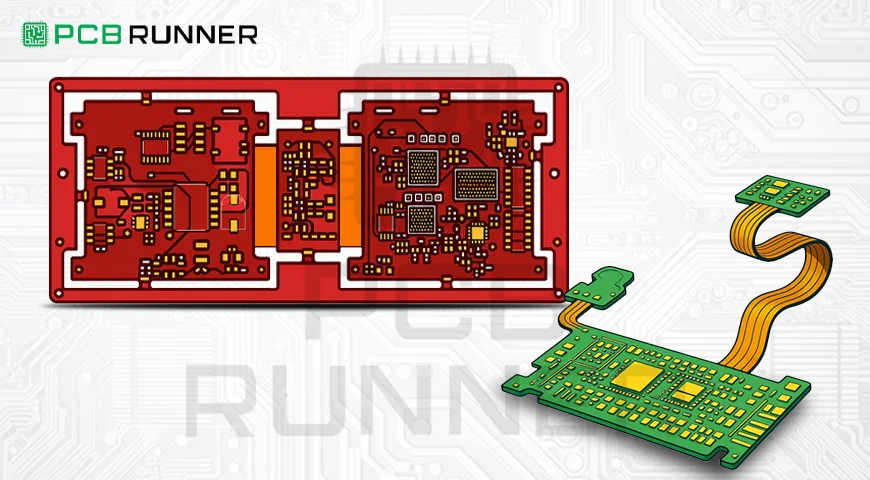

To keep up with the demand for modern electronics, industries are pivoting towards Rigid-Flex PCBs, which are a step in the future. These multilayered versatile circuit boards are an advanced version of traditional circuit boards. They combine the best features of rigid PCBs and flexible circuits, making them appropriate for applications with intricate shapes, lower weight, and superior strength.

Achieving a successful assembly of Rigid-Flex PCB requires an understanding of the key material features, some sophisticated engineering processes, and creative assembly techniques.

A Walkthrough of Rigid-Flex PCBs

Rigid-flex PCBs consist of integrated rigid and flexible regions on the same board structure. Their main advantage over conventional PCBs is that they allow reduced connector counts, better signal integrity, and more excellent design maneuverability. This makes them extremely useful for aerospace, medical, wearable devices, and other consumer electronics.

Categories of Rigid-Flex PCBs

Rigid-flex PCBs can be categorized based on their structure:

- Single-Sided Rigid-Flex PCBs: Flexible layer copper traces are only present on one side.

- Double-Sided Rigid-Flex PCBs: Copper traces are added to both sides of the flexible layer.

- Multi-Layer Rigid-Flex PCBs: Composed of insulating layers with multiple conductive materials added to increase intricateness and greater routing density.

Material Selection for Rigid-Flex PCBs

Selecting appropriate materials for a rigid-flex PCB fabrication process affects the intended performance and reliability. These materials include the cover layer, adhesive, copper foil, and the substrate.

Recommended Materials

- Polyimide Films: These materials are best for use as they have superior thermal stability, dielectric properties, and flexural strength.

- Foils: Flexible copper foils of low thickness provide good electrical conductivity and reasonable mechanical flexibility.

- Adhesive: Polyester and polyimide adhesives are frequently utilized as a solution to dimensional variability.

- The selection of appropriate materials can improve robust mechanical properties and enhance dimensional stability and performance during the assembly process.

Key Production Processes

The fabrication of rigid-flex PBMs is one of the most challenging processes in PCB assembly. Its primary goal is to obtain high-quality results through precision and careful control.

Cleaning and Surface Preparation

Patterning with high precision in flexible PCBs requires high-skill surface preparation due to the difficulties involved in cleaning flexible PCB materials. Since flexible PCB materials are soft and thin, a mechanical approach will not provide adequate surface value.

Preferred Techniques

- Electrolytic Cleaning: The melting electrolytic alloy delivers good roughness value while providing sufficient cleanliness to the surface.

- Micro-Etching: Fine spacing between copper traces with tight tolerance can be achieved by micro-etching.

Layer Alignment

Many materials, such as polyimide, show increased moisture absorption, which can lead to PCB dimensional instability. Flexible, placed multi-layer PCB components require higher precision in flexible layer alignment.

Alignment Techniques

- Alignment Holes: These lower the chances of layers being placed incorrectly.

- X-Ray Drilling: X-ray drilling enables improvements for the drilling offsets, and fixing them determines where the added holes should be placed.

Multiflex Plating

Multiflex plating techniques reinforce critical areas in a rigid-flex PCB. In addition to improving mechanical strength, these techniques also improve electrical conductivity, making it easier for the PCB to bend and endure dynamic loads.

