In today’s electronics industry, pcb circuit board manufacturers and pcb assembly services face constant pressure to deliver high-quality products on tighter schedules. A growing number of companies now embrace vertical integration by bringing every vital step of production under one single roof as a powerful way to gain speed, cost control, and reliability.

In this blog you will explore how vertical integration strengthens PCB fabrication and assembly, explains the benefits of vertical integration, and shows why full turnkey PCBA, turnkey PCBA, and PCBA box build assembly are natural outcomes of this approach.

1. What Is Vertical Integration in the PCB & PCBA Industry?

Understanding Vertical Integration in PCB Fabrication and Assembly

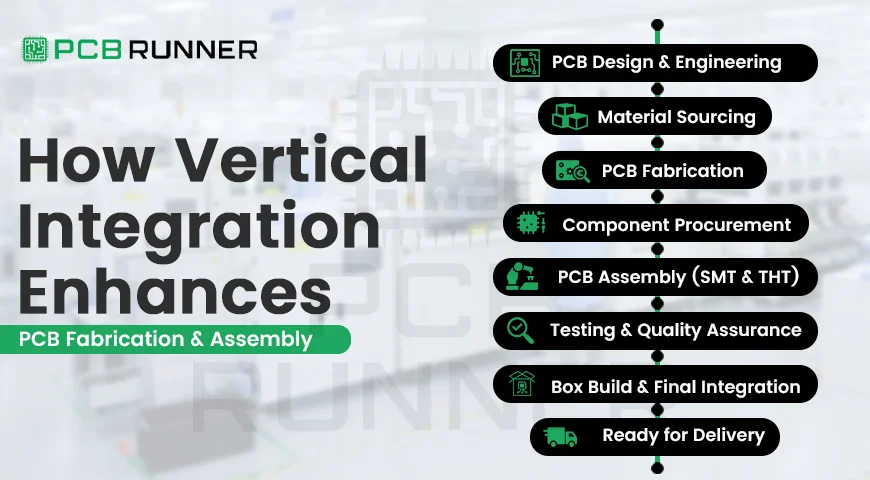

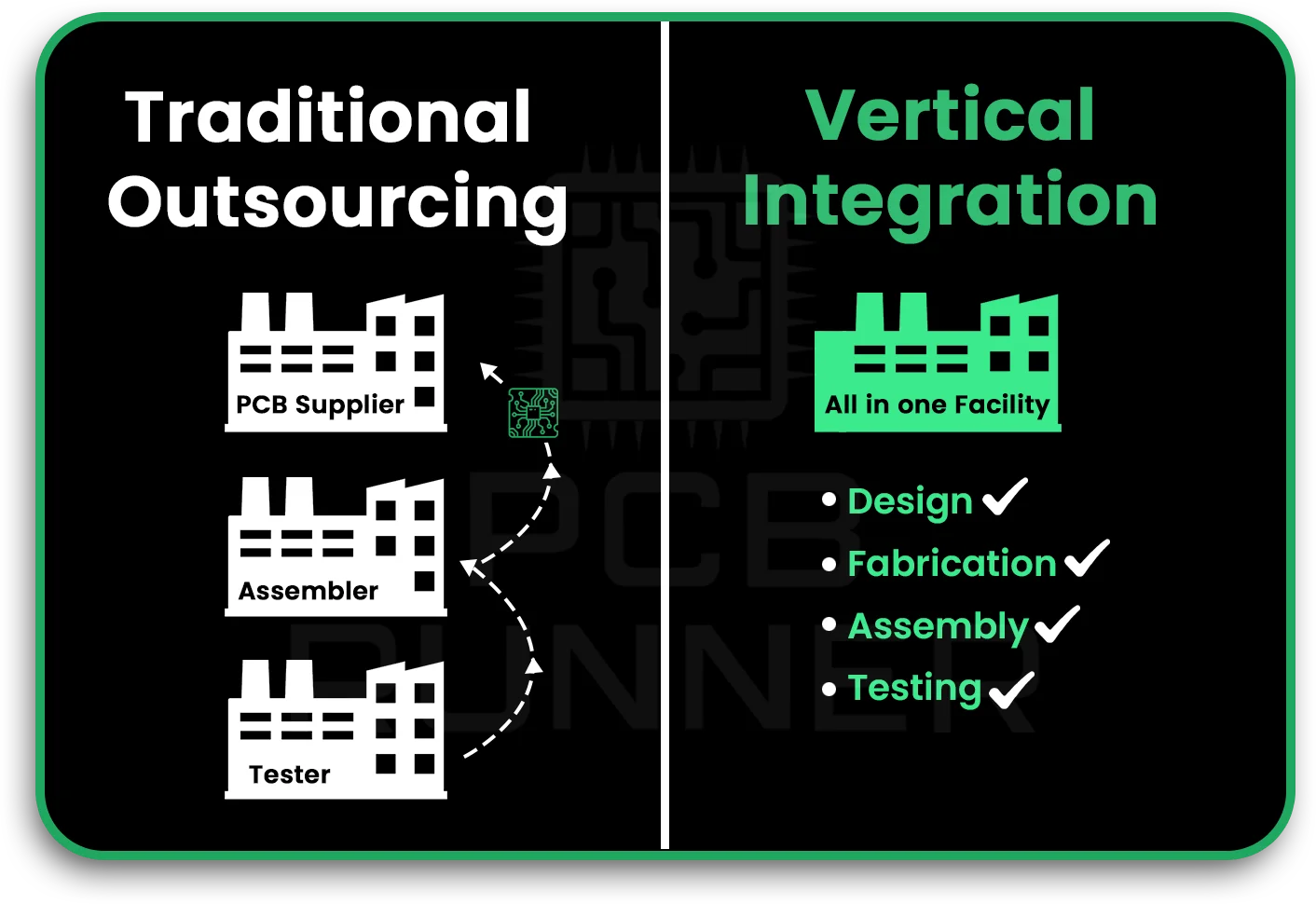

Vertical integration means consolidating everything under one roof from PCB design and material sourcing to fabrication, assembly board, and final testing. Instead of juggling multiple vendors, a single partner manages the entire process, ensuring better control, consistency, and faster delivery.

How Vertical Integration Shapes Modern PCB Circuit Board Manufacturers

For forward-looking pcb circuit board manufacturers and pcb assembly services, integration allows seamless control of the supply chain. It supports advanced service models such as full turnkey PCBA, turnkey PCBA, and PCBA box build assembly, which demand tight coordination and consistent quality from start to finish.

Comparing Vertical Integration with Traditional Outsourcing

In a traditional outsourcing model, a company may purchase bare boards from one vendor, contract electronic board assembly to another, and outsource testing to a third. This structure can lower short-term investment but often causes longer lead times, communication gaps, and quality issues. Vertical integration solves these problems by eliminating external hand-offs.

2. Key Challenges for PCB Circuit Board Manufacturers & Assembly Providers

Supply Chain Fragmentation and Hand-Offs

Each third-party step introduces additional risk. Misaligned schedules or missing components can delay production and increase costs for pcb circuit board manufacturers.

Quality Control and Yield Risks

Dispersed fabrication and electronic board assembly sites make it harder to maintain uniform standards, raising the chance of defects and rework.

Lead Times, Logistics, and Communication Overhead

Multiple vendors mean more shipping, tracking, and meetings factors that can extend time-to-market and reduce flexibility for pcb assembly services.

3. Benefits of Vertical Integration for PCB Assembly Services Providers

The benefits of vertical integration are clear and measurable.

Better Cost Control and Margin Capture

Owning fabrication and assembly board processes minimizes external markups, letting companies capture more value and stabilize pricing.

Shorter Lead Times and Faster Feedback Cycles

When design and manufacturing teams share the same facility, design changes and engineering updates can be implemented quickly. This approach is ideal for full turnkey PCBA projects.

Improved Quality and Fewer Defects

