While developing multilayer PCBs, an engineer has to consider each part of the board, including hole types. The two types of holes that PCB circuit board manufacturers most commonly use are counterbore holes and holes with countersink features. These holes affect the positioning of fasteners and other components and, therefore, the board’s reliability and structural strength.

Understanding the differences between counterbore holes and holes with countersink features is necessary to make a design choice. In this blog post, I will outline the features of these holes, how they are applied, and the details of crafting PCBs for multilayer PCBs.

Explaining Counterbore Holes in PCBs

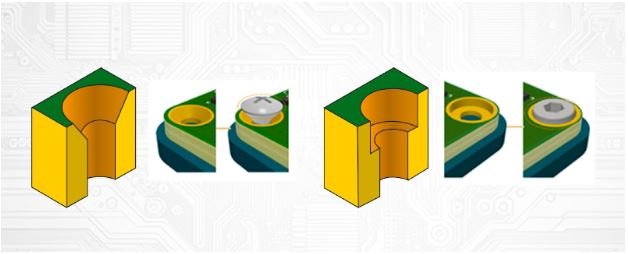

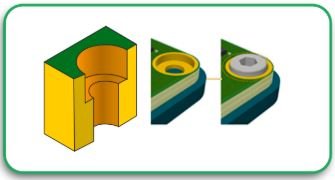

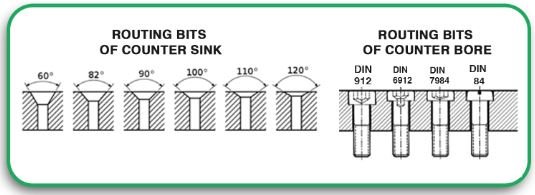

A counterbore hole is a type of hole that has been modified such that the inner face is straight, and the base is flat and cylindrical. Counterbores are common in the industry of PCB manufacture with mechanical fastening as a requirement, whereby the bolt or screw head rests above, continues to be adjusted and allows a general size of tightening within the PCB.

Benefits of Counterbore Holes

- Stable Fastening: Counterboars guarantee that screws and bolts are busy fastened appropriately without disruption.

- Ideal for Thick PCBs: Frequently used in multilayer PCBs, the components of which need to be secured mechanically excessively.

- Counterbore holes can be used for the following: reinforcement designs in the structure that needs the use of machine screws or bolts. For securing heavy components in PCB fabrication. For the use of screws that need to be flush mounted onto the surface of the PCB.

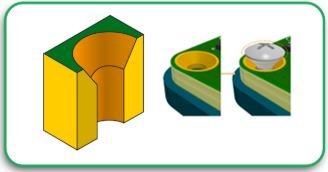

Like with a conical hole, a screw countersink is a cut that permits the screw to be flush with the surface of the PCB. The angle of a countersink is cut to be the same as the head shape of the screw, providing a smooth shift from the screw to the board.

Having countersunk screw holes brings a lot of advantages, such as Aesthetic and design function: It provides smooth covers that do not leave exposed protrusions that can get snagged accidentally. Perfect for thin printed circuit boards: Functions perfectly on thinner boards, barring the use of a counterbore which results in excessive material removal. Improved mechanical strength: Increases stiffness by lowering stress concentration through more evenly distributing force across the PCB.

For printed circuit boards that have limited space, the use of a hole countersink is ideal. Additionally, with the Read-along, face-mounted components eliminate a lot of external protrusion and butt joint screws that are to be sunk into the surface of the board.

How to Decide Between Counterbore and Countersink When Designing a PCB

1. Take PCB Thickness into Consideration

Counterbore holes are more appropriate for working with multilayer PCBs due to the added support they offer. Custom-printed circuit boards benefit more from hole countersink features, as they require less material removal.

2. Review The Needs of Components and Fasteners

If your design has bolts or machine screws, then use a counterbore hole option. If your design utilises flat-head screws that need to rest flush to the surface, you should use the hole countersink option.

3. Consider The Level of Structural Integrity Required

Counterbore holes should be used for added durability in high-stress environments. Hole countersinks work best for applications that require smooth surfaces.

Key Differences Between Counterbore and Countersink Holes in PCBs

| Feature | Counterbore Hole | Hole Countersink |

| Shape | Cylindrical with a flat bottom | Conical with a tapered angle |

| Best for | Thick, multilayer PCBs | Thin PCB fabrication |

| Fastener Type | Machine screws, bolts | Flat-head screws |

| Load Distribution | Evenly spreads mechanical stress | Helps align and secure components |

| Common Applications | Industrial PCBs, heavy components | Consumer electronics, aesthetic designs |

Most Important Tips For The Integration of Counterbore and Countersink Holes in PCB Designs

