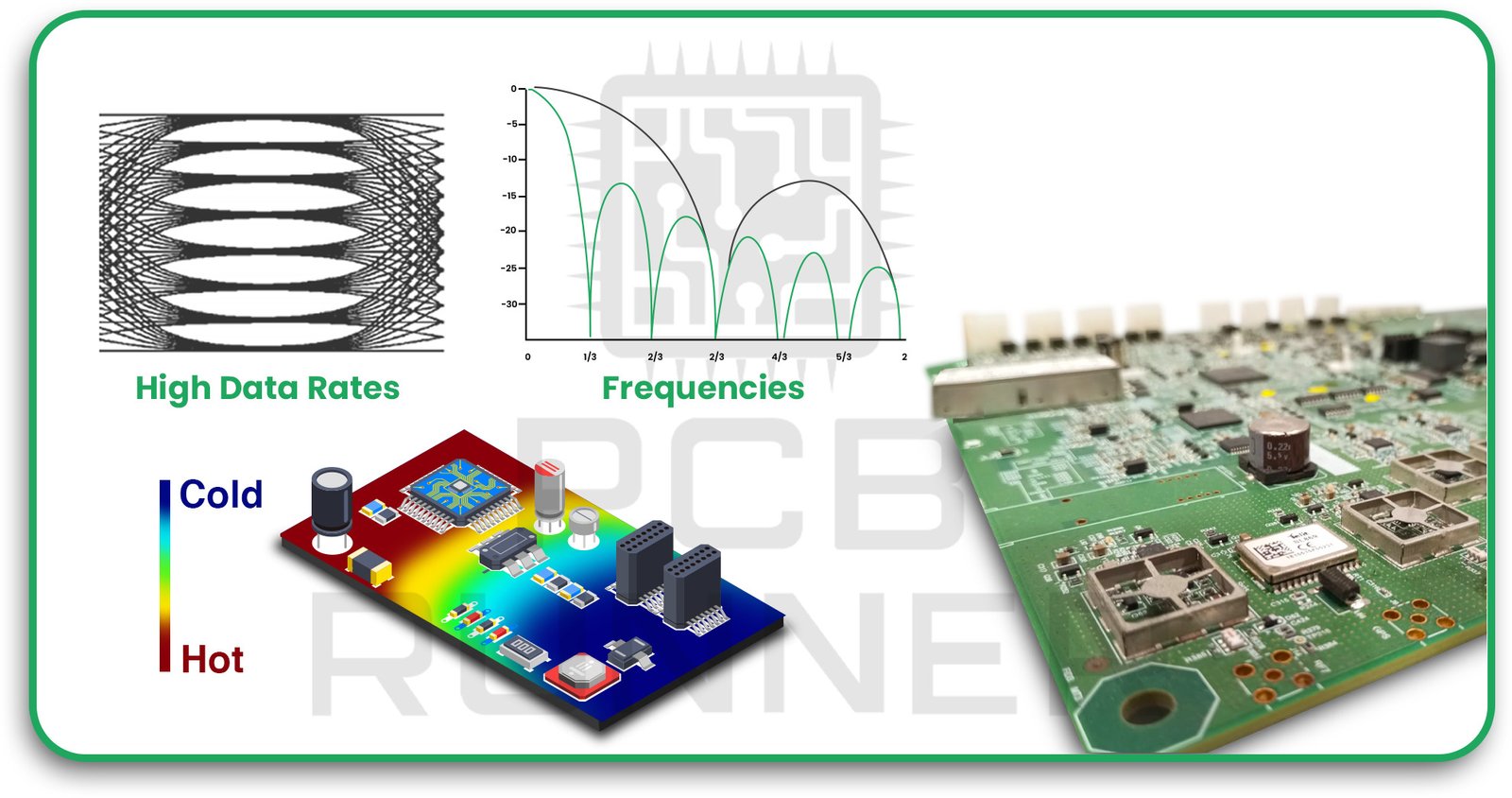

But telecom PCBs face unique challenges:

- They must handle high data rates and frequencies, especially with 5G integration.

- They need to withstand heat, vibration, and constant use.

- They must meet strict global standards for quality and reliability.

If your telecom PCB design or assembly falls short, the result is clear: network failures, unhappy customers, and lost opportunities.

