Have you ever wondered how modern electronics keep getting smaller and more powerful at the same time? Are you building a compact device and worried about fitting all your parts onto one board? Or maybe you’re trying to boost performance without increasing the size. If so, you’re not alone. These are common concerns when working with circuit boards, and double-sided PCBs might be just what you need.

What Is a Double-Sided PCB?

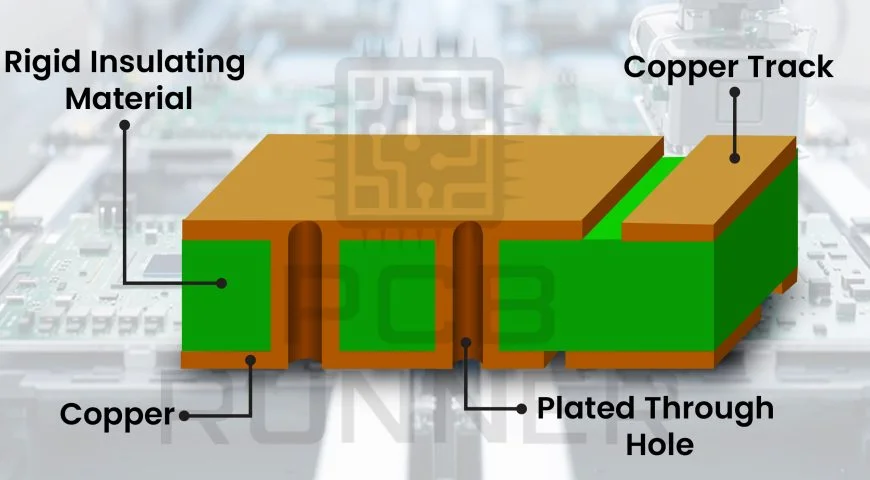

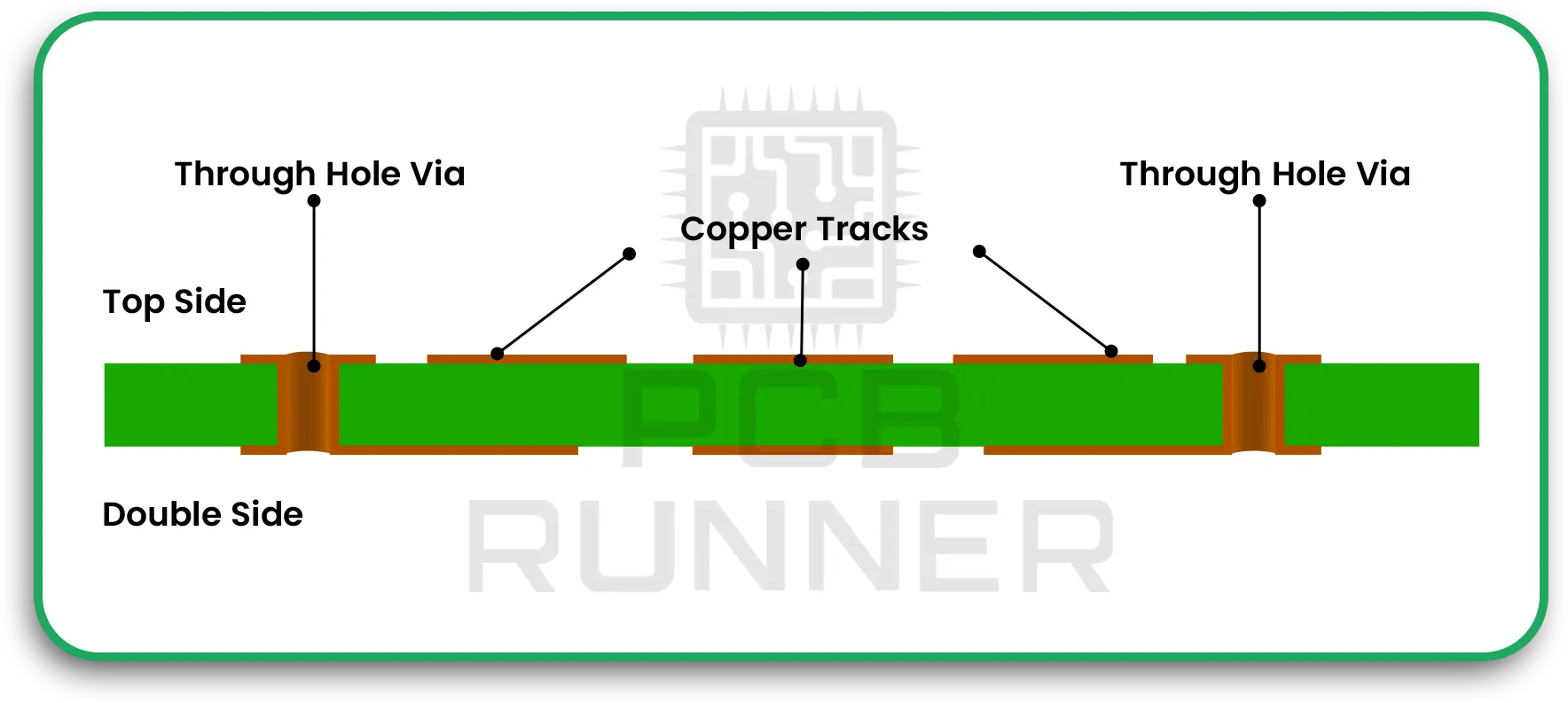

A double-sided PCB is a printed circuit board with copper layers on both the top and bottom. This means you can place components on both sides. That gives you more space and more options when designing your circuit. Unlike a single-sided board, which only has copper on one side, a double-sided PCB lets you connect parts in a more compact and flexible way.

