The Impact of Counterbore vs Countersink on PCB

When designing printed circuit boards (PCBs), it’s essential to understand how different hole configurations impact performance, including counterbore and countersink holes. Each of these types of holes has distinct characteristics that affect fastener placement, board strength, and board integrity. This blog explains when and how to use counterbore or countersink holes on PCBs.

By the end of this blog, you’ll learn how each kind of hole affects your PCB’s durability and assembly process. Whether you are an expert PCB designer or a hobbyist, understanding these differences will optimize your design. We’re also sharing tips on when to use each hole type.

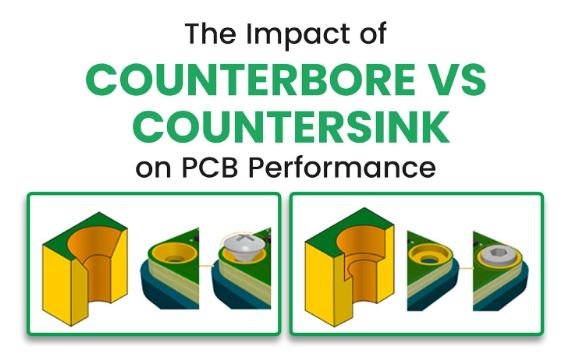

Differences Between Counterbore and Countersink Holes

| Feature | Counterbore Holes | Countersink Holes |

| Shape | Straight cylindrical walls, flat bottom | Conical, tapered shape |

| Function | Allows fastener heads to sit flush with the PCB | Enables screws to sit flush with a slanted surface |

| Opening Size | Larger than screw diameter | Tapered opening size, gradually narrowing |

| Shear Strength | Higher shear strength due to vertical walls | Lower shear strength, especially in high-load applications |

| Material Removal | Less material removed, preserving strength | Requires more material removal |

When to Use Each Type

Counterbore Holes:

- To hold heavier pieces of components in place

- Use them in heavy-duty shear conditions like automotive and industrial systems.

- Screw is held tighter and is not easy to unscrew.

Countersink Holes:

- Ideal for space-saving and low-profile designs

- Common in consumer electronics and aerospace, where aerodynamics are important

- Suitable for aesthetic finishes

Benefits and Application

Knowing when to apply counterbore or countersink holes will directly influence the strength, aesthetic, and efficiency of your PCB designs. For high-stress applications, counterbore holes provide better screw retention and shear strength. They are ideal for industrial or heavy-duty applications.

Countersink holes are ideal if area efficiency or a smooth surface finish are important. In fact, they often dominate applications in electronics, where compactness and sleek finishing are paramount.

The right choice of hole type will, therefore, help improve the mechanical stability and aesthetics of your PCB and achieve the desired performance in its application.

Expert Insight

“Integrating countersink and counterbore holes into PCB design is essential for achieving a seamless mechanical fit within an enclosure while maintaining structural integrity. Countersinking allows screws to sit flush with the board surface, which is particularly beneficial in compact assemblies where space is limited, and a smooth profile is required. On the other hand, counterbore holes accommodate socket-head or cap screws by creating a recessed cavity, offering improved load distribution and enhanced mechanical stability. Altium Designer provides robust tools to define these hole types with precision, allowing designers to specify critical parameters such as mounting hole diameter, countersink angle, and counterbore depth. This level of detail ensures compatibility with chosen fasteners and facilitates accurate manufacturing outputs.”

“To maximize the effectiveness of countersink and counterbore features in PCB layouts, designers must consider factors such as the type of fasteners, enclosure constraints, and fabrication capabilities. Properly defining hole dimensions and tolerances in the design phase minimizes assembly issues and improves product reliability. Altium Designer’s integration with fabrication outputs, such as NC Drill Files and IPC-2581, ensures that counterholes are accurately translated to manufacturing. Additionally, features like the Hole Size Editor and Draftsman tool provide clear documentation and visualization of counterhole specifications, streamlining communication with manufacturers. By leveraging these capabilities, engineers can enhance both the functionality and manufacturability of their PCB designs.”

FAQs

Q: What is the advantage of counterbore and countersink?

A: Counterbore holes are more recommended for applications with heavy burdens since they are more sheared and poor in maintaining screws, so the bolts once tend to be unfixed easily. On the other hand, countersinks are more designed for flush with a tapered edge, which, in turn, is sought out by Small or aesthetic designs.

Q: What is a countersink in a PCB?

A: A countersink in PCB is defined as a hole that has a wider cone shape and allows screws or other mechanisms to fit the surface behind it. This integration goes for a smooth finish, aiding the visual appearance, and is particularly useful in designs that require a low height.

Q: What is the difference between countersinking and counterboring SDI?

A: Countersinking creates a conical hole while counterboring entails creating a cylindrical hole with a flat tip. Thus, there are differences between holes and their intended functionalities—counterbore gives the highest shear strength, but it is only for countersinks if it aims at a smoother flush finish.

Q: What is the disadvantage of countersink?

A: Countersinks remove more material than counterbores do, making the PCB weaker. Additionally, countersinks provide less shear strength and do not suit high-load or high-stress applications well.

Q: What is the advantage of countersinking?

A: The most significant advantage of countersinking is its ability to create a smooth, flush surface for screws and fasteners to be inserted, which would be applicable for applications in which aesthetics and compact design are crucial.

Q: When to apply counterbore?

A: Apply counterbore holes whenever higher shear strength, secure fastener retention, and a smooth, flush screw-and-washer fit are needed. This is especially true in heavy-duty or industrial applications.