Printed circuit boards (PCBs) are the unsung heroes of modern electronics. From smartphones to satellites, they connect and power the devices we rely on every day. But as our technology advances, so must the materials and methods used in PCB manufacture and design. One of the most exciting areas of innovation is in PCB laminate materials. In this blog, we’ll explore how new laminate materials are shaping the future of PCB fabrication, especially in the UK, and what this means for industries everywhere.

PCB Laminate Materials: The Foundation of Modern Electronics

Before we dive into the future, let’s start with the basics. PCB laminate materials are the backbone of every circuit board. They provide the structure, strength, and electrical insulation needed for reliable performance. Think of them as the canvas on which your electronic masterpiece is built.

What Are Laminate Materials for PCB Fabrication?

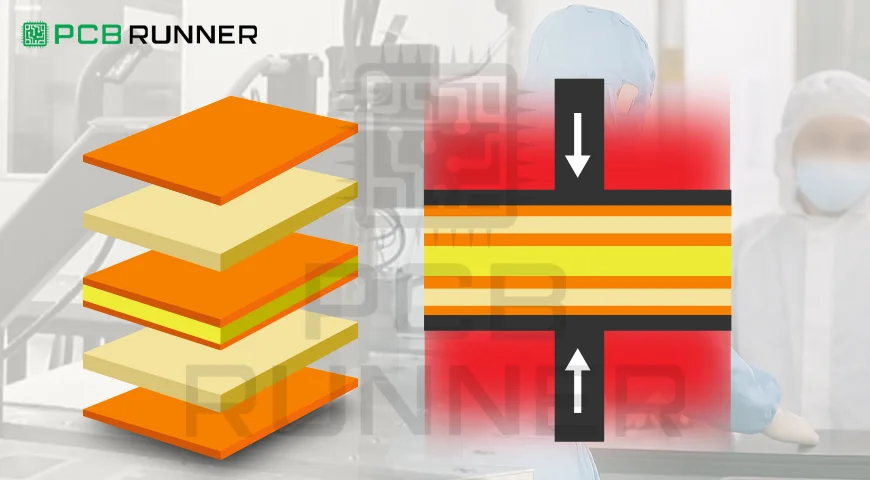

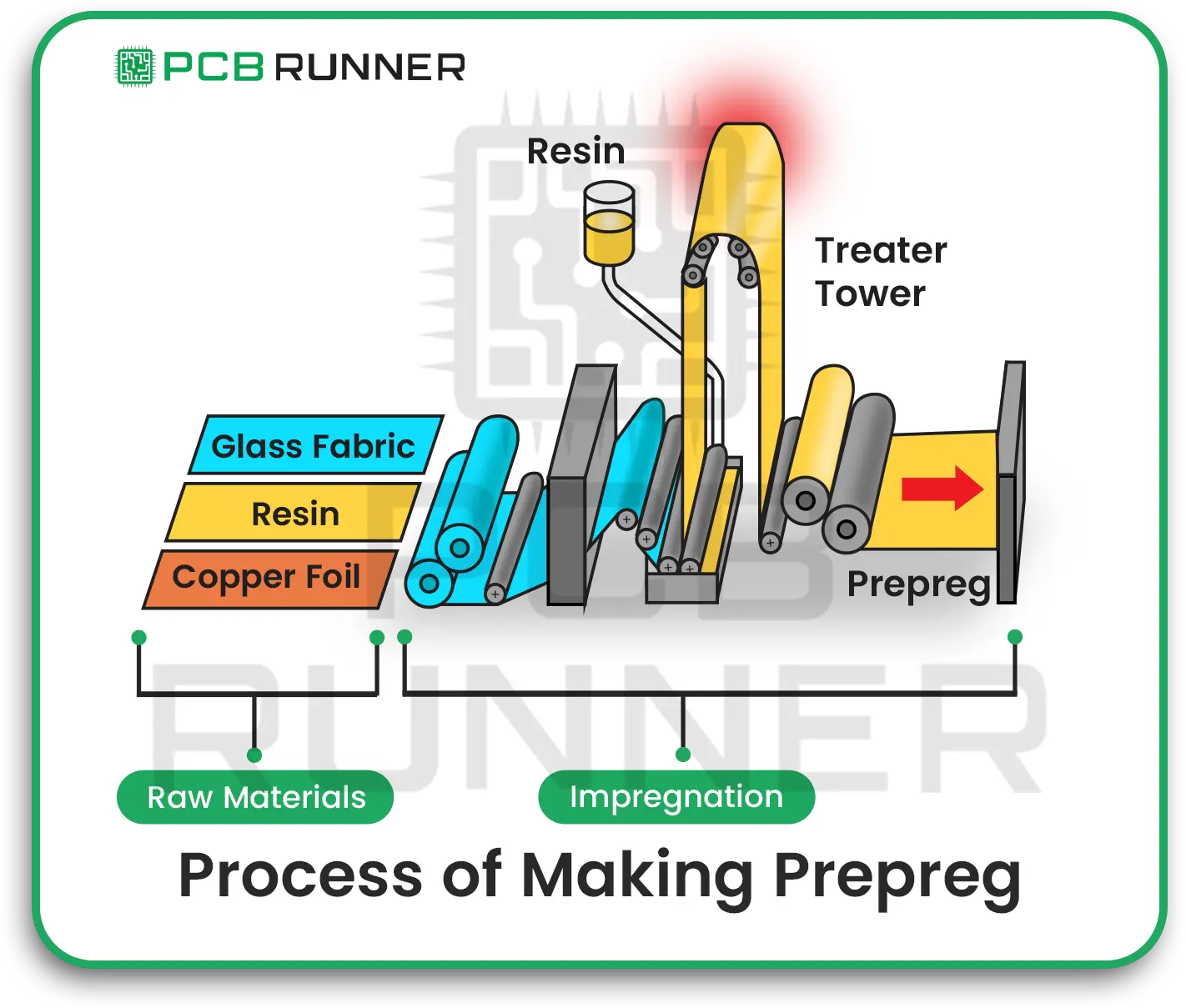

A PCB laminate is typically made from layers of fiberglass and resin pressed together to form a solid, durable sheet. The most common type is FR4, a glass-reinforced epoxy laminate. It’s strong, lightweight, and affordable—making it the go-to choice for many applications.

But as devices get faster and smaller, traditional laminates can’t always keep up. That’s where new materials come in.

Why Laminate Materials Matter in PCB Manufacture

