The demand for high-quality PCB fabrication and assembly is growing rapidly as modern electronics become more complex and compact. Whether you’re designing consumer gadgets, medical devices, or industrial equipment, the circuit board assembly process plays a crucial role in ensuring the reliability and performance of your product.

Choosing the right PCB assembly manufacturer and using the best PCB assembly services can make a significant difference in product quality, durability, and efficiency. In this guide, we will explore the PCB fabrication process, assembly techniques, and key considerations to achieve high-quality PCB printed circuit board assembly.

What is PCB Fabrication?

PCB fabrication is the process of manufacturing printed circuit boards from raw materials like copper, fiberglass, and solder mask. This process involves multiple steps, including designing the board, etching copper traces, drilling holes, and applying protective coatings.

A well-fabricated PCB ensures optimal electrical performance, mechanical strength, and thermal management. The fabrication process must be precise, as even a small error can impact the entire circuit’s functionality.

Key Steps in PCB Fabrication

1. PCB Design and Layout

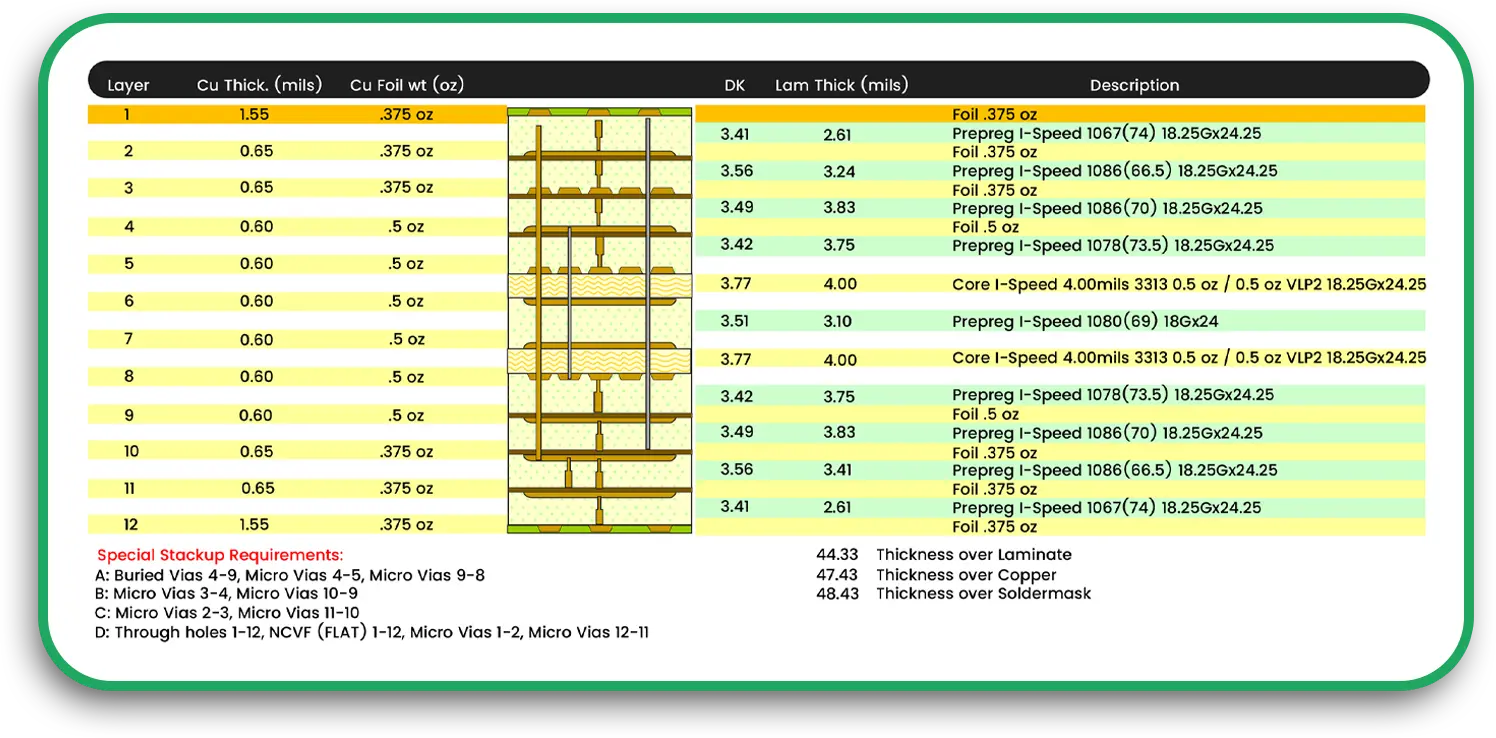

Before fabrication begins, engineers use PCB design software to create the board layout. This includes defining trace widths, hole placements, and layer stack-ups.

