From industrial automation to medical Tools, PCB sensors are pretty critical on a global scale. These sensors are part of a custom printed circuit board (PCB), which can sense temperature, pressure, humidity, movement, and other factors. Engineers can now create ultra-precise PCB sensor designs thanks to the advent of PCBS and printed circuit board design software for specific use cases of constructed sensors.

As modern technology progresses, flexible PCB sensors are becoming popular because they can be placed in tight spots. In this post, we will analyze the benefits of PCB sensors, how they work, what types are available, and identify their applications in modern electronic systems.

What Are PCB Sensors?

PCB sensors are components that are embedded in circuit boards and used for assemblage that measure specific environmental parameters. Such sensors transform the mechanical movement into electrical signals that a monitoring system or automation can process.

Such sensors are used extensively in automobiles, healthcare, consumer electronics, as well as aerospace and industrial applications. Due to the necessity of flexible PCB sensors, multifunctional, thin, lightweight, bendable sensors are being integrated into multilayer PCBs.

The Functioning of PCB Sensors

1. Watching the Surroundings

Every PCB sensor is built to monitor a limit like light, humidity, motion, and temperature. A sensing element in the sensor responds to environmental variations.

2. Signal Conversion

The sensor captures an event and translates it into an electrical signal. The detected changes determine the strength of the signal.

3. Processing the Information

The signal gets routed to a microcontroller or a processing unit in the custom-printed circuit board. The signals are filtered, amplified, and processed by advanced circuits to ensure proper measurement throughout.

4. Sending The Device Data

The information might be displayed on a screen remotely or stored in the location of controlled automation within the system.

For instance, in PCB automation at homes, sensors can monitor room temperatures and communicate with thermostats to activate cooling or heating, depending on the case.

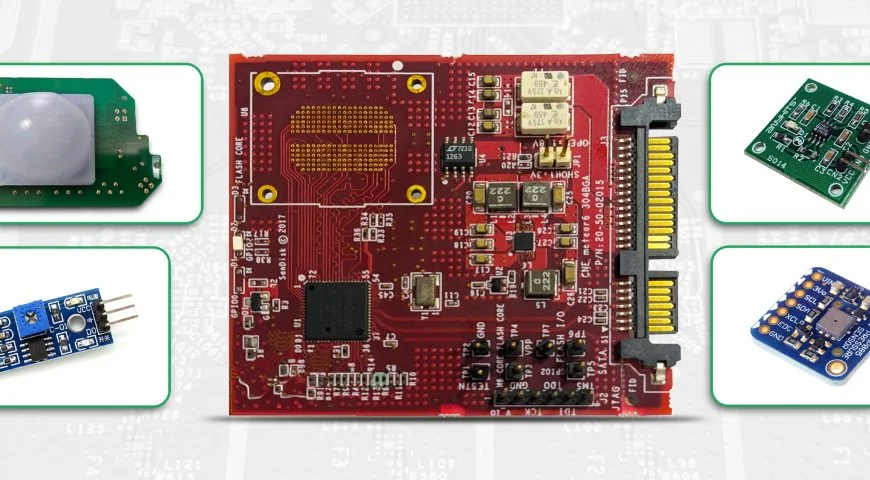

Different Types of PCB Sensors

A range of PCB sensors is tailored for somewhat different tasks. Below are some of the most popular:

1. Temperature Sensors

They are used to measure temperature changes in industrial automation, medical appliances, and HVAC.

