In the global electronics market today, PCB technologies appear to continue revolutionising innovation. Be it consumer technology or industrial automation, printed circuit boards (PCBs) are the centrepieces of almost every modern device. A PCB manufacturer is crucial to the high-technology production processes which enable progress in circuit board assembly technologies and PCB prototyping. As the newest technology in PCB design keeps advancing the performance and miniaturisation boundaries, opportunities for enhancement abound for the engineers and developers as well.

The Evolution of PCB Technologies

The Basics of PCB Design

A printed circuit board (PCB) can be simply considered an electromechanical element consisting of several building blocks integrated into inner interconnections. The initial designs of PCBs were bare, singular-layer boards utilised for essential functions. Over time, tech monoliths produced multilayered PCBs that could integrate higher-complexity systems while optimising the real estate on the sculpted board, thus serving as the industry standard.

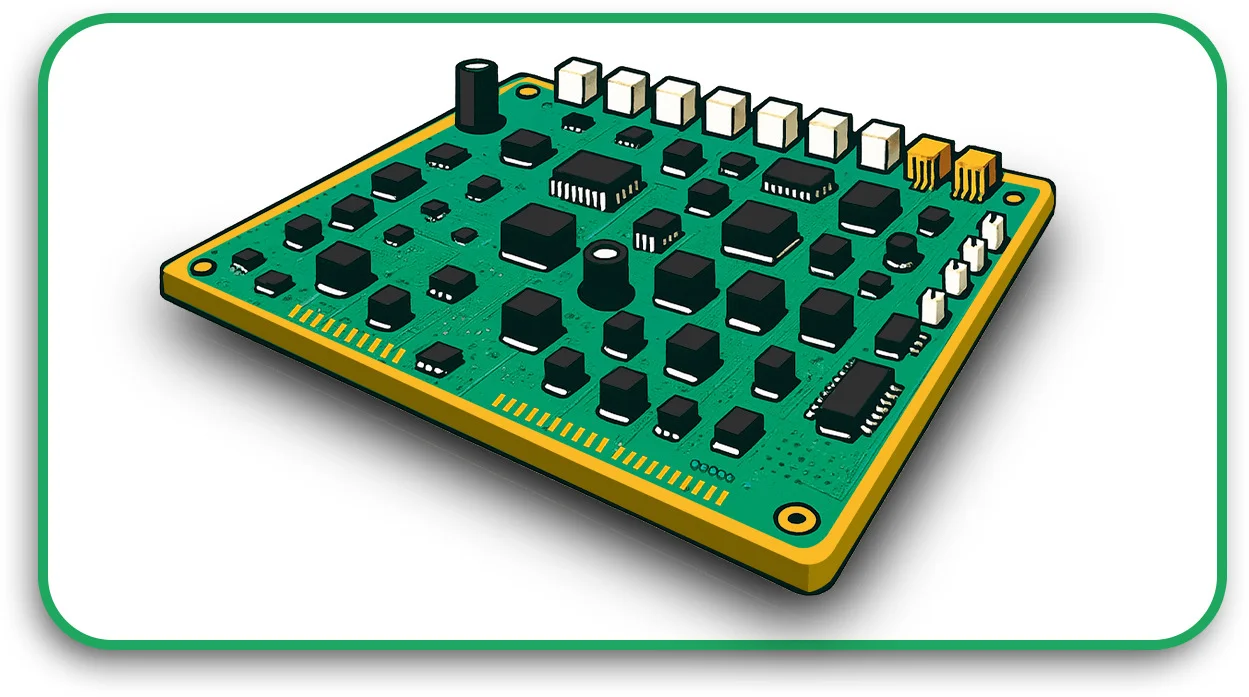

Now, advanced HDI boards are a reality, made possible by modernisation in PCB manufacturing and the introduction of new materials and fabrication techniques. The advent of surface mount technology (SMT) and, even more so, through-hole technology (THT) add tremendous value to the assembly techniques and overall performance of the boards.

Prototypes and Fabrication of PCBs at an Advanced Level

The design process requires building a PCB prototype. This enables an engineer to test and iterate on the circuit’s functionality prior to large production runs. Innovations in rapid prototyping via 3D printing and laser direct structuring have streamlined the industry’s processes by greatly reducing completion times and expenses.

