Choosing the right PCB finish is fundamental in PCB production processes, as it impacts the durability, solderability, and overall quality of the PCB. Whether it’s flex, rigid, or multilayer PCBs, the right PCB manufacturing outline finish can be selected to provide an optimal connection between the components and board, which enhances the board’s durability.

For circuit board manufacturers, the choice of PCB surface finish determines the production cost and environmental and multi-assembly process viability. In this article, different types of surface finishes will be analyzed in detail for their benefits, comparing their differences, and helping choose the most effective one for your preferred manufacturing process.

What Is a PCB Surface Finish?

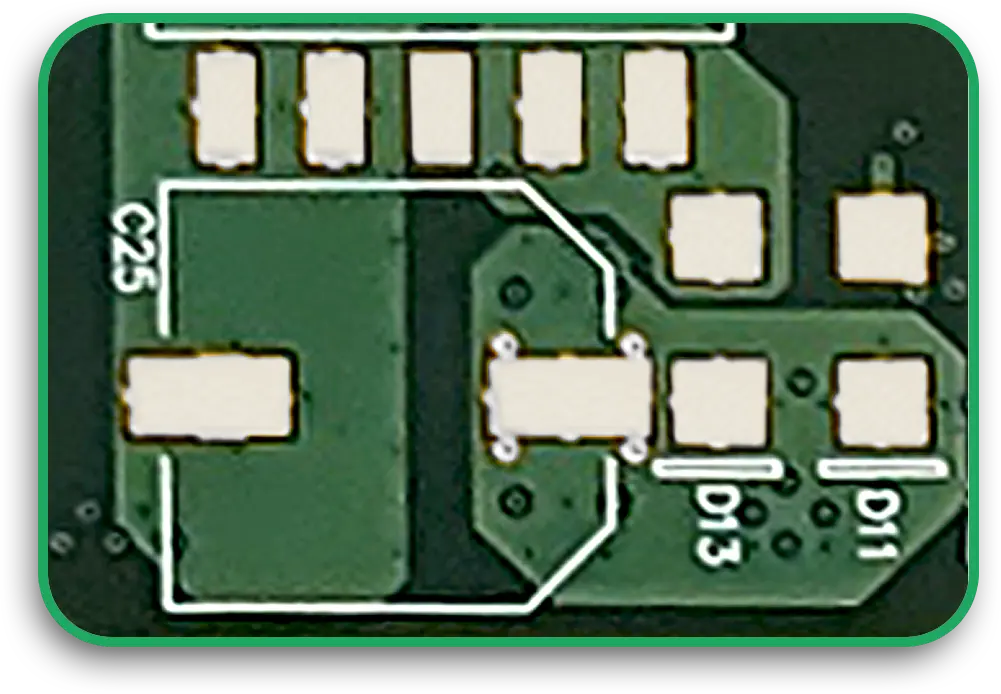

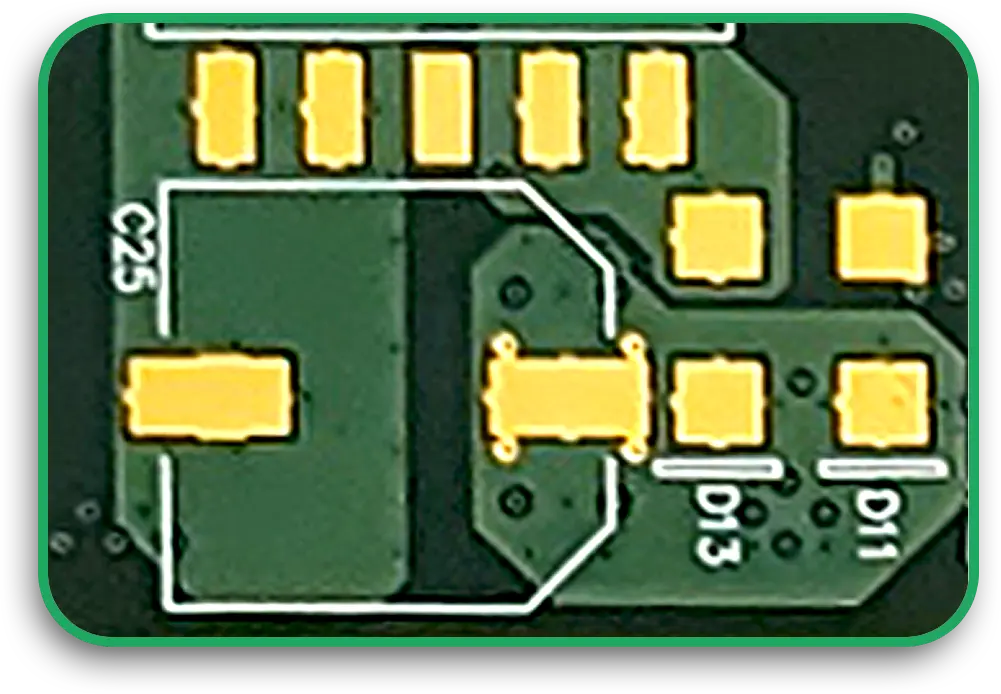

