High-density interconnect (HDI) PCBs have transformed the electronics world by making it possible to design smaller and more powerful devices. They are widely utilised in telecommunications, aerospace, automotive, and consumer electronics.

These advanced PCBs’ ultra-high functionality and dependability are achieved through the use of high-performance materials and innovative solder mask materials. In this blog, we will focus on essential materials employed in the manufacturing of HDI.

The Role of Advanced Materials in HDI PCBs

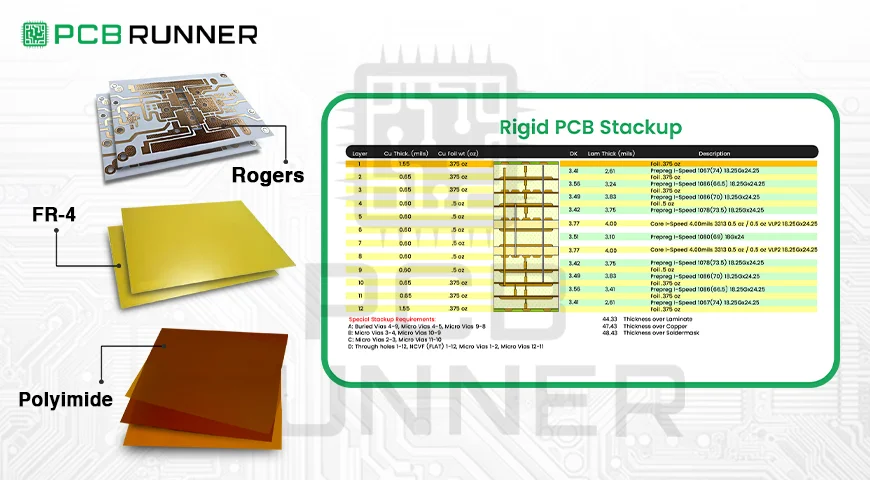

Substrate Materials: Beyond Traditional FR4

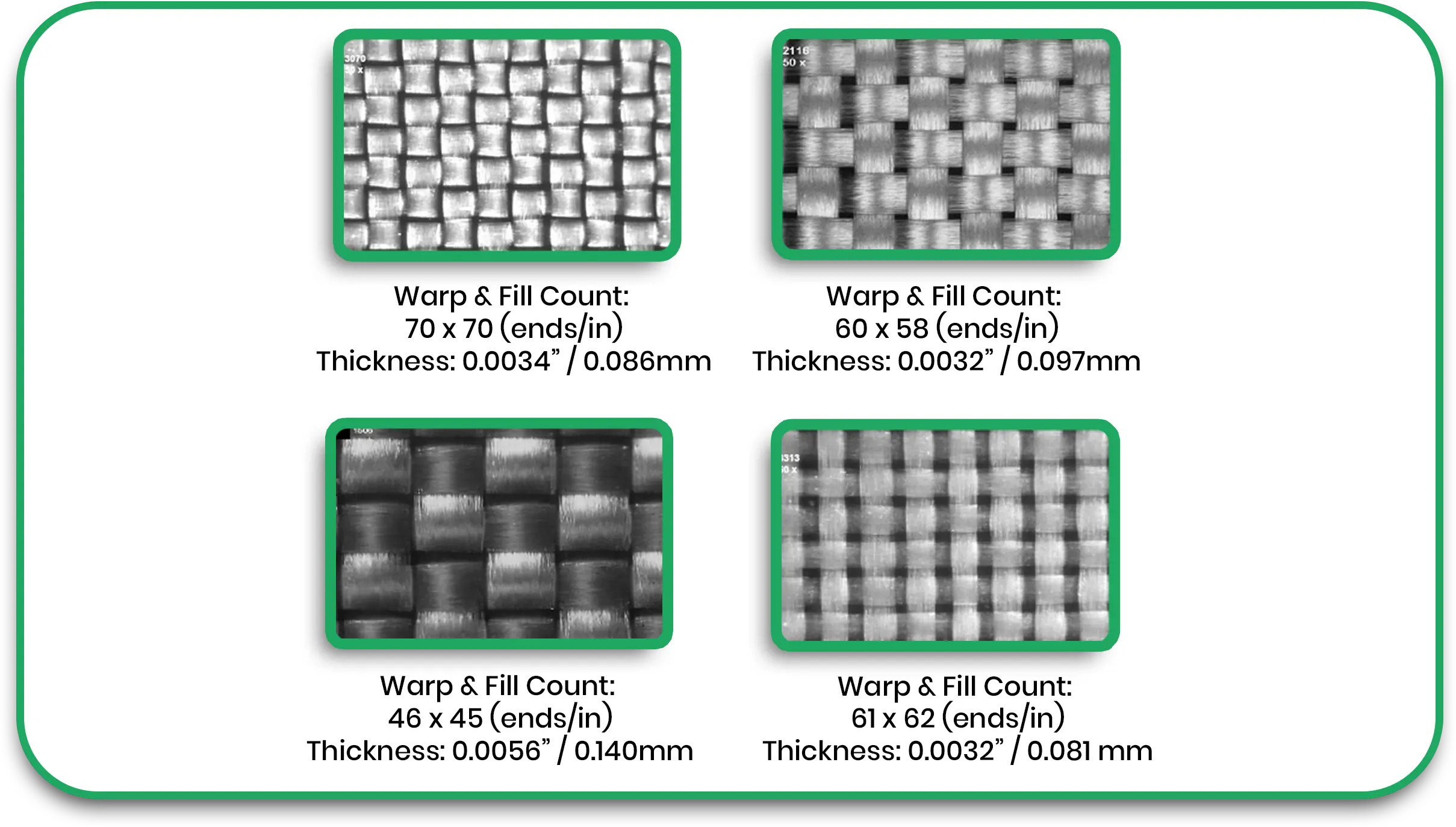

Flame-retardant epoxy laminate FR4 was and still is the preferred base material for the majority of PCBs. However, due to the miniaturisation of devices and their increasing performance, FR4 has been found inadequate in various thermal and electrical specifications. Thus, the shift is taking place towards the usage of polyimide, PTFE (polytetrafluoroethylene), and ceramic-based substrate materials.

- Thermal Stability: Ideal for use in extreme conditions, such as the automotive and aerospace sectors, Polyimide and ceramic-based substrates are able to operate under extreme environments.

- Electrical Performance: PTFE is a low-loss dielectric material with a low dielectric constant and dissipation factor, easily incorporated into 5G and superfast communication systems.

- Miniaturisation: The ability to achieve intricate structures is possible due to advanced ceramic substrates with excellent mechanical strength and low thermal expansion, which can provide punctual and reliable performance.

These innovations make the next generation of electronic gadgets smaller, quicker, and more efficient than ever before.

Expert Insight: Advanced Materials for the Growing Needs of a PCB

Modern electronics are far too advanced to handle using older, outdated materials. This is specifically highlighted in the ResearchGate paper “Advanced Materials in PCB Manufacturing,” which includes this excerpt:

“Along with FR4, there were many materials above it that catered to a large number of applications but slowly, over the years, became irrelevant as devices started to shrink in size and outperformed the older models. The industry has now moved on to polyimide, PTFE, and ceramic-based substrates, which allow unparalleled thermal stability and durability while having blunt electrical components.”

Such developments are critical for industries that depend on compact size, high frequency, and high-speed communication as well as accuracy and reliability.

Conductive Materials: Reliable For Signal Transmission

