Printed circuit boards (PCBs) are the backbone of today’s electronics, and printed circuit board manufacturers continually seek innovations to improve signal reliability and simplify testing. Among the most versatile interconnect components are spring-loaded pins which are also known as pogo pins, have become indispensable in pcb printing and assembly. By offering consistent contact force and exceptional durability, spring-loaded pins help engineers create more dependable connections while reducing manufacturing complexity.

The Role of Spring-Loaded Pins in Modern PCB Circuit Board Manufacturers

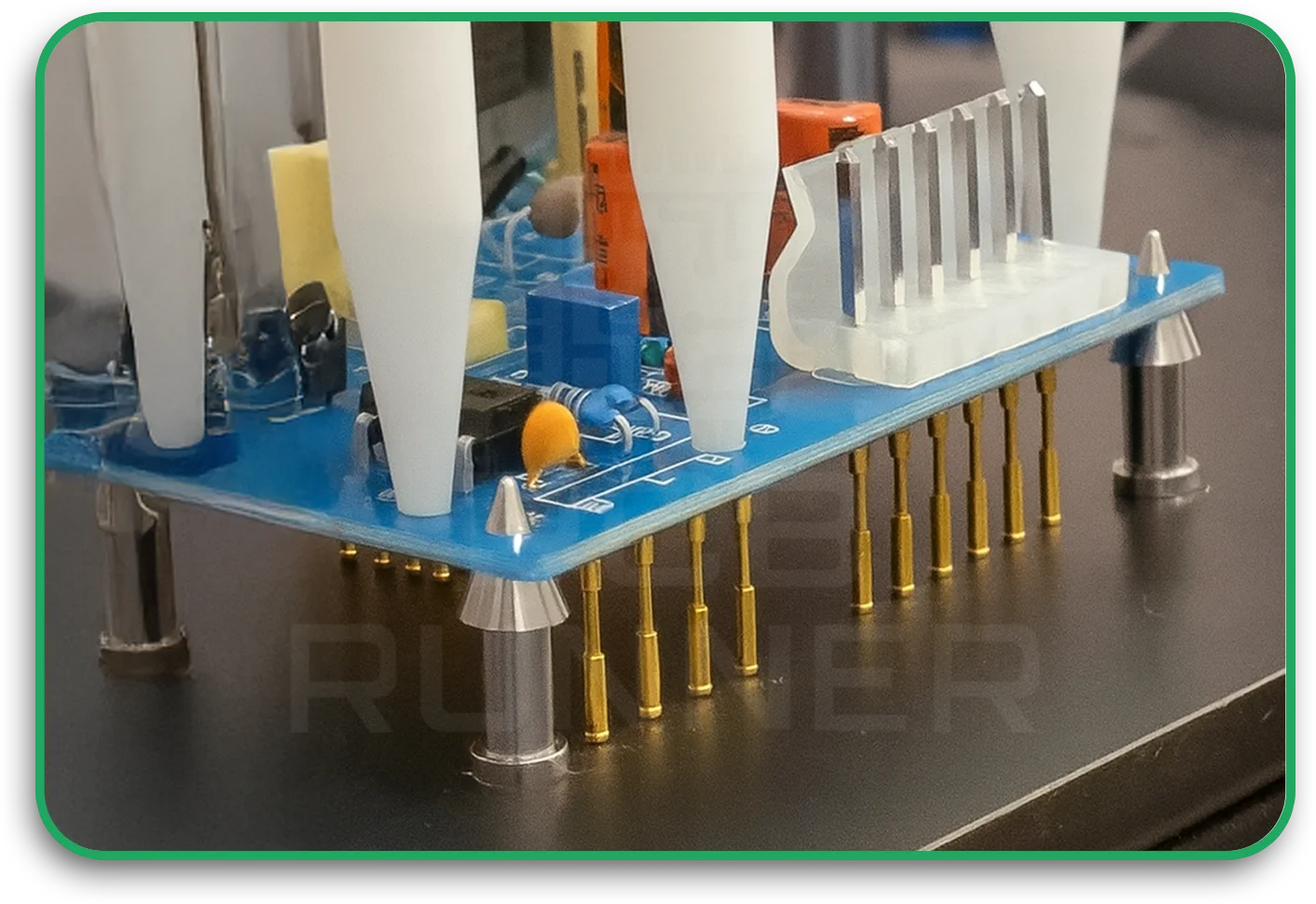

In high-volume production environments, printed circuit board manufacturers need efficient ways to connect test probes, programming fixtures, and modular boards. Spring loaded pin connectors provide a precise, self-compensating contact solution that meets these demands.

