Choosing the right PCB manufacturer can make or break your project. If you want to avoid delays, low-quality boards, or costly mistakes, start with the right partner. This checklist will guide you step by step, whether you need simple or flexible PCB boards.

Why Your Choice of Manufacturer Matters

A strong design means nothing if the board fails in real use. Weak soldering, poor materials, or missing inspections can lead to returns or unsafe products. That’s why your choice of a PCB circuit board manufacturer is a big deal. It’s about more than just price.

Start with Certifications

Look for certifications. Good PCB manufacturers follow global safety and quality rules. These show they have systems in place to make reliable boards.

- ISO 9001: Basic quality management

- UL Certification: For safety checks

- IPC Standards: For board building and inspection

If your project needs high trust, like in medical or car tech, extra certifications matter too.

Ask About Board Types

Not all manufacturers offer the same boards. Make sure they can build what you need:

- Single or double-layer boards

- Multilayer printed circuit boards

- Flexible PCB boards

- Rigid-flex boards

- High-density interconnect boards

You want someone who’s done this before. Ask for real examples.

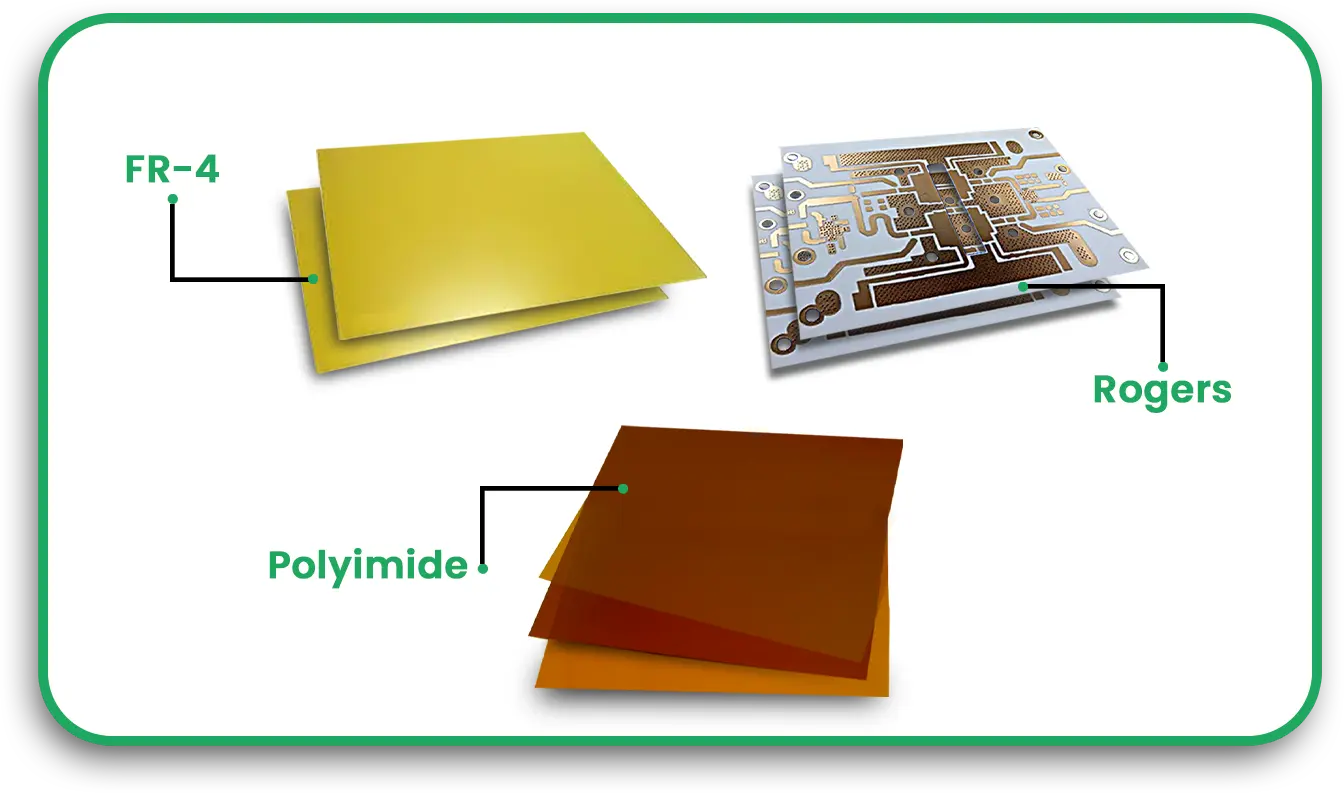

What Materials Do They Use?

The material of PCB affects how well it works. Some materials handle heat better. Others are great for signal flow. Ask about the base they use:

- FR4: Common and cost-friendly

- Polyimide: Great for flexible PCB board needs

- Rogers: Best for high-frequency signals

Check how they test and store these materials too.

