These days, almost every electronic device uses a printed circuit board (PCB). New technologies are constantly emerging, and with them, the demand for advanced PCBs rises, particularly in the aerospace, telecom, and medical device sectors.

One of the most commonly used technologies for achieving strong and durable connections is the Plated Through-Hole technology (PTH).

This article compares PTH technology with other advanced methods of making custom-printed circuit boards, such as HDI circuit boards and their PTH counterparts. It also details the key features of custom-printed circuit boards and their durability with PTH technology.

What is PTH Technology?

With PTH Technology, an entire PCB assembly is utilized, where holes are drilled through the board and plated with a specific metal to create sturdy electrical connections between the board layers. This type of assembly allows for proper soldering of leads through the board using components equipped with leads.

How PTH Works

Drilling: The PCB is drilled with mechanical drills that create precise holes.

Plating: The inside walls of the holes are coated with conductive materials like copper.

Insertion of Components: Components with leads are placed through sufficient holes.

Soldering: A soldering iron is used to solder the leads for a secure connection both electrically and mechanically.

Types of PTH PCBs

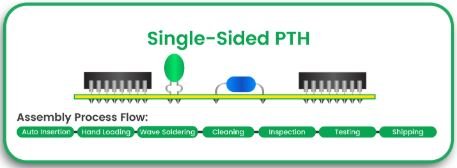

Single-Sided PTH PCB: This is used in basic circuit designs only.

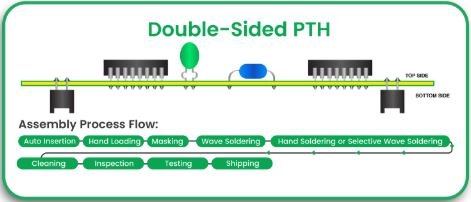

Double-Sided PTH PCB: The components are placed on both sides of the board, increasing the circuit’s complexity.

Multi-Layer PTH PCB: Enhanced features with multiple interconnected layers for a complex, highly efficient multifunctional task.

The Merits of PTH Technologies

Durable Connections: Ideal in applications with high stress, these connections are mechanically rigid and have reliable electrical contact.

Multi-layer Interconnects: Allows for the effortless interconnection of different layers of a custom printed circuit board and its components.

Superior Heat Endurance: Endure highly high temperatures which are prevalent in the industrial and automotive sectors.

Dependable In-Higher Current Applications: Superior current bearing capability in comparison to surface-mounted devices.

Easy Assembly: Suitable for wave soldering and other forms of automation soldering processes.

PTH Technology vs. HDI Circuit Boards

While PTH technology has been a standard for years, High-Density Interconnect (HDI) circuit boards offer an alternative for modern miniaturized electronics.

Key Differences

| Feature | PTH Technology | HDI Circuit Boards |

| Connection Type | Plated through-hole | Microvias & blind/buried vias |

| Board Density | Lower | Higher (supports compact designs) |

| Electrical Performance | Standard | Enhanced signal integrity |

| Manufacturing Cost | Moderate | Higher due to advanced processes |

| Reliability | Excellent for high-stress applications | Ideal for lightweight, high-speed devices |

Choosing between PTH and HDI

For military, aerospace and industrial electronics, choose PTH PCB boards as they are built to sustain extreme conditions.

For consumer electronics, smartphones, and other devices with space constraints, consider using HDI circuit boards.

Expert Insight

With the increase in the complexity of PCB designs, more factors need to be considered apart from conventional PTH processes. An obstacle that has emerged is the mechanical drilled hole size and plating aspect ratio, which could reduce routing density. To achieve high feature density, PCB fabricators focus on enabling all-in-ravaged capabilities with laser micro vias, blind and buried vias, and stacked micro vias. These techniques improve design flexibility and signal integrity.

Thermal cycling and reliability are other key factors. Exposed PTH solder joints have to bear the stress of heat expansion and contraction cycles, which significantly affects their reliability. To reduce the impact of these issues, improved plating processes and innovative materials ensure long-term durability in harsh conditions.

Uses of PTH PCB Boards

- Aerospace and Defense

- Provides exceptional reliability in harsh environments.

- Endures physical vibration shocks.

- Covers vital avionics and radar systems.

- Medical Devices

- All needed electrical connections are sustained over extended periods in lifesaving devices.

- Resistant to harsh surroundings and sterilization procedures.

- Applied to MRI machines, pacemakers, and some diagnostic equipment.

- Automotive Electronics

- Sustains high temperature and vibration experienced in vehicles.

- Controls power management and engine control units.

- Supports ADAS.

- Industrial Equipment

- Allowed the development of harsh designs for factory automation.

- Applied in the distribution of power and the operation of heavy equipment.

- Guarantees dependability within severe industrial conditions.

- Consumer Electronics

- Guarantee reliability for the home electronic devices and video gaming systems.

- Applied in audio systems, televisions, and other smart appliances.

Engineering Considerations for PTH Technology

Hole Size and Aspect Ratio: Ensuring that the ratio enhances the conductivity and the mechanical strength.

Plating Thickness: Sufficient thickness of copper in the drillable region to withstand electrical gaps and make sure that there is no failure.

Signal Integrity: By making a good layer stack up and placing the vias in the correct positions, we do not allow for any electrical contaminations between the different levels.

Future of PTH Technology

As crucial as PTH technology is for high-reliability uses, developments in HDI circuit boards and the via-in pad technique certainly herald a new era in PCB manufacturing. Engineers are increasingly inventing hybrid designs that use a combination of PTH and HDI technologies to achieve an optimal balance of reliability, performance, and cost.

New Innovations in PCB Design and Manufacturing

Use of Novel Materials: New substrates that provide better strength.

More Effective Plating: Increasing the strength and conductivity of the board.

Manufacturing Automation: Improving accuracy and decreasing the cost of the processes.

Hybrid PCBs: The use of the two methods to achieve the best results.

Final Remarks

The importance of PTH technology in the manufacturing of custom-printed circuit boards cannot be overstated; it is the most dependable technology with the greatest effectiveness in high-stress situations.

PTH PCB boards remain the preferred option in industries where long-term durability and performance are critical, even though limited compact designs are beneficial in HDI circuit boards. Appreciating the merits of each technology enables PCB fabricators to design PCBs that meet the requirements of different applications and industries.

Are you looking for a supplier that can produce PCBs with a highly reliable design? Contact us today, and let us help you with your electronic requirements.