When you build electronic devices, one thing matters a lot—reliability. Your circuits must work in all kinds of environments. That’s where selective PCB coating comes in. It protects your printed circuit boards from dust, moisture, corrosion, and even vibration. Whether you’re working with home electronics or high-end machines, this type of protection helps your boards last longer and work better.

If you’re a PCB circuit board manufacturer or someone just learning how electronics work, understanding how selective coating boosts reliability can help you make smarter choices. Let’s break it down in a way that’s simple and easy to follow.

What is Selective Coating?

Selective coating means putting a protective layer only on certain parts of a PCB. Instead of covering the whole board, this process targets just the areas that need it. It’s different from full-board coating, where everything is covered—even parts that shouldn’t be.

The coating used is usually a conformal coating, which is a thin, protective film that “conforms” to the shape of the board and its components.

This makes it a perfect option for PCB circuit board manufacturers who want both precision and protection without wasting time or material.

Why Is Coating Needed?

Printed circuit boards face all kinds of dangers: water spills, dust, temperature changes, and even oil or chemicals in industrial spaces. If a circuit gets damaged, it could stop your whole device from working.

That’s why conformal coating for PCB is so essential. It keeps moisture out, stops corrosion, and makes the whole system more challenging.

In other words, you’re adding a thin shield to the brain of your device.

What Makes Selective Coating Better?

Here’s why selective PCB coating is often better than coating the entire board:

1. Protects Sensitive Areas Only

Some parts on a PCB shouldn’t be coated—like connectors or test points. Selective coating leaves these open while protecting everything else.

2. Saves Time and Money

You’re not wasting coating material or time covering the whole board. This is especially helpful for PC board manufacturers making lots of units.

3. Cleaner Application

Because the coating is applied only where needed, there’s less mess and less chance of coating mistakes.

Types of Coatings Used

Different coatings work better for different situations. Let’s look at some common types used by PCB circuit board manufacturers:

- Acrylic Coating – Easy to apply and remove. Great for general protection.

- Silicone Coating – Stands up to extreme heat and moisture. Used in cars, planes, or factories.

- Urethane Coating – Strong against chemicals. Suitable for industrial use.

- Epoxy Coating – Very tough but harder to remove. Used when strong protection is key.

Want the best conformal coating for PCB? That depends on what your board is being used for. A home device doesn’t need the same coating as a satellite system.

How the Coating is Applied

There are a few main ways conformal coating PCB can be applied:

1. Brushing

A person uses a brush to apply the coating by hand. Suitable for small jobs.

2. Spraying

This can be done with a spray can or automated system. Great for larger batches.

3. Dipping

The entire board is dipped in the coating. It covers everything unless masked beforehand.

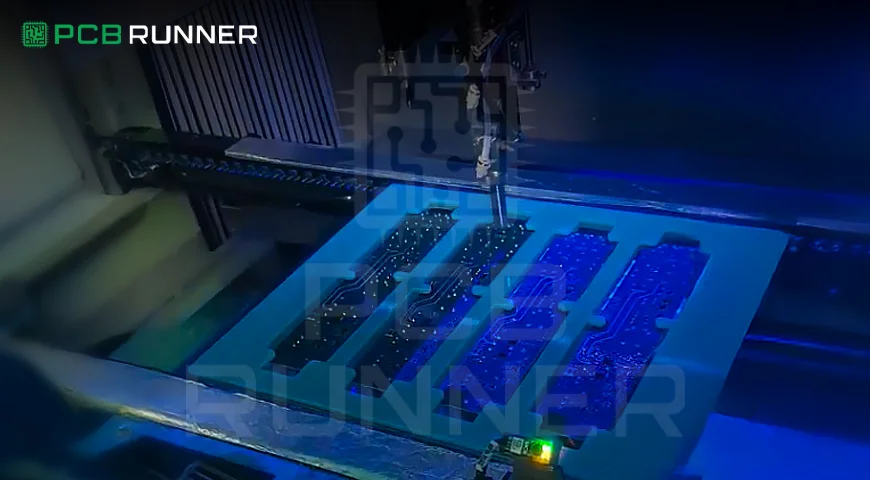

4. Selective Coating Machines

These are machines that apply coating only to selected parts of the PCB using a robotic arm. This is what most modern pc board manufacturers use for accuracy and speed.

Why PCB Reliability Matters

When you think of a PCB, think of it like the brain of your device. If it fails, nothing else will work. That’s why improving PCB reliability is a top goal for every PCB circuit board manufacturer.

Imagine if your phone stopped working just because of a bit of moisture inside. That’s the kind of failure selective coating helps prevent. In harsh environments like aerospace, automotive, or medical devices, even a tiny flaw can be a big problem. Coating helps keep those flaws out.

What Should You Look for in a Coating Partner?

If you’re choosing a PCB manufacturer, ask these questions:

- Do they offer selective coating?

- Can they help you choose the best conformal coating for PCB based on your use case?

- Do they have experience with custom-printed circuit boards in harsh environments?

The right partner will understand which areas of your board need protection and which don’t.

Key Benefits of Selective PCB Coating

Let’s quickly review what selective PCB coating offers:

- Precision: Only coats areas that need it.

- Efficiency: Saves material and reduces costs.

- Protection: Shields from moisture, dust, and more.

- Flexibility: Works with all types of PCBs, including flexible PCB boards.

Common Industries That Use It

Many industries count on conformal coating to keep their boards safe:

- Automotive – for sensors and control units

- Aerospace – for high-altitude conditions

- Medical – for clean and reliable equipment

- Consumer electronics – to keep your gadgets running longer

Everywhere you look, there’s a coated board behind the scenes keeping the system stable.

Real-Life Example: Why Selective Coating Matters

Let’s say you’re building a device that monitors temperature in a greenhouse. The air inside can get humid. Without protection, your board might corrode after a few weeks. But with a conformal coating, especially applied selectively, you can protect the key parts of your custom PCB without covering connectors that need to remain accessible.

That’s how a small layer of coating can prevent a big failure.

Final Thoughts

If you want your PCBs to work longer and better, selective PCB coating is worth considering. It gives your board the protection it needs without wasting time or money on full coverage. For PCB circuit board manufacturers and PC board manufacturers, it’s an easy way to boost reliability and reduce the risk of failure.

When done right, selective coating keeps your boards safe and your products strong—even in the harshest environments. It’s a smart step toward better electronics, no matter what you’re building.

Looking for a PCB partner? Choose one that offers high-quality coating services, understands your design, and helps you protect your investment with the right materials. Your circuits deserve it.