Military active PCBs (printed circuit boards) need to pass grueling tests to endure the straining conditions of a theater of war and work effortlessly. The high working temperature, vibrations, and even moist conditions are some of the hurdles these specialized circuit boards need to overcome.

This blog will discuss the strategies employed by leading PCB manufacturers to fabricate military-grade circuit boards with exceptional strength and toughness.

What Makes a Military Circuit Board Different?

As opposed to standard PCBs, military circuit boards need to operate flawlessly even in extreme conditions like rapid/ sudden changes in temperature, exposure to certain chemicals, and high-amplitude vibrations. To cater to these unusual demands, military PCBs are designed following strenuous requirements like IPC Class 3 and MIL-PRF-31032.

The focus lies on selecting materials, design techniques, and manufacturing processes that offer the best reliability. Also, circular shape requirements have broadened the applicability of circuit boards in the military field.

Key Materials for Military PCBs

For a military-grade PCB, high-performance materials that can resist overpowering heat, chemicals, and even mechanical strain are essential to support. Some common materials are:

High-Tg Laminates: Isola FR408HR and DuPont Pyralux are specified materials that resist temperatures over 200 degrees Celsius.

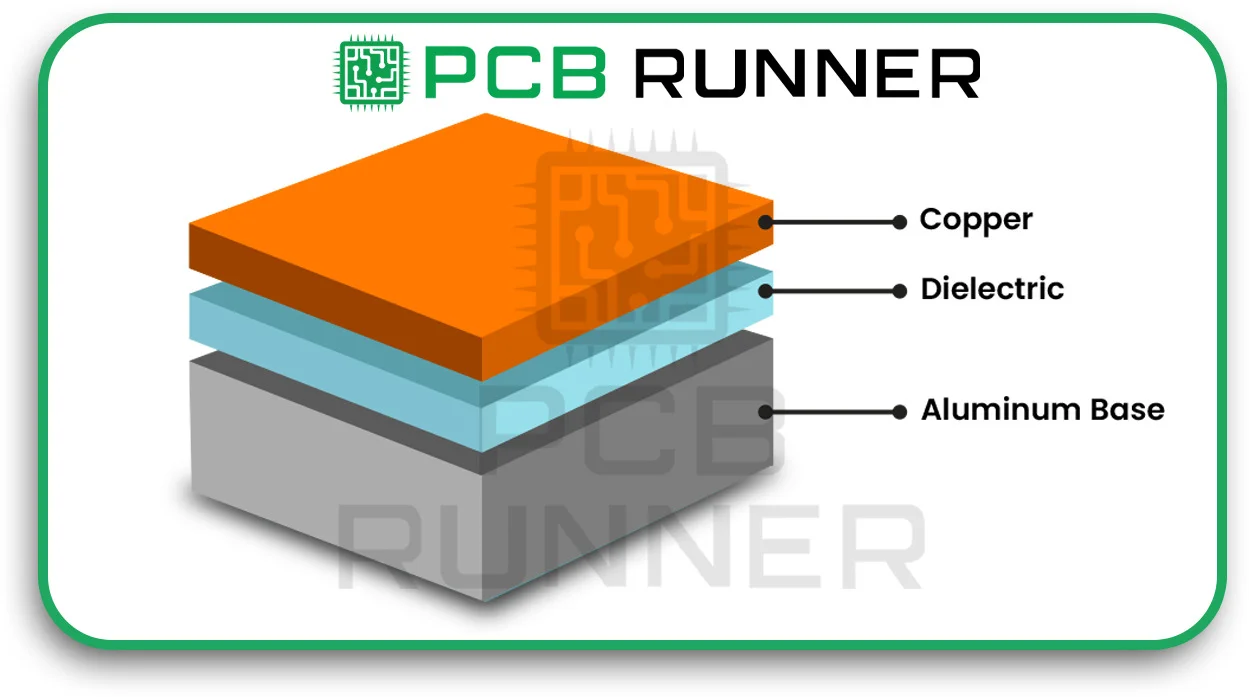

Metal Core Substrates: Aluminum and copper cores aid in the rapid dissipation of heat.