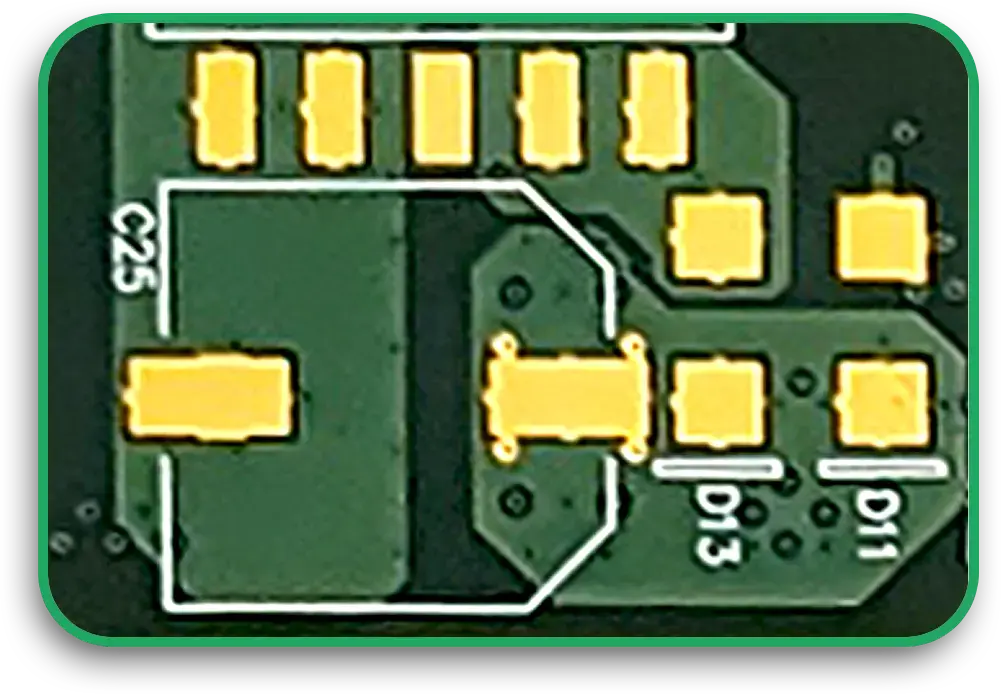

It is a coating layer for circuit boards that are put on exposed copper in order to minimize oxidation and enhance soldering. The exposure of copper makes the PCB lose its reliability and efficiency. Along with PCB surface finishes, it guarantees that the metal is conductive enough to handle the heat during assembly and strong enough to create quality solder joints.

For manufacturers that make PCB boards, picking a PCB finish that guarantees durability requires multiple factors to be taken into account, including:

- Nature of the electronic assembly, that is, whether it’s manual or automatic.

- Climate conditions like humidity and temperatures

- Life expectancy of the product

- Budgetary limits

Each type of finish provides unique features, making them suitable for a particular function.

