Exploring PCB Solder Masks: Types, Colors, and Future Trends

Introduction:

Printed circuit boards (PCBs) are coated with a polymer layer known as solder mask (sometimes called solder resist) to control solder spreading and avoid solder bridges during assembly. Additionally, it aids in shielding traces from electrical leaks and environmental deterioration. To assist PCB designers in making the most effective use of this crucial material, this page discusses solder mask types, qualities, functions, design concerns, application techniques, and faults.

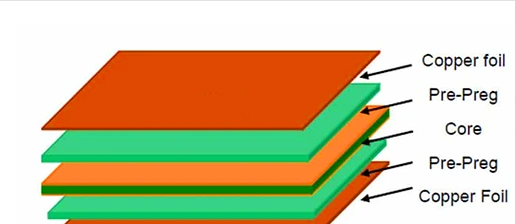

Applied permanently on the surface of finished PCBs, solder mask—also referred to as solder resist, solder stop, or solderable mask—is a thin layer of insulating material similar to lacquer. The solder mask’s primary purposes are as follows:

- Preventing environmental corrosion and oxidation of exposed copper

- Preventing the formation of solder bridges during assembly between pads that are closely spaced.

- Live nets that are electrically insulated to avoid shorting.

- Enabling the selective plating or coating of exposed portions

Most completed circuit boards have a green solder mask covering most of the surface, leaving exposed metalized pads and traces for soldering. It adds a unique look to manufacturing boards in addition to silkscreen.

However, solder masks have uses far beyond aesthetics. Correct design and use significantly improves the manufacturability and reliability of PCBs.

Four Primary PCB Solder Mask Types

Solder mask, sometimes referred to as solder resist, is a robust, long-lasting coating that shields printed circuit boards’ (PCBs) copper traces and their interfaces. A solder mask’s primary purpose is to stop conductive solder from bridging between various electrical components and creating short circuits. There are numerous varieties of PCB solder masks, including top- and bottom-side masks, epoxy liquid, liquid photo imageable, and dry film photo imageable.

Masks on the Top and Bottom

The electronic engineer can see the holes in the green solder mask layer that was applied to the PCB using film, epoxy, or ink processes by using a topside solder mask. Using those marked locations, component pins can subsequently be soldered onto the board. Top traces refer to the conductive trace pattern on the top side of the circuit board, whereas bottom-side mask designates openings on the lower surface.

Liquid Epoxy

The least expensive kind of solder mask is epoxy liquid, which is silkscreened onto the PCB layout. The thermosetting polymer epoxy has a wide range of uses. A woven mesh is used in the printing process known as “silk screening” to support stencils or patterns intended to obstruct ink.

Ink can transfer to open spaces created by the mesh. While silk is frequently employed in art, synthetic fibers are more frequently used in electronic applications. Thermal curing is the last step in the finishing process.

Fluid Ink Capable of Photo image

The liquid photo imageable solder mask is supplied in the form of an ink. The PCB can be coated with ink by spraying or silk screening it, exposing it to the design, and then developing it. Hot air surface leveling is one kind of procedure that is frequently employed with liquid ink formulations (HASL). It needs a spotless setting devoid of impurities and particles. Following the UV light exposure phase, developers—high-pressure water sprays—are used to remove the mask. Thermal curing and organic coating are necessary for circuit board finishing.

Photo imageable Dry Film

Vacuum lamination is used to apply a dry film photo imageable solder mask, which is subsequently exposed and developed. Parts can be soldered to the copper pads once the pattern has been established after development. Electrochemical processing is used to layer copper onto the board inside the holes and on the trace sections. The copper circuitry is shielded with tin. After that, the exposed copper is etched and the dried film is removed. Thermal curing is another step in finishing.

Factors influencing the solder mask color selection

Visibility and contrast

Enhancing the contrast and visibility of your PCB marks and components is a primary motivation for selecting a solder mask color. If you use a magnifying glass or a microscope, a high contrast color can assist you locate and examine the vias, silkscreen labels, and solder connections on your PCB. Although a low contrast color can conceal certain flaws or errors, it can also give the impression that your PCB is more consistent and smooth. In general, colors that are high contrast include green, blue, and red, while colors that are low contrast include black, white, and yellow.

Both branding and aesthetics

Enhancing the aesthetics and branding of your PCB design is another justification for selecting a solder mask color. The color of your solder mask might express your brand, your organization, or the theme of your product. For instance, you may want to pick a color that is bold or distinctive to set your PCB apart from the crowd, or a color that is subdued or neutral to go in with the surroundings. It could be a good idea to coordinate the color of your solder mask with the enclosure, your logo, or other design components. But you should also think about how the color of your solder mask influences your PCB’s durability, solderability, and heat dissipation.

