If you’re building a new piece of hardware, you can’t skip the prototyping stage. A prototype helps you test your idea and see if it works in the real world. It’s a small, working version of your product. For electronics, this means using a PCB board prototype. Prototyping helps you find problems early, save money, and build confidence in your design before full production.

This blog will serve as a guide for new hardware ventures prototyping.

What is a PCB Prototype?

A PCB board prototype is a sample of a printed circuit board (PCB) created to test your circuit design. You use it to check if your idea works before making large quantities. It’s like baking a small batch of cookies to see if the recipe is good. A PCB prototype board helps you avoid costly mistakes. It shows you what needs fixing before your idea hits the market.

Step 1: Choosing the Right PCB Manufacturer

Before making a prototype, you need a PCB manufacturer who can work with you on small, quick batches. Not all PCB circuit board manufacturers are the same. Look for one like PCB Runner, which offers fast turnaround and supports both prototypes and large-scale production. PCB Runner has been serving the UK and European industries for over a decade, handling critical electronics for sectors like aerospace and medical.

What to Look For:

- Ability to handle fast PCB prototyping

- Experience with prototype PCB assembly

- Quality certifications like ISO9001

- Support for design file checks and one-on-one customer service

Step 2: Designing Your Prototype

Designing your prototype means creating a layout for your circuit. You’ll use special software for this. Most hobbyists and engineers use tools like Kicad, Eagle, or Altium.

Tips for Good Design:

- Keep your layout simple for the first version

- Use components that are easy to find and solder

- Label all your parts clearly on the board

Your goal here isn’t perfection. It’s to get a working version that shows your idea in action.

Step 3: Submitting Your Files

Once your design is ready, send your Gerber files to your chosen PCB manufacturer. Gerber files are like blueprints for your board. They tell the manufacturer where to place copper, holes, and other layers.

What You Should Send:

- Gerber files

- Bill of Materials (BOM)

- Pick and place file for prototype PCB assembly

Good manufacturers like PCB Runner offer engineering review for free. They’ll check your files to make sure everything is correct before starting production.

Step 4: Fast PCB Prototyping

Time matters in hardware. If your project has a deadline or you’re trying to beat competitors to market, you need fast PCB prototyping. PCB Runner offers quick-turn manufacturing, meaning your boards are ready in just a few days.

Benefits of Fast Prototyping:

- Quick testing and feedback

- Faster updates to the next version

- Less time wasted waiting on parts

Step 5: Assembly and Testing

After your boards are fabricated, the next step is prototype PCB assembly. This means placing the electronic components on the board. You can do this yourself or have your manufacturer assemble it for you.

Choose Professional Assembly If:

- Your board has small or complex components

- You want to save time

- You need multiple units tested

Once assembled, test your board thoroughly. Check every function and log any issues.

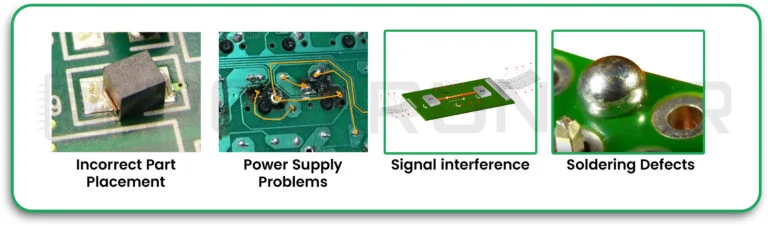

Common Issues During Prototyping

Even if you follow all the steps, you might run into problems. That’s okay. It’s part of the process.

Issues You Might See:

- Incorrect part placement

- Power supply problems

- Signal interference

- Soldering defects

Take notes and update your design before ordering your next version. PCB Runner helps here too, offering support from real people with experience.

Iteration: Making Your Next Version

The prototype is rarely the final version. You’ll likely need two or three rounds of prototyping. This helps improve performance, reduce size, or cut costs. With each version, your design gets stronger and more ready for the market.

How to Speed Up Iteration:

- Keep a checklist of problems

- Use only what you need on the board

- Partner with reliable PCB circuit board manufacturers like PCB Runner

Real-World Example

Let’s say you’re building a smart temperature sensor. Your prototype might be large and use basic parts. After testing, you find that the sensor is slow to respond. In the next version, you choose a better chip and shorten the signal path. Now it works faster and uses less power. That’s the power of prototyping.

Why Choose PCB Runner for Prototypes?

PCB Runner is trusted by startups, hobbyists, and engineers across the UK and Europe. They specialise in both PCB board prototype and full production.

What They Offer:

- Quick-turn prototyping

- Support for fast PCB prototyping

- One-stop service from fabrication to assembly

- Free file review before production

- Reliable customer support, 24/7

With their in-house manufacturing and ISO certification, you know your boards are made to high standards.

Final Tips Before You Start

- Don’t overthink your first version: Start simple and focus on making it work. Your first version doesn’t need to be perfect. The goal is to have a working prototype that you can improve later. Keep it basic and functional.

- Test your board in real conditions: Make sure to test your PCB in the actual environment where it will be used. This helps you identify any issues related to temperature, humidity, or electrical interference early on. Real-world testing can save you from unexpected problems after production.

- Work with a full-service provider: Save time and hassle by partnering with a reliable provider like PCB Runner. They can handle everything from design to manufacturing, helping you avoid common pitfalls and ensuring a smoother process.

- Don’t hesitate to ask for help: If you’re unsure about something, reach out for assistance. A reputable PCB manufacturer will offer guidance and support throughout the process, whether it’s about design specifications, material choices, or quality testing.

Conclusion

Prototyping is a must for anyone working on new electronics. It helps you test your idea, fix problems, and get to market faster. Whether you’re a beginner or an experienced builder, starting with a solid PCB board prototype is key. With expert help from PCB circuit board manufacturers like PCB Runner, you can go from idea to product with confidence. From PCB prototype board to prototype PCB assembly, they’ll help you every step of the way. Don’t wait, start your hardware journey today.

Need a fast quote or want to upload your files? PCB Runner is ready to help 24/7.