Mastering PCB Design: From Schematic to BOM and Production – A Comprehensive Guide by PCB Runner

A consistent visual depiction of a circuit can be found in a schematic diagram of a circuit board. One of the most important aspects of PCB design is the schematic diagram. A sample circuit board schematic can show how different electronic components are connected. This could be the first action in a device’s strategy. Earlier, circuit charts were drawn by designers on paper. They have started using PCB plan instruments, which simplify the plan preparation process. A well-drawn PCB schematic diagram can significantly reduce the need for later PCB rework.

Creating a Clear and Accurate Schematic

Follow conventional schematic guidelines to create an efficient schematic design.

Page size selection:

The majority of design programs include many page sizes. Depending on how much their circuit plan is estimated, the designer might choose it.

Page naming accord:

The schematic’s logical blocks are divided into pages. Pages are arranged alphabetically by us. Most designers edit the history instead of block charts to save time. When other designers attempt to comprehend the schematic diagrams, they are accommodating. The majority of the organizations participating followed each of these guidelines and customs.

Grid Settings:

The tool needs some reference, but the designers are not immediately required to provide this. Designers can more accurately reference and connect parts when they use a grid. Throughout the examination, circuit components need to be continuously connected to the grid and open to network probing.

Page title bar: The page title bar completes all the required information and is situated in the schematic page’s footer. (Page size, modification date, record number, name and purpose of the circuit, and disclaimer from the manufacturer).

Remarks: The circuit’s relevant annotations must be written by the designers. Messages can be written on pages of schematic drawings or stand-alone papers. Annotations for intricate patterns are frequently given on different pages. Jumper states and PCB layout limitations and guidelines are a few of the remarks.

Revision history:

Revision history documents alterations made to the layout. The date, a summary of the modifications, the names of the authors and reviewers, and the review comments are all included in the document. Usually, the main or last page of the schematic layout contains the revision history. Directory of schematic documents: This directory contains a list of the subjects covered in the schematic documentation. This website makes it simple for designers to locate particular modules inside a complex design. If the operation is modest and has a straightforward design, you can omit it.

Block diagram:

Block diagrams significantly aid reviewers in understanding the design for a review by speaking to various modules within the plan and flag flow.

Network label agreement:

The schematic is meant to simplify the circuit for designers to understand. The common symbols of an integrated circuit (IC) in PCB design can be reduced when creating a schematic by minimizing the number of unnecessary network connections. Instead of dragging a bunch of networks across the screen, the designer refers to the well-organized title of a specific stick that is connected to a trap on another device. The names of these pins will be the same. The readability of the schematic diagram is increased by assuming that a pin with the same name is connected. When a network is directly connected to another IC on the same page, network naming is not necessary. But you must give it a name if you wish to link the network to an IC on a different page.

Design rules checking:

A clever CAD function called Design Rule Checking (DRC) verifies the logical and physical integrity of a design. The online check can be completed at plan time and is based on all empowered plan rules.

Verification of net tables:

Create the netlist as soon as the schematic design is finished and the layout is imported. There are two possible extensions for net table files:mnl and.txt. While the.txt file shows every electrical connection between components, the.mnl files are machine-readable. To prevent design flaws, it is advised that the network be manually verified.

