If you’re working on electronics or dealing with any kind of circuit board assembly, you may have heard the term “FR4.” But what exactly is it, and why does it matter so much? In this guide, we’ll break it all down for you. You’ll learn how this important material plays a key role in the performance and reliability of your circuit boards.

What is FR4?

FR4 stands for Flame Retardant level 4. It is the most widely used printed circuit board material in the electronics world. This fibreglass-reinforced epoxy laminate is well known for its strong mechanical strength, thermal stability, and electrical insulation properties. In simple terms, FR4 is the solid green or yellowish material you often see underneath the shiny copper lines on a PCB.

Why is it called FR4? The term “FR” indicates that it is flame resistant, and the “4” stands for the grade level. This material doesn’t catch fire easily and can handle a lot of stress, making it perfect for circuit board applications.

Why FR4 is Popular in PCB Design

For most PCB circuit board manufacturers, FR4 is the default choice when creating both high-performance and straightforward circuit boards. Here are some reasons why:

- Excellent Electrical Insulation: FR4 doesn’t conduct electricity, which helps keep different parts of your circuit board working without interference.

- Strong and Lightweight: FR4 is tough but doesn’t add much weight, which is essential for both small and large devices.

- Moisture Resistant: FR4 does not absorb water easily. That means your circuit board will continue working well even in humid environments.

- Affordable: It’s cost-effective compared to other high-performance materials.

The Importance of Circuit Board Material

When designing a PCB, the circuit board material you choose will affect your product’s overall quality and performance. For high-frequency or high-heat applications, materials must have low dielectric loss and high thermal stability. FR4 hits a good balance for most common uses. That’s why it remains the top pick among circuit board assembly professionals.

In some advanced applications, like aerospace or radio frequency boards, designers may choose special materials like PTFE. But even in those cases, FR4 is often used for internal layers or support.

How FR4 Affects Signal Quality and Durability

Signal quality in a PCB is important. You don’t want signals to weaken or get distorted while travelling through the board. FR4’s stable electrical properties help ensure that doesn’t happen.

Additionally, the mechanical strength of material FR4 helps protect your components. When your board is dropped or handled roughly, FR4 can prevent cracks or breaks.

FR4 Thickness and How It Affects Your Board

FR4 comes in various thicknesses. Common values include 0.8 mm, 1.6 mm, and 2.4 mm. Choosing the right thickness depends on your needs. For example:

- Thicker Boards: Better for handling higher currents or for boards with many layers.

- Thinner Boards: Good for lightweight, compact devices like smartphones.

Talk with your PCB circuit board manufacturer to select the right thickness for your project. If you are building a multilayer board or adding heavy components, thicker FR4 may be better.

Comparing FR4 with Other Materials

There are many other printed circuit board materials available. Some of these include:

- PTFE (Teflon): Excellent for high-frequency applications but expensive.

- Polyimide: Great thermal performance, often used in flexible PCBs.

- CEM-1 and CEM-3: Cheaper than FR4 but not as strong or reliable.

While each of these has its place, FR4 remains the best all-around choice for most general and high-performance PCBs.

FR4 in High-Performance Applications

Even though FR4 is common, that doesn’t mean it can’t handle demanding tasks. Many circuit board assembly experts use FR4 for:

- Automotive Electronics: FR4 can stand up to the heat and vibration in cars.

- Consumer Devices: Phones, tablets, and TVs all use FR4-based boards.

- Industrial Equipment: Machines and tools that need rigid, reliable boards.

In these cases, the FR4 used may be a higher-grade version with better heat resistance or lower dielectric loss.

Best Practices for Working with FR4

If you’re using FR4 in your design, here are some tips to get the best results:

- Plan Your Layout Carefully: FR4 has good electrical properties, but placing high-speed signals too close together can still cause issues.

- Control Heat Flow: Use heat sinks or thermal vias to manage heat buildup.

- Choose Quality Manufacturers: Not all PCB circuit board manufacturers offer the same FR4 quality. Ask about their material sources.

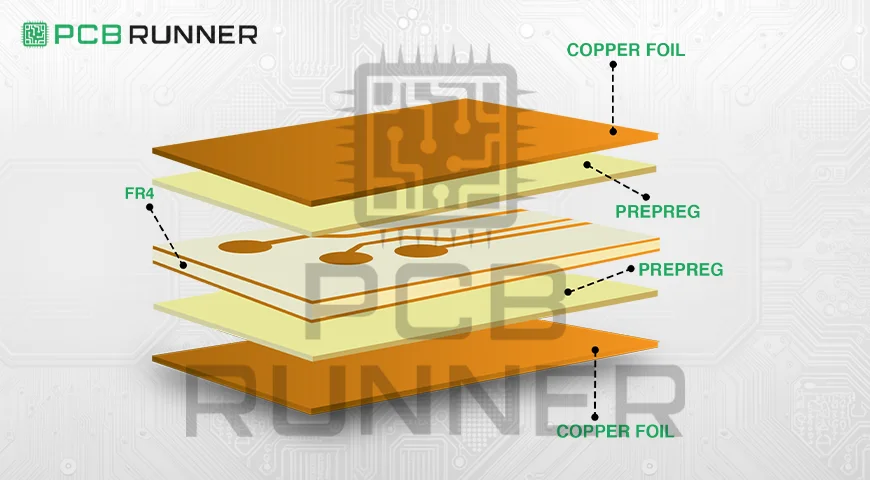

Role of FR4 in Multilayer PCBs

Multilayer boards are made by stacking several layers of FR4 with copper in between. This setup is used in complex electronics where space is limited. Thanks to its strength and thermal stability, FR4 can handle this layered design without warping or cracking.

Circuit board assembly for these designs must be done with care, but FR4 helps make the job easier and more reliable.

FR4 and Environmental Factors

You might wonder how FR4 holds up in extreme conditions. The good news is that it performs well in a range of environments:

- Temperature Range: FR4 can usually operate between -50 to +130 degrees Celsius.

- Humidity: Its water resistance helps avoid corrosion or failure.

That makes FR4 a good fit not just for home devices but also for field equipment and outdoor gear.

What to Ask Your PCB Manufacturer

Before starting your next project, ask your PCB circuit board manufacturer the following questions:

- What grade of FR4 do you use?

- Can you handle multilayer designs using FR4?

- How do you test for material consistency and quality?

Reliable pcb circuit board manufacturers will provide clear answers and even show you their material specs if asked.

Future of FR4 in PCB Design

FR4 has been around for decades, but it continues to evolve. Manufacturers are improving their performance by:

- Enhancing heat resistance

- Lowering signal loss

- Making it more eco-friendly

So, while new materials are emerging, FR4 will likely remain a top choice in the industry.

Final Thoughts

Choosing the right circuit board material is a big decision. FR4 offers a great mix of strength, electrical performance, and affordability. It’s trusted by PCB circuit board manufacturers all over the world. If your project needs reliability, cost-effectiveness, and good performance, FR4 is likely your best bet.

Whether you’re designing a simple gadget or a high-performance system, understanding material FR4 will help you make smarter choices.

Want to get the most from your design? Talk to your manufacturer about how they use FR4 and how it fits into your circuit board assembly process.