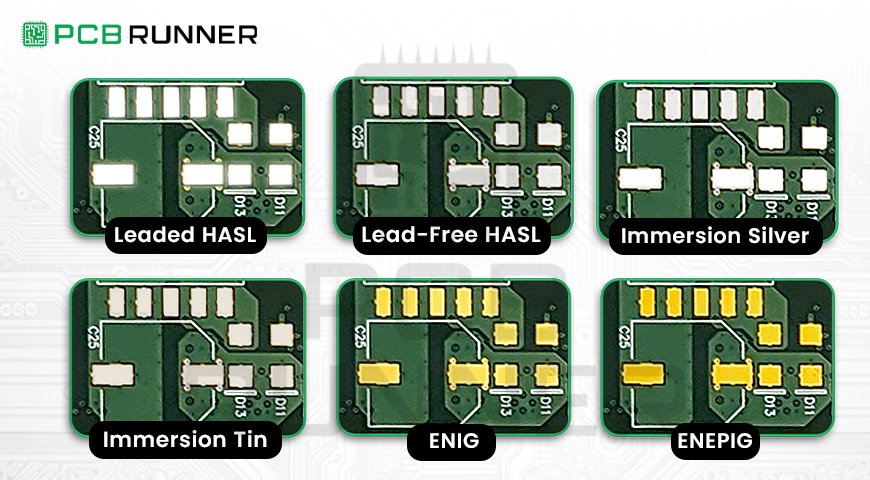

Types of PCB Surface Finishes

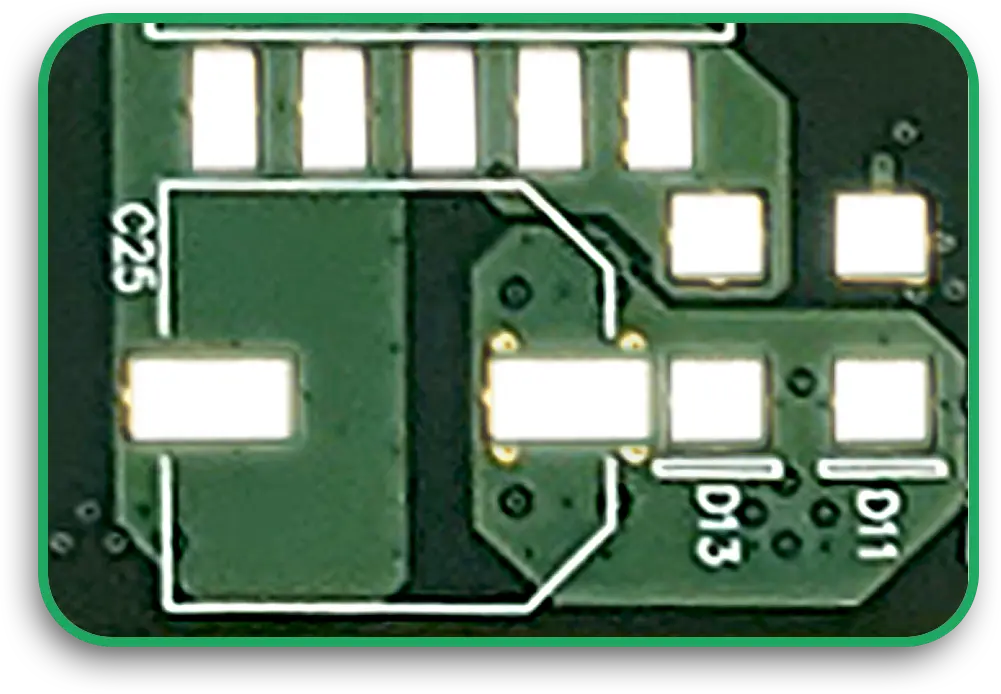

1. Hot Air Solder Leveling (HASL) – The Standard Option

Summary:

HASL is one of the most common PCB surface finish types due to its low cost and dependable solder bonding. The process used involves dipping the PCB in a “heat pot,” or liquid solder, then blasting it with hot air knives to take off the surplus solder.