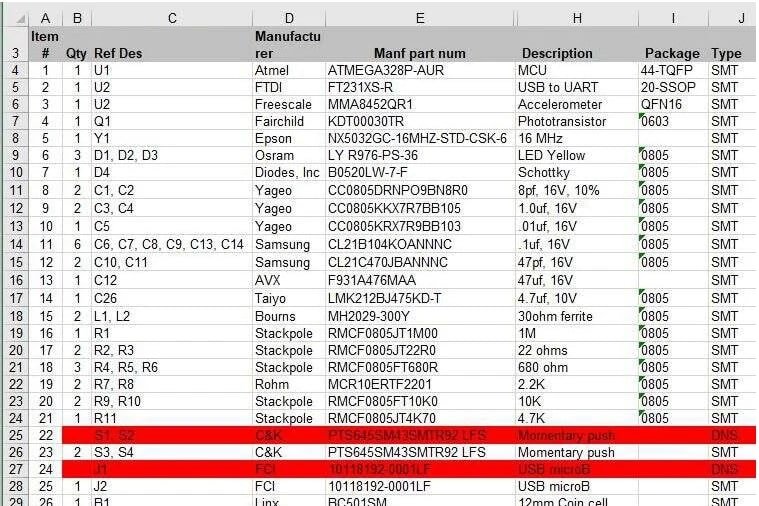

Bill of Materials

BOM generation is currently a crucial capability offered by the CAD tool. If the designer provides all inputs in the tool when building or importing parts from the library, you can generate a complete and sufficient BOM. The manufacturing part number (MPN), package, supplier name, and supplier part number are among the details that can be found on the bill of materials. It is advised to provide all pertinent data while creating symbols.

Beginning with circuit boards, the Bill of Materials, or BOM, is an essential component of any electronic device’s design and manufacturing process. The project might require adjustments in the absence of a comprehensive BOM, which could delay production. As such, one of the most important factors in PCB production is the BOM.

Most of the time, when a customer submits an order, manufacturers request that they upload their BOM list. Nonetheless, it is essential to understand the data that a BOM should contain while designing one. The required information should also be included in the bill of materials. BOMs provide several advantages to consumers and electronic manufacturers alike. Thus, before creating one, it’s critical to comprehend what a bill of materials comprises.

A Bill of Materials: What Is It?

A list of materials, parts, and assemblies needed for product manufacturing is called the bill of materials. Production depends on the data in the bill of materials. Consequently, to produce a product, producers must rely on these bits of information. The BOM needs to be extremely precise and well-detailed. The BOM determines a production’s level of success.

BOMs are essential for producers as well as customers. When a customer orders circuit boards, for example, it is helpful for them to express their needs. To manufacture the circuit board or electronics according to the customer’s requirements, the PCB assembler uses this information. The BIOM can also be used as an ingredient list when producing a product. Creating a BOM is the first step in the production process for all manufacturers. This is so because the product’s basic specifications are provided by the BOM. BOM is utilized by several production sectors in addition to the electronics industry. As the phases progress, the BOM also improves production.

How to make clear and well-organized schematics Space

You must choose how to use the blank space that appears when you first open a new schematic. It relies on several variables, including the project’s size and complexity, target audience, any standards you must adhere to, and the project’s expected life cycle. Additionally, it depends on whether or not you need to print the schematic.

Whether you need more than one sheet or if one will do is the most crucial decision to make. Starting with a single A4 page and switching to an A3 sheet as the project progresses is one method for smaller projects.

The Best Component Arrangement for Understanding and Clarity

Logic and Intuition-Based Component Arrangement

To Reduce Signal Crossings and Improve Flow

Making Explicit and Brief Connections Selecting Line Styles and Thickness that are Correct Steer clear of overlapping and unclear connections Assigning Names, Nodes, and Component Labels

Component Labeling:

Every element in the schematic diagram needs to have a label that corresponds to its reference designator. Alphanumeric identifiers known as reference designators are used to identify each component separately. It is important to label the components suitably once the schematic design has been constructed and they are each represented by a symbol. The circuit design is made clearer and easier to understand by labeling parts, nodes, and signal names.

Labeling Nodes:

In a circuit, nodes are the locations of connection between various components. Voltage nodes (e.g., Vcc for positive power supply, GND for ground), signal nodes (e.g., IN for input, OUT for output), and particular node labels pertinent to the circuit design are examples of common node labels. Troubleshooting and circuit analysis are made easier by labeling nodes.

Labeling Signal labels:

It’s important to give the right labels to the signals in the schematic diagram in addition to labeling the components and nodes.

The purpose or function of a specific electrical or electronic signal inside the circuit is described by its signal name. “CLK” for clock signals, “DATA” for data signals, “RESET” for reset signals, and “ENABLE” for enable signals are a few instances of signal names. Examining and confirming the schematic diagram. Performing Extensive Quality Inspections to Verify Completeness and Accuracy Getting Input from Experts or Peers to Verify.

