If you’re curious about how modern electronics keep getting smarter, you’re not alone. One big reason is the use of RFID, or Radio Frequency Identification, in printed circuit boards (PCBs). Today, you’ll learn how RFID works, how it’s built into PCBs, and what it means for you as someone looking for the best circuit board suppliers UK or PCB circuit board manufacturers. We’ll also show you how custom PCB assembly with RFID can help your business, school, or project.

What is RFID and Why Should You Care?

RFID stands for Radio Frequency Identification. It’s a technology that uses radio waves to read and write information on small tags or chips. You see RFID everywhere, library books, store security tags, pet microchips, and even your school ID card. When you add RFID to a PCB, you get a device that can be tracked, managed, or even updated wirelessly.

Why does this matter to you?

- You can track products easily.

- You get better security for your devices.

- You save time and money on inventory and repairs.

How Does RFID Work?

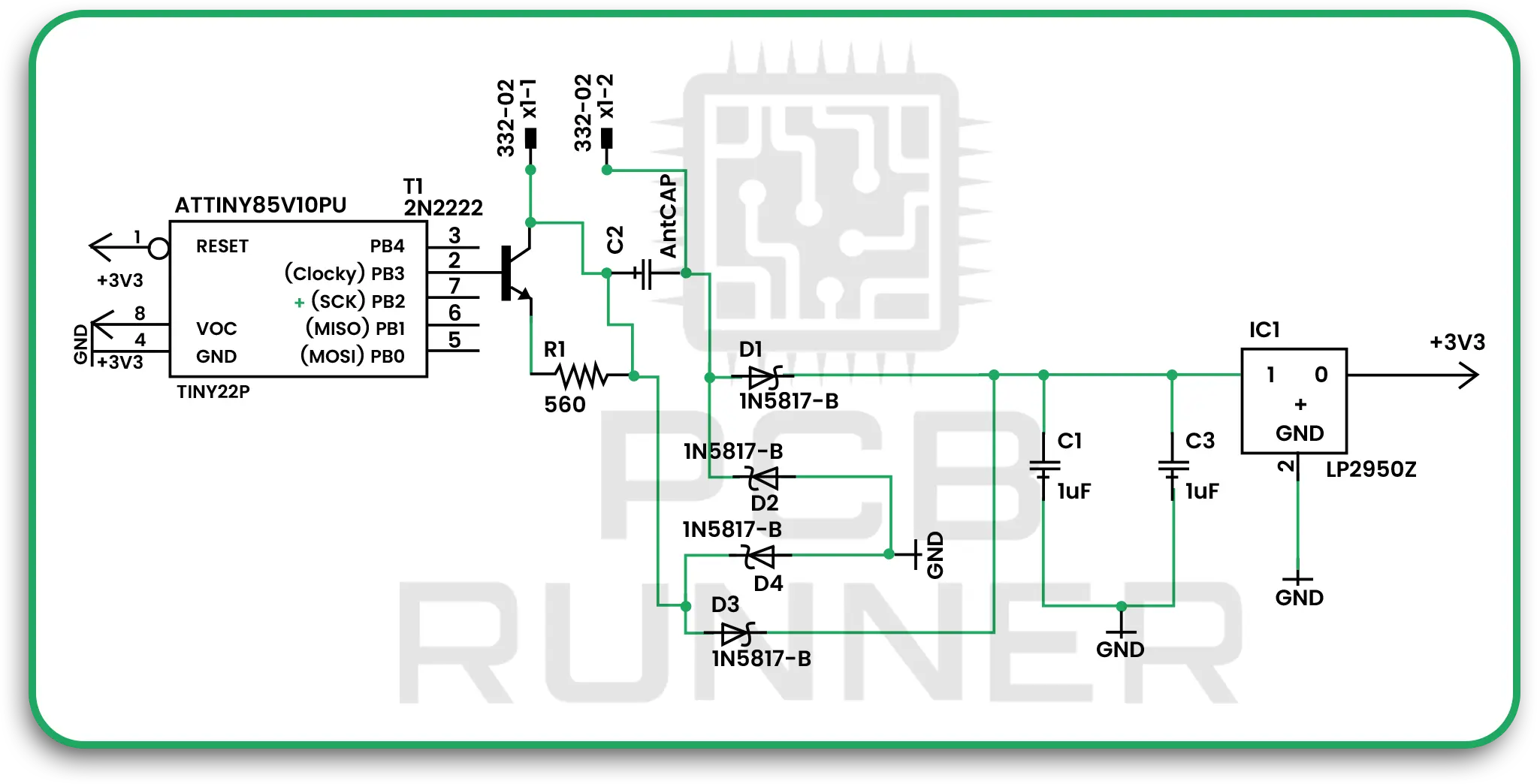

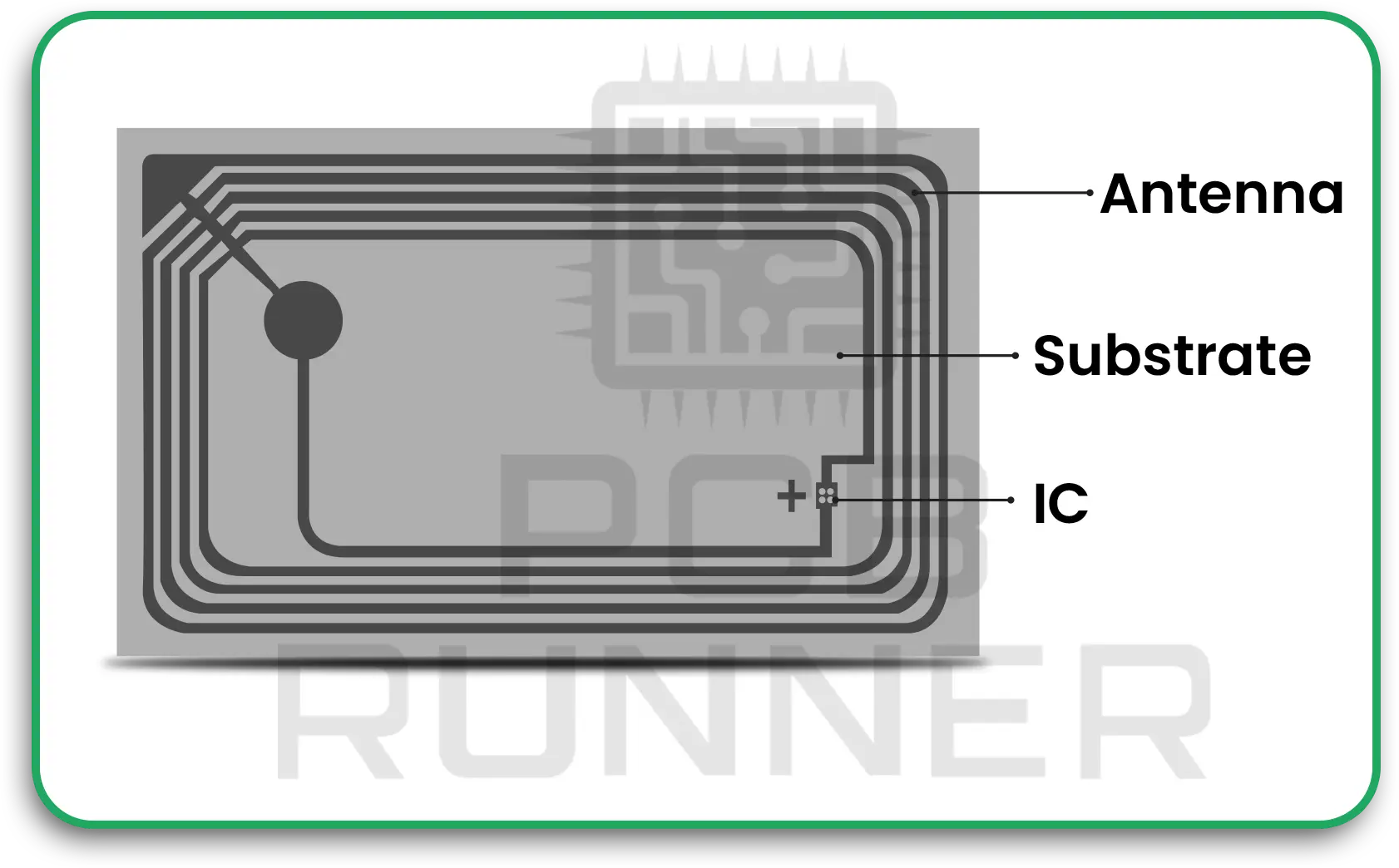

RFID has two main parts: a tag (which holds the chip) and a reader (which scans the tag). The tag contains an embedded RFID chip that stores information. The reader sends a signal, and the chip answers with its data.

