Electronics are getting smaller, smarter, and more powerful. Whether it’s your phone, smartwatch, or car dashboard, everything needs compact and durable circuit boards. That’s where rigid-flex PCBs come in. These boards are helping manufacturers make more reliable and space-saving devices if you’re designing electronics, understanding how rigid-flex PCBs work can really help.

What Is a Rigid-Flex PCB?

A rigid-flex PCB combines two types of circuit boards in one: a flexible part and a rigid part. The rigid part gives strength and support. The flexible part bends and twists as needed. By mixing these two types, you get the best of both worlds. You can place components on both sections, and it all fits together without extra wires or connectors.

Why Are Rigid-Flex PCBs Useful?

Rigid-flex PCBs are helpful in many ways:

- Saves Space: Since you can fold or bend the flexible parts, the overall design can be smaller.

- Stronger Connections: No need for connectors between sections. That means fewer weak spots and less risk of failure.

- Fewer Parts: Everything is part of one board, so you don’t need extra cables or multiple boards.

- Better Performance: These boards handle vibrations, heat, and movement better than traditional boards.

Where Are They Used?

You can find rigid-flex PCBs in lots of products:

- Phones and Tablets: Helps fit more tech into smaller cases.

- Wearables: Smartwatches and fitness trackers use them to stay lightweight and strong.

- Medical Devices: Hearing aids, implants, and diagnostic tools use rigid-flex boards for comfort and safety.

- Cars: Used in dashboards, cameras, and sensors that need to handle heat and vibration.

- Aerospace and Defence: Planes and satellites use these boards because they are light and dependable.

What Makes a Good Rigid-Flex PCB?

If you’re working on your own design or getting boards made, here are things to check:

- Quality of Materials: Choose a good circuit board material that fits your project. FR4 is common for rigid parts.

- Accurate Layout: Make sure your board fits where it needs to go. Mistakes in layout can cause delays.

- Reliable Manufacturer: Choose PCB circuit board manufacturers or pc board manufacturers that understand rigid-flex boards. Experience matters here.