Guidelines for Component Selection

Comprehending Component requirements:

To start, make sure you fully comprehend the mechanical and electrical requirements of the components you require. Temperature tolerances, package sizes, voltage and current ratings, and package dimensions are important factors.

Component Availability:

Take lead times and component availability into account. To avoid project delays, make sure that the selected components are easily obtained from vendors.

Cost vs Performance:

Aim for a balance between the cost and performance of the components. Although cost control is crucial, sacrificing component quality might result in reliability problems.

Environmental Considerations:

Choose components that can survive harsh circumstances, such as high humidity or extreme temperatures, if your PCB will be operating in these kinds of settings.

Verify that the components are compatible with the footprint libraries and PCB design tools of your choice.

Longevity:

Consider a component’s long-term availability, particularly if your project calls for lengthy production cycles.

Validation of Design and Simulation

Design Validation:

Verify the functionality, signal integrity, and thermal performance of the design using simulations and studies. Iterative Refinement: Fix any problems found during validation and make the required changes to the design.

Design Records

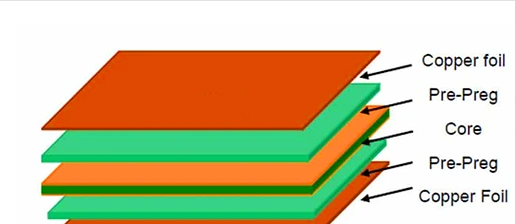

Design File Creation: Produce thorough design files that include manufacturing comments, assembly drawings, bill of materials (BOM), and Gerber files. The files known as manufacturing data, which include copper layers, solder masks, and other components, are what will be used to construct the etched base laminate on your PCB. The exported data in these files was produced from your CAD designs. It’s critical to maintain track of the versions of your files and ensure that the proper version of your CAD design is linked to each file by a clear naming convention.

It is possible, if challenging, to reverse engineer your manufacturing data from an existing PCB. To ensure that you’ll be able to have the source documentation to quickly build your files for manufacturing, it’s critical to keep your design files, record revisions, and back up your data. Cooperation: To ensure efficient production, distribute design documentation among team members, fabricators, and assemblers.

The Importance of Software for PCB Design

Your PCB design is created on a digital canvas using PCB design software. It gives designers the ability to precisely route traces, layout components, and build schematics. Your ability to collaborate, design efficiency, and the quality of the finished project are all impacted by the software you choose.

Advice on Which PCB Design Software to Choose

Selecting the appropriate PCB design software should be in line with your level of experience and the demands of your particular project. Here are some pointers to think about:

Evaluate the level of difficulty involved in your project. Simple designs can be satisfied with inexpensive, user-friendly software. High-end software with sophisticated functionality could be needed for complex undertakings.

Learning Curve: Take your experience with PCB design software into account. While some programs offer advanced features but may have a longer learning curve for beginners, others may be more user-friendly.

Compatibility: Verify that the program you select can import and export the required file types and is compatible with your operating system.

Collaboration: Choose software that allows for both version control and real-time collaboration if you’re working in a group.

Cost: Consider the licensing, upkeep, and extra features while evaluating the software’s cost structure. Remember your financial limitations.

Support and communities: Look into the resources, forums, and user communities that are available to help you when you run into problems.

Future Scalability: Consider if the program can grow with the project in the future and adapt to changing design specifications.

Trial Period: A lot of software vendors provide free trials. Use these to see if the software is appropriate for the task at hand. A crucial first step in making sure your PCB design project is successful is selecting the appropriate PCB design software. You may make an informed decision that will enable you to implement your PCB design ideas successfully and efficiently by considering the particular requirements of your project, your degree of experience, and your financial constraints.

Common Software Tools for PCB Design

A wide variety of PCB design software solutions are available to meet different design needs and user preferences. Among the software tools that are most frequently used are: Altium Designer: Preferred by expert PCB designers, Altium Designer is renowned for its intuitive UI and robust features. It has tools for capturing schematics, arranging components, and collaborating in real-time.