The choice of PCB laminate materials affects everything from signal speed to heat resistance. In high-speed or high-frequency circuits, even tiny losses can cause big problems. That’s why industries like telecom, aerospace, and automotive are demanding better, more innovative materials.

Key Properties of Advanced PCB Laminates

- Low dielectric loss: Keeps signals strong and clear.

- High heat resistance: Prevents warping and failure under stress.

- Mechanical strength: Withstands bending and vibration.

- Environmental safety: Reduces toxic waste and supports recycling.

Latest Trends in PCB Laminate Materials

The world of PCB fabrication UK is changing fast. Let’s look at some of the trends shaping the future.

1. High-Performance Substrates

New high-performance substrates, like advanced epoxies and polyimides, offer better thermal and electrical properties. These materials are perfect for demanding applications, such as 5G networks and automotive radar.

2. Low-Loss Dielectric Materials

For high-frequency designs, low-loss dielectrics are a game changer. Materials like PTFE (Teflon) and special ceramics allow signals to travel faster, with less distortion. This is crucial for hdi pcb board designs, where space is tight, and performance is critical.

3. Eco-Friendly and Recyclable Laminates

Sustainability is becoming a top priority. New bio-based and recyclable laminates, like JIVA’s Soluboard®, are being tested by major companies for their ability to reduce e-waste and support responsible manufacturing7. These materials dissolve in hot water, making it easier to recover valuable components and metals at end-of-life.