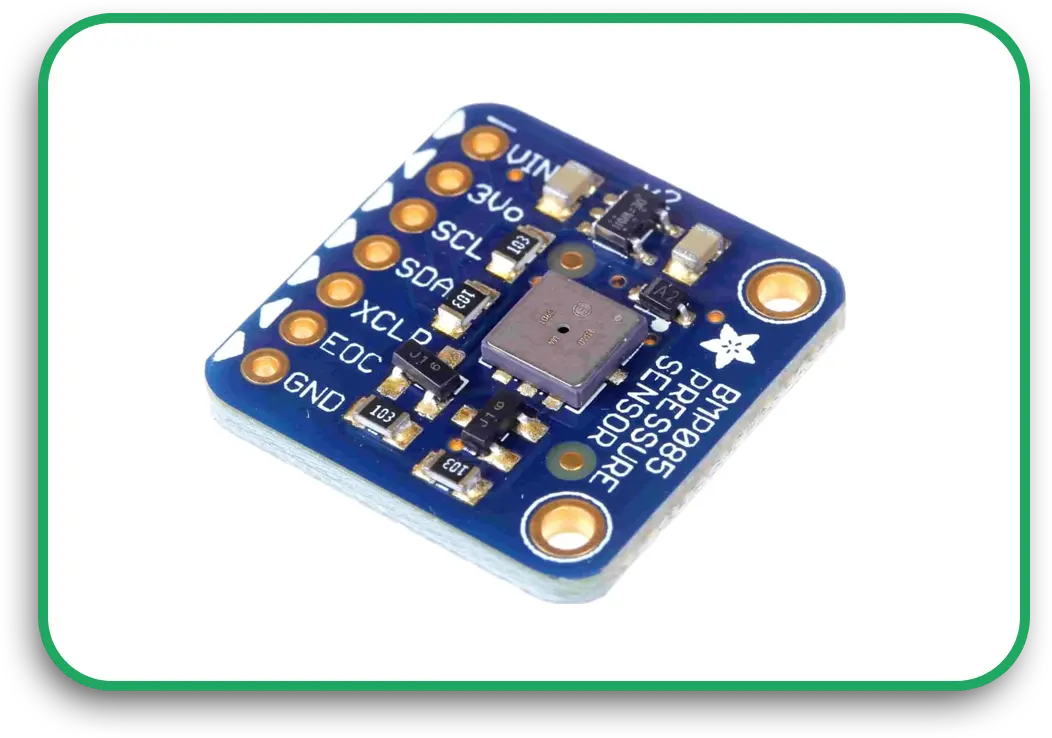

2. Pressure Sensors

These sensors find typical use in measuring fluid or air pressure within automobiles or aerospace systems.

3. Humidity Sensors

These sensors are the most important in controlling climate, monitoring weather, and any agricultural activities.

