If you’ve ever tried to design a printed circuit board, you know it can take a lot of time. There’s the planning, the drawing, the checking, and then the waiting for your board to be made. But what if you could speed up this whole process, without making mistakes or ending up with a poor-quality board? Good news: you can. Let’s walk through how you can accelerate your PCB design process while still getting a board you’re proud of.

Why Speed Matters in PCB Design

Getting your PCB done quickly means you can test your ideas sooner. If you’re working on a new gadget, every day counts. You want to be the first to launch, not the last. But if you rush and skip steps, you might end up with a board that doesn’t work. That’s why you need a plan that’s both fast and careful.

Start with a Clear Plan

Before you even open your design software, take a moment to think about what you need. What is your board supposed to do? How big should it be? What parts will you use? Write these things down. It helps you stay focused and avoid mistakes later.

- Make a list of all the parts you need.

- Decide how big your board should be.

- Think about how your board will fit in your device.

- Talk to your team so everyone knows the plan.

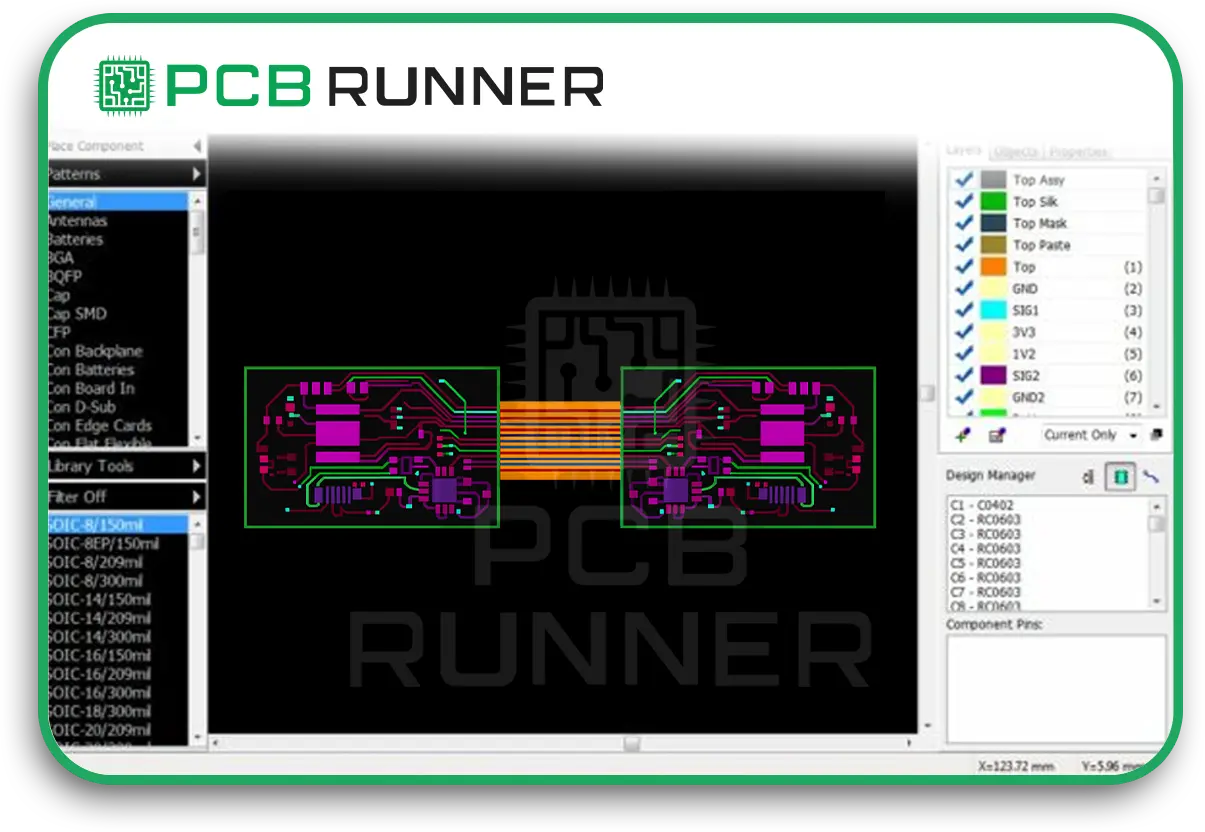

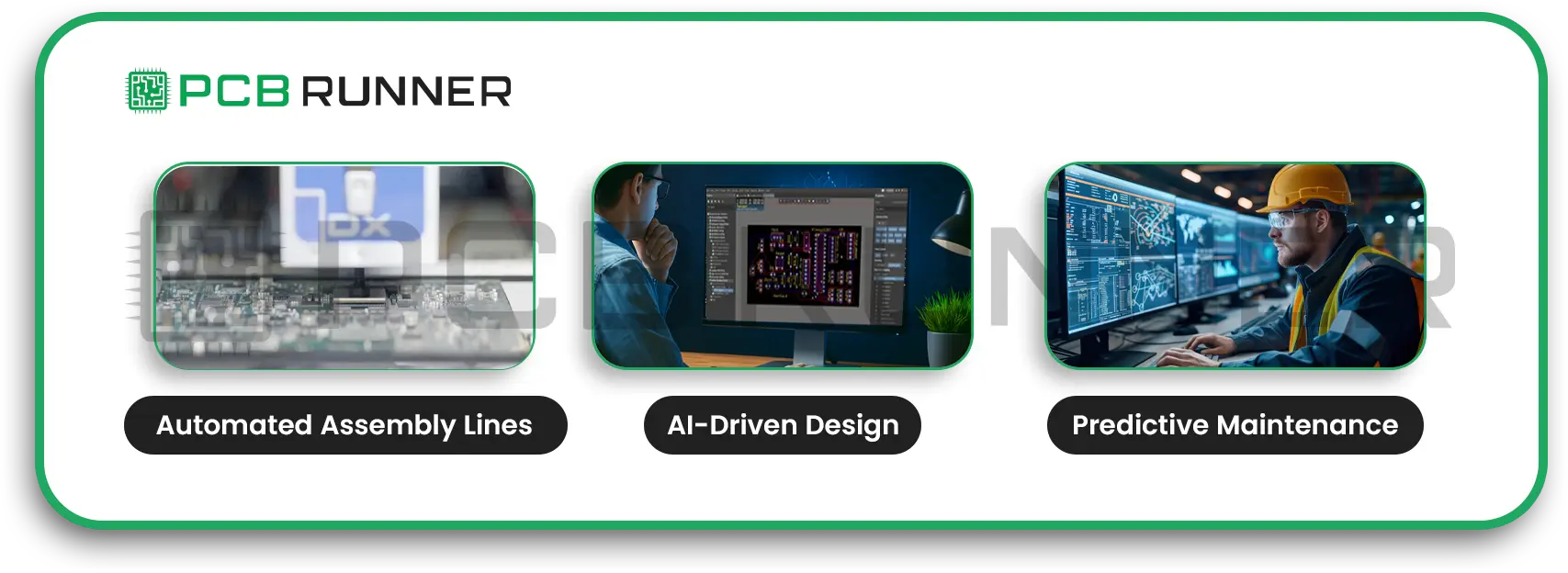

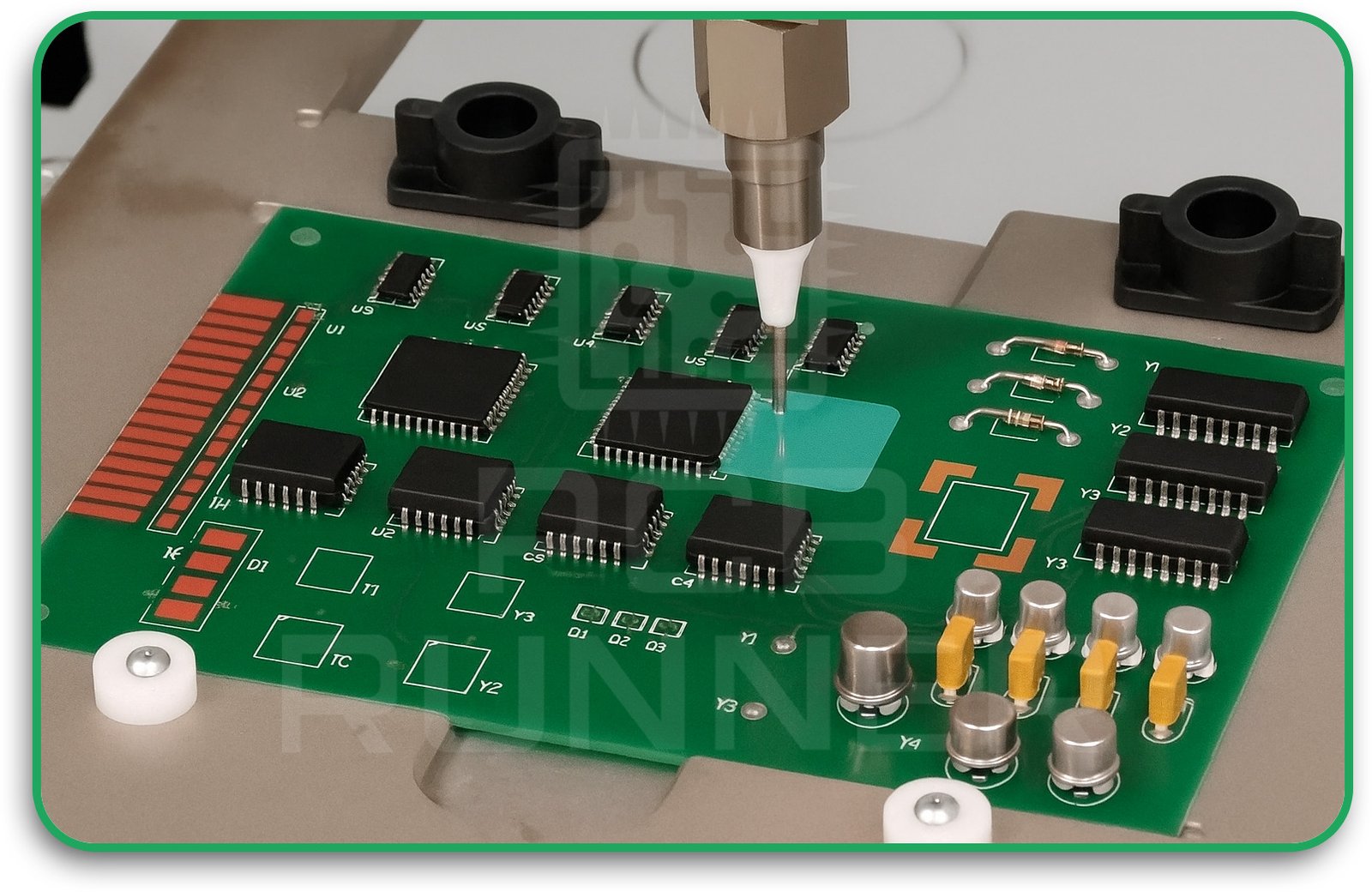

Use the Right Tools

The software you use for PCB circuit design matters. Good tools let you work faster and spot problems before they become big headaches. Some design programs let you move easily from drawing your circuit to laying out your board. This saves time and reduces errors.

- Use design tools that let you check your work as you go.

- Look for software with built-in rules to catch mistakes.

- Try to use the same tool for both the schematic and the PCB layout design.