Eagle: Autodesk’s Eagle is well-known for being both inexpensive and easily accessible. With a large library of components, it’s appropriate for novices as well as enthusiasts.

KiCad: This open-source program is well-liked for its wealth of capabilities, which make it an affordable alternative for novices and experts alike.

Cadence Allegro: Because of its excellent routing and seamless connection with other design tools, this dependable program is used.

OrCAD: OrCAD provides a full range of tools for PCB design, such as simulation, PCB layout, and schematic capture.

Siemens’ PADS offers a variety of design functionalities and is appropriate for small and medium-sized enterprises.

Best Practices for Schematic Capture for Easily Read Schematics

Schematics must be simple to read and comprehend by users in addition to having intelligent components and connectivity features. Layout engineers, component engineers, manufacturing staff, test technicians, and field repair specialists will all use them. They must so explain in detail what their circuitry is doing. When designing a schematic that will be helpful to everyone, keep the following points in mind:

Parts Arrangement: Try to arrange the parts in a clean, well-organized manner. Resistors and other parts should be arranged in rows with enough room between them for text and nets. People farther down the line may find it more difficult to quickly discover a certain element if components are placed on a schematic haphazardly.

Signal pathways: The order of components should be based on their respective signal pathways. The path must begin from the driver pin, follow a logical flow through the circuit, and terminate at the end. This not only improves the design of your schematic and frees up space for more circuitry, but it also makes the circuit easier to grasp for the layout team to work with.

Give Yourself Room to Grow: Your schematic may expand when new features and improvements are introduced, even though it may shrink in size initially. It is wise to allow space for the addition of more circuitry as needed because of this. If nothing else, you’ll probably adjust and revise as you create, and having more space makes it much simpler to move parts and nets around.

Net Connectivity: Just like with component placement, everyone’s work will be much easier if the nets flow in a tidy and ordered manner. Buses ought to be clustered together wherever feasible. Seeing how the busses are arranged and the flow of the signal routes will be especially helpful to the layout team when they are floor-planning the PCB layout.

Don’t Forget the Details: Your schematic isn’t finished when all the parts are arranged and routed together. To make the reference designators readable, they must be shifted and rotated. This also applies to net and bus names, which for readability purposes should be aligned in the same direction as their wires. Dates, other firm information, and board names and numbers must be entered into title blocks. Finally, remember to include any special notes or design information that will aid in the layout, production, and repair of those who utilize the schematic.

Common mistakes during BOM creation

Reason for error: Failure to include all required parts in a Bill of Materials (BOM) is a frequent error. This error may be the result of carelessness or insufficient detail in the BOM creation procedure. Examples: Let’s say a company is making complicated electronic equipment that needs a variety of screws, but the BOM just lists a small number of them. In that scenario, as they wait for the missing screws to arrive, the manufacturer might have to stop manufacturing or postpone shipping. As an alternative, the device might not function properly during testing or usage because the maker used the wrong kind of screws.

How to avoid: Manufacturers should create their BOMs methodically to prevent making this error. This process should begin with a thorough analysis of the product design to determine all the components and materials that are required. To detect any omissions or mistakes, it is crucial to make sure that the BOM is examined by some people, such as engineers, buying managers, and production supervisors. Manufacturers should also routinely update their BOMs to account for modifications to component availability or product design. Ultimately, to guarantee that any modifications to the BOM are accurately recorded and shared with all parties involved, manufacturers must put in place a thorough change management procedure.

Not indicating the precise number of pieces

Neglecting to include the correct number of pieces in the Bill of Materials (BOM) is another typical error. Errors in the conversion between units of measure or inaccurate estimates about the quantity of parts required can result in this issue. As an illustration, let’s say a company has to make 100 units of a product but orders 10 units of a crucial component by mistake rather than 100. Then, there could be a delay or stop to the production process, which would mean lower profits and higher expenses. Alternatively, let’s say a manufacturer orders the incorrect quantity of a component, causing delays in manufacturing or material waste, because they specified the incorrect unit of measurement.