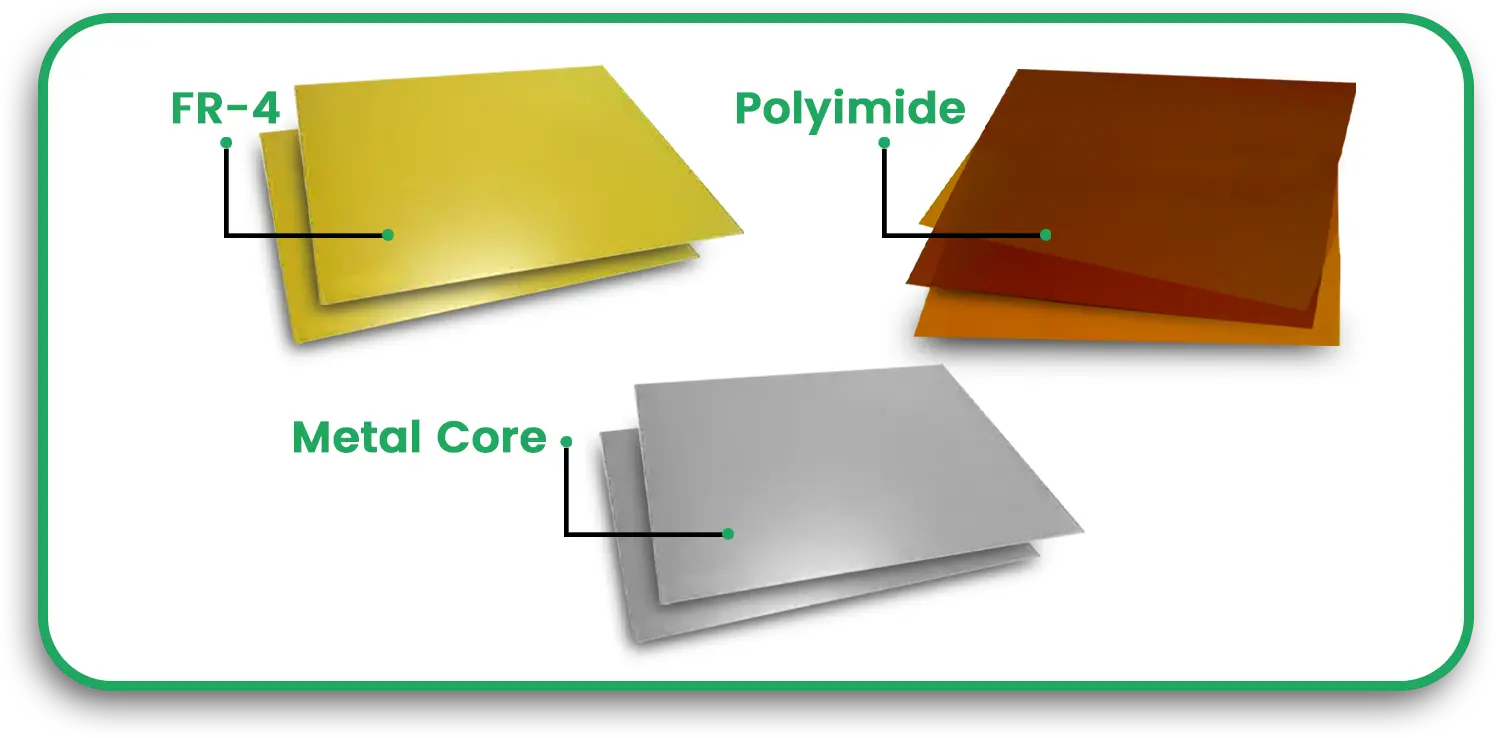

2. Preparing the Substrate

The board’s core material, typically FR-4 (fiberglass-reinforced epoxy), polyimide, or metal, is selected based on application requirements.