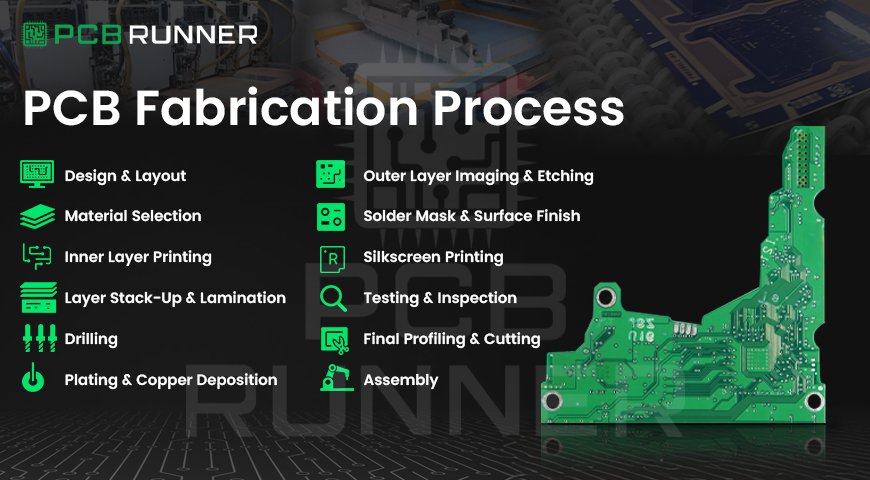

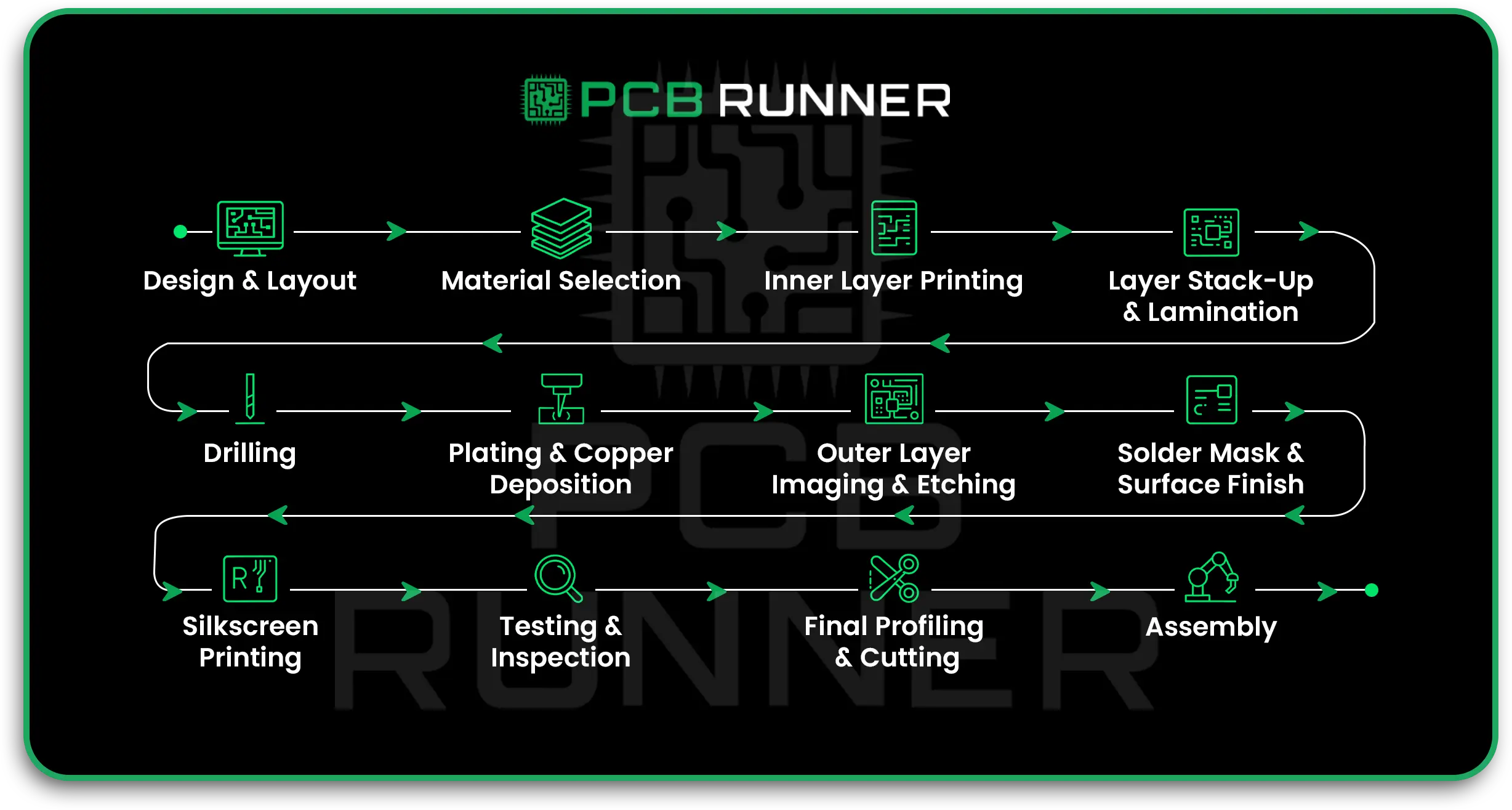

Work with Experienced Printed Circuit Board Manufacturers

Not all printed circuit board manufacturers are the same. Some can make boards in just a day or two. Others take weeks. If you want to move fast, pick a company known for quick service and good quality. Ask them about their process and how they check for mistakes.

- Choose a manufacturer with a solid track record.

- Ask about their quality checks and delivery times.

