When we talk about electronics manufacturing, high-quality printed circuit boards (PCBS) are the foundation for every successful electronic device. At the heart of turning a PCB design into a physical board lies a crucial digital asset: the Gerber files.

These Gerber files PCB serve as the universal language between designers and manufacturers, ensuring that every trace, pad, and layer of the board is fabricated with precision. At PCB Runner, we understand that preparing and using them efficiently is essential for engineers, designers, and electronics manufacturing services (EMS) alike.

What Are PCB Gerber Files?

A PCB Gerber file is a standardised vector format used to describe the different layers of a PCB design. These files communicate everything from copper layers, solder masks, and silkscreens to drill data and mechanical outlines. In essence, Gerber files are the blueprint of your PCB, containing exact information required by manufacturers to create the board.

Modern Gerber files use the RS-274X format, which replaced the older and less capable RS-274D. RS-274X includes embedded aperture definitions and other metadata, making the file self-contained and easier for manufacturers to interpret. The files typically come with extensions like .gbr or .gb, and while the naming convention is not fixed, it’s essential to label files clearly for easier identification.

Why Gerber Files Matter?

Gerber files play a central role in ensuring that the design intent is accurately communicated to the manufacturer. While materials like copper-clad laminates and solder are essential for building the board, nothing can begin without the design details present in the Gerber file.

For instance, traces and vias are represented by draw or flash codes, along with specific coordinates. Pads, outlines, and solder mask areas are all detailed within these files. Manufacturers use this data to program laser plotters or direct imaging tools that translate digital designs into physical patterns on copper and other board materials.

If the Gerber files are incomplete, improperly formatted, or inconsistent with manufacturer standards, the result could be costly errors or delays in production.

Steps to Prepare PCB Gerber Files Efficiently

To avoid pitfalls and ensure an efficient transition from design to manufacturing, it’s important to follow these best practices related to the PCB Gerber file format:-

- Use a Reliable CAD Tool

Start with a PCB design tool that supports Gerber file export in the RS-274X format. Popular tools like Altium Designer, KiCad, Eagle, and OrCAD allow for straightforward Gerber generation. Make sure your software version is updated to avoid compatibility issues with modern formats.

- Check Manufacturer Requirements

Different PCB manufacturers may have varying requirements for file naming, format, units (inches vs. millimetres), and layer stack-up. Always consult your manufacturer’s Gerber file guidelines before exporting.

- Include All Necessary Layers

A complete Gerber files package should include:

- Top and bottom copper layers

- Solder mask (top and bottom)

- Silkscreen (top and bottom)

- Board outline (mechanical layer)

- NC drill file (for hole and via drilling)

- Paste mask (if the board will be assembled with SMT components)

Some CAD tools allow you to bundle these into a single ZIP archive, which is often the preferred method for submission.

- Generate a Drill File (NC Drill)

Although not technically part of the Gerber files, the NC drill file is indispensable. It guides CNC drill machines during fabrication, ensuring holes and vias are precisely placed. Always double-check that drill file units and zero suppression settings (leading or trailing) match those used in the Gerber files.