High-Frequency Materials: High-frequency signals are well handled by materials such as the Rogers 4000 series.

Expert Insights

One of the strictest standards for these boards is MIL-PRF-31032, which covers everything global boards fail to defocus on. Everything from the design of the PCB, the material chosen, and even the method of manufacturing is set in stone. But it doesn’t stop there- military standards define the set components that leave very little breathing space.

Moreover, there are regulations outlined that govern entirely the assembly of the boards. Quality control guidelines are also elaborated to check that the set high-performance thresholds are met.

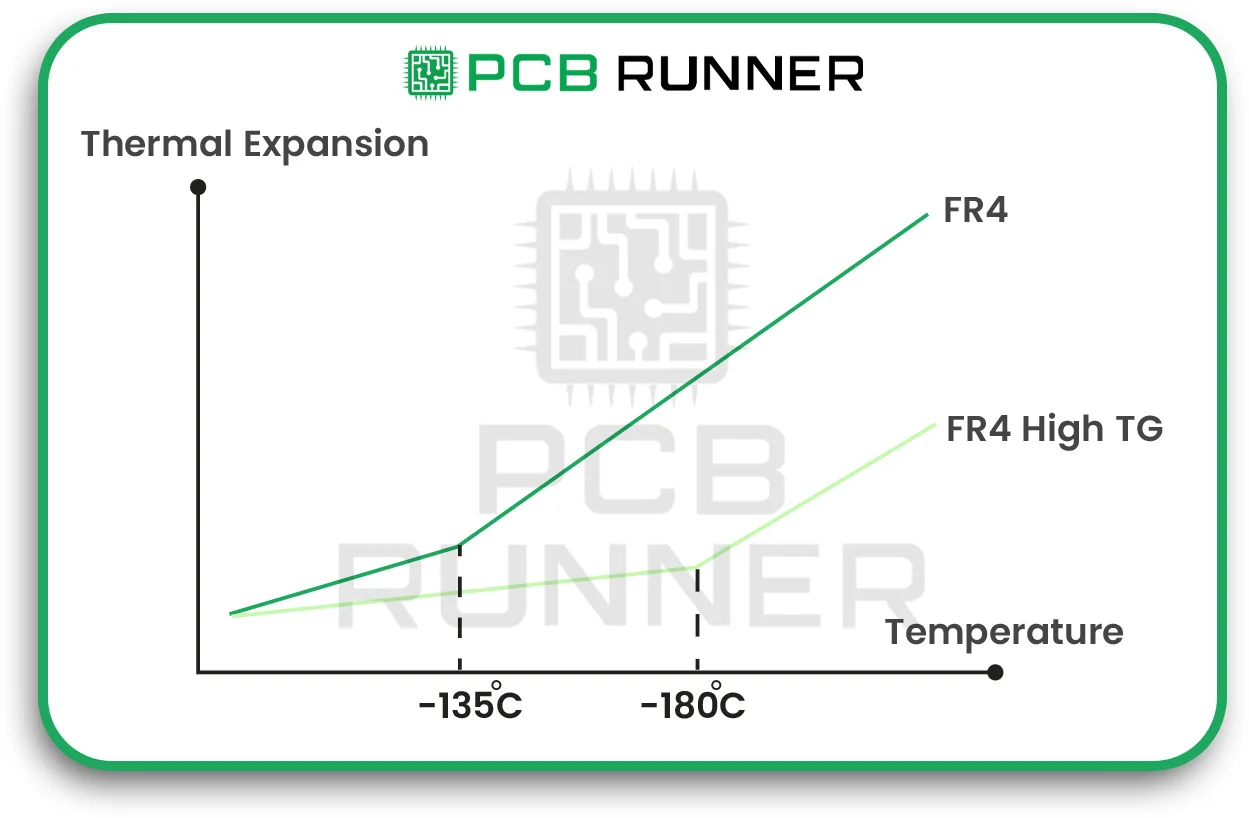

Thermal Properties: The Importance of Tg

The glass transition temperature (Tg) is crucial for military PCBs. It represents the temperature beyond which the material softens, losing its rigid structure. For military applications, designers recommend materials with a Tg of at least 170°C to 200°C or higher.