- Streamlined pcb printing and assembly: Because pogo pins can compensate for slight misalignments, manufacturers experience fewer reworks and higher yields.

- Versatile applications: From battery contacts to charging docks and signal testing, spring electrical contacts are used across consumer electronics, automotive systems, and industrial control equipment.

- Reduced wear and maintenance: Compared with fixed soldered contacts, spring loaded contact pins withstand thousands of mating cycles without degradation.

PCBrunner helps printed circuit board manufacturers integrate pogo pin technology directly into their workflows resulting in faster time-to-market and lower production costs.

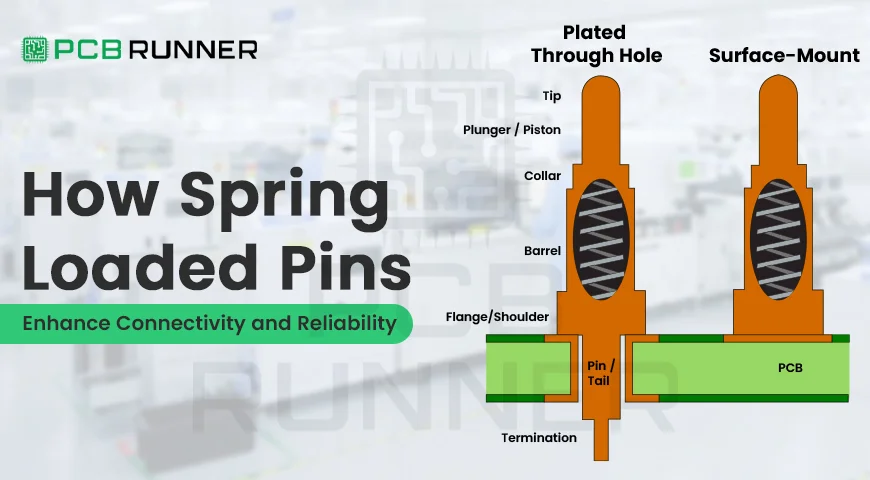

Anatomy and Mechanism of Spring-Loaded Pins

Understanding how pogo pins pcb work helps design teams maximize their advantages.

Components: Plunger, Barrel, Spring, Tip

A typical spring loaded pin consists of three key parts:

- Plunger: The movable tip that presses against the mating pad.

- Barrel: The stationary outer casing that maintains alignment.

- Spring: A precision coil that provides the correct contact force.

All are usually plated with gold or nickel to ensure low resistance and long life.

Contact Force, Stroke, Tolerance and Material Selection

The internal spring defines the pin’s stroke the distance and the plunger travels as the contact force is required. For high-frequency or power applications, choosing the correct plating and barrel material is critical to maintain conductivity and resist corrosion over thousands of cycles.

Key Advantages: Connectivity, Durability, and Reliability

For printed circuit board manufacturers, integrating spring loaded pin connectors brings a host of benefits:

- Consistent electrical performance: The spring maintains stable pressure, ensuring low-resistance connections even with vibration or thermal expansion.

- High mating cycles: Many designs exceed 100,000 insertions, far surpassing typical soldered joints.

- Design flexibility: Whether for pcb printing test points or modular assemblies, engineers can create compact, reusable interconnects.

When you partner with PCBrunner, you not only get access to high-quality pcb printing, but also expert guidance on the right spring electrical contacts for your application.

