When most people think about electronics, they picture flat, rigid circuit boards inside phones, TVs, and computers. But did you know there’s a type of circuit board that can bend without breaking? It’s called a semi-flex circuit board, and it’s changing how we build and use electronic devices.

If you’re working with PCB circuit board manufacturers or designing a new product, it’s essential to understand this technology. Let’s explore what semi-flex PCBs are, how they work, and why they might be the right choice for your next project.

What Is a Semi-Flex Circuit Board?

A semi-flex circuit board is a special type of printed circuit board that can bend slightly in certain areas. These boards are made from a regular rigid material, like FR4, but with special processes that allow part of the board to flex without breaking.

They are not as flexible as full flex circuit boards, but they’re more bendable than standard rigid ones. That makes them perfect for tight spaces or products that need to move just a little.

Why Choose Semi-Flex Over Standard PCBs?

You might wonder: why not just use a regular flex and rigid PCB or a full rigid-flex circuit board?

Here’s why many engineers choose semi-flex PCBs:

- Lower cost than full flex or rigid-flex boards

- Simple to produce using regular materials

- Ideal for tight spaces where a little bend is needed

- Reliable for static bending (not repeated flexing)

If you don’t need your board to move constantly but still want flexibility for installation, this type of board works great.

How Are Semi-Flex PCBs Made?

Unlike full-flex circuit boards, semi-flex PCBs are made using regular FR4 material (a strong, heat-resistant type of fibreglass). A special milling or laser process thins out part of the board to allow it to bend.

These thinned sections are usually placed between two rigid areas. The flexible part connects them and bends when needed,like folding a hinge.

If you’re working with experienced pc board manufacturers, they’ll know how to build these correctly.

Where Are Semi-Flex Boards Used?

Semi-flex PCBs are used in devices where the board needs to bend once or a few times,usually during assembly.

Here are some common examples:

- LED lighting systems

- Medical devices

- Car dashboards and control units

- Industrial control panels

- Consumer electronics like printers or cameras

In many cases, these boards replace costly cables or connectors. They also reduce space and improve reliability.

Semi-Flex vs. Flex and Rigid PCBs

Let’s compare a few features so you can pick the right board for your needs:

