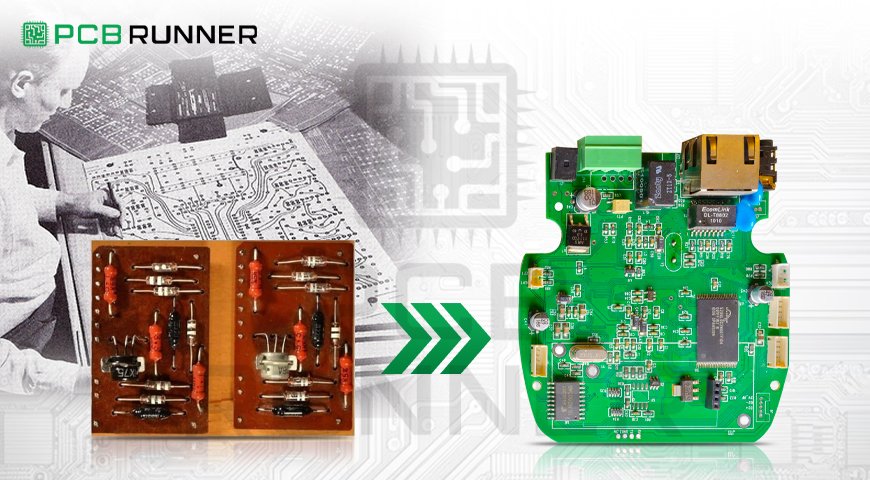

Every innovation has its roots. From essential wiring solutions to the multilayer printed circuit boards today, the history of circuit boards is nothing short of a riveting tale that showcases innovation at its finest. It has even led to modern technology; these days, PCB circuit board manufacturers have sophisticated boards for various industries, including aerospace, healthcare, and consumer electronics. Still, it’s important to note that the modern day PCBs are not what they used to be.

The development of a circuit board’s design has taken more than a century, starting with simple electrical connections and now moving on to advanced software designed for printed circuit boards. Such software enables speed and even the most complex designs. In this blog, we will go through the history of printed circuit boards and discuss the evolution, milestones, and innovation in custom printed circuit board manufacturing.

Where It All Began: Origins of Circuit Boards

Early Electrical Connections (Before the 1900s)

Before PCBs came into the picture, electronic circuits were handheld devices. They were not only bulky but also incredibly unreliable. With the invention of PCBs came the manual wiring of circuits. Early inventors employed the point-to-point wiring method, where components had direct connections via wires. Although effective for basic applications, this method was tedious and prone to short circuits, wear and tear, and mechanical failure.

The First Breakthrough: 1903-1920s

In 1903, a German engineer by the name of Albert Hanson patented a layered electrical conductor mounted on an insulating base. This is where the story of the first significant advancement in circuit board manufacturing came to be.

Although it would take years for the technology to become commercially viable, his concept served as the basis of multilayer printed circuit boards.

Methods to create electrical connections using metal foils and die-cut stencils started in the 1920s, but they were still very clunky and inefficient.

The Birth of the Modern PCB (1930s – 1940s)

The First True PCB and Paul Eisler (1936)

The first true custom printed circuit board for a radio set made by an Austrian engineer, Paul Eisler, in 1936 is regarded as the first actual printed circuit board. It is considered to be the most his most significant innovation to date. Eisler’s innovation included printing tracks onto insulated boards, thereby doing away with excessive wiring.

Military and WWII Adoption

The military value of PCBs for weapons systems and radio communications was recognized in World War II. Eisler’s PCB concept was adopted by the US Army during the war in an attempt to increase mass production efficiency and reduce the size and weight of devices.

Government and Industry started shifting and investing in the innovation of printed circuit board manufacturing specifically for military use, marking a significant change in the history of PCBs.

Mass Production and Commercial Expansion (1950s – 1970s)

The Shift to Consumer Electronics

PCBs became available for commercial use in the 1950s thanks to the improvements done in the processes involved in printed circuit board manufacturing.

