At the heart of modern electronics lie the printed circuit boards (PCBs), which form the backbone of hardware integration. The performance of electronic devices is constantly increasing in magnitude, and in turn, the associated risks of interference and performance-related issues are worsened. The dependability and high performance of these boards require PCB shields and shielding techniques to minimize the risk of electromagnetic interference (EMI).

For heavy copper PCBs that are used with high-current and high-power devices, shielding becomes even more crucial. These boards operate in extreme conditions and thus are suited for aerospace, automotive, and industrial automation applications. Understanding the shielding capabilities of PCBs will help design more robust and efficient boards.

What Are PCB Shields and Why Are They Important?

PCB shields are barriers that protect the circuitry from electromagnetic interference (EMI). They operate by removing unwanted signals and isolating delicate components from harm. Shielding is necessary because circuits will respond to interference by distorting signals, which will reduce performance or cause failure altogether.

Benefits of PCB Shielding

- Reduces EMI and RFI – Minimizes unwanted interference from other devices.

- Improves Internal Signal Integrity – Facilitates stable data transfer.

- Protects Sensitive Components – Shields soft parts from sounds picked outside.

- Increases Reliability – Lessens chances of failure with highly powered devices.

Power electronics and high-density interconnect (HDI) designs employ heavy copper PCBs for their increased current carrying capabilities. However, effective shielding is required to ensure these boards perform efficiently in harsh environments.

What Are Heavy Copper PCBs?

Specific forms of PCBs, known as heavy copper PCBs, include copper layers that are thicker than average. While typical PCBs have 1 to 3 oz of copper per square foot, heavy copper PCBs have 3 to 20 oz. The additional thickness allows these PCBs to carry much higher currents without overheating and deteriorating over time.

Advantages of Heavy Copper PCBs

- Withstands high currents without excess heating.

- Dissipates heat energy effectively.

- Reduces stacking in power applications.

- Withstands extreme environments and, therefore suitable for industrial use.

These enable heavy copper PCBs to be favored by various industries that demand efficiency and durability. However, maintaining signal integrity for these PCBs requires specialized shielding techniques.

Essential PCB Shielding Techniques

1. Faraday Cage Shielding

A Faraday cage is defined as a fully enclosed structure made of metals intended to block and disrupt electromagnetic and radio frequency interference (EMI/RFI) on subcircuits. This form of shielding is primary for power electronics and communication devices.

Ideal for:

Do you require structural support on a high-frequency circuit board? What about on-air communication prototyping devices? Or is it more for PCBs with high-density interconnects?

2.Ground Planes and Shielding Layers

In terms of stabilizing an electrical system, a ground plane is considered a multilayer printed circuit board level that aids in reducing interference. Properly designing ground planes mitigate unwanted signal disruptions.

Ideal for:

Is it for industrial automation systems or automotive and aviation applications? How about high-speed digital circuits?

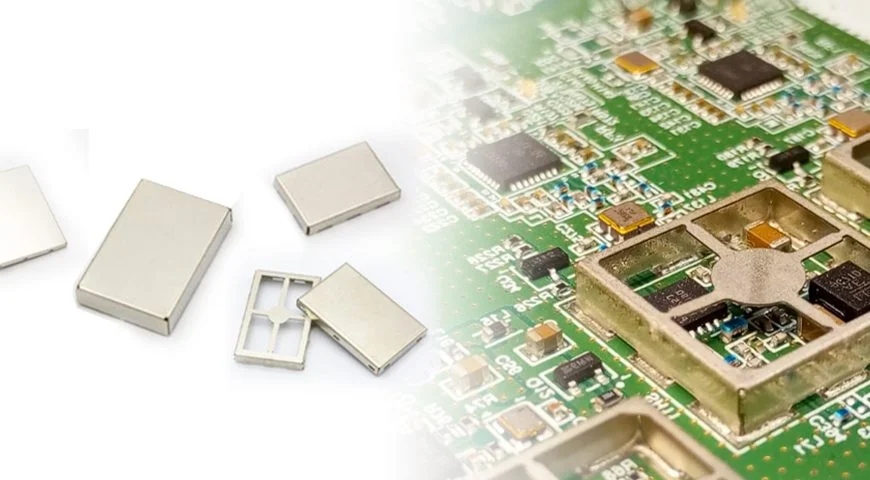

3. Shielding Cans and Metal Covers

Shielding cans are used on wireless modules in RF systems or sensitive analog circuits. They are also well known for use in high-frequency components.

