Selecting a PCB assembler is a crucial decision that impacts the entire project. Correct choices lead to time and cost efficiency, while incorrect decisions can result in hours spent troubleshooting avoidable issues. This blog aims to provide clear, articulated guidance, practical insights, and effective strategies tailored to you.

Why It Matters

Think back to your most recent group assignment. Everyone worked hard, and it almost fell apart because one person did not pull their weight. Choosing a PCB assembler is similar to picking that teammate. You need someone dependable, competent, and someone who does not complicate things further. While building a custom printed circuit board requires skill, it also requires an equally skilled collaborator.

In Their Skill Set, Do They Have Experience with PCB Prototyping?

The same applies to offering specialised services. A plumber cannot attend to automobile issues. In parallel, ask if they have experience managing similar projects. Have they developed prototype circuit boards for comparable products? Do they understand the distinction between a rushed prototype and an elaborate final offering? If a vendor understands prototype PCB manufacturing, it translates to far less guesswork on your end.

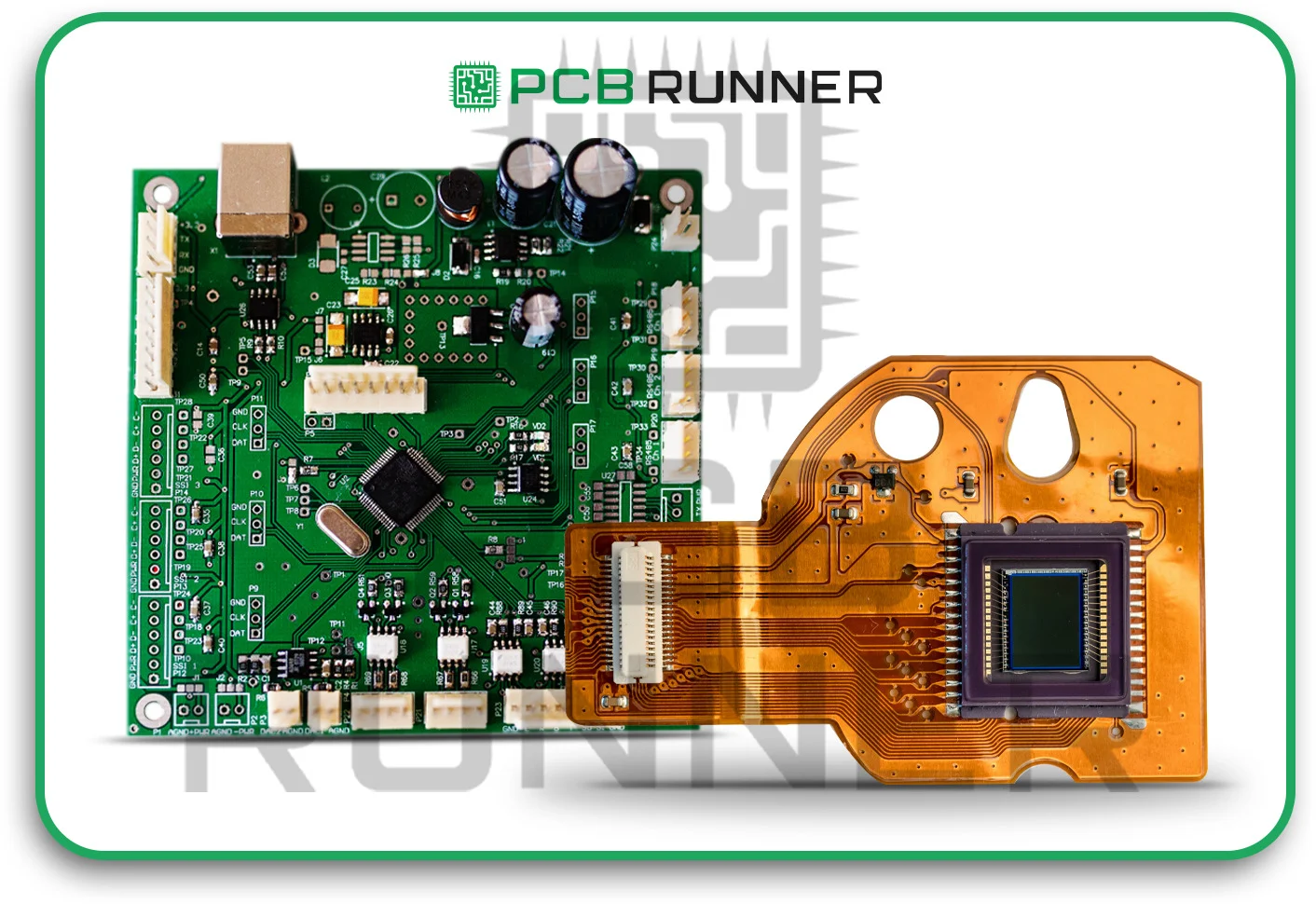

Are They A Full-Service Provider?

