With the development of wearable circuits, monitoring one’s health, wellness, and daily activities has become far easier. These advancements range from fitness trackers to health monitoring devices that use flex PCB boards, printed circuit boards, and other flexible circuit board assembly technologies.

The rapid developments of PCB technology have resulted in lightweight and flexible electronic components that are perfect for wearable devices.

These devices can collect critical health data, track fitness activity, and provide remote healthcare aid. This marks a considerable change towards more proactive healthcare monitoring and extends across industries such as healthcare and consumer electronics.

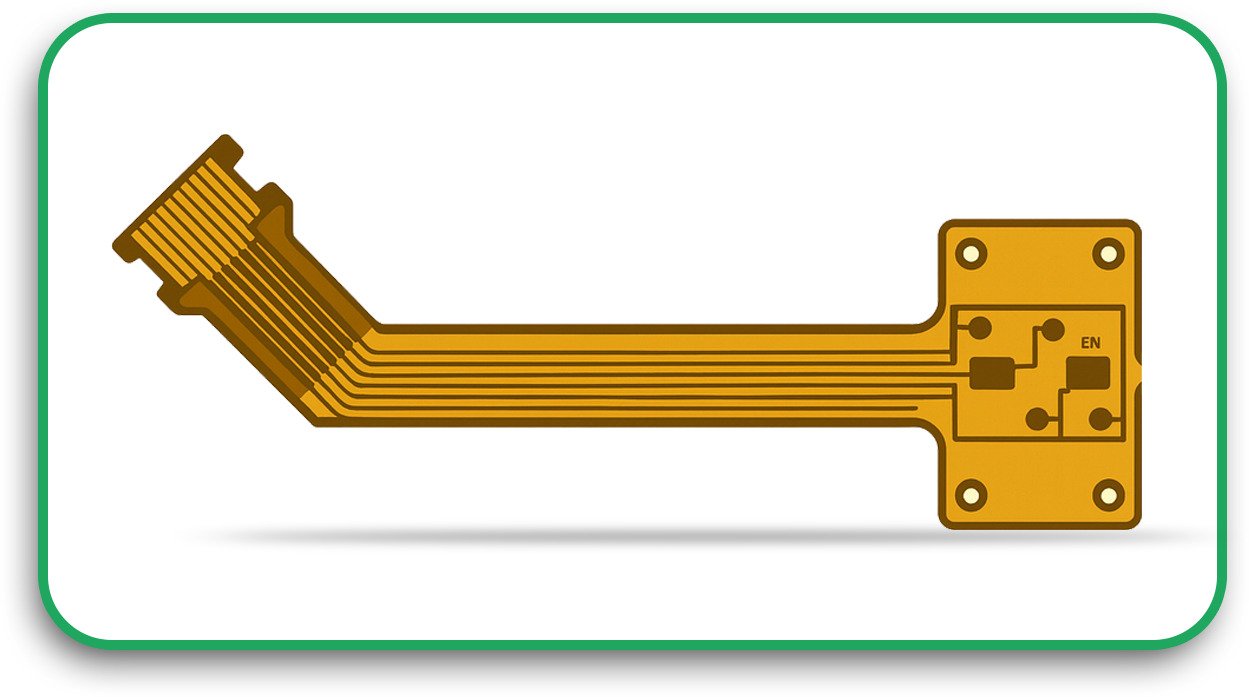

The Role of Flexible Printed Circuit Boards (FPCBs) in Wearables

FPCBs are critical for wearables due to their lightweight and stiff yet pliable attributes. Fitness bands, smartwatches, and health monitors are examples of wearables that integrate these durable circuits. FPCPs can withstand constant motion and harsh environmental conditions.

Here is a summary of some popular wearable applications.

Smart Skin for Health Monitoring

Smart skin technology utilizes adhesives placed on the skin to track metrics such as heart rate, body temperature, and EKG readings. The flex PCB boards embedded into these patches allow for wireless real-time data transfer directly to the healthcare professional’s systems.

Here’s how you can transform your writing:

- Step and calorie counting and sleep pattern tracking fitness trackers

- Augmented reality smart glasses

- Batteries are no longer a necessity with solar-powered wearables.

