Flexible printed circuit boards, also known as flex PCBs, are revolutionising the way we design electronics. They bend, twist, and fit into places where regular boards can’t go. But this flexibility also brings new challenges. Sometimes, you need certain parts of your flexible PCB board to stay firm. That’s where stiffeners come in.

Choosing the right stiffener for your flex PCB design can make all the difference. It can help your product last longer, withstand more stress, and perform better in challenging conditions. Let’s explore why stiffeners matter, how to pick the right one, and what you should know before you start your next project.

Why Flex PCBs Need Stiffeners

Think of a flex PCB like a piece of paper. It bends easily, which is great for fitting into tight spaces. However, if you attempt to attach a heavy sticker or connector to it, the paper will sag or tear. The same thing can happen to a flexible printed circuit board. That’s why flex PCB suppliers and designers use stiffeners; they give support where it’s needed most.

Key Benefits of Stiffeners

- Reduce bending stress: Stiffeners prevent the board from bending excessively in specific areas.

- Support heavy parts: They create a solid base for connectors, chips, and other components.

- Help with assembly: Stiff areas make it easier for machines to pick and place parts during flex PCB assembly.

- Protect solder joints: Less flex means less chance of cracked or broken connections.

- Improve heat handling: Metal stiffeners can help move heat away from hot spots.

Where Are Stiffeners Used in Flexible Printed Circuit Boards (Flex PCBs)?

Not every part of a flexible PCB board needs to be stiff. Stiffeners are usually added to:

- Connector areas: Where cables or plugs attach.

- Component zones: Under heavy or sensitive chips.

- Mounting points: Where screws or bolts hold the board in place.

- ZIF connectors: To meet the thickness requirements for special connectors.

Adding stiffeners only where needed keeps your board light and flexible everywhere else.

Types of Stiffener Materials

Different jobs call for different materials. Here are the most common stiffener types used by circuit board suppliers uk and rigid flex pcb manufacturer teams:

| Stiffener Type | Main Features | Typical Uses |

| Polyimide (PI) | Light, flexible, heat-resistant | Moderate support, easy bending |

| FR4 | Rigid, same as standard PCB material | Strong support, component mounting |

| Aluminum | Very rigid, great for heat dissipation | High-power, heat-prone areas |

| Stainless Steel | Strong, resists bending and heat | High-strength, harsh environments |

| Plastic | Lightweight, not as strong as others | Low-stress, cost-sensitive areas |

Polyimide stiffeners are ideal when you need support but still require flexibility. FR4 stiffeners are commonly used to create a flat, solid area for parts and connectors. Aluminium and stainless steel are best suited when you need to transfer heat or handle large forces.

How Thick Should Your Stiffener Be?

Stiffener thickness depends on the job. Here’s a quick guide:

- 0.2mm to 0.5mm: For light support or small connectors.

- 0.8mm to 1.6mm: For heavier parts or where more strength is needed.

- 2.0mm or more: For very demanding jobs, like large connectors or mounting points.

Always match the stiffener thickness to your board’s needs. Too thin, and it won’t help. Too thick, and you may lose flexibility or make assembly more difficult.