Why Should You Use a Double-Sided PCB Board?

If you’re designing something like a smart device or sensor that needs to be small but fast, a double-sided PCB board can help. Here’s why many people choose them:

- You get more space for parts: You can place parts on both sides instead of just one.

- Your circuits work better: Signals can travel shorter paths, which helps improve speed and reliability.

- They cost less than multilayer boards: You get better performance without paying as much as you would for more complex boards.

Real Benefits of Double-Sided PCB Assembly

Double-sided PCB (Printed Circuit Board) assembly is an essential technique in modern electronics. It involves placing electronic components on both the top and bottom sides of the board. This approach offers several practical benefits that make it a popular choice for many applications. Let’s break down why double-sided PCB assembly is so useful:

1. Better Performance

One of the biggest advantages is better performance. When signals don’t have to travel as far across the board, resistance is lower, and the speed of signal transmission increases. This means that your device can operate more efficiently and respond faster. For example, in devices like smartphones or gaming consoles, quick data transfer is crucial, and double-sided PCBs help achieve that.

2. Smaller Designs

Another major benefit is the ability to create smaller designs. By utilising both sides of the PCB, you can fit more components into a limited space. This is particularly valuable for compact gadgets like smartwatches, fitness trackers, or advanced medical devices, where saving space without sacrificing performance is essential. As technology becomes more compact, double-sided PCB assembly allows engineers to meet these size constraints effectively.

3. Even Heat Spread

In addition to size and performance, double-sided PCBs also offer improved heat management. Since components are distributed on both sides, heat can spread out more evenly, preventing hotspots and reducing the risk of overheating. This balanced heat dissipation ensures that the board stays reliable over time, even in demanding applications like industrial machinery or high-performance computing devices.

4. Flexible Layouts

Moreover, double-sided PCB assembly provides greater flexibility when designing circuit layouts. The extra surface area on both sides gives engineers more options for routing power and signal paths. This means that complex circuits can be designed with fewer compromises, allowing for more efficient and organised component placement. As a result, products can be developed with enhanced functionality while maintaining a sleek, compact form factor.

Where Are Double-Sided PCBs Used?

Double-sided PCBs show up in a lot of products. Here are some common examples:

- Phones and tablets: To keep them slim while still packing power.

- Cars: For control panels, cameras, and safety systems.

- Factories: Machines use these boards in their control units.

- Medical gear: For small tools that track or check health.

Why Choosing the Right PCB Manufacturer Matters

When you’re ready to build a double-sided board, working with the right team is key. Not all PCB manufacturers are the same. A skilled PCB manufacturer can help you avoid problems and build a board that really works.

Here’s what to look for:

- Experience with double-sided PCB assembly

- Ability to meet deadlines

- Support with custom printed circuit board designs

- Good materials and quality checks

You want someone who listens to your needs and delivers solid work.

When You Need a Custom Printed Circuit Board

No two projects are exactly alike. That’s why going custom can be a big help. A custom printed circuit board fits your exact needs, from the shape of the board to the thickness of the copper.

Custom boards let you:

- Pick your own layout and shape

- Decide how much power to handle

- Choose special materials for heat or strength

This kind of flexibility means your design can be faster, smaller, and tougher.

Start With a Double-Sided PCB Board Prototype

Before you make 1,000 boards, it’s smart to test one. That’s what a double-sided PCB board prototype is for. A prototype lets you see how the board fits, works, and holds up in real use.

Fast prototyping helps you catch mistakes early. Good pcb manufacturers can get you a working sample fast, so you stay on schedule.

Why PCB Manufacturers Should Offer Fast Prototyping

Time is important. Delays cost money. That’s why it’s helpful to work with a team that offers fast PCB prototyping. Speed helps you:

- Test ideas quickly

- Fix problems early

- Launch your product faster

Some of the best pcb manufacturers offer 24–72 hour turnaround times on prototypes. That gives you more time to focus on the rest of your project.

Comparing Double-Sided to Other PCB Types

| Feature | Single-Sided PCB | Double-Sided PCB | Multilayer PCB |

| Component Mounting | One side only | Both sides | Multiple inner layers |

| Cost | Low | Medium | High |

| Complexity Supported | Low | Medium | High |

| Space Efficiency | Low | High | Very High |

| Used In | Simple gadgets | Phones, tools | Servers, routers |

As you can see, double-sided boards are the perfect middle ground. They offer more power than basic boards but don’t cost as much as multilayer ones.

What Is Double-Sided PCB Jump Scoring?

Sometimes, a large double-sided PCB needs to be broken into smaller parts. That’s where PCB jump scoring helps. It’s a method where grooves are made on both sides of the board so you can snap parts apart cleanly.

Jump scoring is useful if:

- You’re making panels of small boards

- You need easy break-off sections

Ask your PCB assembler if they offer this service, especially for high-volume jobs.

Choosing a PCB Assembler for Your Project

Once your design is ready, a pcb assembler takes the parts and puts them on your board. You want someone with experience in double sided PCB assembly.

Look for:

- Good reviews and past work

- Fast service times

- Support with testing

A reliable assembler means fewer headaches and better boards.

Final Thoughts

Double-sided PCBs offer a smart way to make your devices smaller and more powerful. They’re great for phones, tools, cars, and more. You get better signal flow, smaller size, and improved heat control.

To get started, work with experienced printed circuit board manufacturers. Whether you need a custom printed circuit board, a fast double sided PCB board prototype, or jump scoring, the right partner will guide you every step of the way.

If you’re ready to upgrade your design, reach out to a trusted pcb manufacturer or pcb assembler today like PCB Runner. Your next smart device might just start with a smarter board.