Types of RFID Tags:

- Passive tags: No battery. They get power from the reader’s signal.

- Active tags: Have a battery. Used for longer distances.

When you put an embedded RFID chip into a PCB, you make the whole board “smart.” It can be tracked, locked, or unlocked with the right reader.

Why Embed RFID in a PCB?

You might wonder, “Why not just stick an RFID tag on the outside?” Here’s why having RFID embedded in PCB is better:

- Security: The chip is hidden and hard to tamper with.

- Space-saving: No bulky tags or stickers.

- Durability: Protected from bumps, heat, and water.

- Easy tracking: You can scan the board even when it’s inside a device.

Ways to Integrate RFID with Printed Circuit Boards

If you’re looking for PCB circuit board manufacturers or circuit board suppliers UK to help with RFID, here are the main ways they do it:

1. Surface Mounting

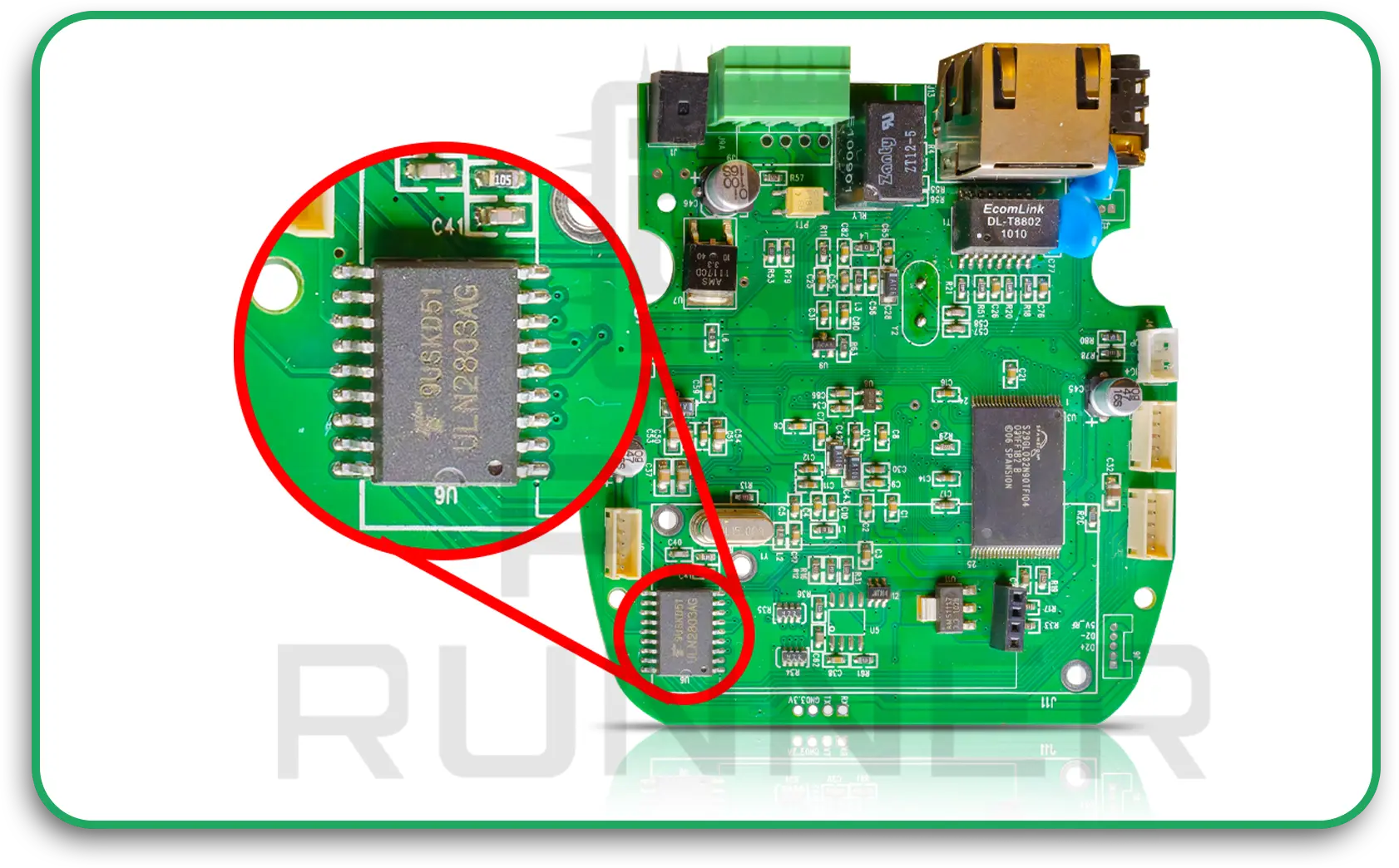

This is like putting any other chip on the board. The embedded RFID chip is soldered right onto the PCB surface. It’s fast and simple, but the chip is still visible and could get damaged if the board is handled roughly.