Understanding the Materials

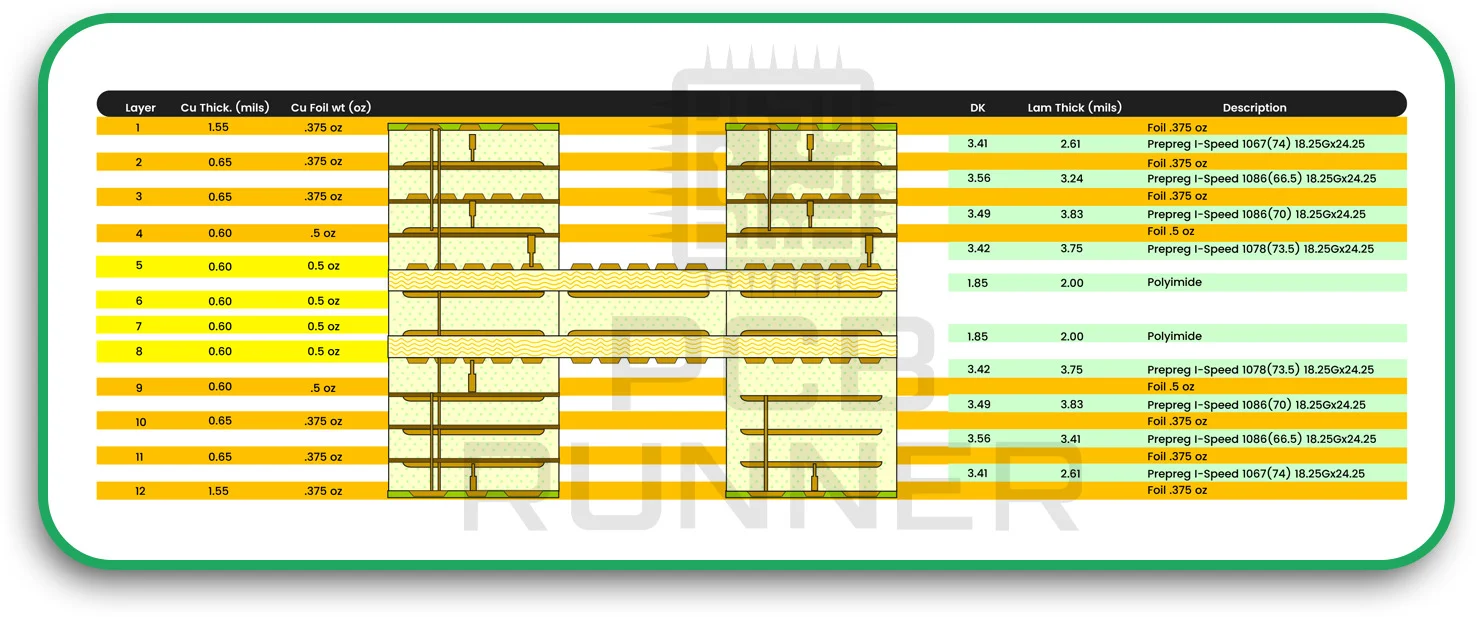

The rigid part of the board often uses FR4. It’s a fibreglass material that doesn’t bend. The flexible part usually uses polyimide. It bends without breaking. Picking the right printed circuit board material is essential. The wrong one can cause your board to fail.

Making a Rigid-Flex PCB

Making these boards is harder than making standard PCBs. That’s why not every PCB board manufacturer offers this service. The process includes:

- Designing the Layout: This includes planning where each part goes and how the flexible parts fold.

- Layering Materials: Each layer of the board is stacked and bonded together carefully.

- Drilling and Etching: Holes are made for parts, and metal paths are etched to form connections.

- Testing: Each board is checked to make sure it works. Good printed circuit board manufacturers will run electrical tests to ensure quality.

Design Tips for Your Project

If you’re designing with rigid-flex boards, keep these tips in mind:

- Avoid Sharp Bends: Bends should be smooth. Sharp corners can crack over time.

- Support the Bend Area: Don’t put soldered parts or holes right on the flex area.

- Plan for Heat: Flex parts can handle heat, but only to a point. Design with that in mind.

- Use the Right Tools: Use design software that supports flex and rigid PCB layout. This helps avoid mistakes.

Benefits for You

Using rigid-flex PCBs can help you:

- Build smaller, lighter devices.

- Make your products more durable.

- Simplify assembly and reduce the number of parts.

- Improve reliability by cutting down on wires and connectors.

These things matter whether you’re building something for a customer or working on a personal project. You want your boards to last and work well.

Why Manufacturers Like Rigid-Flex PCBs

Manufacturers choose rigid-flex designs because they reduce the steps needed to put devices together. Fewer parts mean fewer errors. Also, the devices built with these boards tend to pass quality tests more easily. That saves time and money.

With help from skilled PCB circuit board manufacturers, you can also make custom printed circuit boards that suit your needs exactly. From shape to layer count to special materials, it’s all possible.

How to Pick the Right Manufacturer

Not every company can make good rigid-flex PCBs. When you’re looking for help, find someone who has:

- Experience with flex and rigid PCB types

- A track record of high-quality boards

- Good support during the design stage

- Quick turnaround times

You want to work with people who understand what you need. Ask for samples. Check reviews. Make sure they know what they’re doing.

Real-Life Examples

Smartphone Design: Phone makers use rigid-flex PCBs to fit more features into slimmer cases. Cameras, charging ports, and buttons all connect with fewer parts.

Medical Gear: Doctors rely on tools that can’t fail. Rigid-flex boards in devices like hearing aids help them stay small and dependable.

Automotive Systems: Cars shake, rattle, and heat up. Rigid-flex PCBs handle those stresses better than old-style boards.

Future of Rigid-Flex PCBs

The need for innovative, compact electronics isn’t going away. In fact, it’s growing fast. That means rigid-flex boards are becoming more common in everyday devices. If you’re designing electronics today, knowing how to use these boards gives you an edge.

Companies will continue to invest in better materials and processes. That means you’ll get even stronger, thinner, and more flexible options in the future.

Final Thoughts

Rigid-flex PCBs are changing the way we build electronics. By mixing flexible and rigid sections, they allow for smarter designs that are smaller and tougher. Whether you’re a hobbyist, engineer, or product developer, these boards can help you reach your goals.

When you’re ready to take the next step, look for reliable PCB circuit board manufacturers or PCB board manufacturers who can guide you. Ask about flexible and rigid PCB experience. Test a few samples. The right partner will help you make better products.

Start small if you’re new. Try adding a flexible section to one of your current designs. You’ll see how much space you save and how easy assembly becomes. From there, the sky’s the limit. And remember, great electronics start with great boards. Make sure your design has the support it needs to work well for years to come.