When using your favourite gadget or electronic device, seamless functioning is usually expected. What makes these devices dependable? One primary factor is EMC testing. It is not well known, but very crucial in electronics, especially for circuit board suppliers UK and companies focused on PCB production UK.

We will cover why EMC testing is essential, the connection with PCB manufacturing, and the fundamentals of EMC testing in accessible language so all readers can engage.

What is EMC Testing?

Electromagnetic Compatibility is what EMC stands for. This is a device’s capacity not to damage or be damaged by other devices. Let’s take a phone buzzing during a text near a speaker as an example of bad EMC.

Why do We Need EMC Testing?

Electronics have penetrated all aspects of human life. TVs, cars, even medical devices and traffic lights. Lack of inter-device compatibility can result in problems ranging from minor irritations to life-threatening risks.

Here are the main reasons you need to conduct EMC testing:

- Safety: Everyone, particularly in hospitals or on planes, is kept safe.

- Performance: Ensures that devices are fully operational all the time.

- Legal Rules: Numerous nations have EMC regulations which devices must be tested prior to sale.

- Reliability: Minimises issues and returns with the electronics.

How Is PCB Assembly and Manufacturing Connected to EMC Testing?

Have you ever heard the saying “the heart of electronics”? That is the definition of printed circuit boards (PCBs). Each device we use, be it a phone, computer or microwave, has PCBs embedded in it.

The PCB manufacturing company must collaborate with experienced circuit board suppliers UK and perfect the PCB manufacturing process to ensure that their boards pass the EMC tests and are reliable.

What Are The Steps In The PCB Manufacturing Process?

Let us oversimplify it, starting with the first few steps:

- Design: This is when the engineers fix all the components into the board.

- Printing: The circuits are marked with special printers.

- Etching: During this stage, chemicals will “carve” the board and create pathways for electricity.

- Drilling: Tiny bits create holes for components.

- Assembly: Assembly of components, such as connectors and chips, are done by workers/robots.

- Testing: The boards are tested by powering them to check for issues and including EMC.

EMC Issues During PCB Manufacturing in the UK

While producing PCBs in the UK, special attention is given to passing EMC tests. Here are some real-world problems that can arise:

- Overcrowded devices in one area.

- Poor design on the PCB assembly. Close wires? Big problems!

- Cheap materials that do not adequately block signals.

- Bypasses in the printed circuit board assembly steps.

Often, PCB fabricators in the UK comply with numerous measures to lower vertical interference with extra shields and clever layout designs.

Why does every electronic device require EMC testing?

Even simple electronics can pose issues. For instance, a toy automobile that activates a child’s radio is problematic. Or, a medical instrument that is “confused” by functions in a hospital is dangerous.

Key reasons every electronic device must undergo EMC testing:

- Protects from accidents.

- Preempts product recalls.

- Complies with laws and regulations.

- Provides long-term savings.

EMC Testing: How the Industry-Leading Suppliers Approach It

Circuit board suppliers UK and top PCB manufacturing and assembly teams do these to pass EMC tests.

- Provide quality standards during printed circuit board assembly.

- Perform board-level quality checks before shipment.

- Design with EMC considerations from the planning stage.

- Assist customers in resolving problems as soon as possible.

If you want to make your PCB manufacturing and assembly more reliable, these tips might help.