How to stay away from: Manufacturers should be very careful when indicating the right number of pieces in their BOMs to prevent making this error. To make sure the values are correct, they should verify all computations and conversions between units of measurement again, as well as get feedback from a variety of stakeholders. Manufacturers should also put in place a strong quality control procedure to identify any mistakes before they affect production. Lastly, to account for any modifications to manufacturing specifications or product design, manufacturers should constantly review and update their BOMs.

Failing to update the BOM

Justification for the error: Failure to update a Bill of Materials (BOM) regularly is another typical error made when creating one. Manufacturers may make this error by neglecting to take into consideration modifications to the production procedures, material availability, or product design. As an illustration, let’s say a manufacturer releases a new version of a product, but the BOM that was used to make it isn’t updated to reflect the adjustments. In that instance, misplaced or missing pieces could cause the production process to slow down or stop entirely. Let’s also say that a component that was easily accessible before becomes unavailable, and the BOM isn’t changed to reflect this. Should that be the case, the manufacturer might keep placing orders for the part, which would drive up expenses and cause production delays.

How to stay away from: Manufacturers should set up a procedure for routinely checking and updating their BOMs to prevent making this error. All relevant parties, including as engineers, purchasing managers, and production supervisors, should be included in this process to guarantee that any modifications are carefully considered and recorded. Manufacturers should also have a change management procedure in place to guarantee that any modifications to the BOM are accurately recorded and shared with all relevant parties. Lastly, to account for any modifications to product design, material availability, or production procedures, manufacturers should constantly review and update their BOMs.

not adhering to naming guidelines consistently

Justification for the error: Using inconsistent naming standards while drafting a Bill of Materials (BOM) is another typical error. When manufacturers refer to the same part or material by different names, it can cause confusion and mistakes during the production process. As an illustration, let’s say a manufacturer calls an item a “bolt” in one area of the BOM and a “screw” in another. Then, during manufacturing, misunderstandings can occur and the wrong parts might be used, which would cause delays, material waste, and a drop in product quality. Let’s further say that a manufacturer refers to the same material under multiple names in various BOM sections.

How to avoid: Manufacturers should make sure that parts and materials have defined naming rules and are utilized consistently throughout the BOM in order to prevent making this error. To lower the possibility of misunderstanding, manufacturers should also include thorough descriptions for each item or substance. Manufacturers should also put in place a thorough inventory management system to precisely track inventory levels and place the right number of material orders. Finally, in order to make sure that naming conventions are current and consistent, manufacturers should periodically examine their BOMs.

Not supplying sufficient supporting documentation

Justification for the error: Not include enough documentation in a Bill of Materials (BOM) is another typical error. This error might happen when manufacturers don’t supply adequate safety data, assembly instructions, or material specifications to support the production process. As an illustration, let’s say a producer of a sophisticated product fails to include comprehensive assembly instructions. In that instance, laborers might find it difficult to put the product together correctly, which would cause delays in production, material waste, and a drop in product quality. Let’s also say that a producer fails to supply safety data for a hazardous material that is utilized throughout production. Then, there could be a chance for illnesses or injuries in the workforce, which would result in lower output and more expenses.

How to avoid: Manufacturers must supply comprehensive and lucid documentation for each item and material listed in the BOM to prevent this error. Assembly instructions, material specifications, safety data, and any other pertinent data that aids in the production process should all be included in this paperwork. Additionally, manufacturers need to make sure that staff members have easy access to all paperwork and are well-trained to use it. Furthermore, manufacturers must establish a comprehensive quality control procedure to guarantee that all goods fulfill the requisite safety and quality benchmarks. Lastly, to make sure that their BOMs and documentation are correct and up to date, manufacturers should regularly examine them.

