PCB Manufacturer Belgium

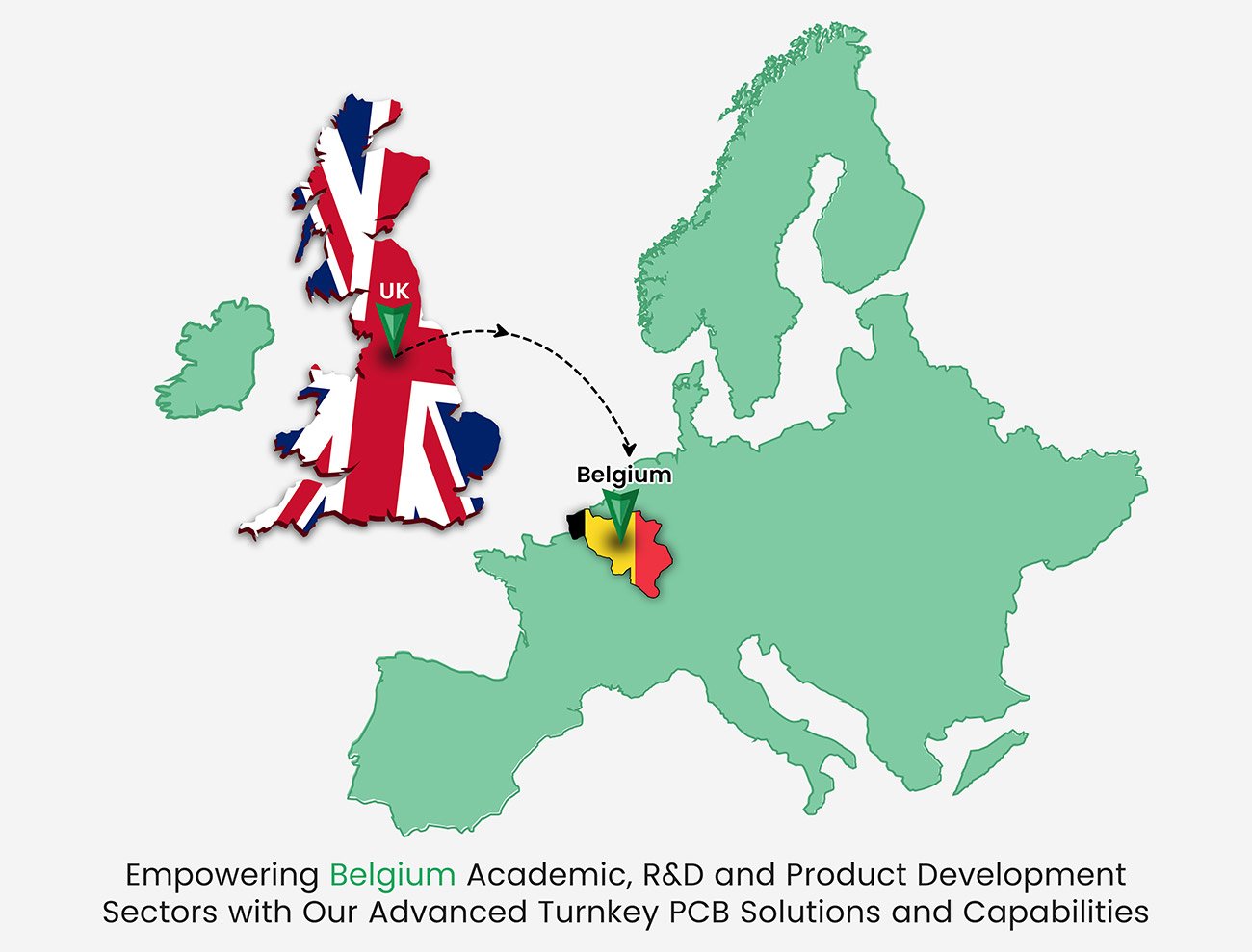

PCB Runner, PCB manufacturer Belgium, has expanded significantly over the past ten years. We are a company that currently produces circuit boards with all the integral features. We are currently Belgium’s most favored solution provider. We provide services to a variety of industries and have clients all around the world.

With our advanced technology and highly effective methods, we deliver our customers with high-quality, full-featured circuit board services. Our services and products meet the highest ranks of quality. Because of this, we have clients in sectors including healthcare, aviation, communication systems and education among others.