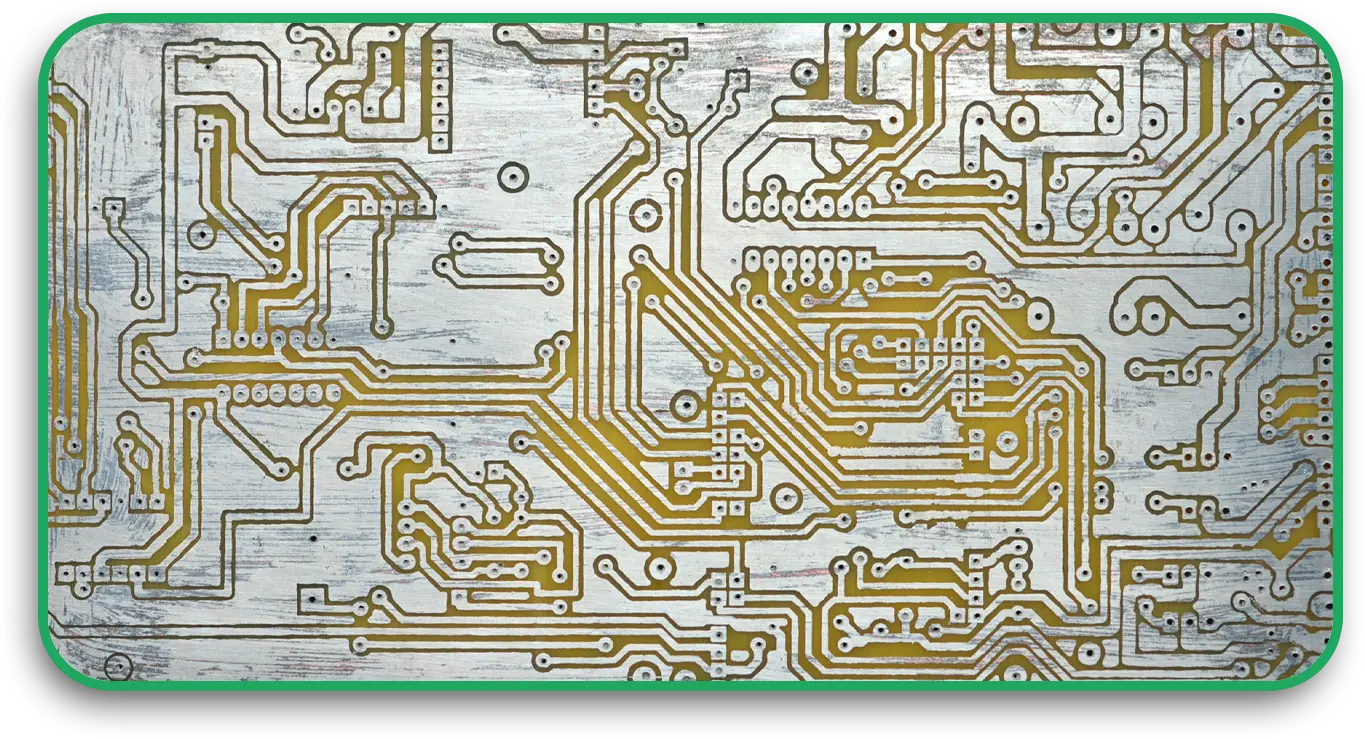

3. Copper Cladding and Etching

A thin copper layer is laminated onto the board, and unwanted copper is etched away to form conductive pathways.