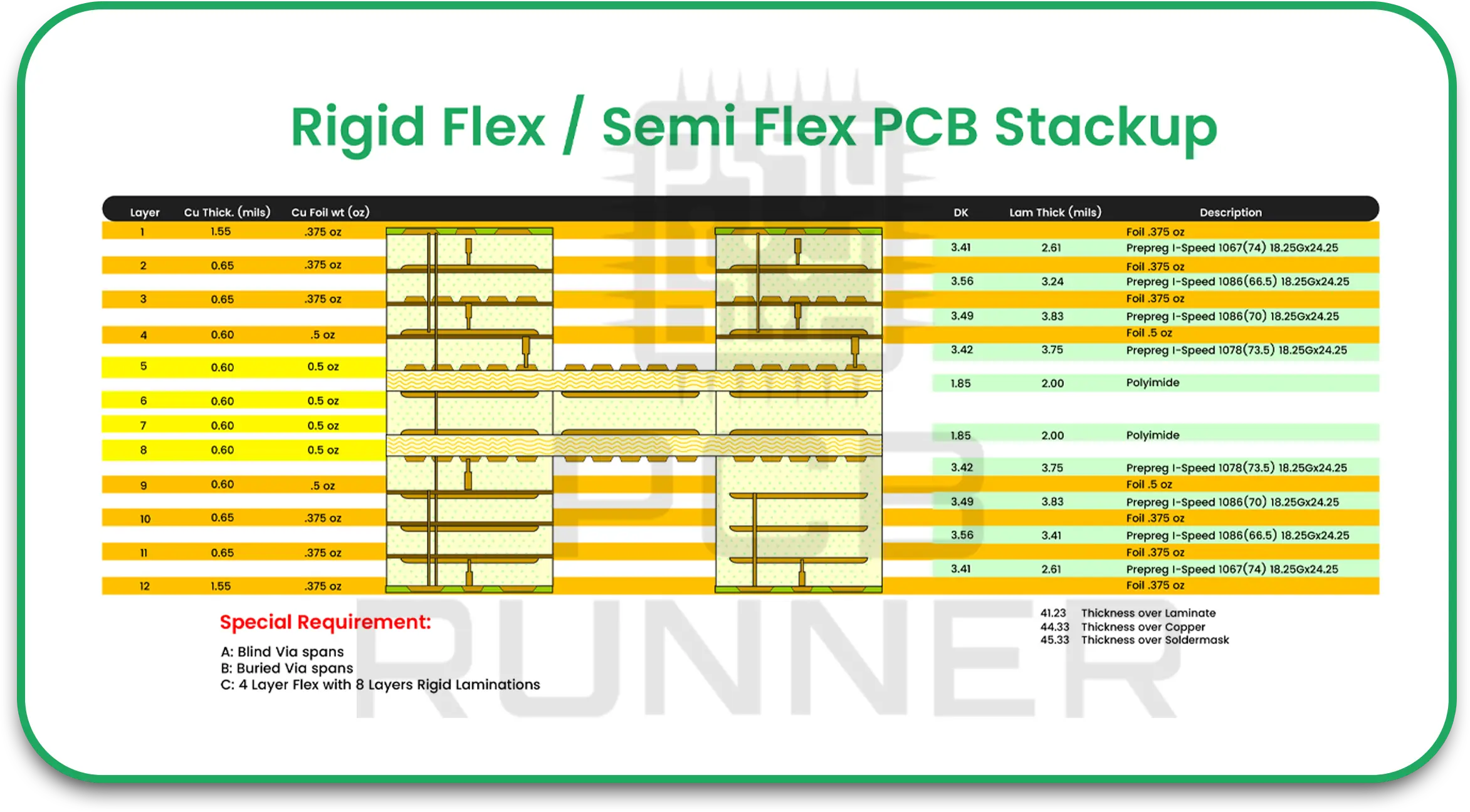

| Feature | Semi-Flex PCBs | Flex Circuit Boards | Rigid-Flex PCBs |

| Bending type | Static (1–2 bends only) | Dynamic (many bends) | Static or dynamic |

| Cost | Lower | Higher | Highest |

| Materials | Modified rigid (FR4) | Polyimide or flexible base | Mix of rigid and flexible |

| Assembly process | Easier and cheaper | Needs special tools | Complex and longer process |

| Space-saving | Moderate | Excellent | Excellent |

Benefits of Semi-Flex Boards

Working with reliable flex circuit board manufacturers or PCB board assembly companies gives you access to many benefits:

1. Space Saving

Bendable boards help fit electronics into small or oddly shaped devices without using extra wires.

2. Stronger Connections

They reduce the need for connectors and cables, which can come loose over time.

3. Lower Costs

Semi-flex boards are cheaper than fully flexible designs but still offer excellent performance.

4. Simpler Assembly

You can bend the board once and lock it in place. That makes the final product easier and faster to build.

Working With PCB Circuit Board Manufacturers

Not all PCB circuit board manufacturers have experience with semi-flex boards. Be sure to ask:

- Have you built semi-flex boards before?

- What’s the minimum bend radius you support?

- Can you handle both PCB fabrication and PCB board assembly?

Choose a manufacturer that can guide you through the design process. They’ll help you avoid errors like placing parts in the bend area or using the wrong materials.

Design Tips for Semi-Flex PCBs

Here are a few practical tips when working with semi-flex:

- Keep parts away from the flex area (at least 5mm)

- Use curved traces in the end zone to prevent cracking.

- Avoid vias in the flexible area.

- Follow proper bend radius rules (ask your manufacturer)

- Use stiffeners if needed for extra support.

Following these rules helps your board last longer and perform better.

Flexible Circuit Board Assembly: What to Expect

Whether you’re building a semi-flex, flex, or rigid-flex circuit board, the assembly process matters. During flex circuit board assembly, parts are usually placed on the rigid sections. The flexible part is kept clear to avoid stress or damage.

Good pc board manufacturers will have trained staff and machines that know how to handle flexible material. If they rush the process or skip steps, your board might not work correctly.

Ask your flex circuit board manufacturers how they handle storage, bending, and inspection.

Future of Semi-Flex in Electronics

As electronics get smaller and more complex, semi-flex boards are becoming more popular. They help make devices lighter, thinner, and more reliable.

New industries are now exploring semi-flex designs, including:

- Wearable tech

- Robotics

- Smart home gadgets

- Drones and electric vehicles

As electronic flex circuit board designs become easier to produce, you’ll see more companies switch to these bendable solutions.

Conclusion

If your design needs a little flexibility without the high price of full flex boards, semi-flex PCBs are a wise choice. They combine the strength of rigid boards with enough flex to fit into tight spaces. You save money, save space, and simplify assembly,all without sacrificing performance.

To get started, talk to trusted pcb circuit board manufacturers or flex circuit board manufacturers who understand your needs. Ask about bend radius, materials, and design tips. And don’t forget to plan for a safe, reliable PCB board assembly process.

By choosing the right board and the right partner, you can create better products,faster and wiser.