- Make sure they can handle your custom PCB design needs.

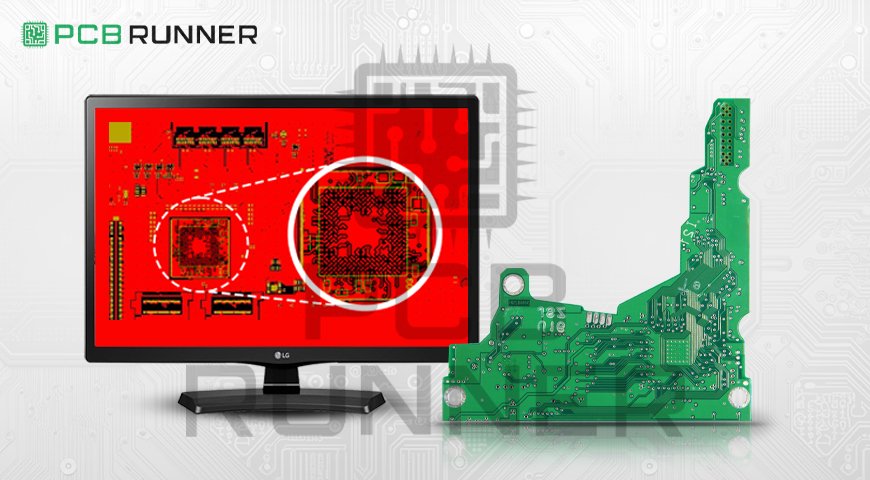

Don’t Skip Prototyping

You might think skipping the prototype step will save time. But if you do, you could end up with a board that doesn’t work, and that costs more time in the end. Quick-turn prototyping lets you test your design fast. If something’s wrong, you’ll catch it early.

- Order a prototype before making lots of boards.

- Use quick-turn services for faster results.

- Test your prototype carefully.