Advantages:

- Widely used and inexpensive

- Dependable solder joints

- Perfect shelf life

Disadvantages:

- The surface is rough, which can lead to issues with fine-pitch parts.

- It is not appropriate for flex PCBs because of thermal damage.

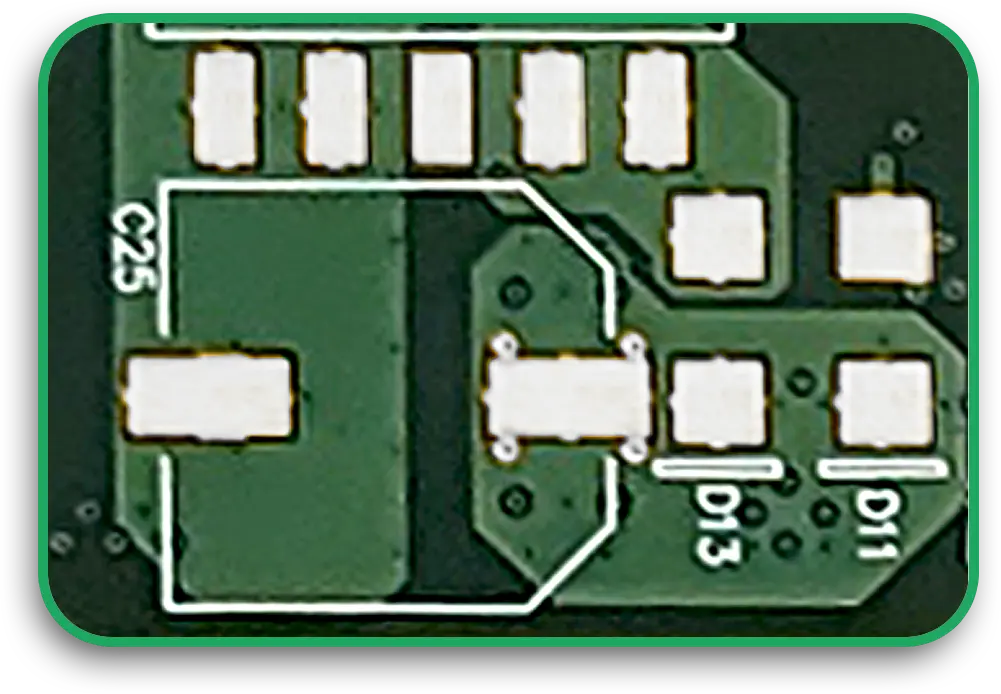

2. Lead-Free HASL – The RoHS Compliant alternative

Like most lead-free HASL processes, this one uses lead-free solder to comply with environmental regulations.

Advantages:

- Meets environmental regulations

- Profitable and widely accepted

- Order soldering is efficient.

Disadvantages:

- Flex and rigid PCBs may be affected by higher processing temperatures.

- Uneven surfaces could cause assembly problems.

