Printed Circuit Boards (PCBs) are critical in every electronic gadget as they ensure the mechanical and electrical interconnections between different parts of the device. PCB technology, like all others, has progressed over time to address the needs of smaller, more efficient and more versatile electronics. Presently, two major categories of PCBs in use are Flex PCBs or flexibles and Rigid PCBs. Electronics designers and engineers need to know the difference between these two variants in order to design and manufacture high-quality and low-cost products.

This blog will discuss the major differences between flex and rigid PCBs, their benefits and disadvantages, and how to select the most appropriate one for a given situation.

Basics of Rigid PCBs

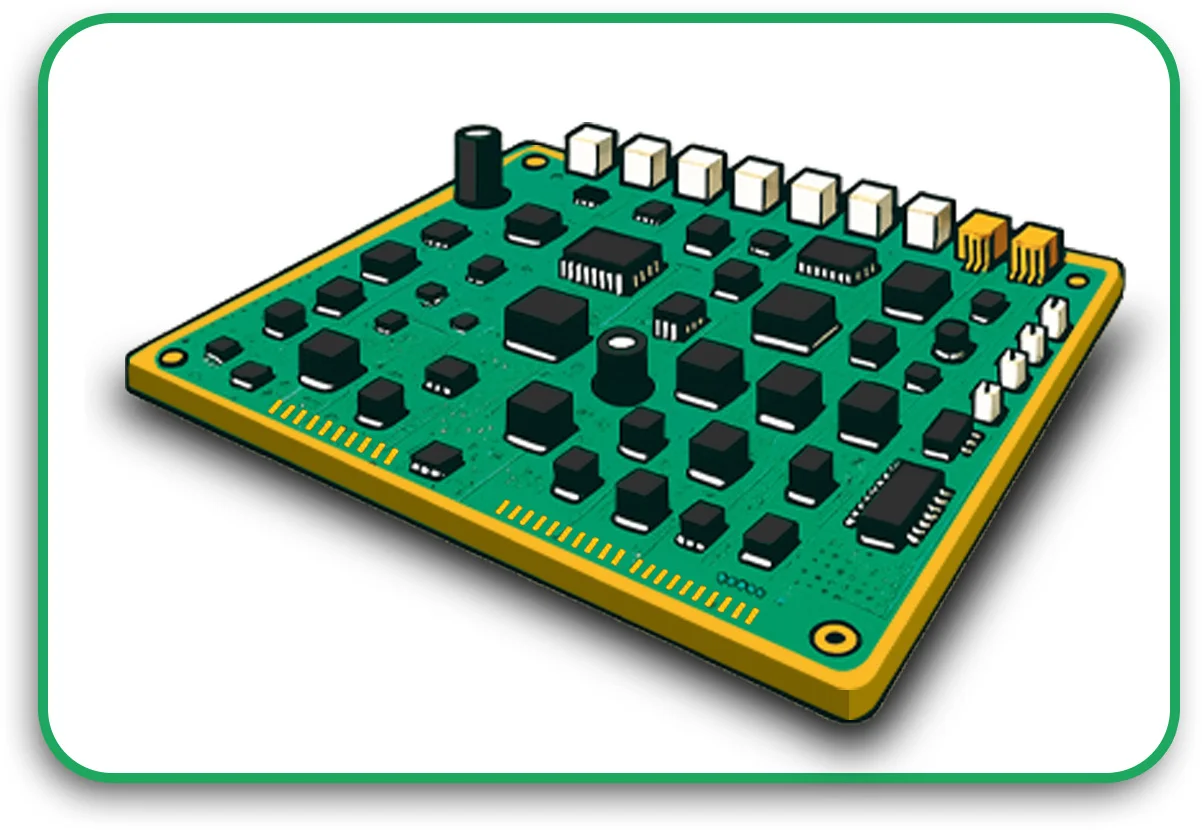

What Is A Rigid PCB?

Rigid PCBs are an older variety of circuit boards fabricated from a single piece of rigid and inflexible material, such as fibreglass (FR4). Such boards retain their shape and are commonly manufactured for use in devices that require strength and proper component alignment.

Dependable Connections: The structure of rigid PCBs guarantees reliable soldering and little movement to the components mounted on them.