PCB Manufacturing and Prototype Belgium

- Multilayer layer PCBs

- Flex and Rigid-Flex PCBs

- HDI Advanced PCBs

- Ceramic, High Temperature Boards, Heavy Copper Boards

- Hybrid RF PCBs, RF Boards

- High Speed Boards, High Frequency Boards

- RoHS Compliant Boards

- Metal Core and Aluminum Backed Circuit Boards

- Custom PCBs (Rectangular, Circular, Special Profiles)

- Quick Turn

- Prototype

- Mass Production

- Layers =1 to 32

- Maximum Panel Size = 400 mm x 450mm

- Minimum Lead Time= 2 days

Cost-Free Special Services

- Penalization

- DFM and DFA Checks

- Stencil Making

- Electrical Testing

- Custom Layer Stackup

- Expedited Circuit Fabrication

- Consultation to reduce Board Production Costs

- Exceptional Client Services

- Hot Air Solder Leveling – HASL

- Hot Air Solder Leveling Lead Free – HASL – RoHS

- Electroless Nickel Electroless Palladium Immersion Gold – ENEPIG – RoHS

- Electroless Nickel Immersion Gold – ENIG – RoHS

- Immersion Silver – IAG – RoHS

- Immersion Tin – ISN – RoHS

- Organic Solderability Preservatives – OSP – RoHS

Flex and Rigid-Flex PCB Manufacture Belgium

PCB Runner peruses incredibly in rigid and rigid-flex to provide our valuable customers with one-stop quick-turn fabrication and assembly services worldwide. To enable customers to speed up their R&D, we respond to RFQs immediately, carry out DFM checks on the same day, and offer rapid production.

Types of Flex and Rigid-flex Boards we are offering:

- Single-sided Flex

- Single-sided Rigid-Flex

- Double-sided Flex

- Double-sided Rigid-Flex

- Multi-layered Flex

- Multi-layered Rigid-Flex

As a renowned and competitive rigid and rigid-flex PCB manufacturer Belgium, our capabilities are more significant and exceptional than other manufacturers. As a top provider, we can design and manufacture flexible boards with track width and spacing as small as 19 microns (0.75 mils) and microvias as small as 1 mil.

Customers with specific requirements can consult with our design and engineering services team to choose the best design for their need. Our customers can quickly evaluate their new design with the support of our rapid quick turn prototyping service.

Our special services include

| Parameters | Specifications For Rigid | Specifications For Flex |

|---|---|---|

| Maximum Panel Size | 400 mm x 450mm | |

| Layers | 1-50 layer | 1-20 layer |

| Copper Thickness |

Inner (minimum) Hoz – (Max) 6oz Outer (minimum) Hoz – (Max) 6oz |

Inner (minimum) Hoz – (Maximum) 3oz Outer (minimum) Hoz – (Maximum) 3oz |

| Board Material |

FR4: KB6164, KB6167, S1000-2M, S1000H, TG150: KB6165 Rogers: R4350B, R4003C MetalCore: T111 AL Halogen: S1150G TG135:ShengyiS1141/ KB6160 (CTI175-249) |

Polymide: Thinflex PI, Panasonic PI Rogers: NA Metal Core:NA Halogen:NA |

| Inner line width/ Line spacing (original) |

1oz = minimum 3 mil& max no limited 2oz = minimum 6 mil 3oz = minimum 8.5 mil 4oz = minimum 11 mil 5oz = minimum 14 mil 6oz = minimum 18 mil |

1oz = minimum 2.5mil & max not limited. 2oz = minimum 6 mil 3oz = minimum 8 mil |

| Outer line width/ Line spacing (original) |

1oz = minimum 3mil & max: not limited 2oz = minimum 6 mil 3oz = minimum 9 mil 4oz = minimum 12 mil 5oz = minimum 15 mil 6oz = minimum 19 mil |

1oz = minimum 3mil & max: not limited 2oz = minimum 6 mil 3oz = minimum 8 mil |

| Line width tolerance | minimum +/-10% & max +/-20% | minimum +/-10% & max +/-20% |

| The impedance value and tolerance | minimum 40+/-5% ohm & max 120ohm +/-10% | minimum 40+/-5% ohm & max 120ohm +/-10% |

| The group of impedance | min & max, no group QTY limited, we can calculate the impedance per your spec | min& max, no group QTY limited, we can calculate the impedance per your specs |

| solder mask bridge |

Glossy Colors, Minimum Bridge: 3.5mil MATTE Colors, Minimum Bridge: 4mil |

Glossy Colors, Minimum Bridge: 3.5mil MATTE Colors, Minimum Bridge:4mil |

| Vias | Blind, Buried, Plugged, Via-in-Pad, Micro via | |

| Board Thickness |

(minimum & Max): 0.2-10mm |

(minimum & Max): 0.1-0.40mm |

| Thickness Tolerance |

(minimum & Max): +/-0.10mm & +/-10% |

(minimum & Max): +/-0.03mm & +/-0.10mm |

| Solder Mask |

Type of Color & Glossy/MATTE Glossy green/matte green Glossy red/matte red Glossy blue Gossy black/matte black Glossy yellow Glossy white Glossy Purple |

Type of Coverlay Color & soldermask color Amber coverlay Black coverlay Glossy green soldermask Glossy blue Gossy black |

| Surface Finish |

Finish Type with Thickness ENIG: gold 1-3u” and Ni 80-160u” HASL-LF, Tin thickness is 1-40um. OSP: 8-20u” Hard gold fingers: gold 3-40u” and Ni 80-160u” Immersion silver: Ag 6-15u” ENEPIG: gold 1-2u” and Ni 80-120u”, Pa:1-2u” Immersion Tin |