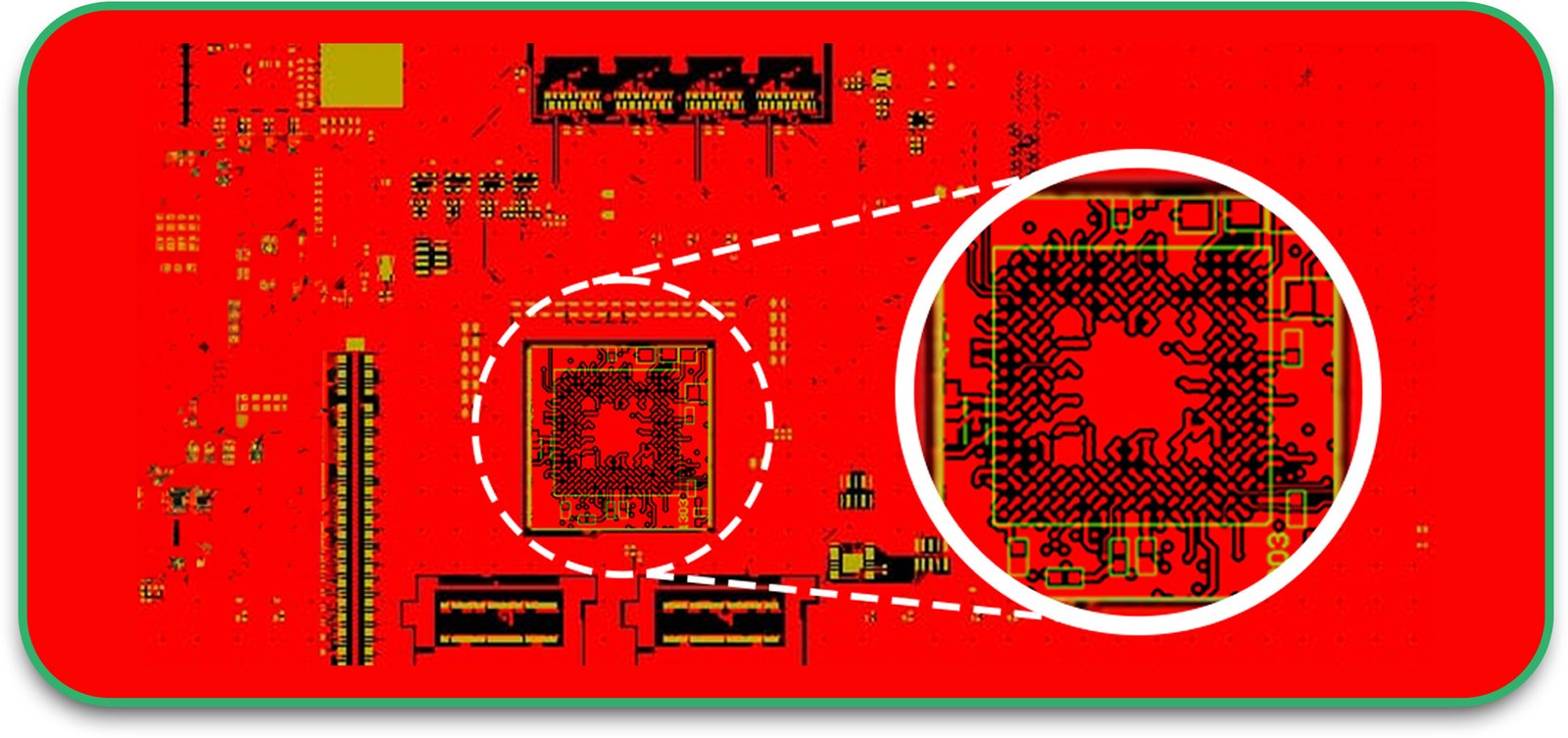

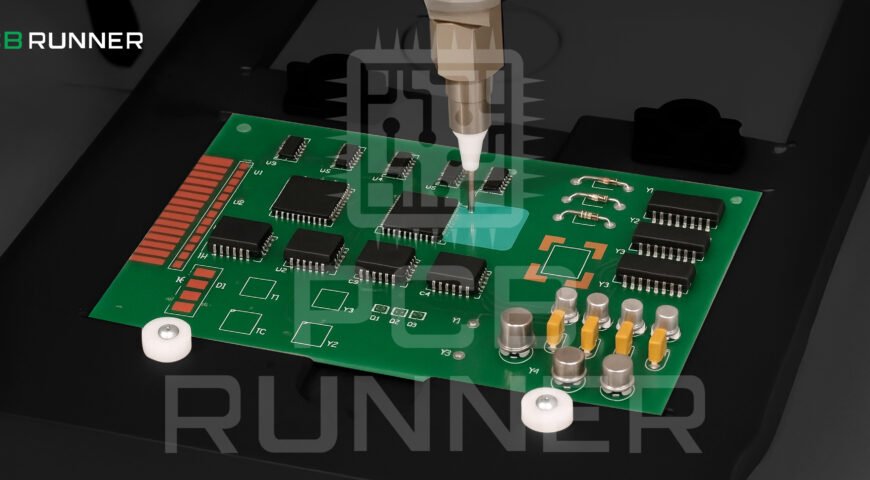

Design for Manufacturing and Assembly

When you’re working on custom PCB assembly, think about how your board will actually be made. If your design is too tricky, it can slow down manufacturing or cause errors. Keep things simple and follow the rules your manufacturer gives you.

