If you are working with modern electronics, you’ve likely come across multilayer printed circuit boards. These boards are more than just a bunch of copper layers stacked together. They are at the heart of your smartphone, laptop, medical device, and even your car. In this post, we will explore how multilayer PCBs help you get more out of your design, why they matter, and what you need to know when choosing a reliable PCB circuit board manufacturer.

What Is a Multilayer Printed Circuit Board?

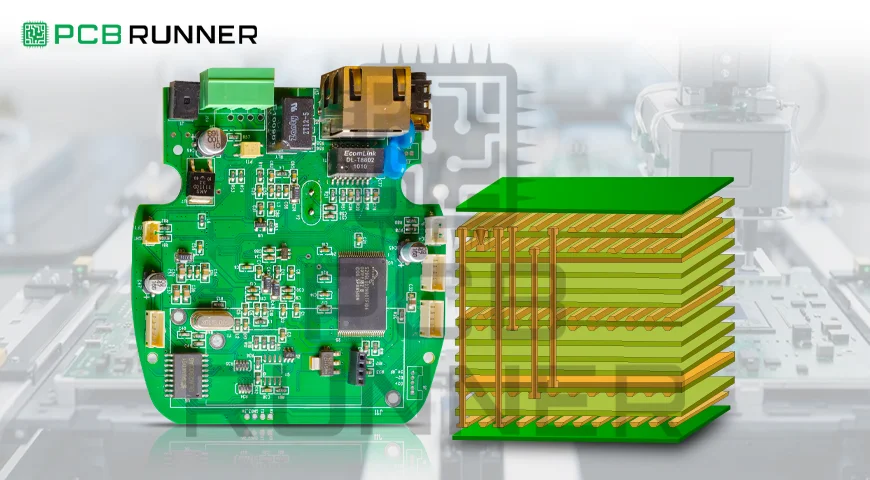

A multilayer printed circuit board has more than two layers of conductive copper stacked with insulating layers in between. This setup allows you to route more signals and power connections in a compact space.

A simple board might have two layers, one on the top and one on the bottom. But modern systems need more. A multilayer PCB board might have four, six, eight, or even over twenty layers.

This type of board offers better performance, a smaller size, and stronger connections. That’s why it is so common in smartphones, routers, tablets, and advanced control systems.

Why Use a Multilayer PCB Board?

If your device is doing a lot of tasks at once or if you want it to be compact, a multilayer PCB design is often the best answer. Here’s why:

-

- Space Saving: More layers mean you can route signals in tighter spaces.

- Better Signal Quality: Having separate ground and power planes helps reduce noise.

- Strong Performance: These boards can handle high-speed signals with ease.

- Less Weight: You can build smaller and lighter systems.

When you choose the right PCB circuit board manufacturer, you ensure these benefits come to life without the risk of faulty builds.

Key Materials in Multilayer PCB Fabrication

A good multilayer board starts with the right materials. You’ll often see boards made of FR-4, a strong and heat-resistant type of fibreglass. For high-performance or high-frequency work, you may need other materials like polyimide or PTFE.

The core, a rigid layer of fibreglass, is in the centre of a multilayer PCB board. It is laminated with prepreg (pre-impregnated) layers, then pressed and heated to form one strong piece.

Choosing the right materials during multilayer PCB fabrication is critical to ensure your board can handle both mechanical and thermal stress. Your PCB circuit board manufacturer will help guide you based on your design and budget.

Multilayer PCB Design Tips

Designing a multilayer board isn’t just about stacking layers. You need a clear plan. Here are some practical tips to follow:

-

- Plan Your Stack-Up Early: Decide how many signal, power, and ground layers you need.

- Keep Signal Paths Short: Shorter paths reduce delay and signal loss.

- Use Ground Planes Wisely: Solid ground planes reduce noise and improve return paths.

- Avoid Crosstalk: Keep high-speed lines apart or route them with space in between.

- Design for Heat Flow: Make sure your board allows heat to spread out.

Work with multilayer PCB manufacturers who offer layout feedback. They can help spot issues before you build the board.

Custom Printed Circuit Boards for Special Needs

Sometimes, off-the-shelf PCBs just won’t cut it. You might need a custom-printed circuit board for a specific job. Whether it’s an odd shape, flexible material, or built-in sensors, your board must meet exact needs.

Custom boards often include:

-

- Unique layer counts

- Odd-shaped outlines

- Cut-outs or slots

- Fine-pitch components

- Special copper thickness

Be sure to work with a PCB circuit board manufacturer who has experience with custom builds. This will help reduce problems and speed up your timeline.

Multilayer PCB Fabrication Process

Knowing the steps of multilayer PCB fabrication can help you make smarter choices. Here’s a simple breakdown:

-

- Design Review: Engineers check your design for manufacturability.

- Inner Layer Imaging: Each copper layer is printed and etched.

- Layer Stack-Up: Layers are stacked with prepreg and core.

- Lamination: Layers are pressed together with heat and pressure.

- Drilling: Holes are drilled for vias and through-hole parts.

- Plating: Copper is added to drilled holes to make electrical paths.

- Outer Layer Imaging and Etching: Top and bottom layers are defined.

- Solder Mask and Silkscreen: Protective coatings and markings are added.

- Testing: Each board goes through electrical testing to confirm function.

A strong PCB board manufacturer will guide you through these steps and help with technical checks.

Cost Factors You Should Consider

Multilayer PCBs are not cheap, but the right design can save money in the long run. Here are some things that affect cost:

-

- Layer Count: More layers mean more material and steps.

- Board Size: Larger boards use more space and time.

- Drilling Complexity: More holes or blind vias increase the cost.

- Custom Features: Special shapes, finishes, or coatings cost more.

- Order Volume: Larger quantities often lower the per-unit price.

Ask your multilayer pcb manufacturers to quote multiple options. This helps you compare prices and find savings.

Common Issues to Avoid

Multilayer boards need careful handling. Watch for these problems:

-

- Delamination: If layers separate, the board fails.

- Signal Interference: Bad routing causes noise or poor performance.

- Thermal Stress: Boards that overheat will crack or stop working.

- Via Misalignment: Poor drilling can break the electrical path.

These issues often happen when you rush or choose a PCB circuit board manufacturer without enough experience.

Choosing the Right Multilayer PCB Manufacturers

Not all shops are the same. Look for a partner who understands your needs and offers support at every step. Good signs include:

-

- Fast and clear communication

- Help with layout and design feedback

- Certifications like ISO or IPC

- A record of handling custom printed circuit board projects

If possible, ask to see samples or tour the factory. A strong PCB board manufacturer is proud of its work.

Benefits of Multilayer PCBs in the Real World

To show how these boards help, let’s look at real-life uses:

-

- In Medical Devices: Small and powerful boards are needed in pacemakers and monitors.

- In Telecom: High-speed data boards need clear signals and solid builds.

- In Aerospace, Systems must be light, compact, and strong.

- In Automotive: Cars today use dozens of small, multi-layer boards.

If your product must perform well and last long, a multilayer PCB board is often your best option.

Final Thoughts

Multilayer printed circuit boards are key to today’s electronics. They help your designs work faster, fit smaller spaces, and handle complex tasks. When you team up with a reliable PCB circuit board manufacturer, you get a board that works right the first time.

Whether you need a basic four-layer board or a custom printed circuit board with special needs, understanding the basics helps you make better choices. Ask questions, learn about materials, and work with trusted multilayer PCB manufacturers. That way, your projects stay on time, under budget, and high in quality.