Introduction

As the world becomes more industrialized, the need for high-performance circuits has increased significantly in the telecommunication, automotive, and IoT industries. The need for improvement has made multilayer rigid PCBs common since they provide an easy and effective way to improve a circuit’s performance.

These advanced substrates enable designers to enhance components’ density and electrical and thermal performance and effectively allow for improvement in performance.

This blog will discuss the multi-layered rigid PCBs’ contribution towards better circuit performance with an emphasis on signal integrity, thermal performance, and mechanical strength.

Also, we will discuss the ways multilayer rigid PCBs can enhance your designs for high-performance applications.

What are Multilayer Rigid PCBs?

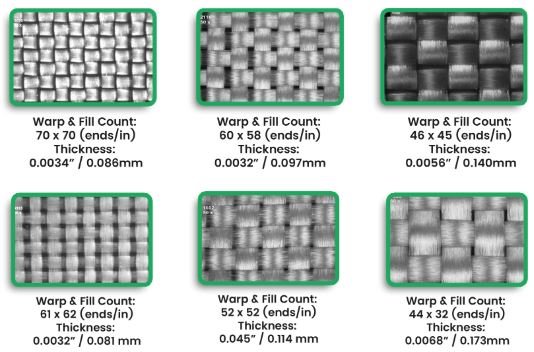

A Multilayer PCB with rigid construction consists of a stack of conductive layers separated by insulating substrates. The construction allows for more routing options for the signal within a compact space.

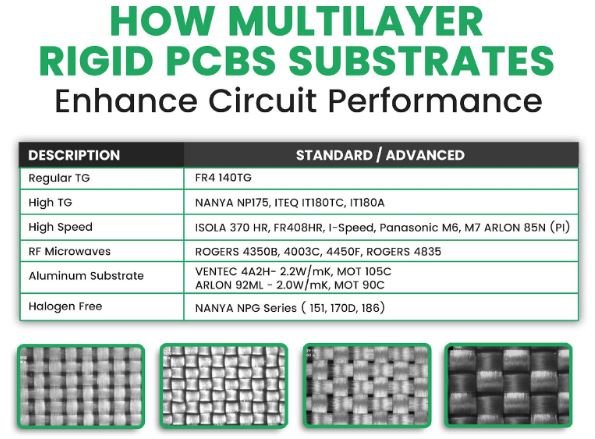

These PCBs improve the connection density and functionality by integrating different layers together with more materials, such as FR-4, a fire-retardant fiberglass epoxy, for reliability and durability.

With multiple layers, the signal integrity is significantly improved because the chance of interference and signal loss is greater over long distances.

Key Properties of Multilayer Rigid PCBs.

Electrical Properties:

- Dielectric Constant: It is one of the properties of signal integrity. Low dielectric constant materials such as FR-4 and others are often preferred for high-frequency applications because these materials have low dielectric constant.

- Dissipation Factor: It is one of the thermal properties of a low dissipation factor material, which helps minimize energy loss in the PCB material and improves the circuit’s efficiency.

Thermal Properties:

- Glass Transition Temperature (Tg): The Tg value determines a material’s thermal stability. A material’s ability to withstand thermal damage is greatly dependent on its Tg value.

- Thermal Conductivity: It is important to manage heat in circuits with high-power components. Multilayer PCBs have better thermal management because they are designed to dissipate heat more effectively.

Mechanical Properties:

- Peel Strength: The peel strength between copper and dielectric layers ensures that the adhesive bonds maintain structural integrity and durability during service.

- Flexural Strength: Flexural strength ensures that multilayer PCBs endure stress or bending forces, which is very useful for portable devices and many rugged applications.

Benefits And Advantages

The electrical inclusion of multilayer rigid PCBs in electronic designs offers several benefits that improve circuit performance:

- Improved Signal Integrity: The use of multilayer PCBs reduces the requirement of long and extensive traces, which cause signal loss and interference. This is critical in high-frequency circuits where signal integrity is a priority.

- Better Thermal Management: With more layers to dissipate heat, multilayer PCBs can use high-power components without overheating. This is very important in devices with intense performance requirements, such as smartphones and automotive electronics.

- Enhanced Miniaturisation: More components can be integrated into one compact board so that multilayer rigid PCBs enable smaller devices without performance degradation.

Expert Insights

The rigid flex multilayer PCB technology permits the use of fewer connectors and large harnesses for the interconnection of functional electronic systems. It increases the performance and makes it less complicated to handle packaging for high-durability space electronic systems while weighing and taking up less space for the modules.

Here, only adhesive-free all-polyimide flexible laminates core, and no-flow glass-polyimide prepregs are utilized. A new process technology is introduced in this work to address manufacturing challenges like registration, coverlay protrusion on rigid areas, and residual copper left at the flexible and rigid junctions.

Science has been worked out and implemented after determining the right combination of flexible, rigid, and low-flow prepreg materials.

FAQs

Q1: What is the difference between single-layer and multilayer PCBs?

Multilayer boards incorporate more than two conductive traces, enabling them to connect to other boards. This makes the signal stronger than on a single-layer board.

Q2: Why is thermal management important in multilayer PCBs?

Multilayer PCBs carry high-power components, which generate a lot of heat and require proper thermal conductivity to operate effectively without damaging the delicate components within the device.

Q3: In what ways do multilayer rigid PCBs positively improve signal integrity?

Using multilayer PCBs helps shorten signal traces while encapsulating them inside layers to reduce signal interference and losses, which is significant in high-frequency circuit scenarios.

Q4: Do multilayer rigid PCBs have a greater budget than single-layer PCBs?

Yes, multilayer rigid PCBs are usually more expensive because of the extra layers and construction means; however, they are far superior in outperformance and compactification.

Conclusion

Multilayer rigid PCBs are instrumental in improving circuit performance. They provide better signal integrity than single-layer PCBs, efficient thermal management, and mechanical robustness. These unique features enable their utilisation in the most advanced systems, including telecommunications, automotive, and IoT.

Take a look at our multilayer PCB solutions for increased efficiency and performance in your designs. Also, remember to subscribe to the latest updates in PCB technology and design.