- Use common part sizes and shapes.

- Keep enough space between parts.

- Avoid strange or hard-to-find components.

- Follow your manufacturer’s guidelines for PCB board layout design.

Communicate with Your Assembly Team

If you’re using a PCB assembly UK service or any custom PCB assembly provider, talk to them early. Ask what files they need and what problems they see most often. This helps you avoid delays and makes sure your board is easy to assemble.

- Share your plans and ask for feedback.

- Double-check your files before sending them.

- Be open to suggestions, they know what works best.

Use Templates and Standard Blocks

If you design a lot of boards, you probably use some of the same circuits over and over. Save time by making templates or reusable blocks. This way, you don’t have to start from scratch each time.

- Save your favourite layouts for future use.

- Build a library of standard circuits.

- Use these blocks to speed up new projects.

Check Your Work, But Don’t Overthink It

It’s essential to check your design, but don’t get stuck in endless reviews. Use your software’s design rule checks to catch mistakes. Then, do a quick review with your team. If everything looks good, move forward.

- Run the design rule check in your software.

- Have a teammate look over your design.

- Trust your process and keep moving.

Choose the Right Assembly Partner

Once your board is designed, you need someone to put it together. Look for a company that offers custom PCB assembly and has experience with boards like yours. If you’re in the UK, working with a PCB assembly UK company can save shipping time and make communication easier.

- Pick a partner with a good reputation.

- Ask about their assembly process.

- Make sure they can handle your board’s size and complexity.

Keep Your Files Organized

Messy files slow everything down. Keep your design files, part lists, and instructions neat and easy to find. This helps your team and your manufacturer work faster.

- Name your files clearly.

- Keep everything in one place.

- Double-check that your files match your design.

Learn from Each Project

After your board is done, take a few minutes to think about what worked and what didn’t. Did you hit your deadline? Were there any surprises? Use what you learn to do even better next time.

- Write down what you’d change for next time.

- Share tips with your team.

- Keep improving your process.

Tips for Even Faster PCB Design

Here are some extra tips to help you speed things up:

- Stay organized: Keep your workspace and files tidy.

- Ask for help: If you get stuck, ask your team or your manufacturer.

- Practice: The more boards you design, the faster you’ll get.

- Use checklists: Make a list of steps and check them off as you go.

Final Thoughts

Speeding up your PCB design process doesn’t mean you have to cut corners. With a clear plan, the right tools, and good partners, you can move fast and still get a high-quality board. Remember to work with experienced printed circuit board manufacturers, use quick-turn prototyping, and communicate with your custom PCB assembly team. Keep your files organized, use templates, and always learn from each project.

You have what it takes to design great PCBs quickly. With these tips, you’ll be ready to tackle your next project, and get it done faster than ever.

Frequently Asked Questions

Q: How do I pick the right printed circuit board manufacturers?

A: Look for companies with good reviews, fast service, and strong quality checks. Ask about their experience with custom PCB design and PCB board layout design.

Q: What’s the best way to avoid mistakes in PCB circuit design?

A: Plan ahead, use good design tools, and check your work often. Don’t skip the prototype step.

Q: Can I speed up assembly with a PCB assembly UK company?

A: Yes. Local companies can often deliver faster and make it easier to fix problems if they come up.

Q: Should I use templates for custom PCB assembly?

A: Yes. Templates and reusable blocks save time and help you avoid repeating the same work.

Q: How can I make sure my custom PCB design is easy to assemble?

A: Use standard parts, keep enough space between components, and follow your assembly partner’s advice.