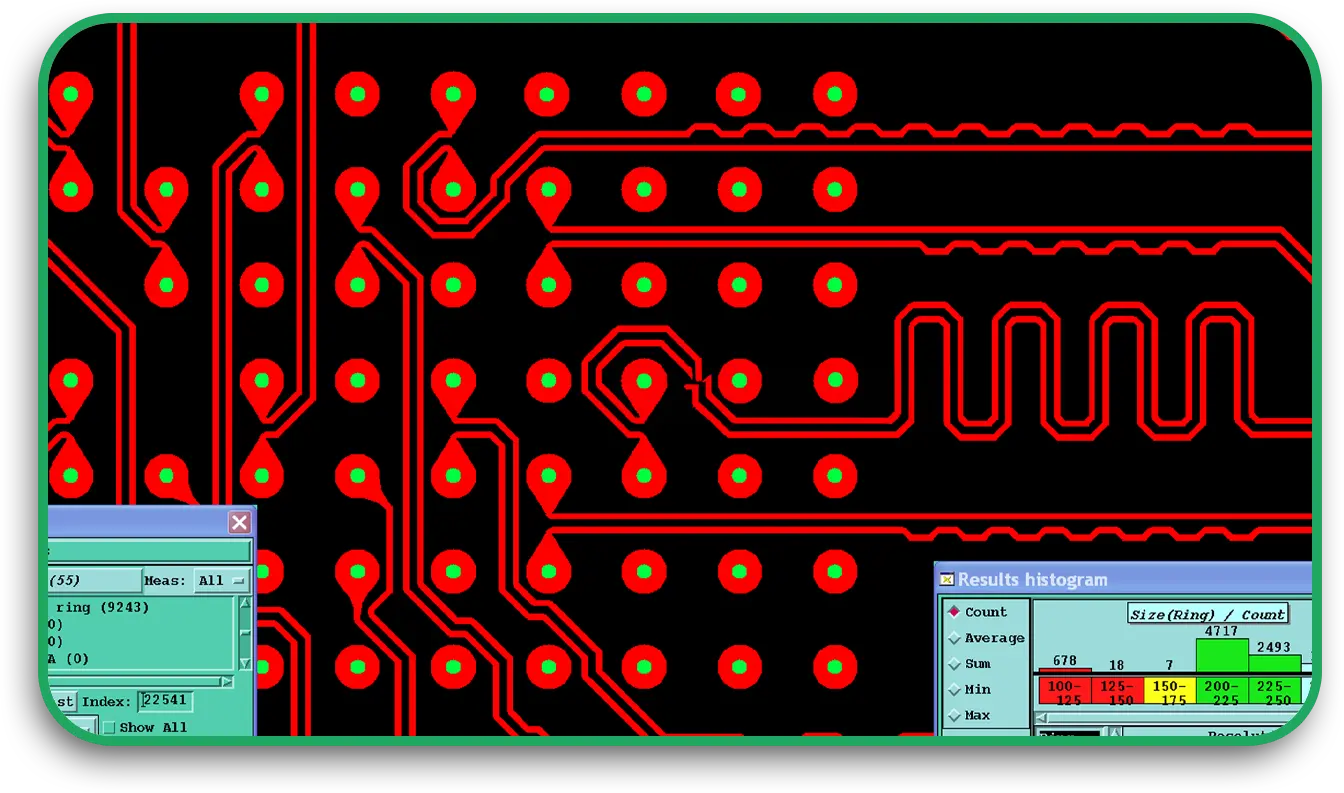

Do They Check Your Design Files?

Even if you use great printed circuit board design software, errors can slip in. Good pc board manufacturers will help you catch mistakes early.

- They should review Gerber files

- Offer DFM (Design for Manufacturing) help

- Suggest small tweaks that cut cost or boost quality

This saves time and avoids waste.

Can They Meet Your Timeline?

Some projects need speed. Others need large volumes. The best PCB manufacturers will offer both.

- Ask about standard and rush jobs

- What’s the lead time for 10 vs. 10,000 boards?

- Can they scale up later?

Make sure faster doesn’t mean lower quality.

Order Size Flexibility

Not every project needs a large batch. Some start with a few boards. Good pcbs-sales partners understand this.

- Do they offer low-volume builds?

- Can they ramp up if demand grows?

- Will they adjust prices as volume changes?

This flexibility helps you grow without stress.

Testing and Inspection

Every board should be checked before it leaves the factory. Ask what PCB inspection methods they use:

- AOI (Automatic Optical Inspection)

- X-ray (for hidden solder joints)

- Electrical testing (to check for shorts or gaps)

They should also follow clear quality steps like IPC-A-600. This is the heart of PCB quality assurance.

Assembly Services

Some pc board manufacturers also build your board with all parts included. That means you get finished boards, not just bare ones.

- Do they offer SMT or through-hole assembly?

- Can they source parts for you?

- Do they test the full board after assembly?

This saves time and lowers the risk of errors.

Communication and Support

You want a team that replies fast, clearly, and with helpful answers. Poor support now means worse problems later.

- Do they respond in 24 hours?

- Can they explain processes without jargon?

- Is there one contact person for your project?

Clear answers build trust.

Company Reputation

Check reviews or ask for references. You can also search online forums for feedback.

- How many years in business?

- What types of industries do they serve?

- Do they offer real success stories or client names?

Past performance often shows future results.

Understand How a PCB Is Made

Even if you’re not the engineer, you should understand how a PCB is manufactured:

- Review design files

- Print the layout on copper layers

- Etch away unused copper

- Drill holes for connections

- Add copper plating to holes

- Apply solder mask and labels

- Test and inspect each board

Knowing this helps you ask smarter questions.

Checklist Summary

Use this final list to compare PCB circuit board manufacturers:

- Are they certified and safe?

- Do they offer the board you need?

- Do they use strong, tested materials?

- Will they review and improve your design?

- Can they meet your timing needs?

- Do they accept your order size?

- Do they test boards fully?

- Can they also assemble the board?

- Do they reply clearly and quickly?

- Do they have strong reviews?

Bonus Tips

- Always ask for a sample before a big order.

- Get a written quote with lead time and terms.

- If it sounds too cheap, ask why.

Final Thoughts

Picking the right manufacturer is more than a quick search. It’s a key decision. The right choice gives you strong, reliable boards that work the first time. It also helps you grow your product without delays or poor quality.

Use this checklist to compare suppliers. Ask clear questions. And trust your gut if something feels off. A good partner will welcome your questions and walk you through each step.

That’s how you build success from the ground up—starting with your circuit board.