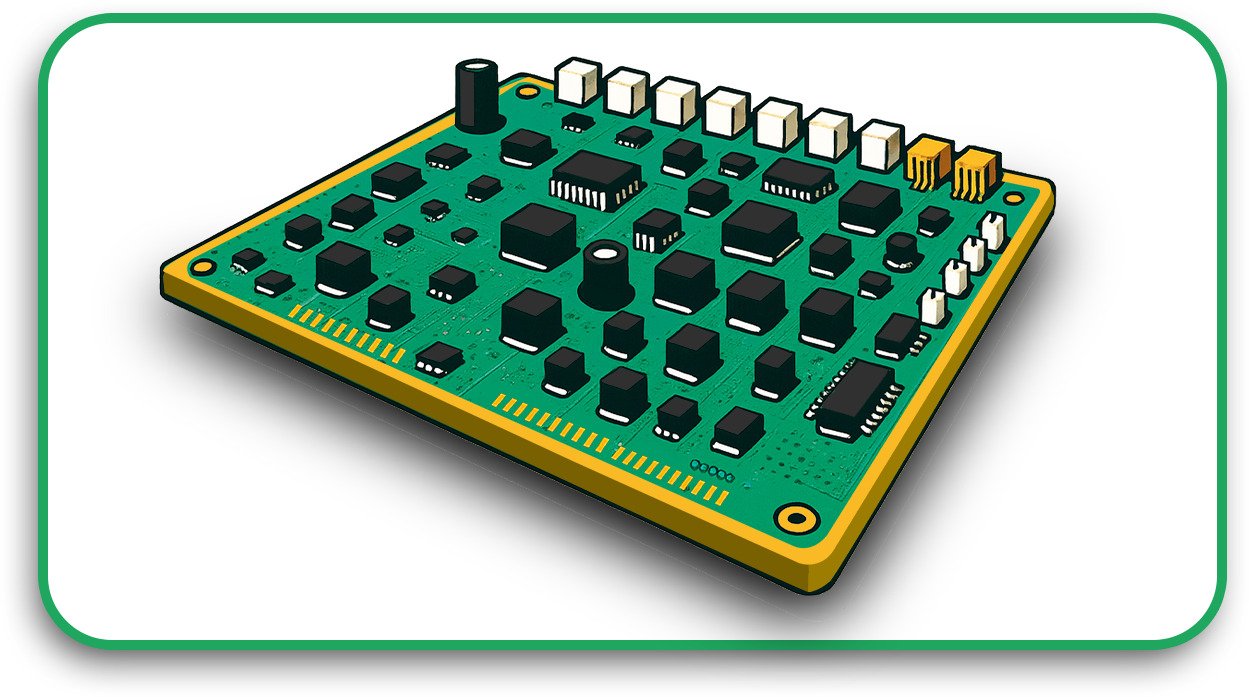

Advanced Applications in Consumer Wearables

Now, consumers can utilize multiple sensors, GPS tracking, and cellular communication in one device—wearable devices that allow for an effortless and enhanced user experience.

Expert Insights on Wearable Technology

‘In the age of smartphones, smartwatches, fitness trackers, and wearable internet-enabled clothing:’ This is how his findings published on ResearchGate portray the technology of today. According to a detailed investigation, “Wearable technology and sensors are set to become one of the most effective tools for monitoring health conditions on a real-time basis. Smart wearables fitted with sensors can capture and analyze multiple parameters, activities, and health conditions of the user.”

Consumers are already using fitness trackers with accelerometers and optical heart rate monitors built into them to measure step count and heart rate during exercise. However, wearable clinical sensors are being developed that can measure blood pressure, respiration rate, oxygen saturation, skin temperature, and hydration level.

Wearable devices are capable of monitoring health parameters 24/7 and interacting with the users by providing feedback due to wireless stitching and machine learning algorithms. According to the research, wearable sensors are capable of enabling medical staff to provide timely medical interventions for patients whose health indicators shift unpredictably by enhancing self-consciousness toward their food intake, sleep, activity levels, and stressors.

Flexible PCBs and Power Sources

Power management is crucial for any wearable device. The current investigation focuses on the development of stretchable power supplies based on the integration of PCB prototype carbon nanotube microfilm and flexible lithium-ion batteries.

Potential Benefits:

- Increased battery life

- Reduced power constraint

- Simplified device ergonomics and usability

- These advancements ensure that circuits in the wearable device are suitable for fitness and other sports professionals at all levels of physical activity.

Future of Healthcare with Wearable Circuits

The future of healthcare will greatly benefit from the increasing use of novel flexible printed circuit boards. New iterations like these are expected:

Enhanced surgical instruments: Improved accuracy and effectiveness in operational procedures.

Neuro-prosthetics: Helping control prosthetics to assist patients affected by neuromuscular disorders.

Biosensors: Effortlessly transmit health-related information to other places without the need for physical human interaction.

Such innovations would greatly facilitate healthcare service delivery, saving time and allowing better healthcare outcomes for the patients.

Moreover, due to wearable circuits, remote monitoring of patients is emerging, which minimizes the frequency of patient checkups in hospitals and allows for prompt treatment responses.

Conclusion

The versatility of custom-made printed circuit boards, flex PCB boards, and sophisticated flexible printed circuit board assembly is going to change the face of healthcare and consumer electronics. This is because they are crucial in the building blocks of purpose-designed wearable gadgets.

PCB Runner is recognized on the market as a provider of top-quality PCBs and specializes in their design and manufacture, including for wearable devices. Let us know what your requirements are, and we will provide a custom PCB prototype or flexible printed circuit board assembly at an affordable price.

Do you want to make your next wearable gadget a reality? PCB Runner is the best company for the construction and design of quality PCBs. Schedule a meeting with us today.

FAQ’s

What are wearable circuits?

Wearable circuits are electronic parts embedded in clothing that enable actions such as health tracking, fitness monitoring, and data uploading.

Why are flexible printed circuit boards important for wearables?

The FPC’s lightweight, flexible, and sturdy nature makes it ideal for shrinking, exceptionally tiny, wearable PCBs.

What industries benefit from wearable circuits?

Wearable circuits find use in healthcare, fitness, consumer electronics, and military applications.

How do contact lenses with wearable circuits help diabetic patients?

These contact lenses communicate data continuously, relaying glucose levels in real-time without the need for finger pricks.

How can PCB Runner help with wearable circuit development?

PCB Runner specializes in custom PCB layout and production, offering flex PCB board design services for wearable technology.