Raising Standards: The Role of PCB Manufacturing Guidelines

To guarantee quality, the telecom industry relies on established PCB manufacturing standards. The IPC-A-600 standard is considered the gold standard for PCB quality, covering material properties, workmanship, and physical characteristics. For telecom PCB assembly, compliance with IPC-A-610 (acceptability of electronic assemblies) and IPC J-STD-001G (requirements for soldered assemblies) is also critical.

Following these standards means:

- Fewer defects and failures in the field

- Consistent performance across all products

- Easier global certification and market entry

Flexible printed circuit manufacturers and custom printed circuit board suppliers who understand and apply these standards help you deliver telecom equipment that meets or exceeds industry expectations.

Flexible PCBs: Meeting Modern Telecom Demands

As telecom equipment gets smaller and more complex, flexible PCBs are becoming essential. Flexible printed circuit manufacturers offer solutions that fit into tight spaces and withstand bending, vibration, and movement, ideal for mobile devices, base stations, and IoT modules.

Benefits of flexible PCBs in telecom:

- Improved signal integrity for high-speed data and 5G

- Enhanced durability in harsh environments

- Space-saving designs for compact equipment

By working with flexible printed circuit manufacturers, telecom companies can create innovative products that are lighter, more reliable, and easier to install.

Custom Printed Circuit Boards: Tailored for Telecom

No two telecom projects are the same. Custom printed circuit boards let you design for your exact needs, whether you’re building a new 5G antenna, a rugged outdoor router, or a next-gen IoT gateway.

Advantages of custom PCB solutions:

- Optimised layouts for signal flow and thermal management

- Special materials for high-frequency and low-loss applications

- Integration of unique features like EMI shielding or advanced connectors

Custom PCB production in the UK means you can work closely with your supplier, speed up prototyping, and ensure your telecom PCB design meets all local and international requirements.