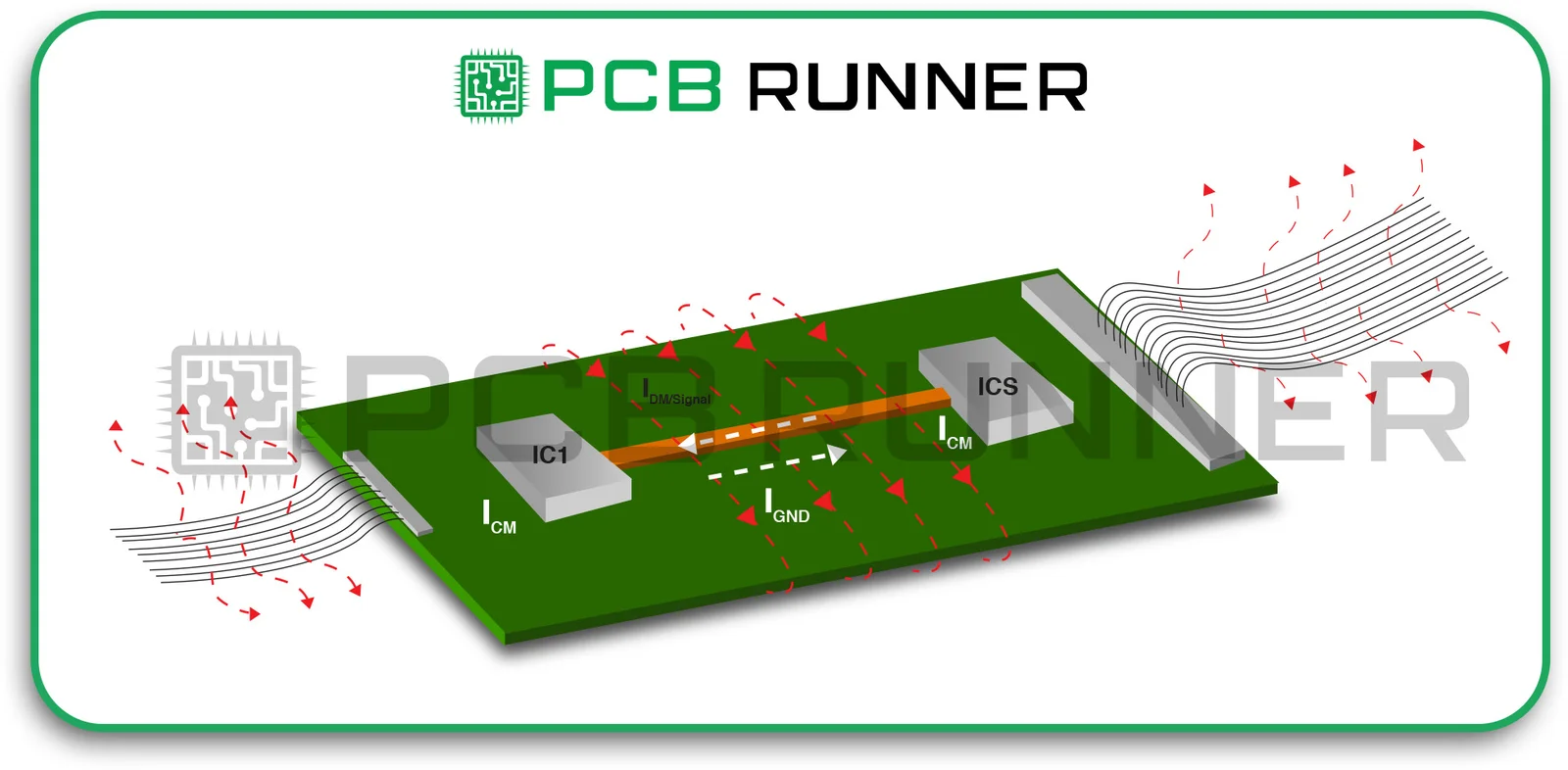

Testing is great, but we can improve more innovative design. Here is what experts suggest.

- Cut high-speed wires to reduce excess noise.

- Use ground planes, which are areas of copper that can soak up signals and help reduce unwanted noise.

- Spread out, instead of cramming hotspots together.

- Use good blocking materials to eliminate interference.

- Simulate EMC before creating the physical object.

If these steps are taken, UK PCB manufacturing companies will be able to eliminate the majority of EMC problems before the production stage.

Compliance and Global Standards: Their Importance

There are stringent regulations regarding electronics sold across the globe. Therefore, reliable PCB manufacturing companies must ensure that the boards are tested to match the European Electronic Communications Committee’s standards (hyperlinked as an example). This helps ensure UK electronics function anywhere in the world.

EMC Testing Techniques

Here’s a sneak peek at how specialists evaluate circuit boards:

- Radiated emission tests: Look at the signal output of the device to see if it is leaking any data that it should not be.

- Immunity tests: Make sure that the device is not interrupted by outside signals like a phone ringing.

- Conducted emission tests: Look for any data signals that are leaking through cables.

- Environmental tests: Simulate shaking or rapid temperature changes.

- Every step ensures that the PCB manufacturing process is being done correctly.

What To Do if Devices Have Failed EMC Tests

While it’s not the worst-case scenario, it does mean that more work needs to be done. If a device fails a test:

- Review the device’s data and parts to see what is malfunctioning.

- Reposition wires, change components, or even rework the circuit board.

- The printed circuit board assembly will often require some modifications.

- Perform all the tests again.

This additional step helps to make sure that the final devices are safe for all users.

Why Efficient EMC Testing is Important for Customer Satisfaction

The last time your WiFi or speaker made unusual sounds, it was pretty inconvenient. Good EMC design not only ensures that the devices work optimally, but it also helps preserve customer satisfaction, allowing manufacturers to enhance their brand image.

How To Work With PCB Manufacturing Companies

If you’re picking a company for PCB work, here’s what to look for:

- Do they have an open conversation about EMC and testing?

- Ask them if they know the UK and international law, and what their experiences are.

- Do they have any after-sales support for issues and inquires made?

- Pick companies that have some type of certifications, for instance, ISO9001.

Having excellent PCB manufacturing and assembly partners will make the work easier and more efficient.

Conclusion: Trust PCB Runner for your PCB needs

Meticulous PCB manufacturing and assembly come with good electronics. The best gadgets in the market will just turn into the biggest troublemakers if they don’t undergo EMC testing. For a good PCB manufacturing company or reliable circuit board suppliers UK, trust brands like PCB Runner, who actually care and have the right experience with EMC.

Ready for your next project? Grab a free quote, instant support, and expert help with all your PCB inquiries at PCB Runner.

For all PCB Production inquiries in the UK and EMC Testing, PCB Runner is ready to assist. Reach out for unparalleled guidance and reliability throughout the entire process.

Frequently Asked Questions (FAQs)

1. What is EMC testing, and why is it necessary?

EMC ensures your electronic devices do not interfere with each other and share unwanted signals. For safety, reliability, and in the name of the UK and overseas operations, it is essential.

2. In what aspects is the PCB Manufacturing Process associated with EMC Testing?

EMC Testing is one of the key processes of the PCB Manufacturing Process because it assesses and verifies the functionality and reliability of the printed circuit boards (PCBs) within their operational environment.

3. What qualities should one look for Circuit Board Supplier in the UK?

Look for proper experience, good after-sales and support services, registration and certifications, and a strong emphasis on compliance with the standards and regulations of EMC and its associated tests.

4. Is it necessary to do EMC Testing for Every Electronic?

All of them. Most jurisdictions, the UK included, have mandated compliance with EMC tests for appliances intended for public use.

5. What can one do to ensure their product undergoes the EMC Tests successfully?

By collaborating with experienced professionals in PCB design, manufacturing, and assembly, improving the product’s design in the initial stages, and exercising appropriate EMC compliance during the production phase.