Finish Type with Thickness ENIG: gold 1-3u” and Ni 80-160u” HASL-LF, Tin thickness is 1-40um. OSP: 8-20u” Hard gold fingers: gold 3-40u” and Ni 80-160u” Immersion silver: Ag 6-15u” ENEPIG: gold 1-2u” and Ni 80-120u”, Pa:1-2u” |

| Minimum dimensions |

Dimensions with routing method Min. board size is 20*30mm. Min. routing width is 0.8mm |

Dimensions with routing method Min. board size is 10*10mm |

| Resin Plug Hole(finished) |

Dimensions with routing method Min holes size is 0.10mm, max is 0.50mm |

Dimensions with routing method Min holes size is 0.10mm, max is 0.50mm |

| Castellated Holes |

Clearance with routing method min hole is 0.50mm |

Clearance with routing method min hole is 0.50mm |

| Legend Printing | White or Custom Colors | White or Custom Colors |

| The height/width of silkscreen | (word height 0.8mm/ word width 0.40mm ratio)2:1 | (word height 0.8mm/ word width 0.40mm ratio)2:1 |

| The impedance value and tolerance | minimum 40+/-5% ohm & max 120ohm +/-10% | |

| The group of impedance | minimum & max, no group QTY limited, we can calculate the impedance per your spec | |

| The height/width of silkscreen | (word height 0.8mm/ word width 0.40mm ratio)2:1 | |

| External dimension tolerance | ± 5 mil | ± 5 mil |

| The board thickness of V-CUT | we can only do v-cut for board thickness from 0.60-2.0mm | ± mil, o v-cut for flex boards, it’s too thin. |

| V-CUT Angle specifications | 20/30/45/60-degree Angles | Angles, no v-cut for flex boards, it’s too thin. |

| V-CUT Angle tolerance | ± 5degree | ± mil—no v-cut for flex boards, it’s too thin. |

| BOARD ROUTING METHOD | CNC | laser cut and punching |

| Edge plating with thickness | 20um copper on edge plating | 15um |

| Mini distance between test point and plate edge | 0.2mm | 0.2mm |

| Fixture test Max size | Dimensions (500mm × 600 mm) | Dimensions (450mm × 558mm) |

| Thickness of peelable solder mask | minimum 0.075 – max 0.20(mm) | minimum 0.075- max 0.20(mm) |

| IPC standard | IPC-6012 | IPC-6012 |

| Kapton tape | Thickness:0.03,0.05, 0.07 mm | Thickness:0.05mm |

| BGA PITCH | minimum 0.10mm- max 0.12(mm) | minimum 0.10mm- max 0.12(mm) |

| Blind VIA / BURRIED VIA |

minimum – max (mm) Stacked 0.10mm Staggered 0.10mm |

minimum – max (mm) Stacked 0.10mm Staggered 0.10mm |

| Laser Drill Size |

Minimum (mm) 0.10 Max (mm) 0.12 |

Minimum (mm) 0.1 Max (mm)0.1 |

| Aspect Ratio |

Laser Drill (minimum 1:1.3& standard 1:1) Mechanical Drill (minimum 1:12& standard 1:8) |

Laser Drill (minimum 1:1 & standard 1:1) Mechanical Drill (minimum 1:2& standard 1:1) |

| Back drilling | Yes, we can do it. | N/A |

| Lead Times | 2 days |

PCB Assembly Belgium

We provide complete solutions for full services for PCB assembly. Our services include component sourcing, board assembly, and testing, which is a complete package under one roof. We, full-feature PCB assembly Belgium are the only company providing entire assembly for the requirements of our valued clients. Here is a list of the premium services we offer:

- One-Stop Fabrication and Assembly

- Full turn-key start-to-finish solutions

- Multiple Assembly (THT, SMT, Mixed, POP, Rigid boards, Flexible boards) Services

- Low volumes Assembly (Prototypes)

- High volumes Assembly (Series Production)

Component Sourcing: After an elaborate review procedure, we are working with reputable distributors and well-known manufacturers to source components. A durable product is the outcome of original and reliable components. We inspect each component before usage to ensure that it is of the finest quality.

Low Cost with High Efficiency: Through our complimentary services like DFM/DFA and expert consultation to designers, we add value with high efficiency.

Quality Control: Quality Control is a very critical concern for us, according to quality assurance. We put each of our products through thorough quality and performance testing. When necessary, we perform X-ray, AOI and visual inspection.

HDI PCB Belgium

PCB Runner Team

Four Types of Circuit Board Assembly Services (One-Stop Board Assembly Services)

We provide our clients with four different types of circuit board assembling services:

Prototype Assembly: This enables our clients to assess their design before going to full-scale production. We efficiently supply prototypes to customers so they can assess any potential design defects, make any modifications, and further improve their products as needed.

Low Volume, High Mix Board Assembly: For certain feature applications, we are providing special services to assemble multiple number of different boards.

High Volume Assembly: Our setup can quickly handle massive assembly requests. In a short notice period, we can provide you with high volume assembly.

Partial Assembly: We accommodate components from the customer, buy the remaining components, and provide the labor for assembly.

Full Assembly: In full assembly, we manufacture the board, procure all the components, and provide the labor for assembly where necessary.