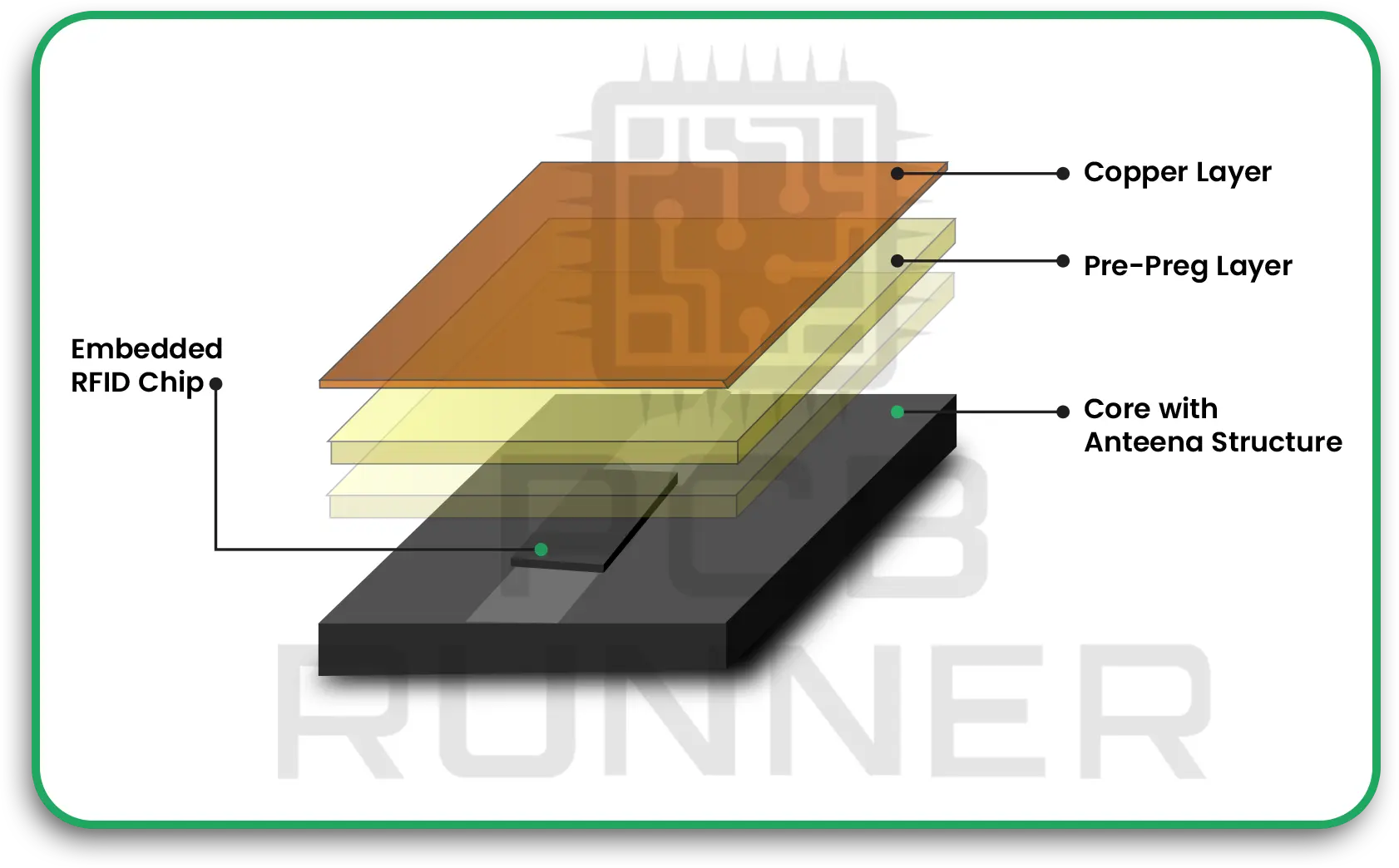

2. Embedding in PCB Layers

Here, the RFID chip or antenna is placed between the layers of the PCB during manufacturing. This keeps it safe and out of sight. It’s a popular choice for custom PCB assembly because it protects the chip and helps prevent tampering.