Shortcomings of Rigid PCBs

Inflexibility: Rigid PCBs cannot be bent or molded to fit into curved or contoured closed spaces.

Additional space needed: Unlike flexible PCBs, rigid PCBs occupy more area in compact devices.

Increased chance of mechanical failure: Rigid PCBs will tend to develop cracks or break over time in an environment with constant vibration or movement.

Interpreting Flexible PCBs

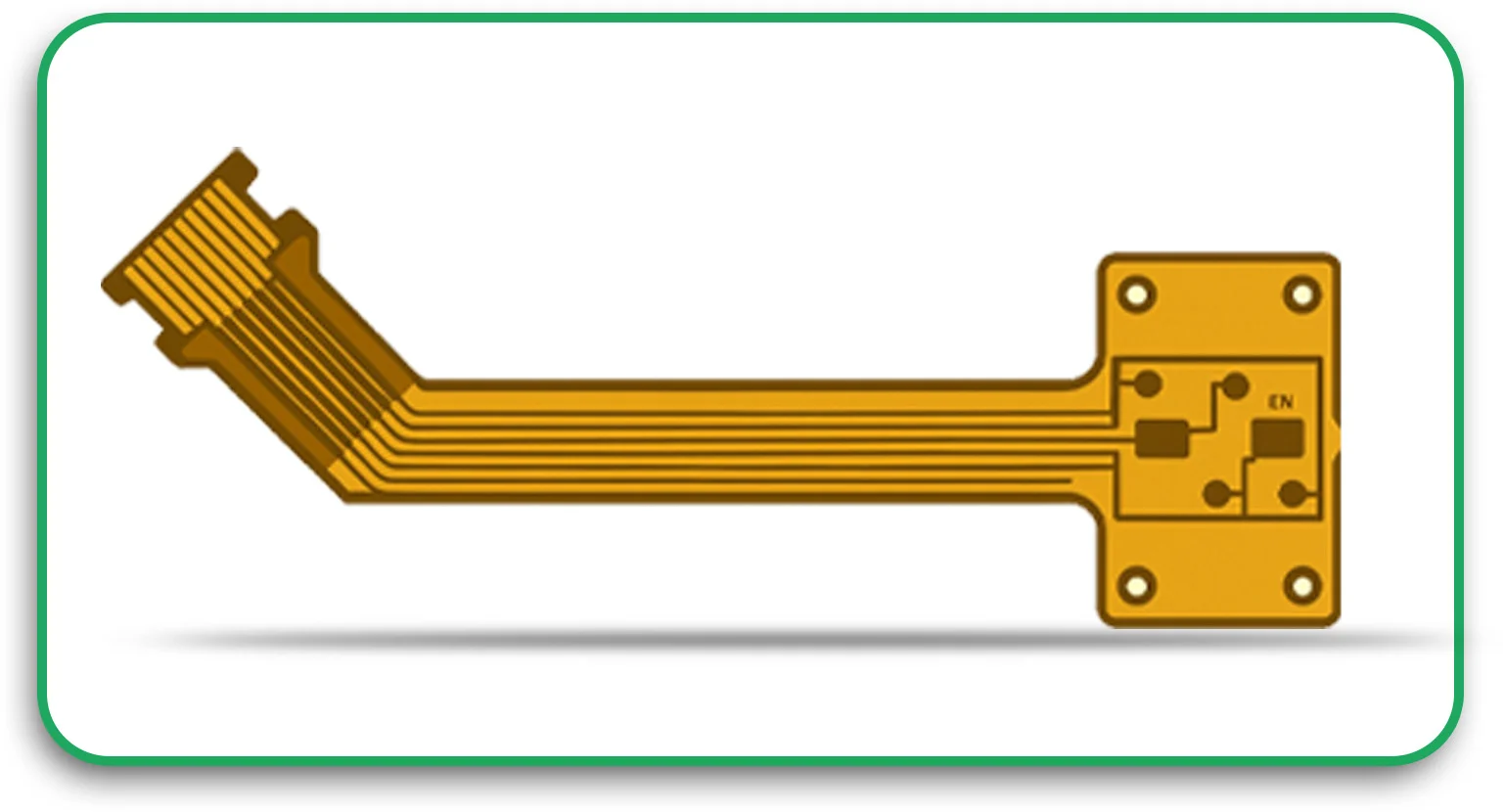

Defining a flexible PCB

As the name implies, a flexible PCB (flexible printed circuit board) is a printed circuit board made of thin, pliable polyimide materials that allow the board to bend and take on different shapes. These PCBs are applicable in scenarios where the space available is small or when the circuitry needs to be in motion.