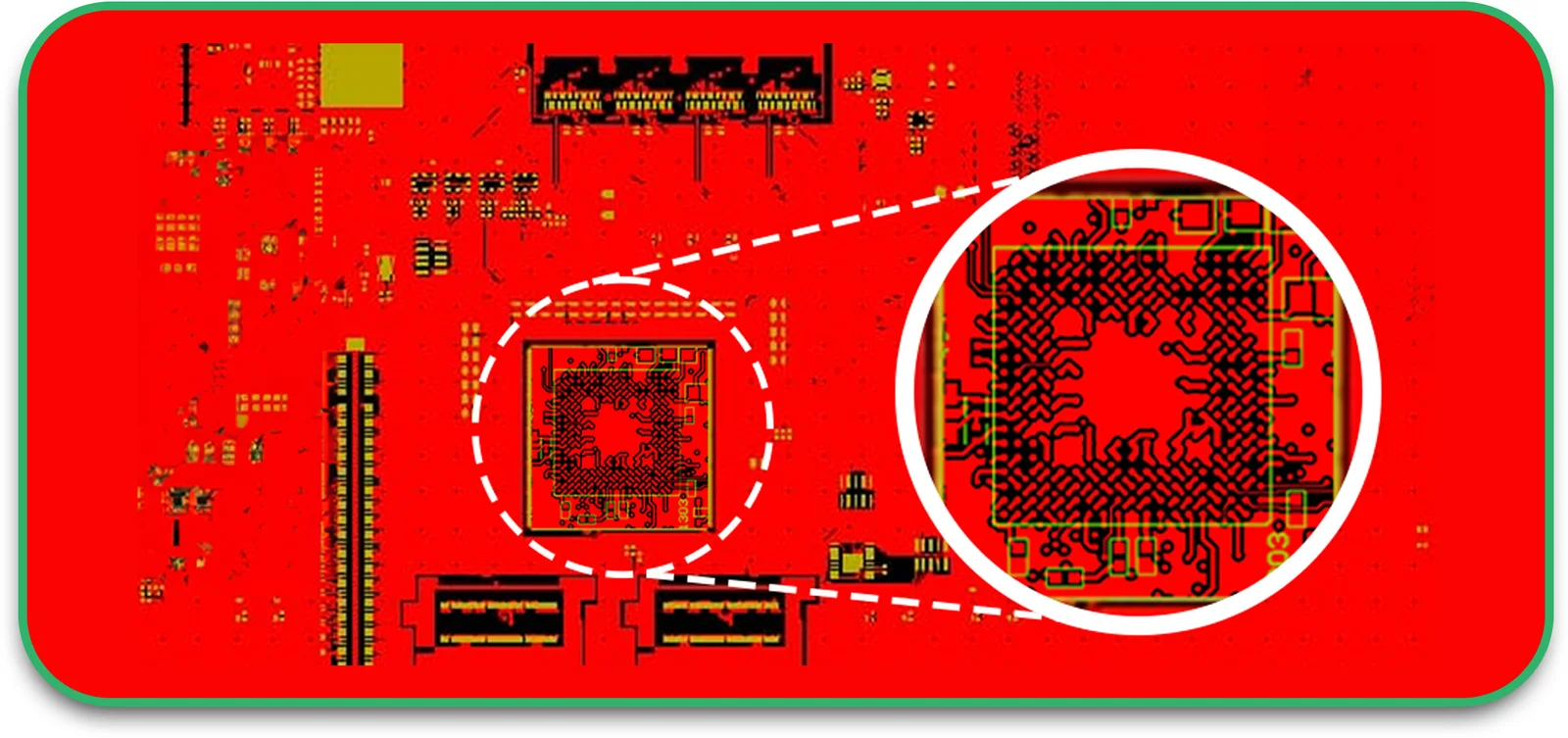

- Use a Gerber Viewer for Verification

Before sending files to a manufacturer, it’s critical to inspect them with a Gerber viewer such as Gerbv, ViewMate, or the built-in tools in your CAD software. This step helps you catch common issues like missing layers, incorrectly aligned pads, or inverted silkscreens. Consider this your last line of defence against fabrication errors.

Efficient Use of Gerber Files in Manufacturing

With advancements in PCB manufacturing technology, the use of Gerber files has also evolved. Traditionally, photo-plotters converted Gerber files into tooling films using vector light beams—a time-consuming and limited process. Today’s laser photo-plotters have improved speed and resolution, converting Gerber data into raster images for direct imaging.

Even more advanced processes now bypass film entirely, projecting Gerber-defined images directly onto copper-clad boards using UV lasers. This not only speeds up fabrication but also allows for more complex designs with tighter tolerances.

Modern Gerber files are also incorporating “intelligent” data, including netlist information, which helps manufacturers verify electrical connectivity. While older file formats remain in use, the industry trend is clearly moving toward more innovative, faster, and more integrated data exchange.

What are the Common Mistakes to Avoid?

- Incomplete Layer Set: Missing a solder mask or drill file can halt production.

- Inconsistent Units: Mixing mm and inches or different zero suppression methods can cause misalignment.

- Unverified Output: Failing to use a Gerber viewer often leads to undetected design flaws.

- Incorrect Aperture Settings: Improper trace widths and pad sizes due to incorrect definitions can compromise functionality.

How to Choose the Right Manufacturer for Multilayer PCB Fabrication and Assembly?

A multilayer printed circuit board is essential for modern electronic devices that demand compact size and high performance. Leading PCB circuit board manufacturers use advanced technology to fabricate these complex boards with precision and reliability. Once the board is fabricated, the next critical step is circuit board assembly, where all components are mounted and soldered to ensure full functionality. Choosing the right PCB board manufacturer is crucial, as it impacts the overall quality, durability, and performance of the final electronic product.

Conclusion

Efficient preparation and usage of Gerber files are non-negotiable for quality PCB fabrication and assembly. By understanding the file structure, adhering to manufacturer standards, and using reliable verification tools, designers can streamline the production process and reduce costly errors.

At PCB Runner, technology evolves continuously, staying updated on best practices in Gerber file preparation will remain essential for designers and manufacturers alike. We emphasise the importance of precision and communication, qualities that start with a well-prepared set of them.