Maker Faire Arduino UNO Board – PCB Production Project

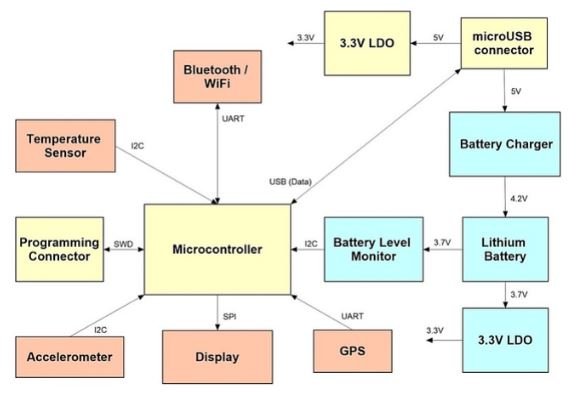

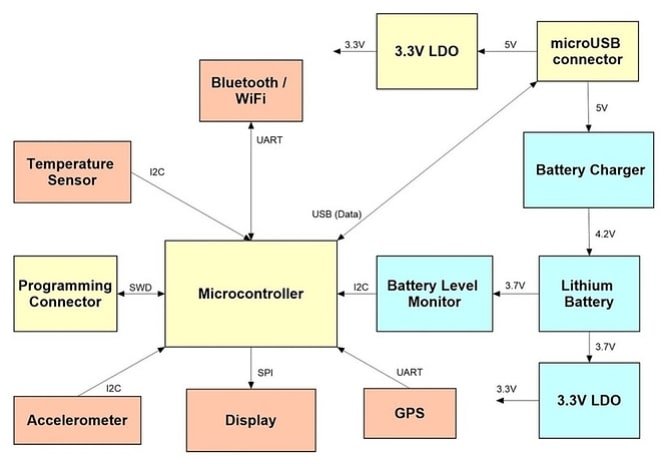

Explain The System Block Diagram

Choose a Production Component.

The intended uses and intended retail price of your device will determine the microchips, sensors, displays, and connectors to use in its creation. You will then be able to draft a Bill of Materials (BOM) thanks to this.

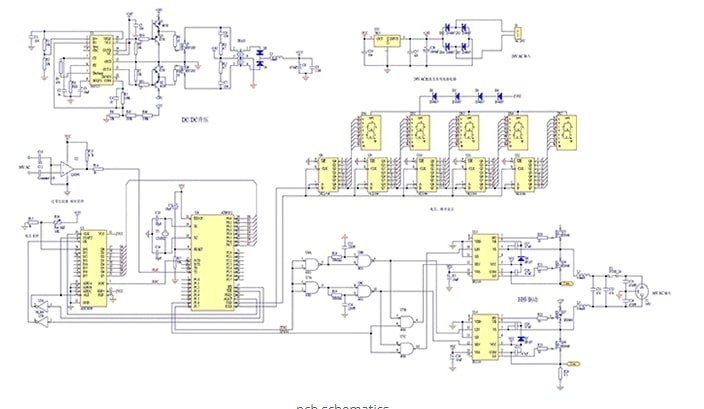

Create The Schematic

Using the system block diagram you produced in step 1, generate the schematic circuit diagram.

The schematic includes all the information needed to assemble the electronics, including information on how each part is related to the others.

There will be a final Bill of Materials (BOM) that includes information on each electronic component.