3. Antenna Etching

Some PCB circuit board manufacturers will etch the RFID antenna directly onto the board. This saves space and makes the board even thinner. The chip can be connected to this antenna, creating a complete RFID system inside the PCB.

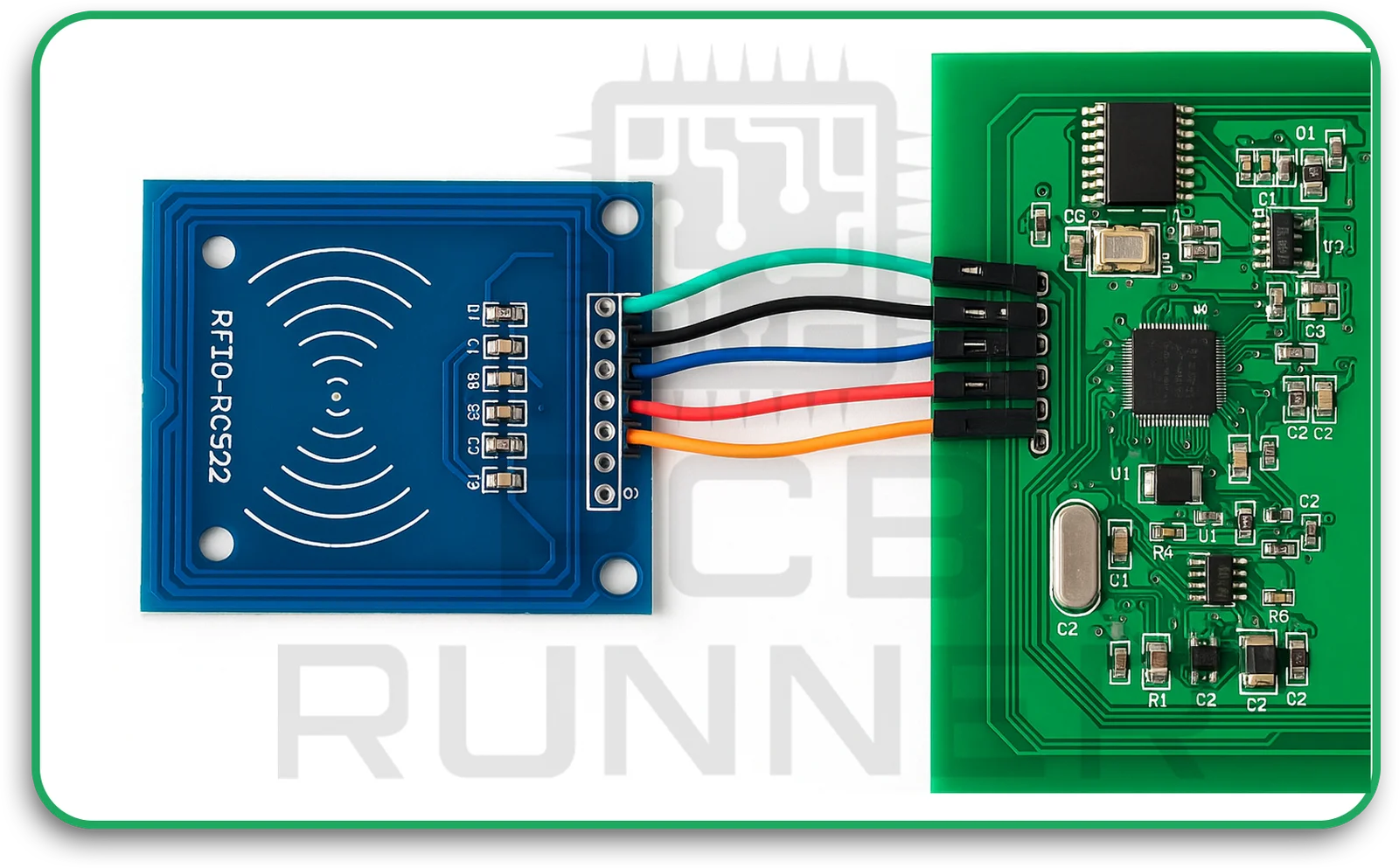

4. Using RFID Modules

For larger projects or prototypes, you might use a small RFID module that plugs into your board. This isn’t as sleek as embedding, but it’s excellent for testing and learning how Radio Frequency Identification in PCB works.