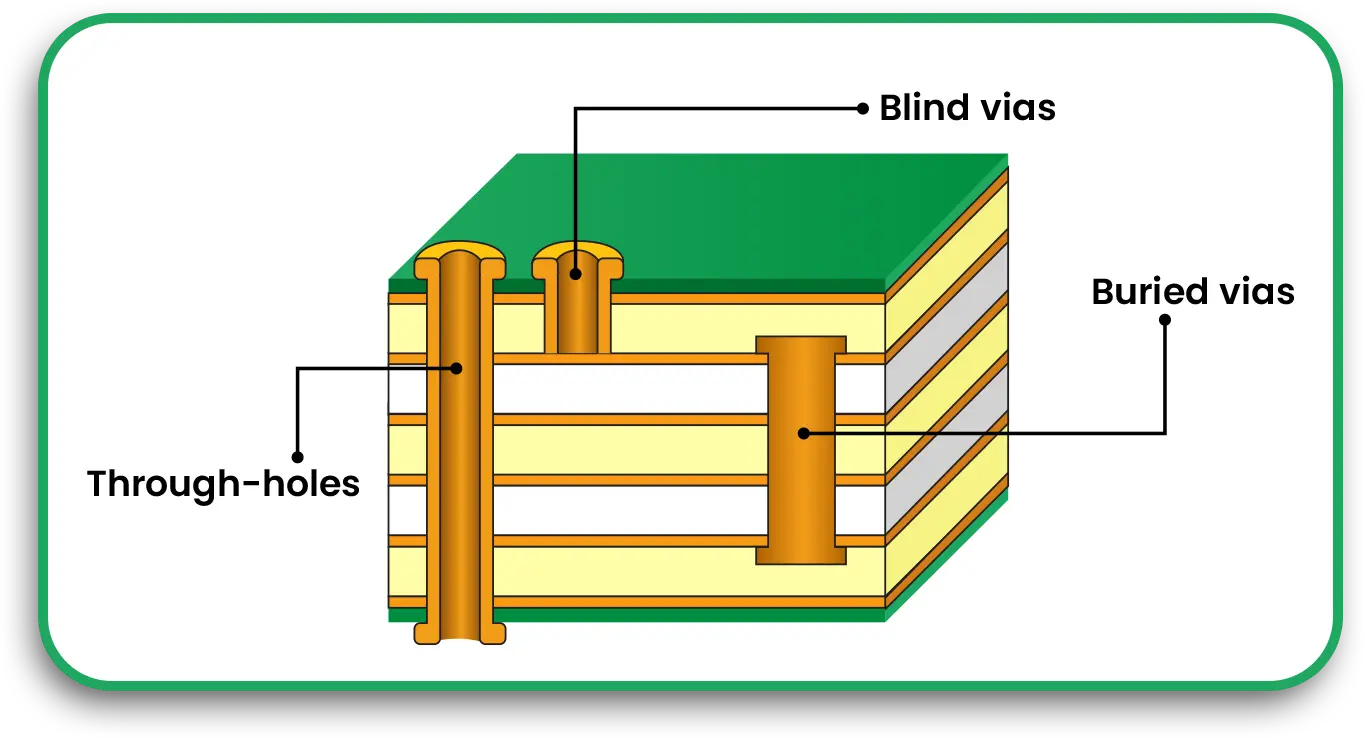

4. Drilling Holes

Holes are drilled for mounting components and vias, which connect different layers in multilayer PCBs.