The discontinuation of vacuum tubes in favor of transistors made electronic devices smaller, more efficient, and cost-friendly. This period marked the advent of:

- Television sets

- Radios

- Early computing devices

The Advancement of Multilayer Printed Circuit Boards

Multilayer PCBs optimized the manufacturing of electronics in the 1960s. By adding more layers of circuitry, engineers were able to design compact and powerful devices.

The Introduction of Automated PCB Fabrication (1970s)

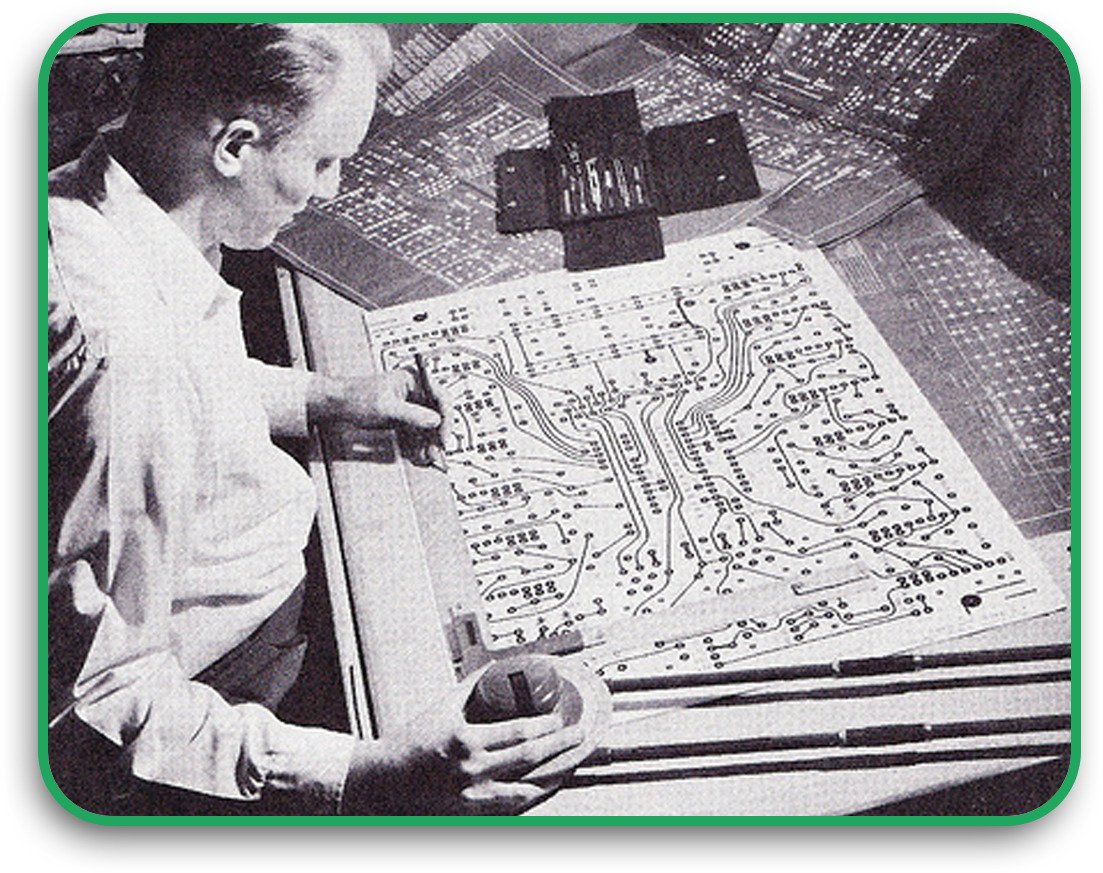

At this time, software for designing Printed Circuit Boards started to surface, enabling algorithms to design PCBs more effectively. The automation of PCB fabrication further improved:

- Accuracy and trustworthiness

- Economy of scale

- Decrease in price

This period laid the groundwork for the industrial era of PCB manufacturing.

The Digital Revolution and Surface Mount Technology (1980s-1990s)

Introduction of Surface Mount Technology (SMT)

The 80s saw the replacement of traditional through-hole soldering with Surface Mount Technology (SMT). In addition to inserting leads into drilled holes, components were directly soldered to the outside of the board. SMT contributed to:

- Greater density of components

- Decreased size of PCBs, increasing efficiency

- Expansion of speed in production

All of these changes greatly impacted PCB manufacturers, as they made production faster and easier to scale.

