RoHS Compliance

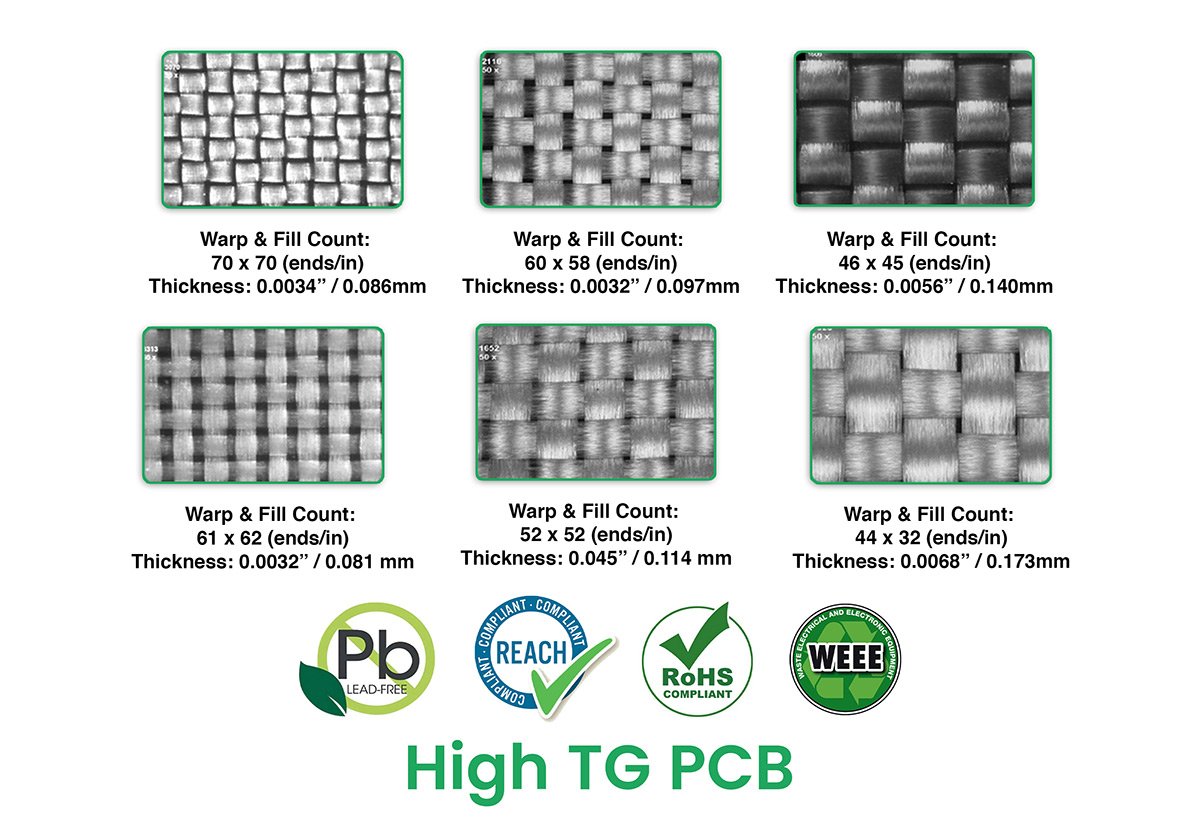

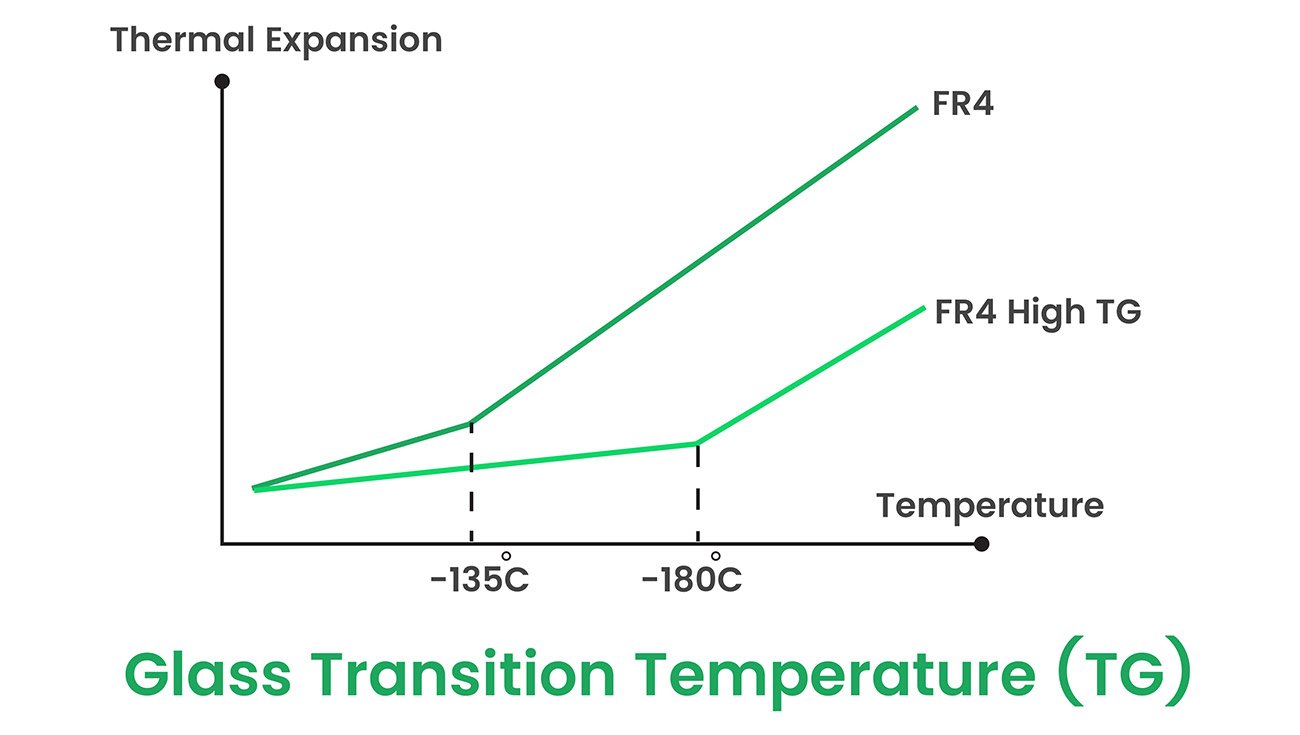

High Tg PCB Material

Our High Tg PCB material is much superior to that available in the market. PCBs made with this material can go through multiple thermal excursions without damage—six solder tests at 288 degrees each. We have optimized the material for superior drilling performance—high aspect ratio holes with up to 10 mil dia. The unique resin chemistry of this material offers CAF resistance along with long-term reliability, even for boards built with small feature designs. Even with regular fabrication techniques, this material allows improved productivity because of its fast cure capability.

We also supply RoHS-compliant PCBs with Lead-free surface finishes such as:

- ENTEK / OSP (Organic Solder Preservative)

- Immersion Gold (IAu)

- Immersion Silver (IAg)

- Lead-Free Solder

- Immersion Tin (ISn)

and many others.

Materials Excluded

As our products comply with RoHS or the directive for Restriction of Hazardous Substances, we limit the use of substances such as:

- Polybrominated Biphenyl Ethers (PBBE) or PBDE

- Polybrominated Biphenyls (PBB)

- Mercury (Hg)

- Lead (Pb)

- Hexa-valent Chromium or Cr(VI)

- Cadmium (Cd)

For more details and quotations, please visit our website PCB Runner, email us, or call us over phone.