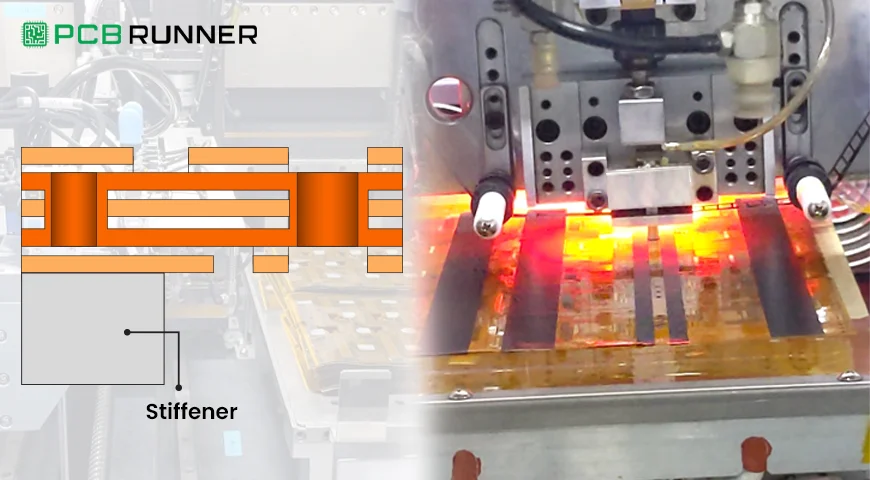

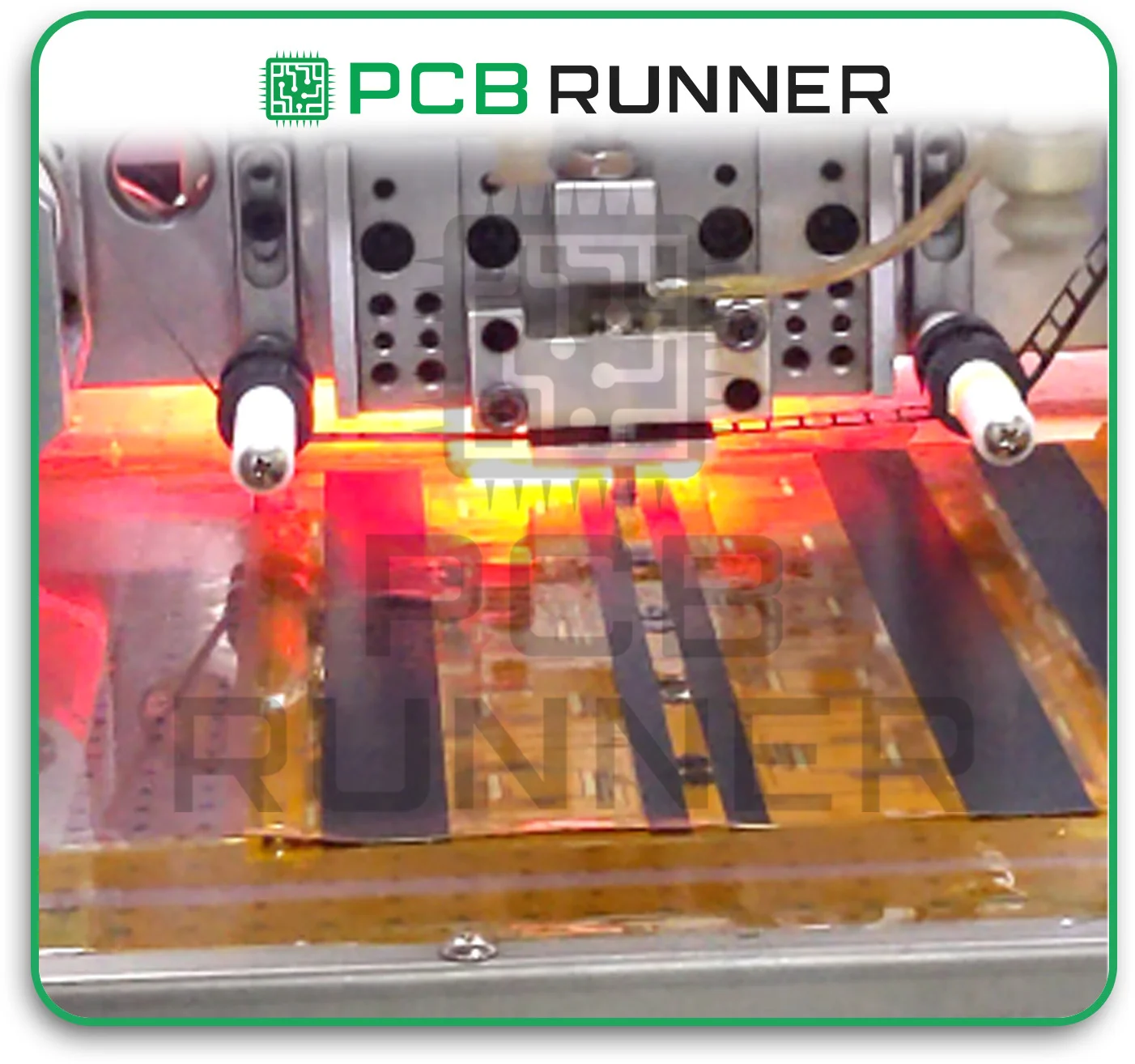

How Stiffeners Are Attached

There are a few ways to add stiffeners to a flexible printed circuit board:

- Adhesive bonding: Glue holds the stiffener in place.

- Lamination: The stiffener is pressed and heated onto the board.

- Mechanical fastening: Screws or clips hold the stiffener (less common).

Most flex PCB suppliers use adhesive or lamination because it’s fast and reliable.

Design Tips for Using Stiffeners

When planning your flex PCB design, keep these tips in mind:

- Overlap coverlay: Ensure the stiffener overlaps the coverlay (the flexible solder mask) by approximately 0.75 mm. This spreads out stress and keeps the board firm.

- Maintain even thickness: If you use more than one stiffener, try to maintain a uniform thickness.

- Place stiffeners on the same side as the parts: This makes assembly easier and facilitates soldering.

- Consider heat: Use metal stiffeners if your board becomes too hot.

- Double up for extra strength: For boards that face bending in both directions, add stiffeners to both sides.

Real-World Example: Wearable Tech

Imagine you’re designing a fitness tracker. The board needs to wrap around a wrist, but it also needs a solid spot for the charging port and battery. By adding an FR4 stiffener under the connector, you ensure it stays in place, even after hundreds of charges. The rest of the board remains thin and bendy, making it comfortable to wear.

Common Mistakes to Avoid

- Adding stiffeners everywhere: This makes your board heavy and stiff, losing the benefits of a flexible PCB board.

- Using the wrong material: Avoid using plastic where heat resistance or strength is required.

- Ignoring thickness: Using materials that are too thick or too thin can cause problems during assembly or use.

- Not talking to your supplier: Always check with your flex PCB suppliers or circuit board suppliers UK before finalising your design.

Product Highlights: What Makes a Good Stiffener Choice?

A good stiffener:

- Matches the needs of your design (strength, heat, flexibility)

- It is placed only where needed.

- Uses the right thickness for the job

- Is attached securely and evenly

Rigid-flex PCB manufacturers often assist in selecting the optimal stiffener for your project. Don’t be afraid to ask for advice.

Tips for Different Types of Flex PCB Assembly

For lightweight wearables:

- Use polyimide stiffeners for gentle support that won’t add bulk.

For industrial or automotive boards:

- Pick FR4 or metal stiffeners to handle vibration, heat, and heavy use.

For medical devices:

- Select materials that are safe and reliable, and ensure that stiffeners are only used where necessary to maintain comfort and stability.

Final Thoughts

Stiffeners might seem like a small detail, but they can make or break your flexible printed circuit board. The right stiffener keeps your board strong where it matters and flexible everywhere else. It helps your product last longer, work better, and handle the real world.

So, next time you start a flex PCB design, remember to think about stiffeners. Contact your flex PCB suppliers or circuit board suppliers in the UK as early in the process as possible. Test different options if you can. And always match your stiffener choice to your project’s needs.

A smart stiffener strategy is the key to maximising the benefits of your flex PCB assembly, no matter what you’re building.