The world of electronics is evolving fast, and at the heart of every breakthrough lies a printed circuit board (PCB). The fabrication of PCBs powers modern devices such as smartphones, wearables, and electric vehicles. Designing and manufacturing PCBs is being reshaped by trends like miniaturization, flexibility, and sustainability.

Here are the latest trends shaping PCB manufacturing. If you’re curious what’s next, you’ll find this blog informative. The future of PCB circuit board manufacturing is in the hands of AI-assisted designs and flex PCB fabrication.

Why Keeping Up with PCB Trends Matters

Did you know? The global PCB market is projected to reach over $100 billion by 2030, according to industry forecasts. This growth is driven by demand for compact, innovative, and energy-efficient electronics. As a result, the PCB board fabrication process is becoming more sophisticated, fast, and adaptive to meet these needs.

Whether you’re a startup building prototypes or a major electronics brand, keeping up with the latest fabrication trends helps you:

- Cut costs without compromising quality.

- Speed up time-to-market

- Design more advanced, space-efficient products.

- Compete globally with sustainable and reliable PCBs

This blog will discuss the key drivers pushing PCB fabrication service providers into the future.

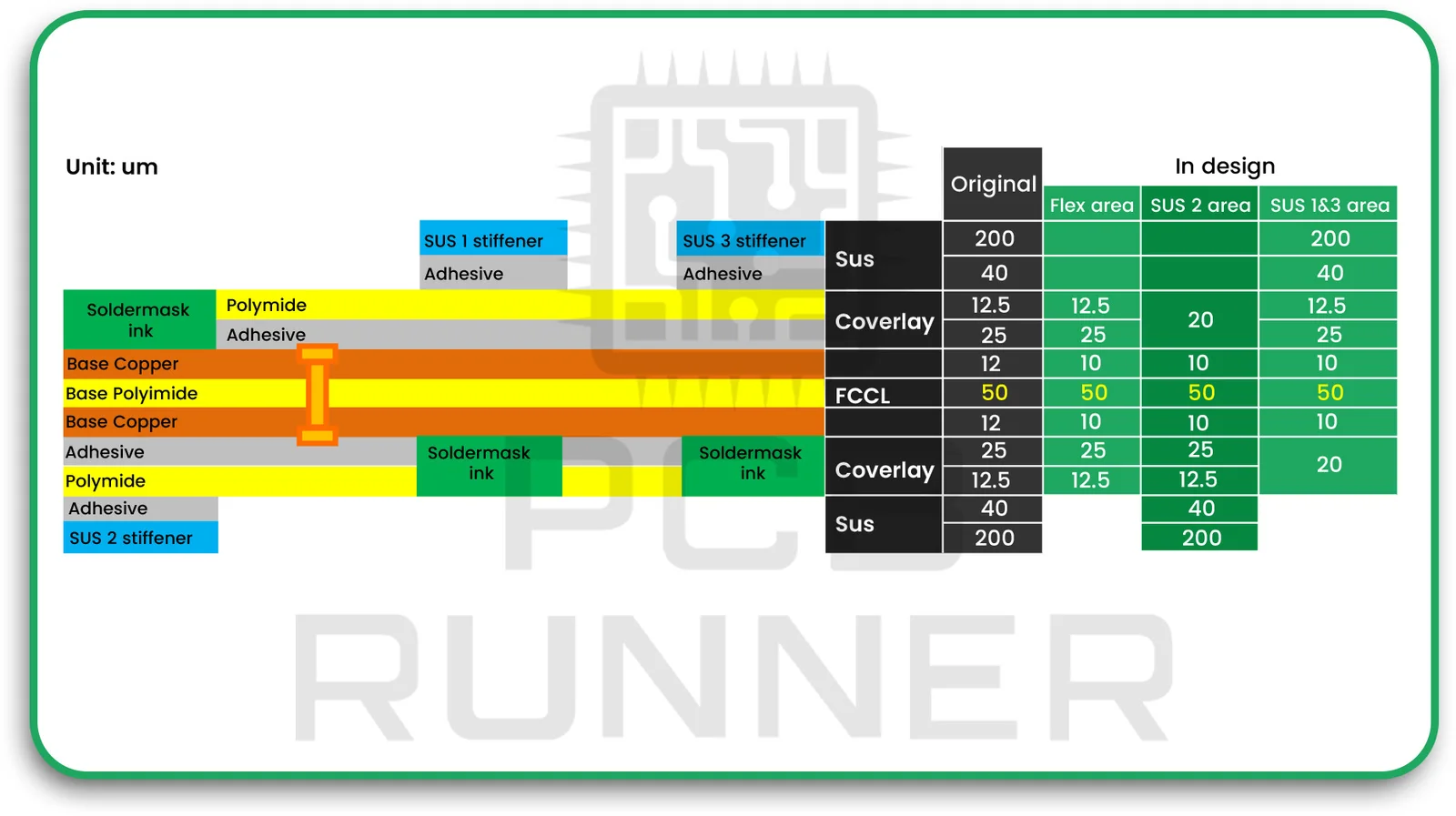

1. The Rise of Flex PCB Fabrication

One of the most significant shifts in recent years is the growing demand for flexible PCB fabrication.