Design Considerations when Integrating Spring-Loaded Contact Pins

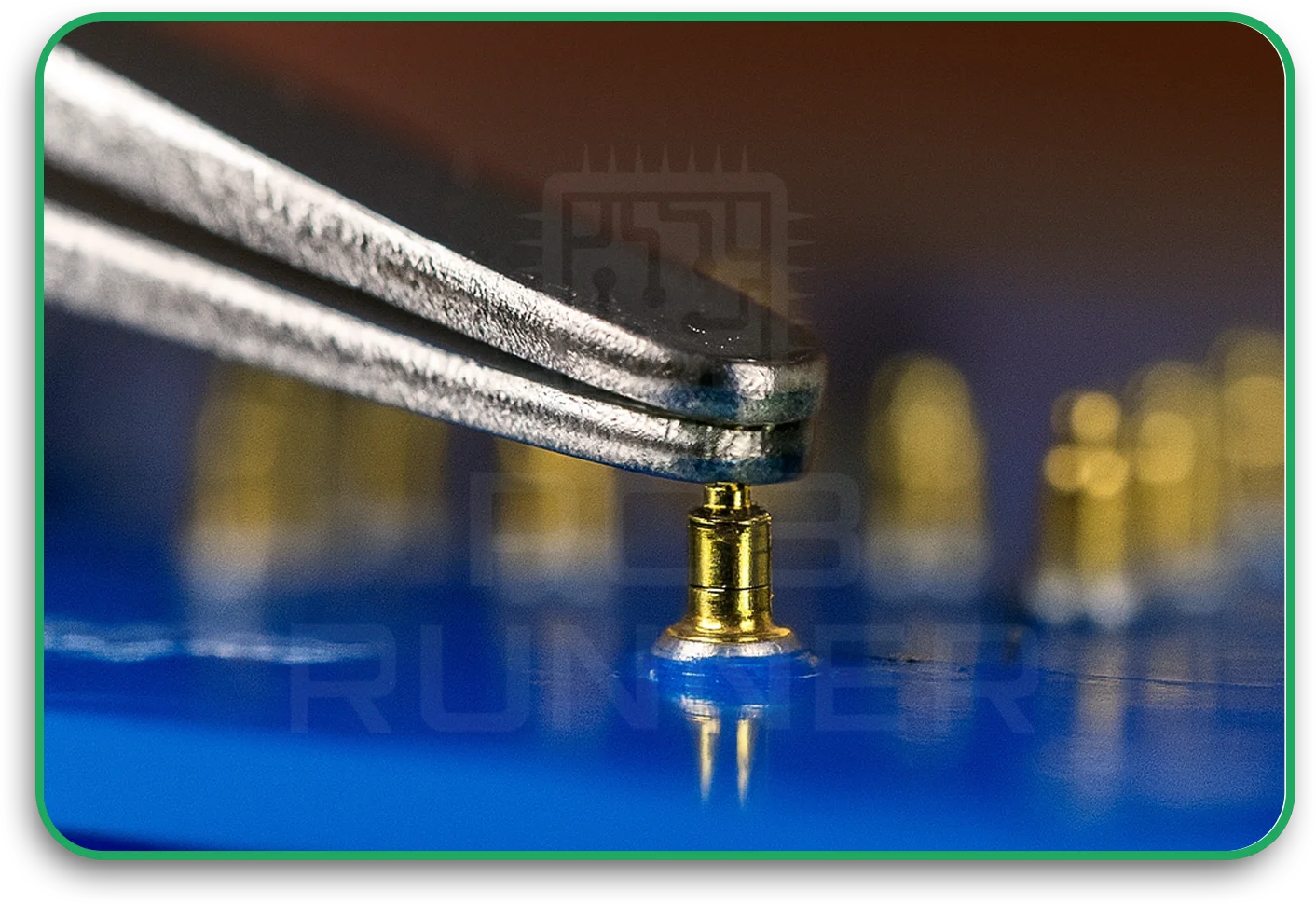

Proper design ensures that spring loaded contact pins perform to specification.

Alignment, Pad Design, and Tolerance Management

Engineers should carefully size landing pads to match plunger diameter, and maintain tight tolerance on board thickness. Misalignment or insufficient pad area can reduce contact reliability.