At the moment, copper is the only material used in high-density interconnect PCBs since it is the most reliable and conductive. In dense layouts where more intricate designs are required, the copper on the micro vias and fine lines serve the purpose well.

Solder Mask Materials: Performance Protection and Improvement Enhancements

In HDI PCBs, the solder mask is one of the important layers to prevent damage from the environment, solder bridging, or contamination, as well as protect the device. The development of solder mask materials for high-density designs is crucial because they can maintain a high level of resolution and thermal stability.

Key Properties of Advanced Solder Masks:

- Precision: Finer lines and spaces are critical.

- Resistance: Endures degradation over several cycles of soldering.

- Low Dielectric Values: Elevate the signal preservation in high-frequency uses.

The advancement of new solder mask materials with better thermal and electrical qualities is crucial.

Final Thought

The choice of advanced substrates, solder masks, and any additional components is essential for the high-density interconnect PCBs. Improved thermal control, enhanced electrical performance, and increased support for the miniaturisation of electronic components.

At PCB Runners, we take pride in using the newest materials and advanced manufacturing methods to create the highest-quality high-density interconnect (HDI) PCBs that exactly meet your needs. From advanced substrates to high-performance solder masks to other comprehensive PCB needs, we are ready to assist.

Reach out to us today to discover more about HDI PCBs and how we could assist your next venture.

FAQs

Q1: What are HDI PCBs?

A1: HDI Printed Circuit Boards (PCBs) have high wiring density relative to the surface area of the board, meaning they can link more components together at a time. They employ finer lines and spaces, reduced vias, and enhanced component density.

Q2: Why is material selection important in HDI PCBs?

A2: The materials selected determine the electrical performance of the PCB, the thermal management capability of the laminate, and the mechanical stability. These factors directly relate to the PCB’s reliability and functionality.

Q3: What are the advantages of using advanced solder mask materials for HDI PCBs?

A3: The latest solder masks are less susceptible to damage from exposure to external elements while maintaining signal stability with excellent resolution, low dielectric constants, and high thermal stability.

Q4: Why do advanced substrates enhance PCB performance?

A4: Advanced polyimide and ceramic substrates offer improved thermal and electrical performance, compact design support, and enhanced performance due to higher stability.