Integrated teams use real-time data to detect issues early. Feedback from electronic board assembly immediately informs PCB design, boosting first-pass yields.

4. How Vertical Integration Powers Full Turnkey PCBA and Box Build Assembly

Vertical integration makes advanced service offerings like full turnkey PCBA, turnkey PCBA, and PCBA box build assembly not just possible, but efficient.

From Bare Board to Assembly Board to Final Box Build

An integrated plant can handle everything from bare-board fabrication to assembly board population and the final mechanical box is built within a single continuous workflow.

Seamless Electronic Board Assembly with In-House Integration

Bringing fabrication and electronic board assembly under one roof eliminates vendor coordination gaps, accelerating schedules and maintaining consistent quality.

5. Considerations & Best Practices When Adopting Vertical Integration

Capital Investment, Facility Layout, and Workforce Alignment

Expanding capabilities requires careful planning of equipment, cleanroom areas, and skilled staff. pcb circuit board manufacturers should analyze ROI and capacity needs.

Maintaining Flexibility and Modularity

While vertical integration centralizes production, modular lines and scalable processes preserve agility for varying batch sizes and product types.

Ensuring Alignment of Design, Fabrication, and Assembly Teams

Shared digital platforms and cross-functional engineering reviews help teams coordinate smoothly, maximizing the benefits of vertical integration.

6. Real-World Examples and Hypothetical Use Cases

A PCB Circuit Board Manufacturer That Integrated Assembly

A mid-size firm that added pcb assembly services cut lead times from six weeks to two and increased yields by 12% by integrating fabrication and assembly.

A Full Turnkey PCBA Provider Offering Box Build

A full turnkey PCBA company expanded into PCBA box build assembly, letting clients ship directly to end customers without extra handling.

Metrics: Yield Improvement, Time Saved, and Cost Savings

Across the industry, integrated providers report reduced defects, faster market entry, and stronger cost control.

7. Conclusion & Strategic Recommendations

Vertical integration is becoming essential for pcb circuit board manufacturers and pcb assembly services that want to stay competitive. By merging design, fabrication, and electronic board assembly, companies gain:

- Cost efficiency through tighter control of materials and processes

- Speed to market via shorter lead times and fewer hand-offs

- Quality assurance through continuous, in-house oversight

For organizations seeking the simplicity of full turnkey PCBA or PCBA box build assembly, partnering with a fully integrated provider can deliver significant advantages.

At pcbrunner, we specialize in end-to-end PCB solutions from bare-board fabrication to turnkey PCBA and complete box-build assembly. Our vertically integrated model ensures consistent quality, rapid turnaround, and transparent communication.

For technical inquiries or project quotes, reach out to sales@pcbrunner.com. Our team will help you design, fabricate, and assemble electronic products that meet today’s most demanding standards.