| Material Type | Tg Range |

| Low Tg | 130°C – 160°C |

| Medium Tg | 160°C – 200°C |

| High Tg | 200°C + |

Top Design Rules for Military PCBs

Here are essential design considerations when creating a military circuit board:

1 Surface Mount and Land Considerations

- Defects on the sides of rectangular lands should not exceed 20%.

- Lands for circular mounts (BGAs, for example) should strive to have minimal defects, ideally below 10 percent of the circumference.

2. Porous Plating Method Hole Specifications

- For the required thickness, copper plating should be a minimum of 80% of the thickness.

- Voids in the plating should not be more significant than 5% of the PCB thickness.

3. Via Copper Plating

- For filled vias, there should be no voids or bumps that can give access to internal layers.

- Moisture damage will be prevented with proper copper plating of vias.

Additional Tips for Designing Durable Military PCBs

Use heat compounds and heat-resistant enclosures to control excessive heat.

- Component Isolation: High, more sensitive components should be placed away from low-frequency parts to minimize interference.

- Simulations before Layout: Simulations should be done to measure performance in real-life situations.

Clock signals should be covered with aluminum shields to limit interference.

The use of chemical resistant and anti-moisture conformal coatings can be used to shield the components.

The Role of Circular Circuit Boards in Military Applications

Due to their compact, efficient features, circular circuit boards are becoming increasingly prevalent in military applications. These boards have a lot of advantages, such as:

- Space Efficiency: These are essential to installations that need compact electronic integration.

- Concise Signal Traces: The radius of the board reduces trace lengths, thus enhancing performance.

- Mechanical Strength: Because of their unique shape, mechanical stress is evenly distributed, giving them strength.

Choosing the Right PCB Manufacturer for Military Circuit Boards

To ensure compliance with military specifications, select ITAR-registered PCB manufacturers.

- A reliable PCB partner should:

- Abide by the IPC and MIL standards.

- Have the necessary equipment to manufacture multi-layer and circular circuit boards.

- Conduct adequate tests and quality control measures.

Here at PCB Runners, we focus on military-grade PCB manufacturing, emphasizing quality, durability, and precision to satisfy the toughest requirements.

Conclusion

Achieving a military-grade PCB means stricter policies on materials used, layout design, and standards set. And with any circuit board, be it traditional or circular, strength and dependability come first. No question, working with a reputable PCB manufacturer guarantees that your military circuit boards will work in the most demanding situations.

If you need a PCB manufacturer who is sensitive to the intricacies of military applications, PCB Runners is your perfect solution.

Reach out today to find out more about our services for custom military circuit board construction.

FAQs

What are military circuit boards?

Military circuit boards are specially designed PCBs that can sustain extreme conditions, such as high temperatures and powerful mechanical forces.

What materials are used for military PCBs?

Commonly used materials include high-Tg laminates, metal core substrates, and high-frequency Rogers 4000 series.

Why are circular circuit boards used in military applications?

Circular circuit boards can save space, enhance the efficiency of signal paths, and improve the distribution of mechanical stress.

How do I select a suitable PCB manufacturer?

You should seek out ITAR-registered manufacturers that specialize in military-grade PCBs and have a strong compliance record with IPC standards.

Which standards are military PCBs subjected to?

These include, among others, the seminal MIL-PRF-31032 and IPC Class 3, which guarantees quality and reliability in the design and construction of the PCB for military purposes.