Ideal for:

What about IoT and medical devices? Or perhaps, unattended terminals for automobiles?

4. Trace Shielding

What is trace shielding? It encloses significant traces or wires with grounded copper hugs or guard traces. These are designed to minimize interference.

Ideal for:

What is applicable for sensor-based applications? Isn’t it amazing what can be achieved on high-speed data circuits?

5. Solder Mask Shielding

Solder masks have the ability to prevent oxidation and short circuits, as well as cover the surface of PCBs. Some types even offer additional shielding as a conductive form of protection.

Ideal for:

- Copper-heavy PCB layouts

- High current circuitry

- Electronics for the medical field and military

Selecting Shielding for a PCB

Take the following things into consideration when choosing a PCB shielding method:

1. Operating Frequency

Distortion is much more significant with higher frequency circuits. Thus requires more powerful shielding.

2. Power Handling Capability

For heavy copper PCBs, current-carrying ground planes and shielding cans should be used for the safe handling of heavy current loads.

3. Component Sensitivity

Use a Faraday cage or shielding enclosure if your PCB integrates sensitive analog or RF circuitry.

4. Ambient Conditions

For industrial and automotive applications, corrosion-resistant, durable solder mask materials that shield against external damage should be used.

5. Area Limitations

Effective and compact shielding without additional volume at the expense of area is offered by trace shielding and conductive solder masks.

Different Industries Applications Relating to PCB Shielding

1. Power Electronics

Power supplies and converters use heavy copper PCBs. These require shielding in order to avoid excessive overheating and power loss.

2. Automotive

EVs employ monitor systems that require shielded PCBs for protecting battery management systems and motor controllers from interference.

3. Aerospace and Defense

Military-grade PCBs have sensitive circuits that operate under severe environmental conditions. These require Faraday cages and metal enclosures.

4. Telecommunications

The interconnect (HDI) circuit boards used in 5G networks and satellites require shields to ensure the clarity of signals.

5. Medical devices

Wearable medical devices, imaging equipment, and other peripherals utilize custom-printed circuit boards, which employ shields to ensure accuracy and reliability.

Why Work with a Professional PCB Manufacturer?

Selecting a PCB board manufacturer plays a vital role in designing heavy copper PCBs with proper shielding.

What to Look for in a PCB Manufacturer:

- Profound knowledge in heavy copper PCB fabrication

- Familiarity with high-density interconnect (HDI) technology.

- Prior work on PCB shielding methods

- Capability to offer tailored shielding methods

- Use of high-standard solder mask materials

If you are working on a high-performance PCB project, partnering with an adaptable PCB board manufacturer can help ensure that your design is compliant with regulations.

Conclusion

They are essential for signal integrity, minimizing interference, and improving shielding, cutout, and port durability. Be it power electronics, automotive systems, aerospace, or telecommunications, the proper PCB shielding method will guarantee efficient functionality.

Grasping how the various shielding techniques work allows for the circuit board assembly to be more targeted at reliability and performance.

On the hunt for top-notch, Heavy Copper PCBs?

We at PCB Runners deal with custom fabrication of PCBs and offer advanced shielding solutions as well. Please get in touch to discuss your requirements.

FAQs

1. What is PCB shielding?

Shielding involves the use of metal parts, ground planes, and shielding layers to prevent electromagnetic interference (EMI) from damaging the circuit.

2. Why is shielding important for heavy copper PCBs?

Heavy copper PCBs rely on proper shielding because they carry heavy currents that tend to interfere. Shielding ensures signal and loss stability.

3. What are the best PCB shielding techniques?

Common methods are Faraday cages, shielding cans, ground planes, and solder masks.

4.How does a solder mask help with PCB shielding?

A solder mask protects PCB traces from oxidation while adding another level of noise electrical shielding.

5. Where can I buy good quality heavy copper PCBs?

We provide custom heavy copper PCB solutions with advanced shielding techniques to suit your needs. Reach out to get a quote today.