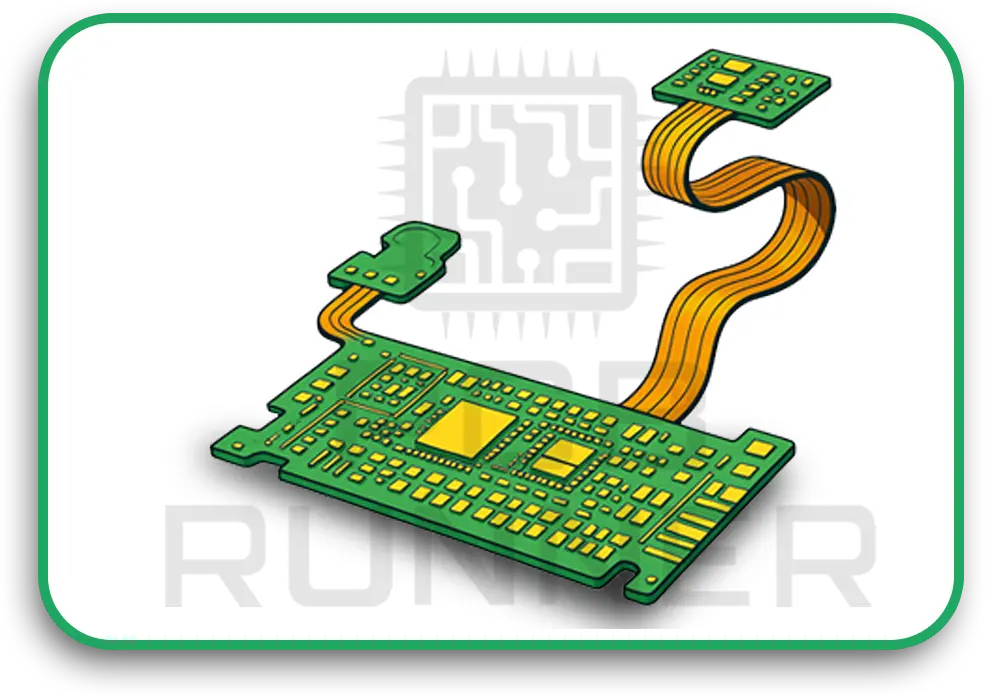

Assembly of Rigid-Flex PCBs

The assembly of rigid-flex PCBs is more difficult than assembling rigid boards because they are lightweight and very thin.

Fixtures and Carriers

During surface mount technology procedures, assemblers use specialized fixtures and carriers to hold the flexible parts of the board.

Common Fixtures

- Board Trays: Used to keep the board in shape and its position.

- Baking Fixtures: Reduce the absorption of moisture before assembling the boards.

- Electrical Test Fixtures: Different tests are performed, which include a credibility check.

Adjustments in the SMT process

- Low-Temperature Soldering: Flexible components are not thermally damaged by soldering.

- Component Placement: Careful handling reduces assembly deformation.

Panelization

The rigid-flex PCBs are usually panelised to facilitate assembly. After assembly, the separate boards are punched out one by one from the assembly panel.

Ensuring Product Quality

Because a rigid-flex PCB has challenging tasks, the product quality must always be high.

Key Quality Control Measures

- Soldering Reliability: Achieves a mechanical bond that remains intact.

- Anti-Static Precautions: To avoid interfering with electronics sensitive to static.

RoHS and Lead-Free Compliance

For the environment, RoHS and lead-free regulations are more stringent than for any other industry. In that regard, the rigid-flex PCB manufacturing process has to be updated to work with high soldering temperatures. This means that process and material selection must be made with great care.

Cost Considerations

Unlike standard rigid boards, a rigid-flex PCB’s assembly process is more costly, which means the entire assembly procedure is more complex, requires fixtures, and takes longer to complete. But thanks to process and technology advancements, the cost is slowly but surely lessening.

Factors Affecting Cost

- Fixures and accessories: A baseline for custom fixtures.

- Manufacturing Periods: Benchmark timelines for precision processes.

- Staffing Requirements: Skilled assembly labour.

Expert Insights on the Future of Flexible and Rigid-Flex PCBs

Flexible PCBs can be twisted and bent, which allows for the fabrication of small and light devices. Meanwhile, rigid-flex PCBs offer controlled flexibility while retaining the structural strength of rigid boards, providing robustness for designs intended for the automotive, medical, aerospace, and even consumer electronics industries. Rich functionality and durability have allowed the invention of modern designs, which are smarter and more compact than ever.

Their versatility and potential are illustrated by the increasing adoption of flexible and rigid-flex PCBs in wearables, electric vehicles, and IoT devices. For instance, in automotive systems, these PCBs allow manufacturers to fulfill the requirements of advanced driver assistance and in-vehicle connectivity due to their compact size. In medical devices, flexible PCBs enable the creation of highly conformable wearable health monitors.

Ongoing automation and materials innovation will enable manufacturers to overcome challenges such as increased costs and complicated processes. The ability of these PCBs to increase efficiency and functionality will determine the future of electronics design, from smart devices to aerospace technologies.

Conclusion

Rigid-flex PCBs are essential for many applications due to their increasing requirements in engineering sophisticated electronic devices. Meticulously implemented multiflex plating, precise layer alignment, and advanced assembly techniques allow manufacturers to produce high-quality, defect-free PCBs. Although there are higher upfront costs, the long-term savings achieved from their performance, durability, and design flexibility make rigid-flex PCBs cost-effective.

Contracting professionals in PCB assembly maximize the efficiency and accuracy of your project by implementing the newest techniques. For an effective and smooth rigid-flex PCB assembly service, work with a reputable PCB manufacturer like PCB Runners who has considerable experience in this area.