Unlike rigid boards, flex PCBs can bend, twist, and fold to fit into tight spaces. They’re made of flexible materials like polyimide, allowing for dynamic designs that are lightweight and durable. This makes them ideal for wearables, medical implants, foldable phones, and aerospace systems.

Benefits of Flex PCB Fabrication:

- Saves space in compact electronics

- Resists vibration and mechanical stress

- Allows 3D circuit layouts

- Reduces the need for connectors

Flexible PCB Fabrication Process Involves:

- Material selection (polyimide or polyester base)

- Circuit pattern creation using photolithography

- Etching and plating for accurate traces

- Lamination and overlay application

- Component mounting with surface mount or through-hole tech

As product designs grow smaller and smarter, flexible PCB fabrication is no longer a luxury, it’s becoming the industry standard.

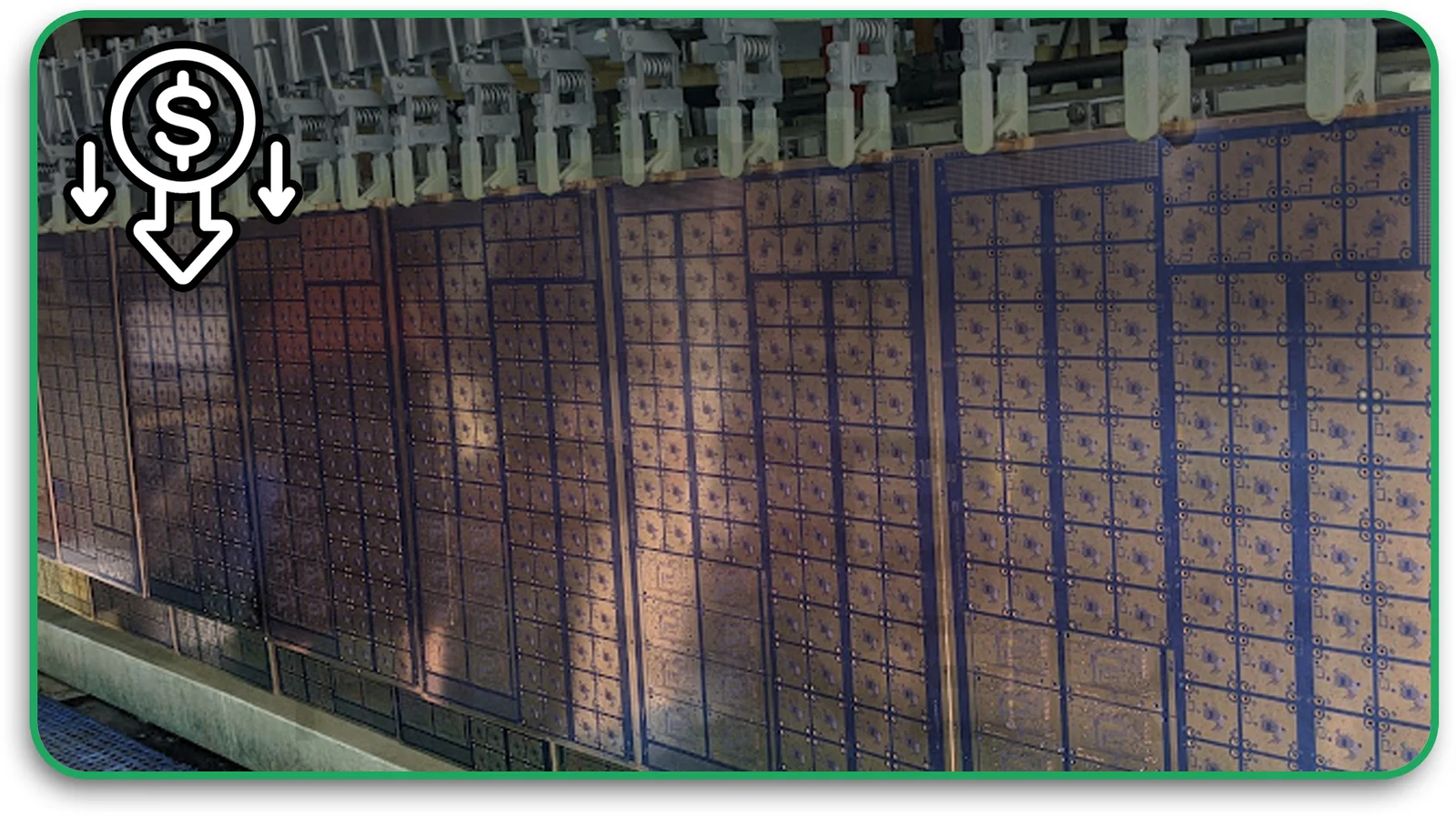

2. Low-Cost PCB Fabrication Without Compromise

As electronics production scales up, cost becomes a deciding factor. Companies are searching for PCB fabrication low cost options that still offer high precision, quality, and turnaround.

