Every detail matters when it comes to printed circuit boards (PCBs). Using the right materials and following the proper manufacturing process affects the final product’s quality and performance. Prepreg is one of the most essential materials that beginners often ignore. What is it, and why does it matter so much in modern PCB manufacturing?

In this blog, we will discuss everything about PCB prepreg.

What is PCB Prepreg Material?

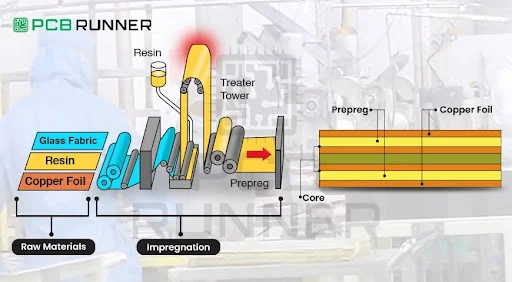

Let’s begin with the basics. Prepreg is short for “pre-impregnated” material. It is like a sheet of woven glass fiber that is fully saturated with resin and partially cured. Because of this, Prepreg can act like a sticky adhesive and insulating layer between the various layers of a PCB during manufacturing.

Consider it like the adhesive that bonds the pages of a book. Without this adhesive, the pages would fall apart. In the same way, without Prepreg, the layers of a PCB would not bond so securely, and multilayer boards would not be able to perform with the reliability required.

This specific type of resin is usually an epoxy and only cures during the heating stages of PCB production. Prepregs not only fill the gaps between the copper layers but also provide electrical insulation and mechanical adhesion throughout the PCB stacks.

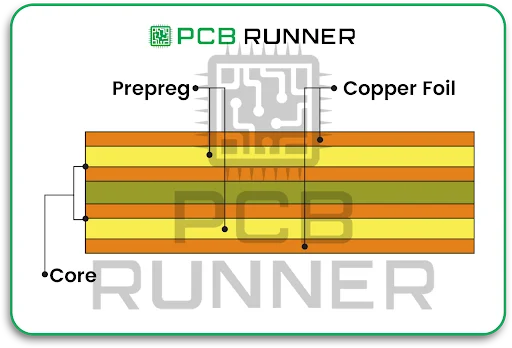

Core and Prepreg are usually referred to as working in multiplicative synergy in a PCB. These two always complement one another and are key to a functional PCB.

Core: This is the cured sandwich layer of the PCB stack-up. This part is usually a fiberglass board that has been copper-clad on both sides. It offers essential stiffness and strength on its own.

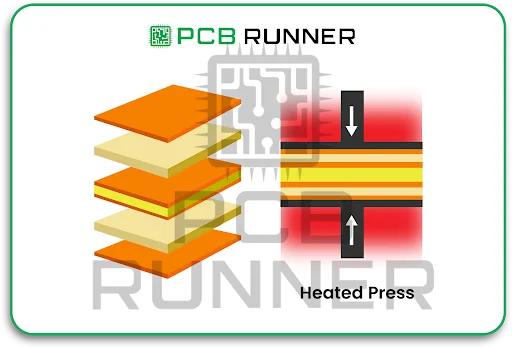

Prepreg: Prepreg is applied to the areas of interest in the PCB. These areas are between the core layers and the copper foil layers. If a prepreg layer is to be applied between core layers and copper layers, then after heating, these layers of Prepreg are hot-pressed exactly as the name suggests.

Think of stacks of sandwiches; that is the core layer, and peanut butter spread in between the bread slices. If you take out the peanut butter, then the sandwiches do not stick together, which depicts how the layers fall out without proper adhesion.

This method of combining core and Prepreg in PCB construction also helps ensure the layers not only stick together, but have the desired insulation and thickness. This construction also determines how long the PCB lasts and its electrical characteristics.

What Makes Prepreg Important in Today’s PCBs?

You may be thinking that Prepreg is just some kind of glue, but remember:

With regards to electrical insulation, Prepreg stops short circuits and signal interference because it insulates excellently between copper layers.

With regards to mechanical strain, Prepreg contributes to the effectiveness of the copper board of the PCB, and it also resists bending and warping. This is crucial to board reliability.

With regards to heat resistance, the modern electronic devices we use must be able to take a certain degree of heat, and prepreg material is made to endure high heat during operation and soldering processes.

With regards to signal integrity, with high-speed and high-density PCBs, the integrity of the signal is preserved because Prepreg regulates the dielectric constant, which is crucial in signal transit in the PCB.

Layer Bonding: Prepreg makes certain that all layers of PCB are firmly glued during the fabrication process to avoid delamination or any sort of defects.

In a nutshell, the quietly heroic PCB prepreg material is responsible for ensuring the PCB’s life and performance are maximized.

Specific Prepreg Types Utilized by PCB Board Manufacturers

There are different types of Prepreg suitable for different uses. They are categorized based on the PCB design that needs to be manufactured.

Standard FR4 Prepreg: The most used Prepreg due to its affordable price and the high number of applications, and is used by manufacturers.

High-Tg Prepreg: Used for circuits that will face a higher load and require a more resistant material for higher temperatures.

Low-CTE Prepreg: Helps in reducing the thermal expansion, which is a critical feature in high sensitive and dense PCBs.

High Frequency Prepreg: Benefits RF and microwave PCBs by improving signal clarity.

Cost and board prepreg selection factors are interrelated, as all choices influence the board’s cost, performance, and longevity.

Impacts of Prepreg Selection on PCB Fabrication in the UK

The quality of the Prepreg directly affects the success of the fabrication process, and so UK and overseas manufacturers pay close attention to it. A good PCB fabrication UK specialist will:

Maintain stackup control by observing design requirements and prepreg thickness balance.

Avoid voids and delamination by using high-quality resin and glass fiber prepreg.

Ensure the prepreg selection in question meets the PCB’s mechanical and electrical specifications.

Incorrect prepreg selection and/or its poor application could result in expensive rejection, soldering issues, and device failures.

How to Properly Choose PCB Prepreg for Your Project

As an OEM, designer, or engineer, all of you should remember these prepreg materials tips:

Understanding the layers and the thickness: Total PCB thickness and layer count define the required prepreg thickness.

Reinforce thermal and electrical requirements: Special prepregs are required for high-power or high-frequency boards.

Verify: Confirm the compatibility of the prepreg resin with copper foil and core materials.

Source from seasoned fabricators: Good manufacturers will know to recommend the most suitable Prepreg.

If you need help understanding all the details, professional PCB suppliers typically include comprehensive data sheets and offer additional help.

Prepreg and PCB Printed Circuit Board Assembly: Essential Information

Prepreg consistency affects the quality by having an impact on how well the PCB manages precision during heat soldering in the following ways:

Excellent prepreg matters are essential during assembly as they protect against failures like cracks and delaminations in the board during operation, preventing board collapses.

Having the right board will make assembly more dependable and will lessen expensive mistakes.

Final Thoughts: Prepreg Serves A Function Beyond Adhesive

Without a doubt, it is a vital constituent of present-day PCBs. Pre-preg holds and protects every signal, allowing your designs to work in the challenging conditions of the outside world while ensuring the components stay tough and protected.

Make it a point the next time you partner with a PCB circuit board fabricant or relocate your business for PCB fabrication assembly in the UK. Be on the lookout for the prepreg materials that core and Prepreg fulfill, as that will help you engine for better control.