What Does This Mean for You?

If you’re a business owner, student, or hobbyist, RFID embedded in PCB can help you:

- Track parts and products in real-time

- Prevent theft or loss by locking devices until they’re scanned

- Speed up inventory and repairs

- Make your products smarter and more valuable

Real-Life Uses for RFID in PCBs

You might be surprised how many things use Radio Frequency Identification RFID tags in PCBs. Here are some examples:

- Retail: Stores use RFID to track electronics, shoes, and even clothing.

- Healthcare: Hospitals track medical tools and devices to prevent loss.

- Schools: Student ID cards and library books often have RFID chips.

- Factories: Machines and tools are tracked for safety and repairs.

- Access Control: Only people with the right RFID card can unlock doors or devices.

How to Get Started: What to Ask Your Supplier

When you talk to circuit board suppliers UK or PCB circuit board manufacturers about RFID, ask these questions:

- Can you embed RFID chips or antennas in my PCB?

- What size and type of RFID chip do you recommend?

- How will the RFID chip affect my board’s performance?

- Can you help with custom PCB assembly for my project?

- What testing do you do to make sure the RFID works?

Step-by-Step: Adding RFID to Your PCB

Here’s a simple guide if you want to know how the process works:

- Choose Your RFID Type: Decide if you need passive or active RFID and what frequency range is best for your use.

- Design Your PCB: Work with your supplier to plan where the chip and antenna will go.

- Manufacture the Board: The supplier will build the PCB with the RFID chip embedded or mounted.

- Test the Board: Make sure the RFID tag works with your reader.

- Assemble Your Device: Use custom PCB assembly to add other parts and finish your project.

- Deploy and Track: Use RFID readers to scan and manage your boards in the real world.

Tips for Success with RFID Embedded in PCB

- Plan Early: Talk to your supplier about RFID at the start of your project.

- Test Often: Check the RFID function at each step, design, manufacturing, and assembly.

- Think About Security: Use encrypted RFID chips if you’re worried about copying or hacking.

- Keep It Simple: Start with a basic design and add more features as you learn.

RFID Integration Methods for PCBs

| Method | Description | Best For | Pros | Cons |

| Surface Mounting | Chip soldered on PCB surface | Simple projects, prototypes | Fast, easy to repair | Chip is exposed |

| Embedded in Layers | Chip or antenna inside PCB layers | Secure, durable devices | Hidden, protected | More complex to make |

| Antenna Etching | Antenna pattern etched onto PCB | Thin, space-saving designs | Saves space, sleek look | Needs careful design |

| Plug-in Module | RFID module attached to PCB | Learning, testing, upgrades | Easy to swap or replace | Bulky, less secure |

Final Thoughts

Adding RFID embedded in PCB is a smart move if you want to make your products easier to track, safer, and more efficient. Whether you’re building smart gadgets, managing inventory, or keeping your business secure, RFID gives you a significant advantage. The right PCB circuit board manufacturers can help you choose the best method, design your board, and make sure everything works as it should.

If you’re ready to take your project to the next level, reach out to trusted circuit board suppliers UK who understand Radio Frequency Identification in PCB. They’ll help you with custom PCB assembly, answer your questions, and make sure your boards are ready for the future.

Take the next step, explore RFID with your next PCB project and see how much easier life can be!

Frequently Asked Questions (FAQs)

Q1: What’s the difference between RFID and a barcode?

Barcodes need to be seen by a scanner, while RFID can be read through plastic or even inside a device. RFID tags can also store more information and can be updated wirelessly.

Q2: Can RFID chips be added to any PCB?

Most modern PCBs can have RFID chips embedded, but it’s best to plan for this during the design phase. Some very small or complex boards might need special solutions.

Q3: Are RFID chips safe from hackers?

Many RFID chips use encryption to protect your data. For extra safety, talk to your supplier about secure chips and best practices.

Q4: How far away can an RFID tag be read?

Passive tags work up to a few feet away. Active tags, which have batteries, can be read from much farther. The exact distance depends on the chip and reader.

Q5: Who can help me add RFID to my project?

Look for experienced PCB circuit board manufacturers or circuit board suppliers UK who offer custom PCB assembly with RFID. They can guide you through every step.