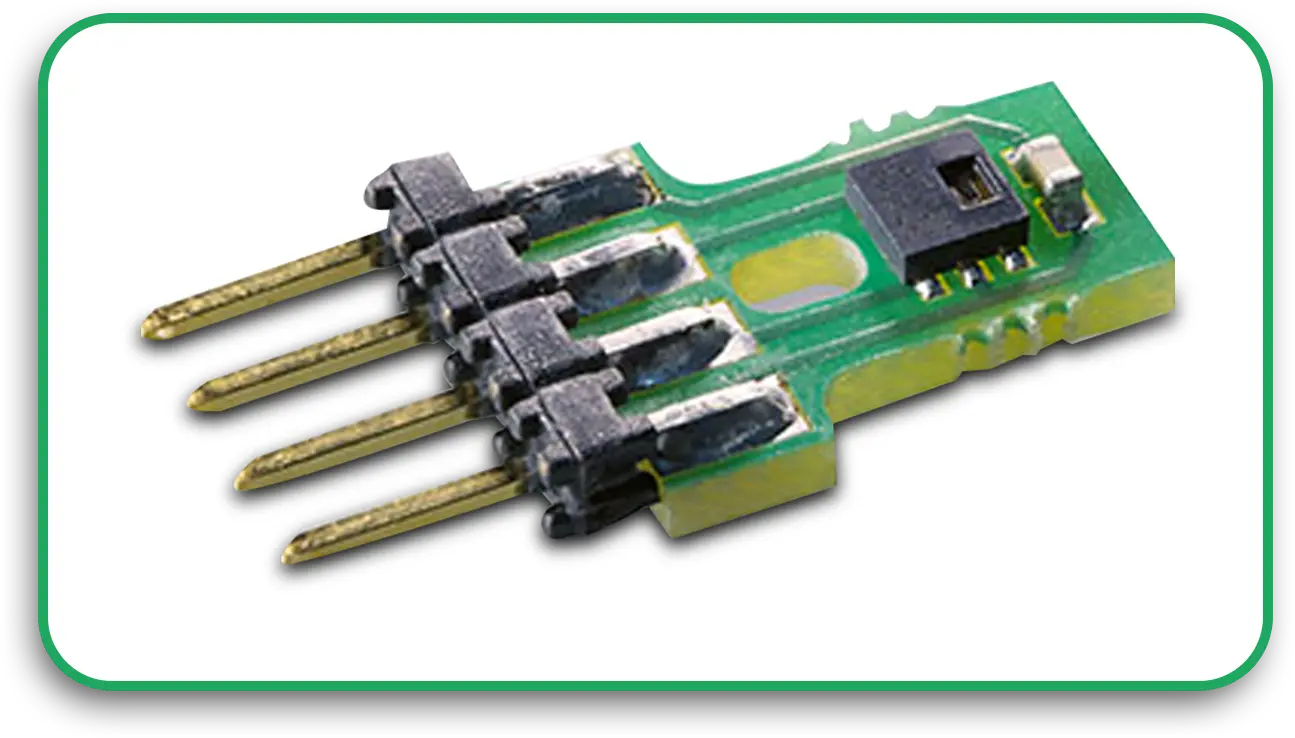

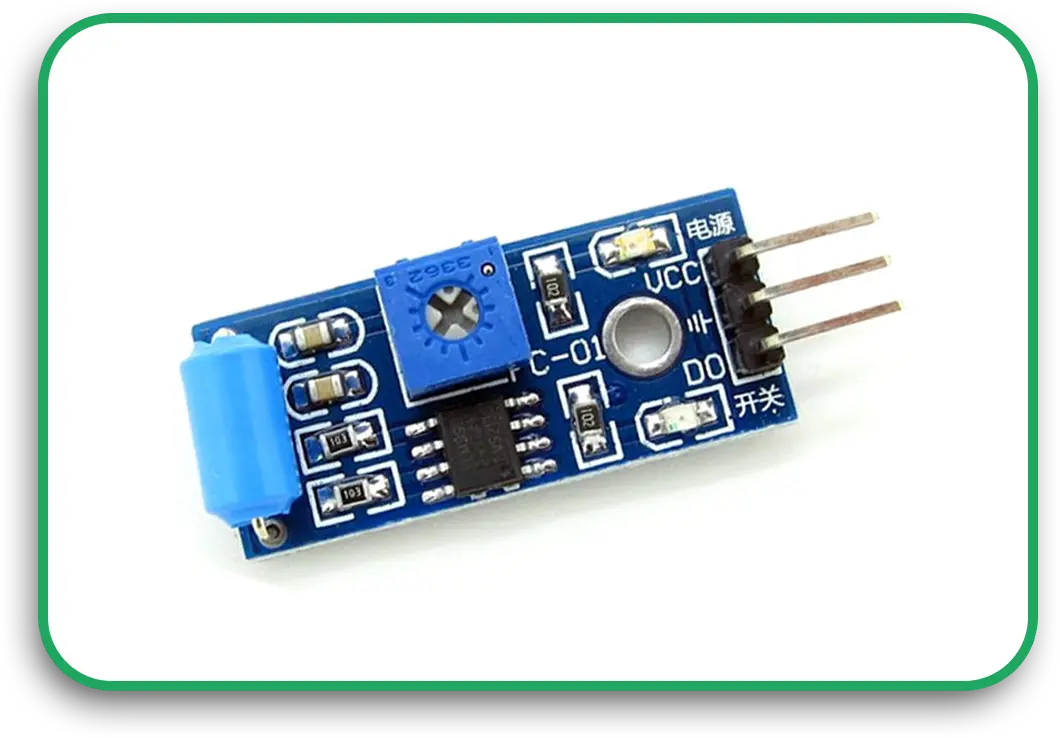

4. Motion and Vibration Sensors

Such sensors can be employed in security systems, gaming equipment, and industrial machines for noting motion or vibrations.