4. 3D Printing and Additive Manufacturing

3D printing is transforming the fabrication of printed circuit boards. With conductive inks and printable laminates, manufacturers can create complex, custom boards with less waste and faster turnaround times. This is especially useful for prototyping and small-batch production.

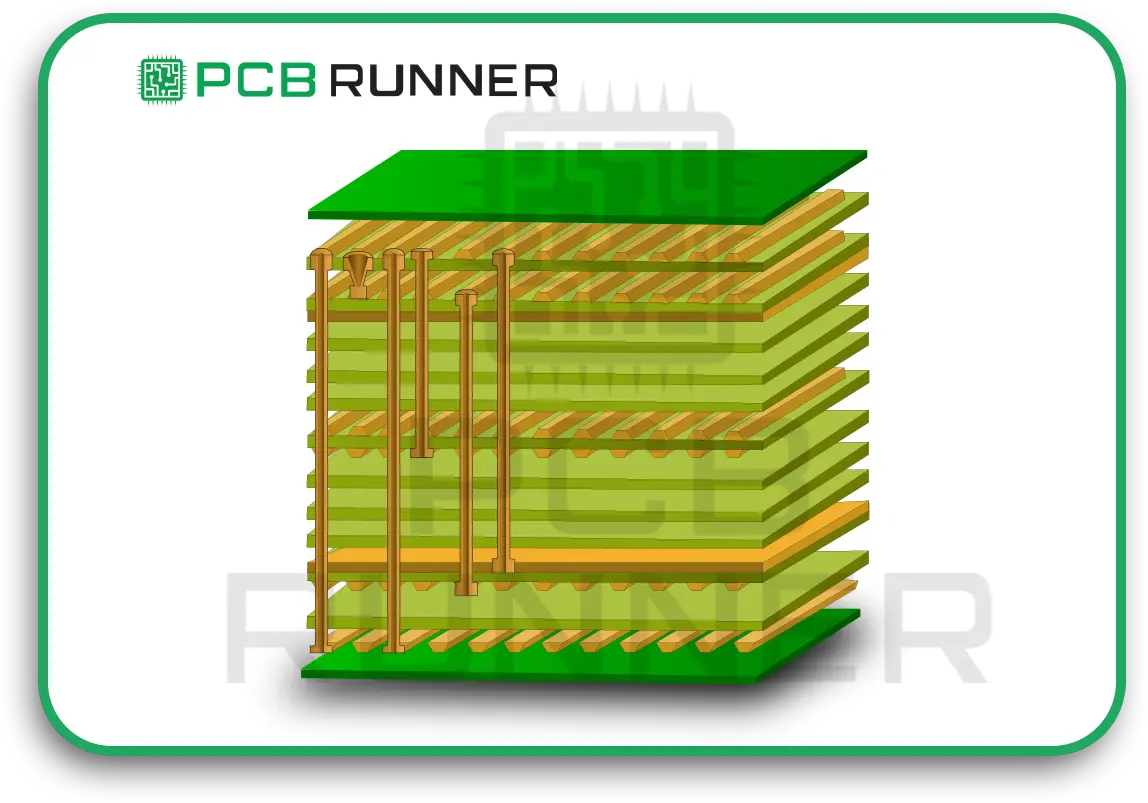

The Role of HDI PCB Board Technology

High-density interconnect (HDI) PCB boards are leading the miniaturization revolution. By using thinner laminates and microvias, HDI boards pack more power into less space. This technology relies on advanced laminate materials that can handle tight tolerances and high signal speeds.

Benefits of HDI PCB Boards

- Smaller size: Perfect for wearables, smartphones, and IoT devices.

- Better performance: Supports high-speed, high-frequency signals.

- Greater reliability: Reduces risk of defects and failures.