Designing a multivibrator

Placing the Multivibrator Parts

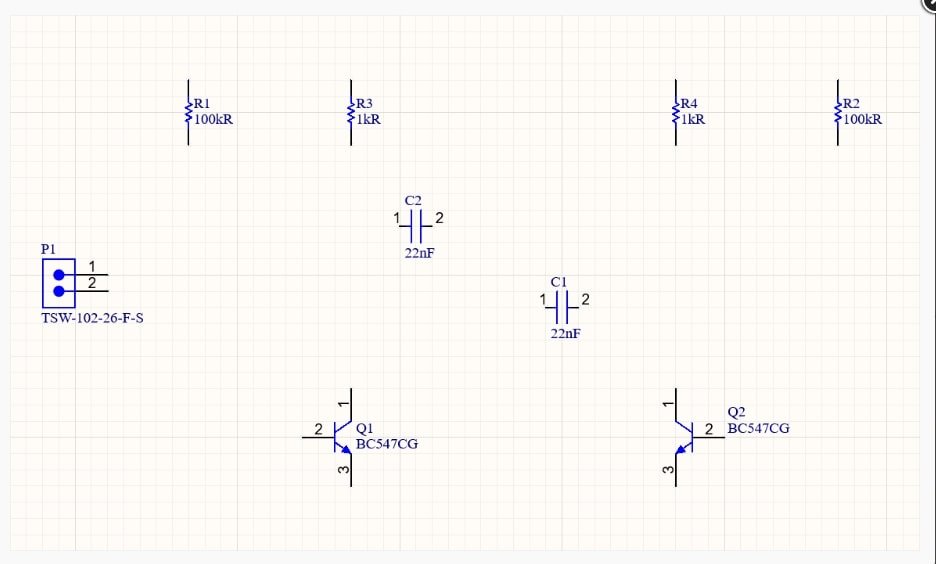

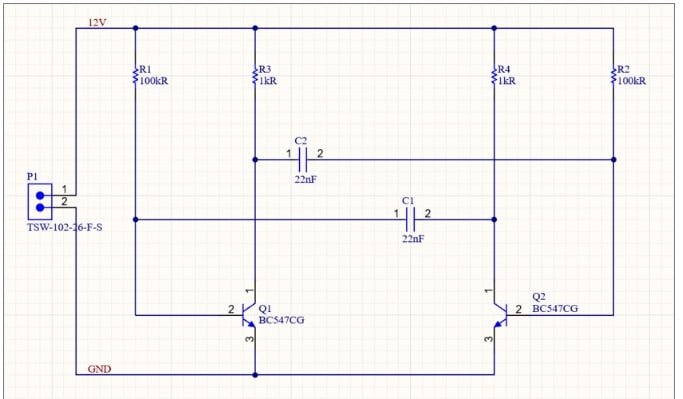

The Multivibrator circuit will be assembled using components that were obtained from Manufacturer Part Search using the Components panel. The schematic ought to resemble the picture below when the components have been assembled.

Netlabels and wiring

You can use Net Labels to assign names to significant nets in the design, making it easier to find them. As indicated below, you will identify the 12V and GND nets in the multivibrator circuit.

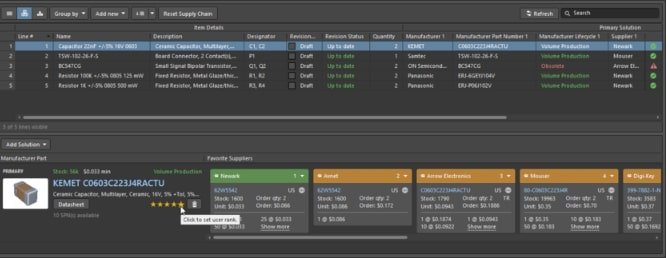

Setting Up the Bill of Materials

In the end, comprehensive supply chain data must be included for each component used in the design. You can add this information in an Active BOM (*.BomDoc) at any time during the design cycle, instead of having to add it to each design component or as a post-process in an Excel spreadsheet.

Conclusion

Through the use of standardized symbols to express component connectivity and interactions, circuit schematic diagrams offer a fundamental depiction of electronic systems. creating schematics. The bill of materials is essentially the lifeblood that synchronizes the whole manifestation of a complicated PCB assembly from first conceptions into a tangible product; it is much more than just an ordinary parts list. It offers best practices and advice for producing a high-quality design in addition to covering the fundamentals of schematic capture and the regulations that must be adhered to throughout PCB routing. The industry standard tools and software for schematic design are also covered in the guide. Whether you are new to PCB design or looking to advance your knowledge, this guide offers helpful advice and information for creating printed circuit boards of the highest caliber.

PCB Runner team has an experienced team of development & simulations team which can make schematics & BOM for customer base don input & output requirements. Feel free to reach out to our team at sales@pcbrunner.com & engineering@pcbrunner.com