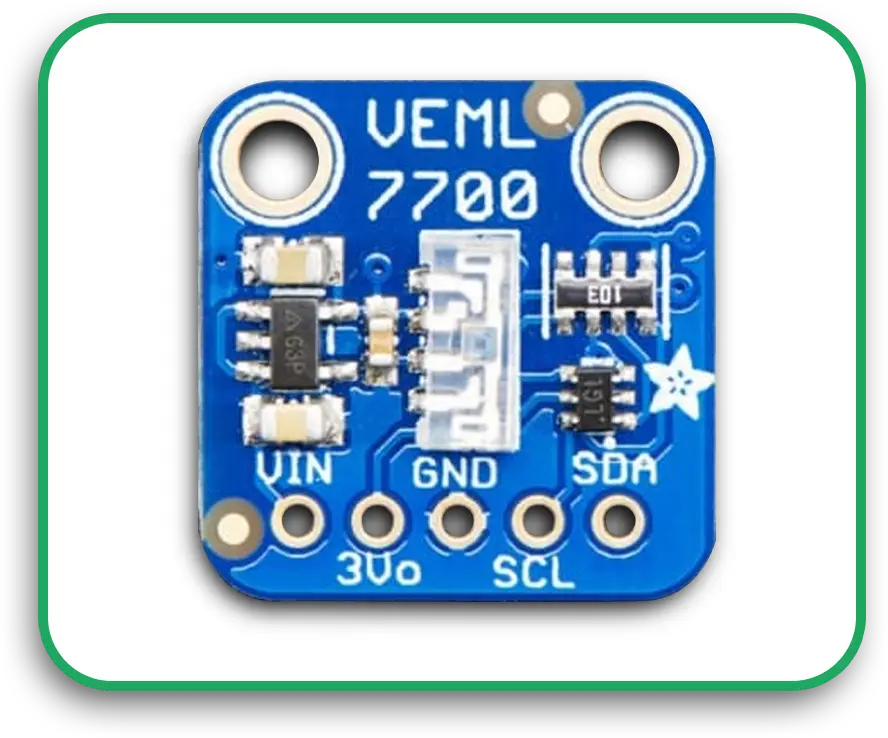

5. Light Sensors

Light sensors are used in controlling the degree of brightness exhibited by a screen, the environment, or a camera system.

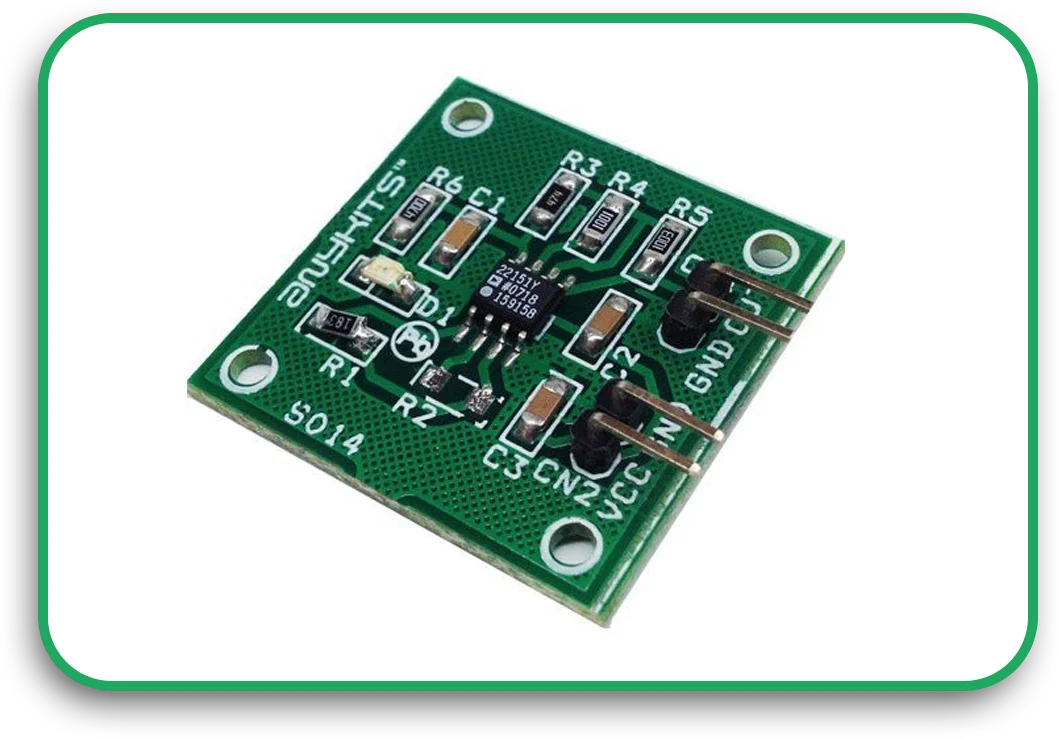

6.Gas Sensors

Gas sensors are essential in spotting dangerous gases in chemical plants, a home, or even in an industry safety system.

7. Magnetic Field Sensors

MagnificField sensors are known to be used in the navigation system, electric motors, and even in some automobiles.

All of these sensors are capable of being combined onto a PCB circuit board assembly for integration into multiple electronic devices.