Comparing Traditional vs. Advanced PCB Laminates

| Feature | Traditional FR4 | Advanced Laminates (PTFE, Polyimide, Ceramic) |

| Dielectric Constant | Moderate | Low (better for high-speed) |

| Heat Resistance | Good | Excellent |

| Environmental Impact | Non-recyclable | Some are recyclable or biodegradable |

| Cost | Low | Higher, but dropping as tech matures |

| Use Cases | General electronics | 5G, aerospace, automotive, HDI |

How PCB Laminate Innovations Impact PCB Printed Circuit Board Assembly

Advancements in PCB laminate materials don’t just improve the board—they also make PCB-printed circuit board assembly faster and more reliable. With better laminates, soldering is easier, components stay put, and the finished board is less likely to fail in the field.

Real-World Example

Imagine assembling a high-speed router for a 5G network. Using a low-loss, high-heat laminate means the board can handle fast data without overheating or dropping signals. That’s a win for both manufacturers and users.

Sustainability: The Next Frontier in PCB Fabrication UK

The push for greener electronics is driving change in the PCB fabrication UK sector. Manufacturers are adopting:

- Lead-free and halogen-free laminates: Safer for workers and the environment.

- Energy-efficient production: Using renewable energy and recycling water.

- Biodegradable substrates: Reducing landfill waste and supporting circular economies.

These changes are not just good for the planet—they also help companies meet strict regulations and appeal to eco-conscious customers.

The Future: What’s Next for PCB Laminate Materials?

The future looks bright—and busy. Here’s what to watch for:

AI and Automation in PCB Design

AI-powered tools are making it easier to choose the right laminate for each project. These systems can predict how different materials will perform, optimize layouts, and even spot potential problems before production begins.

Embedded Components

New laminates allow for components to be embedded directly into the board, saving space and improving reliability. This trend is significant for medical devices, aerospace, and automotive electronics.

Custom and On-Demand Fabrication

With 3D printing and advanced laminates, it’s now possible to create custom boards on demand. This means faster prototyping, less waste, and more flexibility for designers and engineers.

Key Takeaways: Why Laminate Innovation Matters

- PCB laminate materials are the foundation of every electronic device.

- Advancements in laminates enable faster, smaller, and more reliable PCBs.

- Eco-friendly and recyclable materials are shaping the future of PCB Fabrication UK.

- AI, automation, and 3D printing are making custom, high-performance boards more accessible than ever.

- Choosing the right laminate is key to success in modern PCB manufacture and assembly.

Conclusion: Building the Future, One Layer at a Time

The world of PCB laminate materials is evolving fast. As technology pushes boundaries, so do the materials and methods behind every circuit board. Whether you’re designing for speed, sustainability, or both, the right laminate can make all the difference.

At the heart of this change is a simple truth: better materials mean better electronics. For anyone involved in PCB manufacture, PCB fabrication UK, or PCB printed circuit board assembly, staying ahead of these trends is the key to building the next generation of smart, sustainable devices.

Ready to take your PCB designs to the next level? Explore the latest in laminate materials and see how innovation can power your next big idea.

FAQs: Your Questions About PCB Laminate Materials Answered

Q1: Why are laminate materials so necessary in PCB manufacture?

Laminate materials determine the strength, speed, and reliability of a PCB. The right choice ensures your board can handle high speeds, heat, and stress without failing.

Q2: What’s the difference between FR4 and advanced laminates?

FR4 is a standard, affordable option. Advanced laminates like PTFE or ceramics offer better performance for high-speed or high-frequency applications but may cost more.

Q3: Are eco-friendly laminates as reliable as traditional ones?

Yes, many new eco-friendly laminates match or even exceed the performance of traditional materials. Companies like Microsoft and Jaguar are already testing them in real-world products.

Q4: How do new laminates affect the fabrication of printed circuit boards?

They make boards easier to assemble, more reliable, and better suited for demanding applications like 5G, IoT, and automotive electronics.

Q5: What’s next for PCB laminate materials?

Expect more recyclable, biodegradable, and high-performance options, along with more brilliant AI-driven design and on-demand manufacturing.