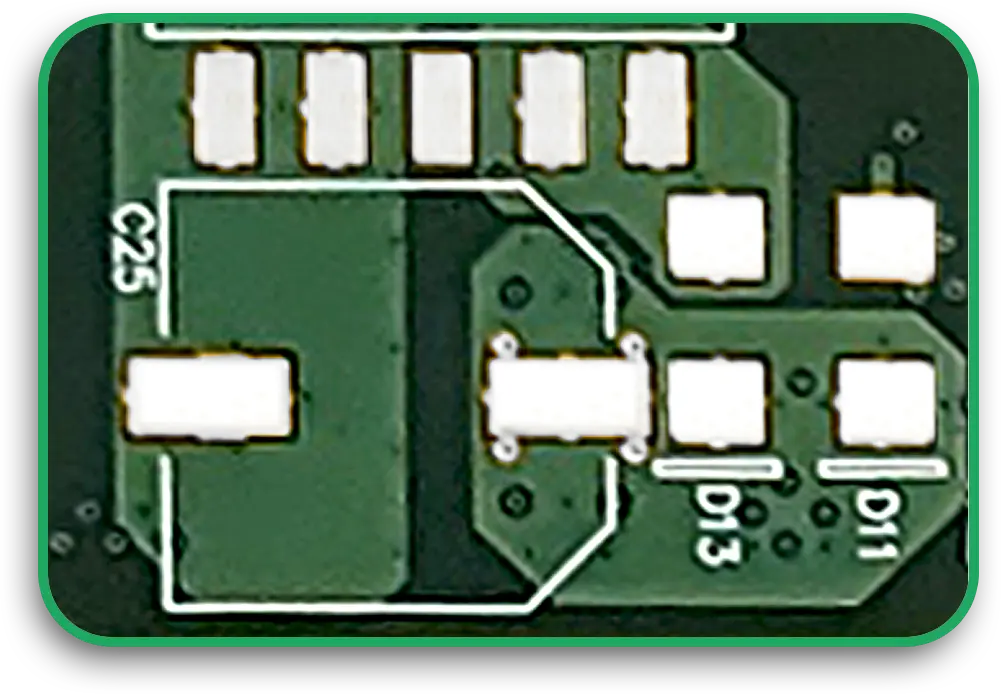

3. Immersion Silver (ImAg) – Best For Signals That Require Fast Processing

Immersion silver is considered to be the best silver plating for printed circuit boards. ImAg plating process excels at providing a reliable interface for high speed signals by needs of performance application consideration.

Advantages:

- Flat surface finish of delicate pitch components.

- Excellent conductive for RF and high-frequency circuits.

- Less expensive than gold plating.

Disadvantages:

- Doesn’t tarnish quickly when stored.

- Difficult to handle without contamination.

4. Immersion Tin (ImSn) – Has a Good Appearance and an Attractive Price

Immersion tin is a good option for soldering that involves the application of copper because it provides a smooth surface that would make soldering a lot easier.

Advantages:

- Provides a smooth surface to accommodate precision placement of components.

- Lead and RoHS compliant.

- Affordable.

Disadvantages:

- Over time, electrical shorts due to tin whiskers could potentially occur.

- It may not have a long shelf life due to oxidation issues.

5. Electroless Nickel Immersion Gold (ENIG) – Ideal and Durable

ENIG bestows a surface with a Thin nickel layer with immersion gold on top, which ensures the highest corrosion resistance and reliability for years.

Benefits:

- Very tough and oxidation-proof

- Even surface for soldering

- Long durability

Drawbacks:

- Relatively expensive when compared to HASL and immersion finishes

- Possible “black pad syndrome” if not executed correctly

6. ENEPIG: The gold standard of finishes.

ENEPIG adds a palladium layer between nickel and gold, enhancing its durability.

Benefits:

- Excellent resistance to corrosion and oxidation

- Great for various reflow cycles

- Less risk of black pad syndrome

Drawbacks:

- More expensive than standard ENIG

- Difficult to manufacture

7. Hard Gold – Primarily Used Where There Is Abuse

Hard gold is applied by plating and is mainly used in connectors, switches, and edge contacts that are subjected to repetitive usage.

Benefits:

- Very durable and wear-resistant.

- Great for multilayer PCB connectors and various industrial uses.

Drawbacks:

- Very costly because of its substantial gold content.

- The hardness makes it unfavorable for soldering.

- Selecting a Finish for Your PCB Needs

- Mutual Exclusions

Assembly Process: For fine-pitch fighters, ENIG and immersion silver work best.

Environmental Conditions: Adverse conditions favor ENEPIG and hard gold.

Cost vs. Performance: While HASL is relatively cheap, gold finishes offer the most effectiveness.

Shelf Life: The economic advantage of gold-silicon finishes like ENIG lies in their extended shelf life.

When selecting a finish for PCB manufacturing, a circuit board maker must consider all of these aspects in order to satisfy the needs of their product.