Some recently integrated technologies in PCB manufacturing are as follows:

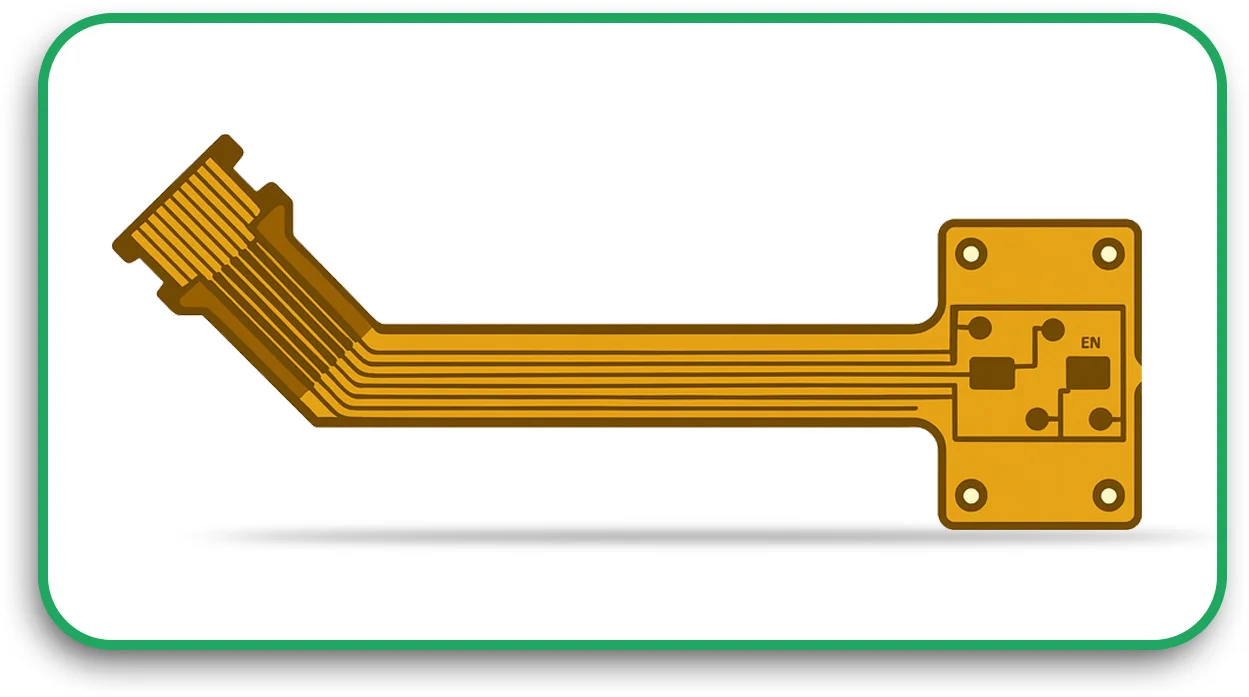

Flexible PCBs: These PCBs are used in Compact Electronics and wearables due to their ability to be bent.