PCB Design Sensor Issues

When constructing PCB sensors, engineers have to keep a number of criteria if such sensors are to work flawlessly, accurately and optimally. Using state-of-the-art printed circuit board design software, designers can develop layouts with increased performance for the sensors.

1. Component Placement

Proper positioning of PCB sensors is essential to avoid interference from other components. Designers place sensors in isolated areas of the custom printed circuit board to ensure accurate readings.

2. Choosing a Material

The choice of PCB materials has an impact on sensor performance. Quality PCB circuit board manufacturers utilize specialized substrates that increase sensitivity and durability.

3. Preservation of Signal Quality

Using proper routing for signal traces decreases impertinent sounds and improves the precision of sensor readings.

4. Efficient Usage of Power

Due to the fact that numerous PCB sensors are found in devices that utilize batteries as power sources, it is essential to improve power usage to prolong battery life.

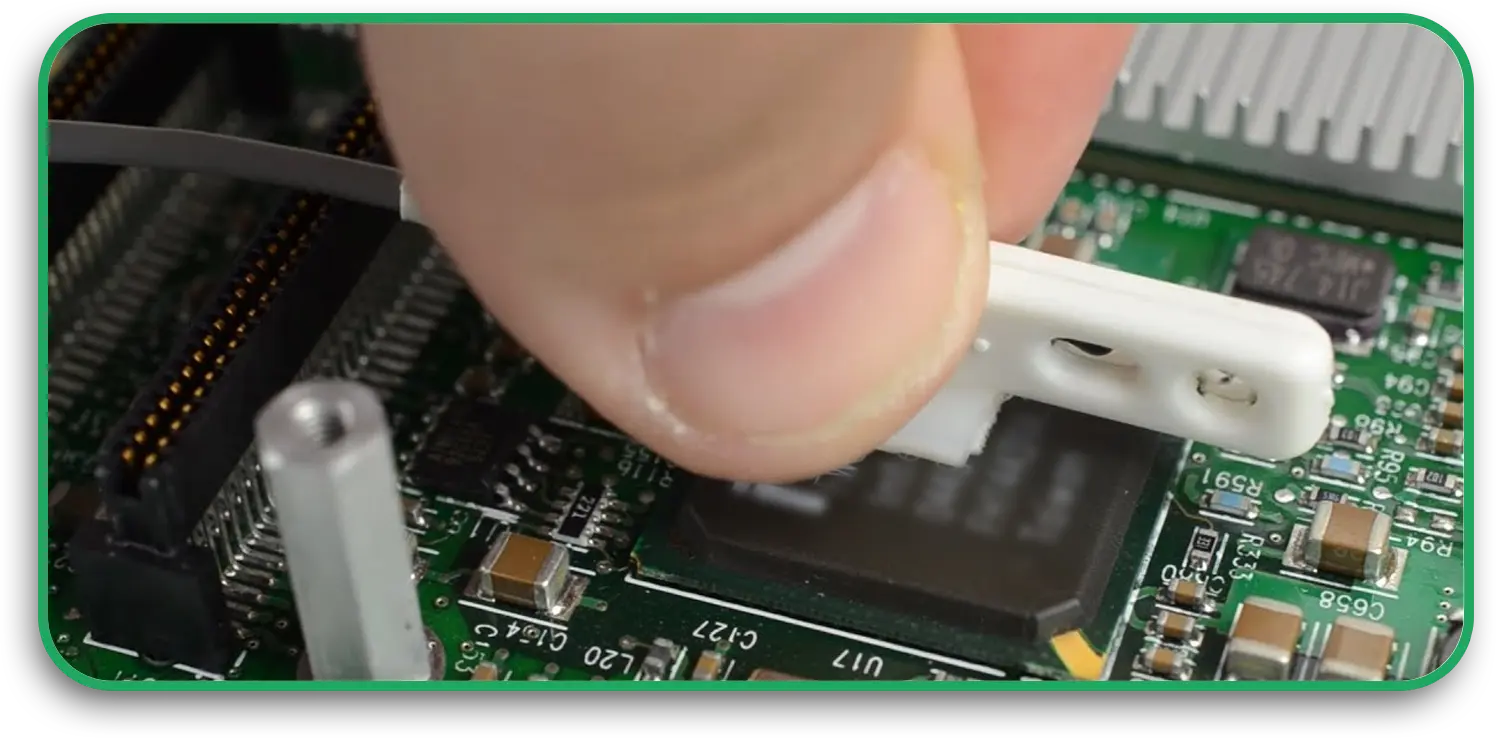

5. Protection of the Environment

During harsh conditions, moisture, dust, and chemicals can be detrimental to PCB sensors. Designers use encapsulation techniques and their combination with conformal coatings for more excellent protection.