Benefits of Flexible PCBs

Light and Compact: The structure of flexible PCBs makes them perfect for portable and wearable electronic devices.

Toughness in Active Situations: They can also endure bending, vibrations, and motion without being damaged.

Reduced Circuit Complexity: Simplifies circuit design as fewer connectors and cables eliminate points of failure and increase reliability.

Enhanced Heat Dissipation: Flexible PCBs have improved dimensional tolerance and expansion efficiency compared to rigid PCBs.

Hurdles of Flexible PCBs

Increased Cost of Production: The average rigid PCB’s expense is greatly increased due to the costs of specialized materials and the manufacturing processes involved.

Difficult assembly: The assembly of flexible PCBs is challenging and should be done with extreme care.

Limited Load-Bearing Capacity: Unlike PCBs, flexible ones cannot support substantial weights.

Deciding Rigid Over Flexible PCBs:

It is important to understand the scope of the design or the application as it determines the type of PCBs to use. Consider the following points:

- Size and shape of the device

A rigid PCB is more suitable if your device has a simple shape and a flat, erect outline.

For designs with circular or folding parts, a flexible PCB is most appropriate.

- Durability and surroundings

Flexible PCBs are ideal when it comes to high-motion or vibration environments like the automotive and medical fields.

Rigid PCBs are highly durable and perfect for static environments like desktop systems or industrial machines.

- Cost of production

If budget is a restraining factor, then rigid PCBs are the most affordable.

Flexible PCBs are a better spend where cost does not matter, saving space and enhancing performance.

- Load of components and interconnects

When heavy components are a necessity in design, structural support is provided best by Rigid PCBs.

Flexible PCBs are an improvement over the design and provide reliability with minimal connectors and wires.

Flex vs. Rigid PCBs: Key Differences

| Feature | Rigid PCB | Flexible PCB |

| Structure | Solid and inflexible | Bendable and adaptable |

| Material | Fiberglass (FR4) | Polyimide or flexible plastic |

| Durability | High in static environments | High in dynamic environments |

| Space Efficiency | Requires more space | Saves space with flexible designs |

| Manufacturing Cost | Lower | Higher due to advanced processes |

| Application | Computers, industrial equipment | Wearables, medical devices, automotive |

Expert Insights

Manufacturers will be familiar with flexible PCBs; as the name implies, these are designed to bend and twist, allowing for the adaptation of electronics to various shapes and sizes. In comparison, rigid-flex PCBs combine rigid and bendable parts, providing the user with the best of both worlds by offering the structural support common with traditional PCBs as well as the pliability of bendable circuits. In several areas, these innovations are fostering new developments and increasingly so in the next few years, even more so.

The combination of rigid and flexible elements in rigid-flex PCBs allows for both the rigidity necessary for the stable placement of components and the flexibility required for active and versatile layouts. This is essential in fields such as electronics for aerospace and medical devices, where electronic components must function in severe conditions and unconventional structures. Economically, rigid-flex PCBs can eliminate the need for connectors and cables, resulting in reduced overall design complexity, increased reliability, and lower production costs.

Conclusion

Both rigid and flexible PCBs have unique advantages and cater to specific needs. While rigid PCBs are cost-effective and allow stable, dense component placements, flexible PCBs are adaptive, durable, and save space.

A careful analysis of the advantages and disadvantages of these two technologies allows PCB manufacturers and electronics engineers to make optimal design choices during PCB production. Progress in technology will allow multilayer PCBs and rigid-flex designs to remain at the forefront of developing next-generation, high-performance, innovative electronic products.

If you are wondering how to find the best PCB solution for your project, seeking direction from a professional circuit board assembly provider is the surest way to guarantee optimal performance while ensuring reliability and cost efficiency.