Telecom PCB Assembly: Precision and Reliability

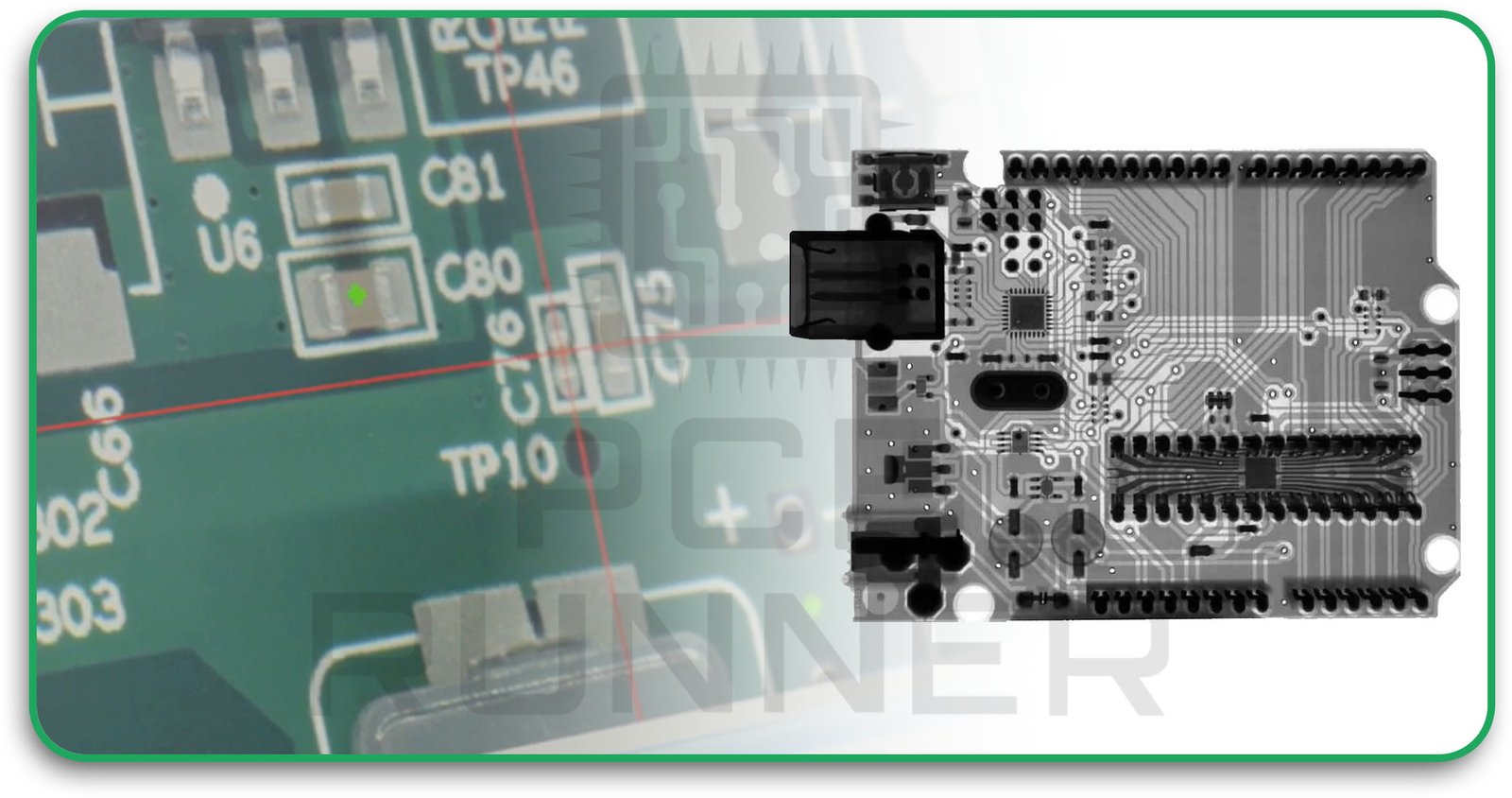

Telecom pcb assembly is about more than just putting components on a board. It’s about precision, repeatability, and quality control at every step. Leading PCB production UK facilities use automated optical inspection (AOI), X-ray analysis, and rigorous testing to catch defects early and guarantee performance.

Key assembly practices for telecom excellence:

- Careful component placement for signal integrity

- Controlled soldering for strong, reliable joints

- Thorough inspection and testing for every board

By choosing a partner with a proven track record in telecom PCB assembly, you reduce the risk of costly recalls and ensure your products perform in the field.

Driving Market Reach with PCB Innovation

How does PCB excellence help you expand your market? It’s simple: better boards mean better products. When your telecom equipment is more reliable, efficient, and innovative, you can:

- Win bigger contracts with telecom operators and network providers

- Enter new markets with confidence, knowing your products meet global standards

- Build a reputation for quality that sets you apart from the competition

With the rise of 5G, IoT, and smart cities, the demand for advanced telecom PCBs is only growing. By investing in PCB excellence, you position your business for long-term success.

Latest Trends Shaping Telecom PCB Design

The telecom industry is evolving fast. Here are some trends to watch:

- 5G Integration: PCBs must handle higher frequencies and data rates, requiring advanced materials and layouts for signal integrity and thermal management.

- Sustainable Practices: Eco-friendly materials and processes are becoming more critical for global telecom brands.

- Smart PCBs: Built-in diagnostics and monitoring help predict failures and improve uptime.

- 3D Printing: New manufacturing methods like 3D-printed PCBs enable unique shapes and faster prototyping.

Staying ahead means working with suppliers who understand these trends and can help you adapt your telecom PCB design and manufacturing processes.

Actionable Steps for Telecom Manufacturers

Ready to improve your manufacturing standards and market reach? Here’s what you can do:

- Partner with flexible printed circuit manufacturers who know the telecom sector and can deliver high-quality, reliable boards.

- Invest in custom printed circuit board design to optimise your products for performance, durability, and innovation.

- Choose PCB production UK facilities for fast turnaround, local support, and compliance with UK/EU standards.

- Demand rigorous telecom PCB assembly with thorough inspection and testing at every stage.

- Stay informed about the latest telecom PCB design trends and update your processes to stay competitive.

Final Thoughts

Telecom equipment manufacturing is more competitive than ever. The companies that succeed are those who put PCB excellence at the centre of their strategy. By raising your standards, embracing flexible and custom PCB solutions, and partnering with leading PCB production UK experts, you can deliver better products, reach new markets, and build a reputation for reliability and innovation.

Don’t let poor PCB quality hold your business back. Invest in telecom PCB design and assembly that meets tomorrow’s standards, today.