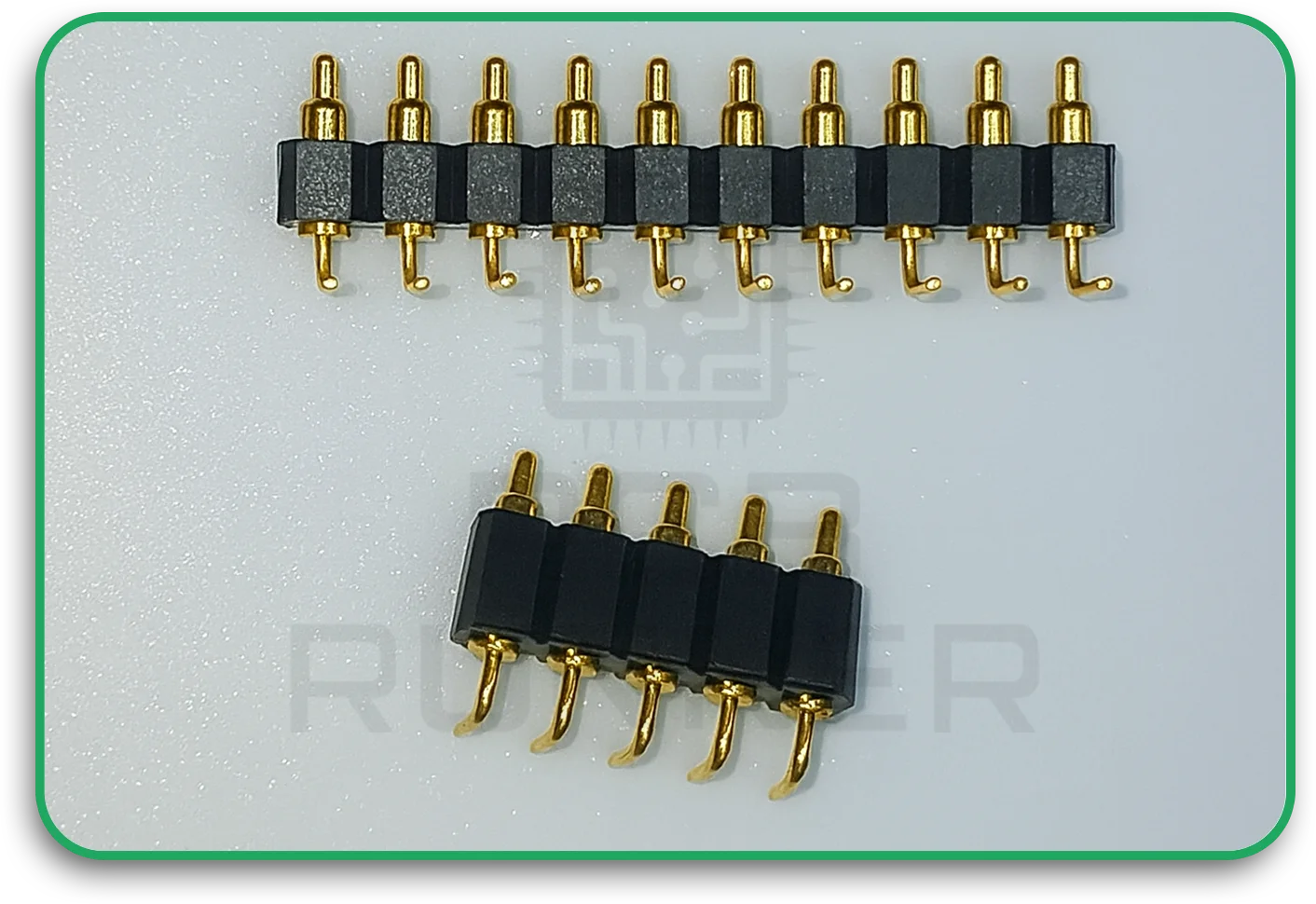

Mounting Options: Through-Hole vs SMT for Spring-Loaded Pin Connectors

Depending on the application, designers can choose through-hole for mechanical strength or surface-mount (SMT) for automated pcb printing. Each method affects assembly cost and long-term reliability.

Use Cases: Where Spring Electrical Contacts Shine

Spring-loaded technology supports a variety of B2B applications:

- Test fixtures and programming jigs: Spring electrical contacts enable high-speed functional testing without permanent soldering.

- Battery and charging interfaces: Portable devices, industrial scanners, and medical electronics rely on spring loaded pin connectors for quick connect/disconnect.

- Modular and stacking PCBs: In products where boards must be removable or upgradeable, pogo pins pcb create secure but serviceable links.

These applications highlight why leading pcb circuit board manufacturers integrate pogo pins into their design toolkits.

Best Practices and Maintenance for Spring-Loaded Pin Connectors

Although highly robust, spring pins benefit from preventive care to ensure maximum lifespan.

Cleaning, Lubrication, and Wear Mitigation

Regular cleaning with isopropyl alcohol and applying a thin protective lubricant help prevent oxidation and wear, especially in harsh industrial environments.

Troubleshooting Contact Failures and Testing

If resistance rises or signals drop, check for debris, misalignment, or worn plating. Many printed circuit board manufacturers schedule periodic electrical testing to maintain quality.

Final Thoughts: Boosting PCB Reliability with Spring-Loaded Pins

By combining mechanical compliance with electrical stability, spring loaded pins enable more reliable, cost-effective solutions for pcb printing and assembly. For engineers and procurement teams working with printed circuit board manufacturers, incorporating spring loaded contact pins or pogo pins pcb can simplify production, improve product longevity, and lower total cost.

At PCBrunner, we don’t just deliver pcb printing but we also provide complete solutions, including high-quality pogo pins and expert engineering support.

Ready to upgrade your connectivity? Contact us today at sales@pcbrunnner.com to discuss your project. Let PCBrunner be your trusted partner in building more reliable, high-performance electronics.