Advantages of PCB Sensors

1. Lightweight and Compact

By eliminating the requirement for bulky external sensors, which need to be put on separate enclosures, PCB sensors are great for compact and portable devices.

2. Increased Sensitivity and Accuracy

Environmental parameters are detected accurately and with high precision, guaranteeing reliable data collection with modern PCB sensor designs.

3. Economical

Integration of the PCB sensors into the main circuit board assembly eliminates additional external wiring and components, thus minimizing production costs.

4. Customization Potential

Design Printed Circuit Board software allows engineers to create custom-designed printed circuit boards for specific applications.

5. Durability and Reliability

Physical damage and environmental concerns are not as pertinent with PCB sensors embedded within the board as they are with external sensors.

6. Improved Signal Transmission

The direct integration of PCB sensors into the board increases signal transmission quality and decreases interference, providing superior clarity.

The Rise of Flexible PCB Sensors

Flexible substrates like polyimide or PET (polyethylene terephthalate) have made flexible PCB sensors that are conformable to different shapes increasingly popular.

Why Use Flexible PCB Sensors?

- Perfect for Wearable Technologies: Found in smartwatches, fitness bands, and medical monitoring devices.

- Increased Functionality: This can be placed on a variety of bent surfaces, including automobile dashboards.

- Improved Physical Resilience: Better able to withstand vibrations and other mechanical forces.

- Lightweight Construction: Lowers the weight of electronic devices overall.

Due to the growing popularity of flexible PCB sensors, PCB circuit board producers are adopting new construction methods to improve functionality and dependability.

Selecting The Best PCB Manufacturer For Sensors Integrated Circuits

In the event that your designs call for PCB sensors, it is essential to work with a dependable circuit board manufacturer. Here are tips to guide you:

1. Experience in Sensor PCB Design

Such a manufacturer will understand the intricacies of PCB sensor design and will maximize efficiency and reliability.

2. Sophisticated Manufacturing Equipment

Check whether they can produce multilayered PCBs and flexible PCB sensors for advanced-level applications.

3. Superior Grade Materials

Identify manufacturers that use high-quality substrates for PCBs to boost the accuracy and lifespan of the sensor.

4. Quality Assurance and Control

Engage a contractor that carries out strict defect testing before mass production to avoid numerous defective pieces.

At PCB Runners, we specialize in high-quality custom-printed circuit boards, including PCB sensors for industrial, medical, and consumer electronics.

Overview

Sensors based on PCBs are altering interactions between electronic gadgets and their surrounding environment. Creating compact, lightweight, dependable, and reasonably priced gadgets is possible through the incorporation of said flexible PCB sensors in circuit board assemblies. Knowledge about the operation of PCB sensors combined with best practices in PCB sensor design enables reliable and efficient performance over diverse applications. Therefore, whether it is smart wearables, automotive electronics, or industrial sensors, experienced PCB circuit board manufacturers help achieve the desired results hassle-free.

Top Notch PCB Sensor Solutions, Look No Further! Reach out to us at PCB Runners if you’re looking for custom-made PCB solutions and state-of-the-art PCB sensors. We offer unrivaled circuit board assembly and fabrication so you can have the best service in the industry.

Frequently Asked Questions

1. For what purpose are PCB sensors utilized?

Sensors detect changes in the environment, so they are helpful in the automobile, medical, consumer, aerospace, and industrial electronics industries.

2. What’s the operation mechanism of PCB Sensors?

Sensors identify physical alterations, translate them into electric signals, and relay the information to a processor for further processing.

3. What are the advantages of flexible PCB sensors?

They are lightweight, easy to adjust, durable, and ideal for wearable electronics and other technology that have curved surfaces.

4. What is the process of designing PCB sensors?

Custom sensor placement, signal routing, and material selection are possible for engineers through specialized PCB design software.

5. Who is offering the best deals on PCB sensors?

Reach out to us today to receive custom PCB solutions with advanced sensor integration that we offer for multiple industries at PCB Runners.