Guidelines and policies

Adhering to the rules and specifications that are relevant to your PCB design is the third justification for selecting a solder mask color. Certain industries or applications, like the military, medical, or automotive sectors, could have particular demands or suggestions about the solder mask color of their printed circuit boards. For instance, some medical PCBs use white solder mask to denote cleanliness and sanitation, whereas some military PCBs use red solder mask to show excellent reliability. Before selecting the color of your solder mask, you should always make sure it complies with all applicable rules and laws. These can have an impact on the functionality, security, and caliber of your PCB.

Price and accessibility

Taking the price and accessibility of your PCB fabrication into account is a last justification for selecting a solder mask color. Depending on market supply and demand, different solder mask colors may have varying costs and lead times. Since most PCB manufacturers utilize and supply green solder masks, it is typically the most affordable and common hue. Certain colors could need unique materials or methods, which could make them more costly or take longer to produce. Before selecting the color of your solder mask, you should always check with your PCB manufacturer as they can have different possibilities and restrictions.

Advantages of covering bare copper on a PCB with a solder mask

Using a solder mask over bare copper on a PCB has numerous advantages. Among its primary advantages is its potential to shield copper from oxidation. Also, it may aid in preventing solder from bridging copper lines next to one another. By creating a barrier between the copper and the environment, a solder mask can shield the metal from oxidation and other forms of deterioration.

Furthermore, a solder mask can act as a sort of barrier between the PCB’s various conducting layers. By doing this, crosstalk can be decreased, and the PCB’s overall electrical performance can be enhanced. By creating a low-impedance channel between the copper traces, this can enhance the PCB’s electrical performance.

Design Considerations for PCB Solder masks

Solder mask is a crucial component in assuring the correct operation and dependability of the finished product, and PCB design encompasses many other important considerations. It’s important to take a number of factors into account while designing a PCB using solder mask, including material choice, thickness, tolerances, and clearance needs. We’ll talk about these design factors in this part and offer tips to help you make the best PCB design possible for a solder mask application.

Selection of Materials

Solder mask materials come in a variety of forms, as was previously mentioned, and each has special qualities and functions. Think about things like electrical insulation, flexibility, chemical resistance, and thermal stability when choosing a solder mask material for your PCB design. To select the best material, consider the needs and operation environment of your PCB. To find out which solder mask materials are suitable for your particular design, speak with your PCB maker.

Thickness of Solder mask

The PCB’s overall performance, including mechanical stability, electrical insulation, and thermal management, can be impacted by the solder mask layer’s thickness. You must weigh these considerations and make sure that your design complies with industry requirements in order to decide on the right thickness. For suggestions on solder mask thickness, refer to the IPC guidelines. To find out the maximum solder mask thickness that will work for your design and production process, speak with your PCB manufacturer.

Registration and Tolerances

For the solder mask layer to be precisely aligned with the copper traces and pads underneath, solder mask tolerances and registration are essential. To prevent solder bridging or shorts during assembly and to shield delicate components from the elements, alignment must be done correctly.

Utilize the solder mask design guidelines and tolerances that are acceptable for the capabilities of your PCB manufacturer.

Incorporate alignment features or fiducial markers into your PCB design to enable precise solder mask registration during production.

Clearances & Openings at solder mask

The regions of the PCB where the solder mask is purposefully left off to facilitate soldering, testing, or other activities are known as solder mask clearances and apertures. For PCB assembly and functioning to be successful, these areas must be defined correctly.

Based on component pad sizes, soldering specifications, and manufacturing tolerances, design solder mask clearances.

If more space is required, add it for test points, fiducial marks, or other functional requirements.

You may maximize the performance, dependability, and manufacturability of your PCB design by giving careful thought to these solder mask design considerations.

What color of solder mask should be?

The dye that is utilized in the solder mask material determines the color of your solder mask, and the cured solder mask thickness is influenced by the chemical properties of the dye. The ability to produce thin solder mask dams (~0.1 mm) is one of the reasons green solder stop mask is so widely employed. Different colored solder mask dyes typically result in thicker solder mask dams. IPC-SM-840D defines solder resist thickness on PCBs for usage in specific industries or applications, regardless of the dye you choose to employ.

A crucial component of automated or human visual inspection is the color of the solder stop mask. The least contrast between the board and traces is produced by black solder mask, which can make automated inspection challenging. This is an additional justification for favoring green masks. During manual inspection, the color of the silkscreen you choose will also affect visual contrast and visual fatigue.

You should prepare your design to account for the sensitivity of your final application, just like you would with any other fabrication parameter or process. It’s crucial to talk to your manufacturer about your fabrication possibilities at all times. Depending on their ability, they might even be able to recommend better choices.

Which Solder Mask Is Best ?