The Rise of Consumer Electronics

PCBs became an essential component supporting new technologies, such as:

- Personal computers

- Mobile phones

- Gaming consoles

The Growth of Consumer Electronics

The skyrocketing demand for custom PCBs resulted in progress in both PCB design software and manufacturing systems.

Now, we focus on the modern milestones of the 21st century along with the advancements in the technology used for PCB fabrication. Focusing on the period from the 2000s to the present, we see significant developments in manufacturing technology specific to:

- HDI PCBs Integration– Incorporated in smartphones and smart wearables.

- Flexible and Rigid-Flex PCBs– Pivotal in medicine and aerospace industries.

- Eco-Friendly PCB Manufacturing– Adherence to RoHS standards and green production techniques.

AI and Automation’s Role

Currently, printed circuit board manufacturers use AI in combination with PCB design software for tasks such as:

- Streamlining circuit configurations

- Automating the identification of flaws

- Minimizing material use

This has substantially improved the history and innovation of PCBs, as it renders the fabrication process smarter and more efficient.

Expert Insight

Why PCBs are Important to Modern Technology

Transforming Communication

PCBs are vital components in smartphones, satellites, and communication infrastructures. They are critical for the transmission of data at high speeds and over long distances.

Encouraging Innovations in Healthcare

The invention of medical devices like heart monitors or diagnostic tools becomes possible due to custom PCBs that enable precise functioning.

Progress Automotive and Aerospace

Used in Electric vehicles (EVs) and aircraft are multilayered printed circuit boards, which further increase efficiency and safety.

Fueling the Internet of Things (IoT)

The development of smart home technologies and industrial automation, which enables the use of smart sensors, IoT devices, and their functionalities, can be seamlessly executed using miniaturized PCBs.

The Future of PCB Manufacturing

1. 3D PCBs

The fabrication of 3D-printed PCBs will provide a new standard for the industry as it will allow fast and low-cost prototyping.

2. Sustainable PCB Production

The use of biodegradable PCBs and PCBs produced using energy-efficient methods will become the industry standard. Eco-friendly manufacturing will be prioritized.

3. AI-Driven Design Optimization

AI will only enhance the age of innovation in components and board design software. Designing printed circuit boards will be less error-prone and layout optimizations will improve for decades to come.

Conclusion

The innovation history surrounding printed circuit boards is one of the most intriguing topics in modern history as things are still changing. Industry sectors all across the globe have gotten the use of technology in areas like manufacturing, building automation, and robotics, with the earliest primary level point-to-point wiring growing into the multilayered, complex PCB we are accustomed to today.

Manufacturers of PCB circuit boards play an enormous role in modern times, guiding the evolution of circuit board technology with automation, AI battles, and combat for sustainable practices. In the future industry, custom-printed circuit boards will be a core aspect of growth.

Looking for Reliable PCB Manufacturing?

Discover cutting-edge solutions specialized for your business with custom-printed circuit board services from PCB Runners. Reach out to us today and let’s partner together for effective results.

Frequently Asked Questions (FAQs)

Who invented the first printed circuit board?

An Austrian engineer, Paul Eisler, invented the first custom-printed circuit board in 1936 for a radio set.

Why are multilayer printed circuit boards important?

Ideal for modern electronics, multilayer PCBs offer greater circuit density, better performance, and more compact designs.

How has printed circuit board design software changed PCB manufacturing?

With software designed for PCB layout, manufacturers can more accurately place circuits, eliminate redundancies, and optimize the assembly process of printed circuit boards.

What industries rely on PCBs the most?

Automotive, healthcare, aerospace, and telecommunications industries rely heavily on processed PCBs from PCB circuit board manufacturers.

What is the future of circuit board manufacturing?

Advanced Efficiency in sustaining environmentally friendly PCB production alongside 3D printed PCBs and AI-designed PCBs is the foreseeable future.