How PCB Circuit Board Manufacturers Are Cutting Costs:

- Panelization: Placing multiple boards on a single panel to reduce waste

- Automated fabrication lines: Faster production with fewer errors

- Global sourcing: Leveraging cost-effective materials without sacrificing standards

- Lean manufacturing practices: Streamlining every stage from design to shipment

What’s important is finding a PCB fabrication service that balances cost-efficiency with excellent customer support, material options, and testing procedures. It’s not about going cheap, it’s about going smart.

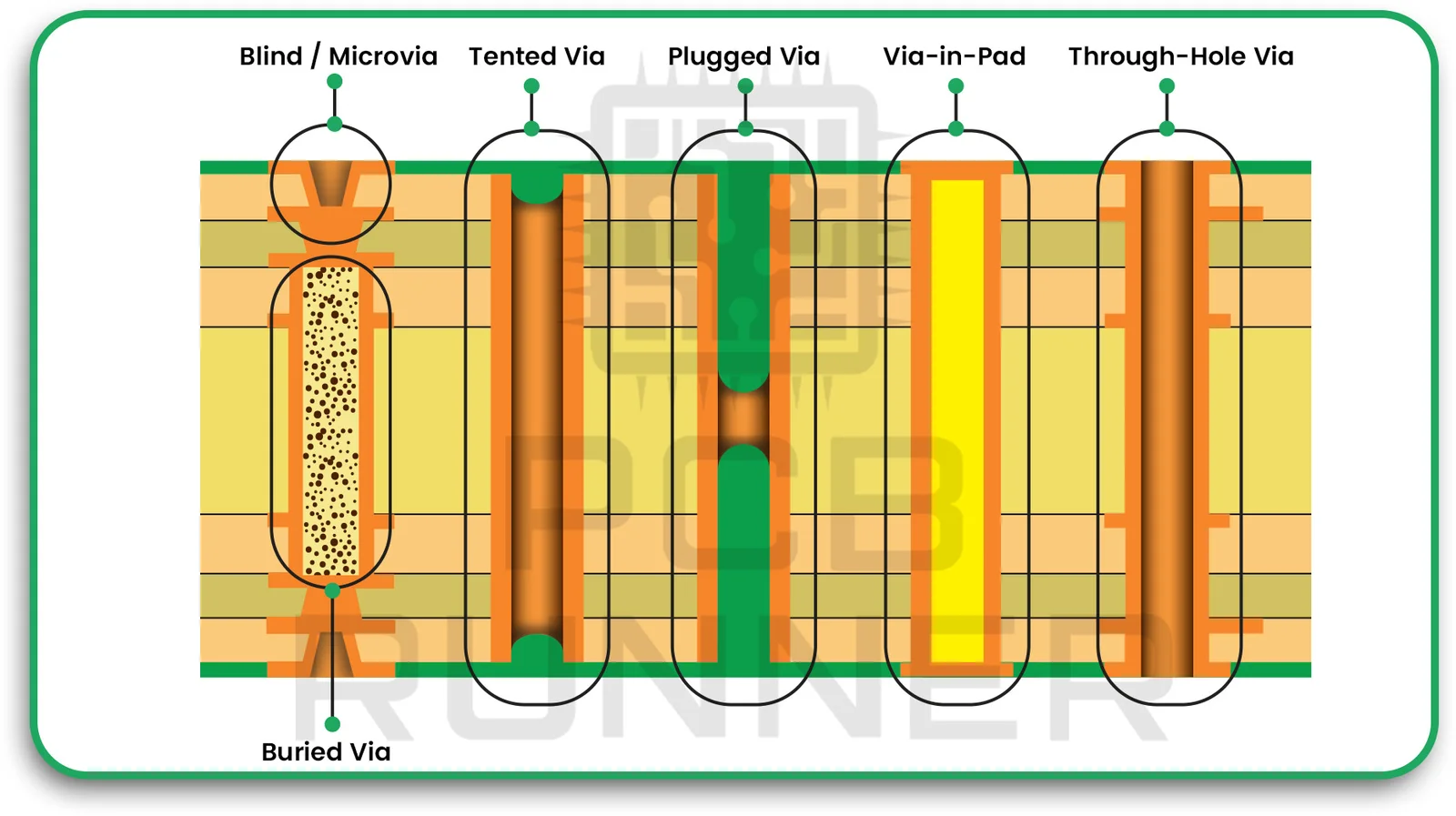

3. HDI and Miniaturization

High-Density Interconnect (HDI) boards enable tighter and more complex circuit paths in a small footprint. With micro vias, laser drilling, and fine lines, HDI boards are leading the miniaturization trend in PCB manufacturing.