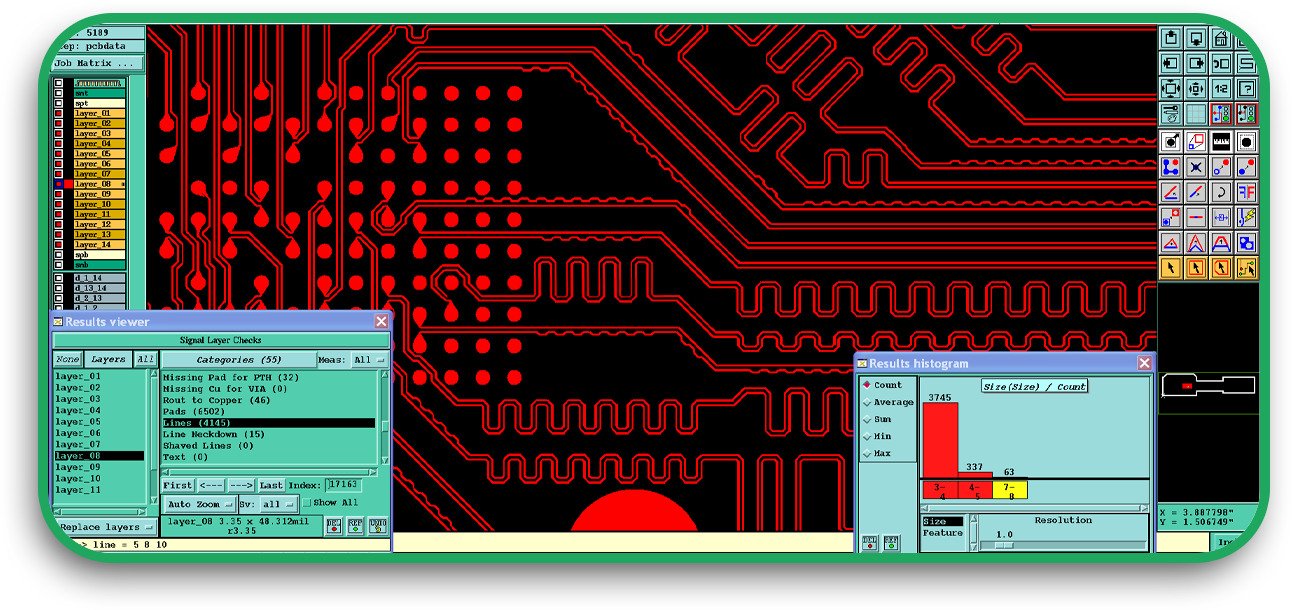

Integrate Counterbore or Countersink Holes using Standard PCB CAD Software.

Aim for precision and accuracy when integrating counterbore or countersink holes in your design. Using standard PCB CAD software is important when aligning components to holes or specifying the depth of the holes.

Confirm Hole Depth

Whether you are designing multilayer PCBs, thin boards, or custom boards, correct tolerance and hole depth should be sufficient. Always consult with the State’s PCB circuit board manufacturers to confirm that they meet the criteria.

Enhance Manufacturing Efficiency

The decision on whether to select counterbore or countersink features must also consider PCB fabrication cost and time. Drilling a perfectly operational hole might involve an additional complication that would increase the charges and lead time for construction.

Test Prototypes For Optimal Results

Producing a printed circuit board prototype enables the designer to analyse the effect of counterbore or countersink holes on assembly practices prior to any large production run.

Expert Insights

This paper describes a mechanical model that attempts to forecast the behaviour of various screw lap shear joints with the aid of a spring-mass model. The spring-mass approach incorporates the axial, bending, bearing, and Shear components of stiffness as well as the masses at the joint. The springs of the model characterise the stiffness resulting from each deformation that occurred. We show how the other components spring-mass model can be simplified. We demonstrate that the joint stiffness we identified can allow for the mechanical behaviour of counterbore and countersink screw lap joints to be observed. We did experimental validation in nine observably different joint positions. The different configurations of the joints are also modelled with the aid of linear finite element methods. In addition, the effect of the individual stiffness components on the total joint behaviour can be investigated by changing the plate’s height and width.

Conclusion

The counterbore and countersink features are both important in PCB fabrication and assembly. The choice of using one rather than the other will rely on the thickness of the board, the type of fasteners used, and the structural strength that must be achieved. Counterbore holes are typically advantageous in multilayer PCBs that have heavy components, while hole countersink features are often needed in custom thin-printed circuit boards for a flush fit.

These differences are crucial for optimised designs that function properly and meet the mechanical requirements of reliable PCB circuit board manufacturers. The appropriate hole type should be chosen in the early stages of development, whether it is a prototype or mass production, to achieve the best performance with little difficulty in fabrication.

Need Expert PCB Solutions?

Are you in need of high-quality PCB fabrication with optimised hole designs? Contact us through PCB Runners today to discuss your industrial PCB manufacturing needs!