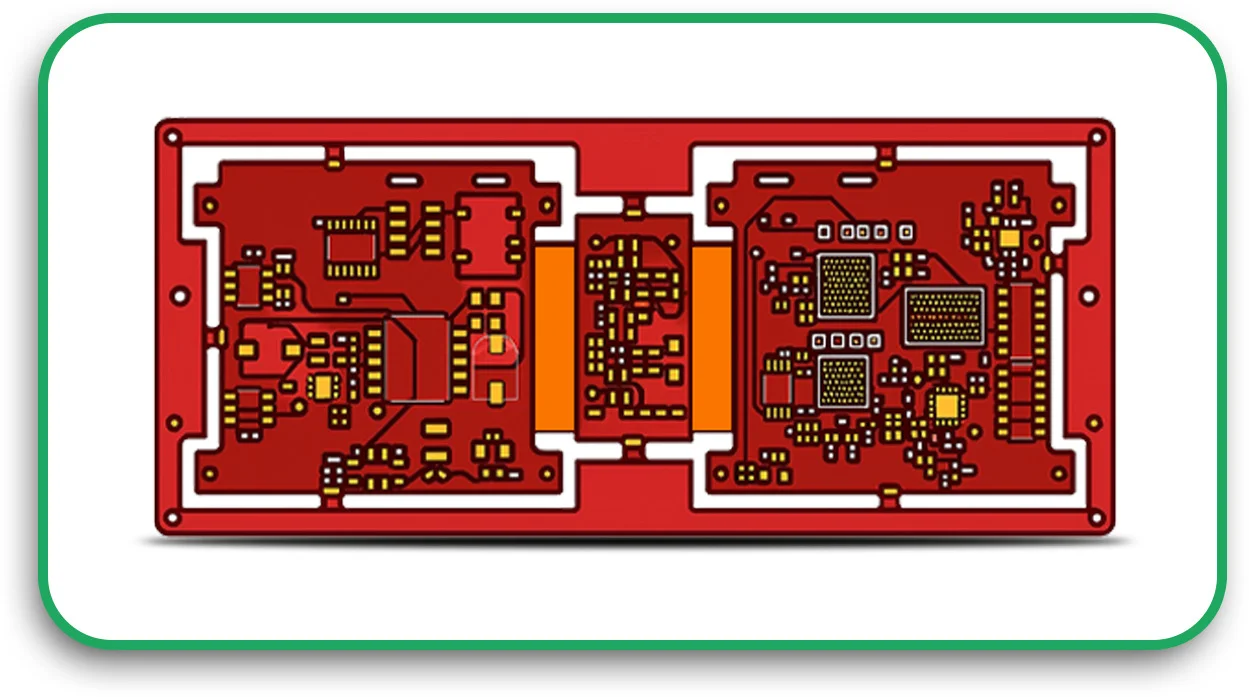

Rigid-Flex PCBs: These are suited for avionics and medical engineering applications, integrating the advantages of rigid and flexible boards.

High-frequency PCBs: They are made for RF and microwave usage, and they specialise in performing with minimal signal loss.

Metal-Core PCBs: These are used in high-power applications that require high thermal dissipation.

Modern Electronics and The Importance of Circuit Board Assembly

Precision in Placing Components

The assembly of a printed circuit board consists of positioning and soldering electronic parts on the PCB. The most significant change is the shift from semi-auto to fully automated assembly. As a result, the speed with which items can be manufactured has increased, and their precision has improved dramatically. The newly developed multi-axis automated high-speed pick and place machines, combined with reflow soldering, provide exceptional precision and ensure the reliability of the electric joints.

Quality Control and Diagnostics

To assure the reliability of the PCBs, several rigorous tests are conducted:

- Automated Optical Inspection: Measurement devices recognize faults in components, soldering, and graphic patterns, and they automatically inspect the soldering and placement of electronic components.

- X-ray Inspection: This method analyses the internal structures of multilayered PCBs.

- In-circuit testing (ICT): Guarantees performance and validates electrical integrity.

- Functional Testing: Checks whether the PCB works adequately in an intended system.

Newest Innovations in PCB Design

Miniaturisation, Along with Increased Interconnect Density

Modern PCB design research is directed towards miniaturisation because devices are getting smaller and more powerful. Micro HDI (high-density interconnect) PCBs allow compact layouts with narrower traces, micro vias, and buried vias, which increases performance while reducing interference.

AI and Machine Learning in PCB Development

PCB technologies are changing due to Artificial Intelligence (AI) and Machine Learning, which improve design layouts, issue predictions, and automated testing processes. AI algorithms assist engineers in creating more complex circuit patterns while lessening manufacturing expenses.

Additive Manufacturing and 3D Printing

Additive manufacturing prints PCBs in no time by allowing endless rotation for computer-aided design models during the 3D printing process to make prototypes different from each other. These techniques enable complex shapes and embedding components, which are essential for next-generation electronics.

Expert View

The breakthrough in Altium Designer has come with the acquisition of 3D-MID. This enables the production of complicated 3D circuit elements that have both mechanical and electronic parts in one integrated component. The use of 3D-MID technology offers a significant advantage by incorporating lighter and more versatile components with highly functional capabilities.

Equipped with efficient software, designers are enabled to create intricate shapes and designs with multiple layers. This is essential in areas where both weight and volume are critical. For instance, the automobile and aerospace industries can greatly benefit from lighter electronic parts since they improve fuel economy and performance. Similarly, compact and light wearable technology components are vital to user comfort and practical use.

The Future of PCB Technologies

With the passage of time and more industries adapting to advanced forms of technology in PCB design, the future holds the following:

- Eco-Friendly PCBs: To lessen the impact on nature, new advanced materials and environmentally friendly soldering practices will be employed.

- IoT Integration: Smart PCBs that have built-in sensors and can connect automatically.

- Wearable and Flexible Electronics: Greater use of flexible PCBs in healthcare and consumer electronics.

- Quantum Computing PCBs: Custom designs for the upcoming computing systems.

Conclusion

The changes and enhancements made to PCB technologies are transforming the electronic industry and encouraging innovation in various fields. Be it modern circuit board assembly, quick turnaround PCB prototype manufacturing, or using the newest electronics in PCB design, PCB manufacturers are central to the industry’s future. Investing in smart PCB technologies will be essential to remaining competitive as the market shifts toward intelligent, compact, and efficient devices.

Are you interested in advanced and modern PCB technologies? Contact PCB Runners and let us show you how our PCB manufacturing capabilities can help turn your ideas into reality.