Some firms are limiting themselves to an assembly-only approach, while others undertake everything from design and fabrication to assembly and testing. Life becomes easier when dealing with full-service printed circuit board manufacturers in the UK. You do not have to manage multiple vendors. Diagonal communication problems are less likely to occur. Issues are resolved more quickly. You receive a custom-printed circuit board designed specifically for you.

What Certifications And Standards Do They Follow?

Certification and standards are relevant because they demonstrate your company’s commitment to quality. Look for ISO 9001 and IPC-A-610 certifications. These demonstrate that your company values quality processes. If your company is serious about safety, it will also follow RoHS regulations. Do not be shy to ask for verification. A reputable prototype PCB board manufacturer will provide documentation without any problems.

How Soon Can They Deliver?

Time is money. When testing ideas, getting results is critical. Are urgent orders accepted? Is rapid PCB prototyping offered? If deadlines cannot be met, continue searching. A reliable assembler understands that sometimes flexibility is a must.

What Kind of Engineering Support Do They Provide?

Assess the nature of communication with the company. Does the support team include an engineer? Do they offer resolution assistance, or do they opt to provide apologies for errors made? During the phases of prototype fabrication, support helps ease troubleshooting within the design. Timely prototype manufacturing support encourages builders to focus more on construction than on worrying.

How Do They Source Components?

Assess the nature of communication with the company. Does the support team include an engineer? Do they offer resolution assistance, or do they opt to provide apologies for errors made? During the phases of prototype fabrication, support helps ease troubleshooting within the design. Timely prototype manufacturing support encourages builders to focus more on construction than on worrying.

What Quality Control Tests Are Performed?

Negligence should never be tolerated, especially when it comes to orders placed to cater to specific needs. Engineers have shamed the profession by designing circuits whose faults may not be eyeballed. Automated Optical Inspection (AOI) cameras have also been collectively linked, albeit unphonically. Automated Optical Inspection (AOI) cameras indiscriminately index their targeted boards and overlook thoroughly tested units with disregard.

Can They Scale with Your Project?

You may begin with ten boards; however, consider the flexibility of scaling up to one hundred orders or even a thousand the following year. Determine if they can handle larger orders as demand increases. A capable prototype PCB board manufacturer should be able to scale production when needed.

What Equipment Do They Use?

Outdated devices may be prone to more errors. Do they have modern pick-and-place machines? Are both surface mount and through-hole parts within their capability range? The proper equipment increases the chances of better boards. Don’t hesitate to request a tour or pictures.

What Do Other Customers Say?

Do they complete orders on schedule? Are the products functioning as specified? If possible, try to talk to someone who has used the service. Actual experiences are much more valuable than brochures filled with flowery language.

Are They Honest and Helpful After the Sale?

Everyone makes mistakes sometimes. Will they help you resolve issues? Good assemblers take responsibility for their work. After paying, most people expect services to disappear, but responsive businesses continue to engage their clients.

What About Pricing?

The cheapest option isn’t always the best option. Ensure that you receive a detailed estimate. What does it cover? Are there additional fees for testing or expedited services? Ensure that all costs are transparent and that there are no hidden fees. A dependable assembler will always provide cost transparency.

Product Highlights: What Sets a Good Assembler Apart

Prompt delivery for PCB prototyping

- Orders ranging from single pieces to a thousand are welcomed

- Genuine engineering guidance, beyond just marketing

- Design, fabrication, assembly, and testing services offered under one roof

- Backed by quality certifications and customer testimonials

Project guidance tips

- Prototypes that are simple in design:

- Opt for flexible order management. Select a vendor that combines agility and reliability in delivery timelines to ensure streamlined order completion.

- Elaborate custom and complex printed circuit board projects:

- Focus on thorough, advanced testing, engineering support, and the integration of complex components.

- Ready for expansion?

Look for scalability in the partner/vendor. Confirm their staffing and equipment capabilities for larger workloads.

Your Success Checklist

- Do they have a proven track record with similar projects?

- Are they a single-source supplier?

- Are they compliant with industry norms?

- Can they meet milestones?

- Will real engineering staff provide support?

- What is their policy regarding parts and sourcing?

- What are their testing protocols?

- Can they grow with you?

- What is their equipment?

- What do customers report?

- Are they transparent regarding support and pricing?

Final Remarks

In choosing a PCB assembler, one cannot simply consider price or quick turnaround. It requires a diligent evaluation of a partner that genuinely cares about your success. Use this checklist prior to placing your order. Pose queries. Ensure responses and trust your instincts.

The PCB is the heart of the product. It deserves the best care and attention. It can help transform ideas presented in sketches into working prototypes and could even become the next market sensation.

Have this checklist handy at all times. Never forget, the foundation of every outstanding product starts with a single, precisely engineered prototype. Ensure yours is memorable.