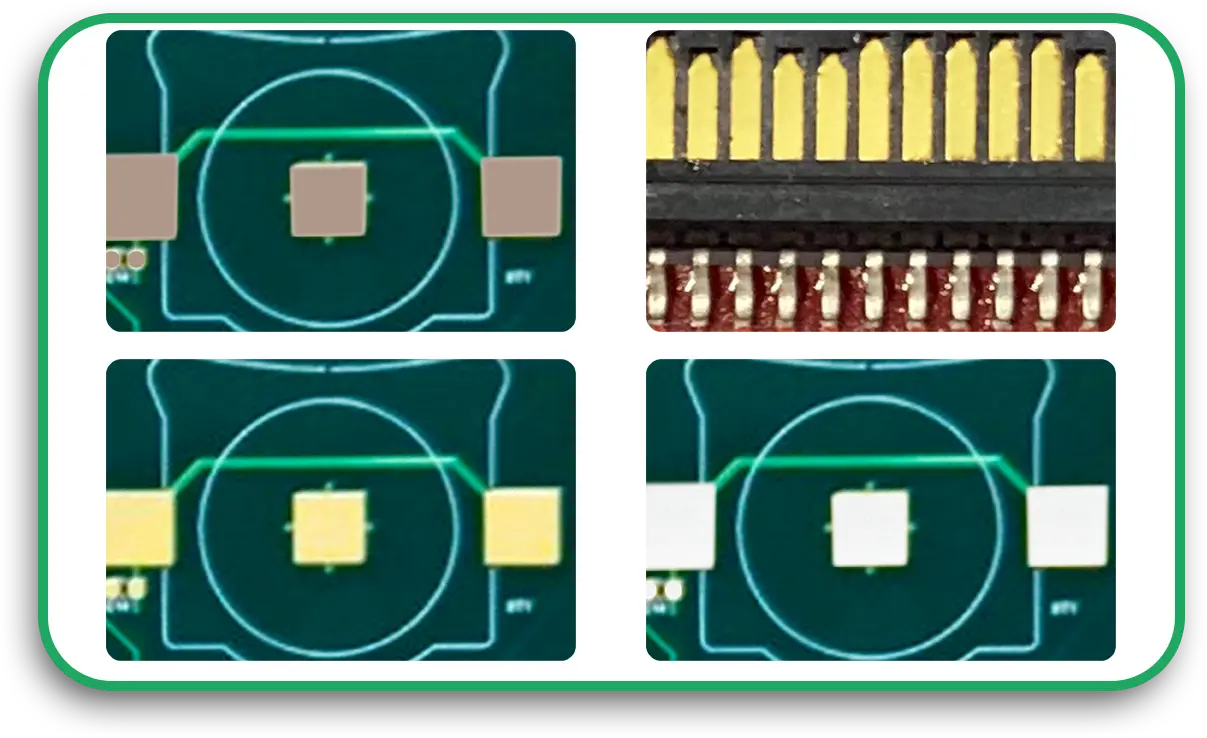

5. Plating and Surface Finishing

Copper-plated vias and surface finishes, such as ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling), improve conductivity and durability.

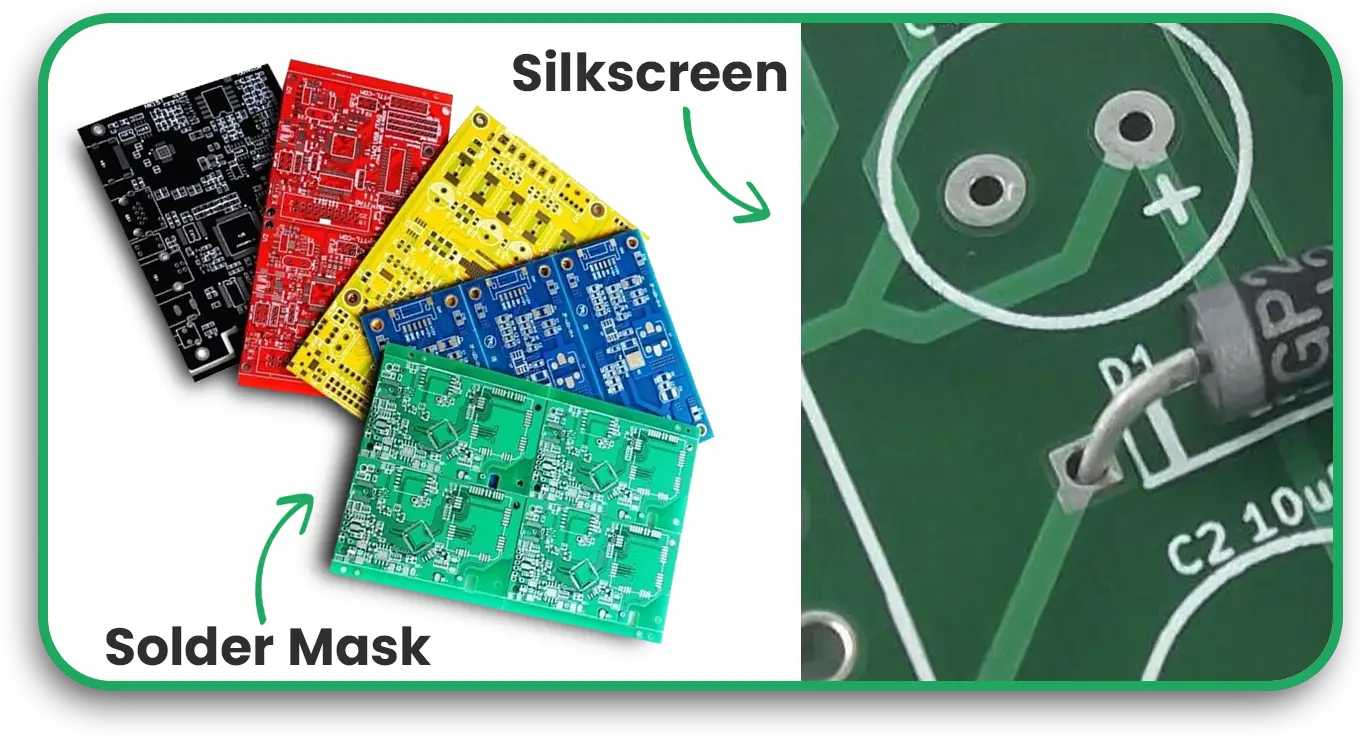

6. Solder Mask and Silkscreen Application

The solder mask protects copper traces, while the silkscreen layer adds component labels and reference marks.

7. Final Inspection and Testing

Each PCB undergoes electrical and optical testing to ensure it meets design specifications before moving to circuit board assembly.

What is PCB Assembly?

PCB assembly (PCBA) is the process of mounting and soldering electronic components onto a fabricated circuit board. This step is critical in turning a bare PCB into a fully functional electronic circuit.