Used widely in smartphones, tablets, and IoT devices, HDI allows engineers to:

- Place more components per square inch.

- Increase electrical performance

- Reduce layer count in complex boards.

When paired with flex PCB fabrication, HDI designs can be incredibly compact and powerful.

4. Green PCB Fabrication: Sustainability in Focus

Environmental responsibility is now a significant concern in electronics. More PCB board fabrication processes are being retooled to lower the carbon footprint and reduce toxic waste.

Key Sustainability Trends:

- Lead-free soldering for RoHS compliance

- Water-based cleaning agents instead of solvents

- Recyclable substrate materials

- Eco-friendly etching chemicals

Forward-thinking PCB circuit board manufacturers are offering certifications like RoHS, REACH, and ISO 14001 to show their commitment to sustainable production.

5. AI & Automation in PCB Fabrication

Artificial Intelligence (AI) is helping engineers create better PCBs faster. From automating design verification to predicting manufacturing defects, AI is transforming the PCB fabrication service industry.

Applications of AI in PCB Fabrication:

- Auto-routing optimization in EDA tools

- Defect detection via image analysis during inspection

- Yield prediction to reduce waste and rework

- Smart scheduling for production efficiency

Automation tools are also being used in the flexible PCB fabrication process, where precision is key to avoid deformation or delamination.

6. 5G and High-Frequency PCB Design

The rise of 5G networks and high-frequency devices demands PCBs that can support faster signal transmission with minimal loss.

5G-ready PCBs require:

- Special dielectric materials

- Low signal loss traces

- Controlled impedance

- Precise layer alignment

Whether rigid or flexible, these boards need specialized PCB fabrication processes and expertise. Working with manufacturers who understand high-speed design is essential to avoid signal integrity issues.

7. Quick-Turn Prototyping Services

Time-to-market pressures are pushing companies to build prototypes faster than ever. That’s why many PCB fabrication services now offer quick-turn options, delivering boards in as little as 24-48 hours.

Benefits of Quick-Turn PCB Services:

- Rapid design iterations

- Fast MVP testing

- Competitive product launches

Advanced software integrations between design and manufacturing teams help streamline the flow from schematic to board in record time.

8. Integration of PCBs in Wearable Tech

From smartwatches to health monitors, wearable electronics are everywhere, and they rely heavily on flexible PCB fabrication. These PCBs must endure daily flexing, body heat, and sometimes even moisture.

That’s why the flexible PCB fabrication process includes special coatings, encapsulations, and thin materials to ensure durability and performance. As demand for wearables grows, expect even more innovation in this space.

9. Hybrid PCB Solutions: Rigid-Flex Is Booming

Rigid-flex PCBs combine the strength of rigid boards with the flexibility of flex circuits. This hybrid solution reduces connectors, lowers assembly time, and enhances durability, especially in foldable devices or aerospace systems.

Benefits of Rigid-Flex PCBs:

- Greater mechanical stability

- Simplified assembly process

- Reduced overall weight and size

While slightly more expensive, their performance and space-saving benefits make them worth considering for next-gen applications.

How to Choose the Right PCB Fabrication Partner

With so many advances in PCB manufacture, choosing the right partner matters more than ever.

Look for PCB Circuit Board Manufacturers That Offer:

- Expertise in flex PCB fabrication and HDI designs

- Transparent PCB fabrication service pricing

- Quick-turn prototyping and low-volume options

- Eco-friendly processes

- Custom material support for unique applications

An experienced team can guide you through the PCB board fabrication process, recommend the best materials, and deliver reliable boards that power your innovation.

Conclusion: The Future of PCB Fabrication Is Here

The trends driving PCB fabrication today, from flexible designs to AI automation, are shaping the future of electronics. These advancements are not just technical; they’re making products smaller, smarter, greener, and faster to build.

Whether you’re exploring flexible PCB fabrication for wearable tech or seeking PCB fabrication low cost options for scaling production, staying ahead of these trends ensures you remain competitive in a rapidly changing market.

Ready to build the future? Partner with a forward-thinking PCB fabrication service provider that helps you turn ideas into reality, faster, better, and more affordable.