Comparing PCB Surface Finishes

| Surface Finish | Cost | Durability | Solderability | Applications |

| HASL | Low | Medium | High | General-purpose PCBs |

| Lead-Free HASL | Low | Medium | High | RoHS-compliant PCBs |

| Immersion Silver | Medium | Low | High | High-frequency applications |

| Immersion Tin | Medium | Low | High | Fine-pitch components |

| ENIG | High | High | High | Aerospace, medical, automotive |

| ENEPIG | Very High | Very High | High | Military, industrial |

| Hard Gold | Very High | Very High | Low | Edge connectors, industrial |

Expert Insights

Printed circuit boards (PCBs) are essential in electronic devices, providing both structural support and electrical connections for components. To protect the copper (Cu) pads on a PCB before soldering, different surface finishes are applied. These finishes not only prevent oxidation but also improve solderability, ensuring strong and reliable connections.

During soldering, an intermetallic compound (IMC) layer forms between the PCB pad and solder. While this layer is necessary for a secure bond, excessive IMC growth can weaken solder joints, impacting reliability. The electronics industry closely monitors IMC layer formation, as controlling its growth is critical for long-term performance.

One effective way to manage IMC growth is by modifying PCB surface finishes. Different types of finishes influence how the IMC layer develops, making material selection an important factor in ensuring strong and durable solder joints. By choosing the right surface finish, manufacturers can enhance PCB performance and extend the lifespan of electronic devices.

Future Trends in PCB Surface Finishes

1. Environmentally Friendly And Free of Lead Solder

PCB manufacturers are gradually adopting lead-free and RoHS-compliant surfaces due to growing environmental regulations. Lead-free HASL, immersion tin, and ENIG are becoming more popular as many sectors try to be more responsible.

2. Sophisticated Protective Coatings

New nanotechnology-based standard PCB design packages are allowing engineers to create novel surface coatings that provide better protection from corrosion, oxidation, and mechanical abrasion. This is particularly advantageous for flex and rigid PCBs used in automotive and aerospace components.

3. Application Of Nanotechnology

New approaches to nanomaterial-based finishes for increasing the conductivity and thermal conductivity of PCBs are being investigated. Everything listed here will surely change the way durability and performance for PCB circuit board manufacturers are viewed.

4. Merging Three Dimensional PCB and Flexible PCB Technologies

As multilayer PCB technology and flexible PCB technology progress, so will the usage of finishes, which are for adaptive PCB manufacturing. With ENEPIG and other hybrid finishes, the dependability of complex, high-density PCBs can be attained.

Conclusion

The selection of PCB surface finish is a crucial step for printed circuit board manufacturers who aim to get the best durability, reliability, and performance out of their boards. Whether opting for cost-efficient HASL, precision-based ENIG, or the ultra-durable hard gold finish, possessing knowledge of each finish’s strengths and weaknesses guarantees a seamless manufacturing process.

In the United States, where high-quality PCB manufacturing finishes are needed, PCB Runners provides expert assistance and offers solutions for high-quality fabrication. We aim to assist PC board manufacturers by providing the highest quality surface finishes specific to the industry.

Need Expert PCB Solutions?

Reach out to PCB Runners today for seamless PCB fabrication and surface finish solutions that guarantee performance and durability.

Frequently Asked Questions (FAQs)

What is the most durable PCB surface finish?

Hard gold and ENEPIG are the strongest finishes, as they are resistant to wear, corrosion, and oxidation.

Which PCB finish is best for fine-pitch components?

ENIG and immersion silver feature non-textured surfaces that are suitable for fine-pitch components and high-frequency devices.

How do I choose the right PCB surface finish?

Define your requirements based on cost, assembly process, environmental factors, and product life to choose the best finish value.

Are PCB finishes without lead as dependable as the conventional ones?

Yes, lead-free options, such as ENIG and immersion tin, are compliant with RoHS standards and offer good solderability and durability at the same time.

What impact do PCB surface finishes have on the sustainability of the ecosystem?

Eco-friendly finishes like lead-free HASL and ENEPIG help the reduction of dangerous wastes and aid in adherence to international environmental standards.