A reliable PCB assembly manufacturer follows strict quality control procedures to prevent soldering defects, misaligned components, or poor electrical connections.

Key PCB Assembly Methods

1. Surface Mount Technology (SMT)

- Uses automated machines to place small components onto the board’s surface.

- Ideal for compact, high-density designs.

- Faster and more cost-effective than traditional through-hole assembly.

2. Through-Hole Technology (THT)

- Components with leads are inserted into pre-drilled holes and soldered in place.

- Provides stronger mechanical bonds, making it ideal for high-stress environments.

3. Mixed Technology Assembly

- Combines SMT and THT for optimal performance and reliability.

- Used in aerospace, medical, and industrial applications requiring both miniaturisation and durability.

Essential Factors for High-Quality PCB Assembly

1. Choosing the Right PCB Assembly Manufacturer

A trusted PCB assembly manufacturer ensures precision, reliability, and compliance with industry standards. Look for certifications such as ISO 9001, IPC-A-610, and RoHS compliance.

2. Component Sourcing and Quality Control

Using high-quality, genuine components prevents failures and ensures long-term reliability.

3. Optimised PCB Design for Assembly (DFA)

Designing for efficient assembly reduces defects and improves yield. Consider factors such as proper pad sizing, component spacing, and thermal relief.

4. Effective Soldering Techniques

Reliable PCB assembly services use reflow soldering for SMT components and wave soldering for through-hole components to create strong electrical connections.

5. Testing and Inspection

- Automated Optical Inspection (AOI) detects misalignments and solder defects.

- X-ray Inspection checks hidden solder joints in BGA and high-density PCBs.

- Functional Testing ensures the assembled PCB performs as expected.

Benefits of High-Quality PCB Assembly

1. Enhanced Reliability

Proper PCB fabrication and assembly techniques prevent short circuits, solder cracks, and component failures, ensuring long-term durability.

2. Improved Electrical Performance

Precision assembly ensures optimal signal integrity, reducing noise and interference in high-speed applications.

3. Faster Time-to-Market

Efficient PCB assembly services streamline production and reduce design revisions, accelerating product development.

4. Cost Savings

Minimising assembly defects reduces rework and production waste, leading to lower manufacturing costs.

5. Scalability for Mass Production

Reliable PCB assembly manufacturers can handle high-volume orders while maintaining consistency and quality.

Latest Innovations in PCB Fabrication and Assembly

1. High-Density Interconnect (HDI) PCBs

HDI PCBs feature smaller traces, microvias, and stacked layers, allowing for compact and high-performance circuit designs.

2. Flexible and Rigid-Flex PCBs

Flexible PCBs improve durability in wearable devices, aerospace, and automotive applications.

3. Lead-Free Soldering

With growing environmental concerns, manufacturers are shifting to RoHS-compliant, lead-free soldering techniques.

4. AI-Driven Quality Control

Artificial intelligence (AI) is improving defect detection and process optimisation in modern PCB assembly lines.

5. Automated Assembly for Faster Production

Fully automated circuit board assembly increases efficiency and reduces human errors, improving overall yield.

Conclusion

High-quality PCB fabrication and assembly is essential for developing reliable, high-performance electronics. From advanced PCB fabrication techniques to precise assembly methods, every step plays a vital role in ensuring product success.By partnering with a trusted PCB assembly manufacturer, you can achieve faster production, improved quality, and cost-effective solutions for your electronic projects.

Looking for Expert PCB Fabrication and Assembly?

At PCB Runners, we specialise in custom PCB fabrication, circuit board assembly, and high-reliability PCB solutions. Contact us today to discuss your PCB assembly needs and get a free quote.

Frequently Asked Questions (FAQs)

1. What is the difference between PCB fabrication and PCB assembly?

PCB fabrication is the process of manufacturing the bare board, while PCB assembly involves mounting electronic components onto the fabricated board.

2. What factors affect PCB assembly quality?

Key factors include design optimisation, component quality, precise soldering, and thorough testing procedures.

3. How do I choose the best PCB assembly manufacturer?

Look for certifications, industry experience, component sourcing capabilities, and quality control measures when selecting a PCB assembly manufacturer.

4. What are the advantages of multilayer PCBs in assembly?

Multilayer PCBs offer higher circuit density, improved signal integrity, and better heat dissipation, making them ideal for advanced electronic applications.

5. Why is functional testing important in PCB assembly?

Functional testing ensures the assembled PCB works as intended, preventing failures in real-world applications.