The physical dimensions of your board, the holes, components, and conductors, the surface layout, and the intended use of your product all play a role in selecting the right solder mask. You will need a photo imageable solder resist for the majority of contemporary printed board designs. A liquid or dry application will depend on the topography of the surface. A dry application applies a consistent layer of solder mask to the whole surface. Nonetheless, a particularly flat board surface is ideal for dry mask adhesion. For improved contact between the copper of your traces and the laminate, you’re usually better off using a liquid (LPSM) option if your surface characteristics are intricate. A liquid application’s drawback is that the thickness isn’t consistently the same.

Additionally, you can apply various finishes to the mask layer. Discuss what your manufacturer has available and how it will impact production with them. For instance, if you are employing a solder reflow process, a matte coating helps to minimize solder balls.

Solder masks are required for PCBs produced by the solder reflow process. The quality of the reflow might be impacted by the mask’s polish.

The range of colors for Solder Masks in printed circuit boards: advantages and disadvantages

Green

For good reason, green solder masking is currently the most widely available hue on the market. It is a suitable hue for maintenance and repairs because it provides one of the biggest visual contrasts of any accessible color between planes, traces, and empty areas. Owing to its widespread appeal, almost all large-scale PCB manufacturing facilities can obtain it, and it is regarded as the standard hue for circuit boards globally. It is also the least costly circuit board color that is offered as a result. It has one of the thinnest coats and can hold the smallest solder mask dams to avoid solder bridging because of intensive research and development.

Red

A visually arresting choice, red solder masking is frequently utilized in designs that highlight interior hardware. The hue is now among the most often used alternate PCB colors, but there’s a catch: it’s less visible and has less contrast than a typical green PCB. When doing maintenance on a red PCB, technicians might need to use more magnification to see problems on the board. Almost always, people choose red for its beauty rather than its usefulness.

Blue

Though it has less contrast than circuit boards that are red, green, or yellow, blue is the second most popular hue utilized in the production of PCB boards. They are usually connected with open-source electronic projects since they are the preferred color for Arduino boards due to the way silkscreen appears on them. Furthermore, the coloration of blue solder masking makes it perfect for installation behind LCD screens.

Black

Compared to other colors, black solder masking is one of the priciest color options and frequently requires more time to make. It should not be used in high-heat applications because of its propensity to absorb heat. It also has very little contrast, which makes maintenance and repairs challenging. Additionally, during the production process, it has the highest failure rate.

Silkscreen looks really good on black PCBs, despite the low trace contrast on these boards. It is also the least reflective light, which makes it perfect for circuits where light is undesirable. While black solder masking may be visually appealing to businesses such as Apple that value sophisticated design, it is seen as a challenging hue to work with from a practical standpoint. Selecting a circuit board with a black print should be done carefully.

White

White PCBs are the hardest to visually analyze since they have even less contrast than black PCBs. Over time, they also clearly gather dirt. White solder masking is frequently used with LED lights, especially when they are attached to surfaces with lighter colors. When the lights are on, white offers the least noticeable color and blends in the best. Since white is one of the colors that reflects light the most, it also emits pure white light when lit.

Make sure your manufacturer is utilizing a solder with high reflectivity when choosing white PCBs for LED applications, as not all solders are created equal.

Future Trends in Solder Mask Technologies

There is a constant exploration for new developments in materials and methods to deliver the highest quality product possible as technology continues to advance toward tighter features and larger circuit densities. In terms of capital expenditure and collaborating with suppliers to overcome these issues related to material, process, and quality, Advanced Circuits is still in the forefront. Our investment in enhanced solder mask (SM) materials and laser direct imaging (LDI) equipment will give the best overall quality solution to fulfill current and future technological demands. Advanced Circuits Colorado will start switching to the higher performance solder mask on October 23 in order to specify the tight SM features that are frequently encountered in modern technology. This solder mask is intended for LDI.

Thermal management

More thermal management will be a top priority for solder masks in the future. This is to account for the increasing power density of contemporary electronics. Maintaining optimal performance will require improved heat dissipation qualities.

Nanotechnology

In the formulation of solder masks of the future, nanotechnology may be extremely important. Better feature resolutions and general performance enhancements might be made possible by it. Precision and miniaturization could advance as a result of this integration.

Customization

More customizable solder masks are probably in store for the future. This is a result of the growing popularity of flexible and wearable electronics. This will enable stretching and bending without compromising functionality. This evolution aligns with the growing demand for flexible printed circuit boards. They are employed in numerous contexts.

Conclusion

In order to safeguard the copper traces on PCBs, solder masks are necessary. It offers defense against short circuits and oxidation. Manufacturers must to be knowledgeable about the appropriate thicknesses and methods for integrating the electronic components on PCBs. They ought to adhere to industry norms as well. Because it acts as an insulator between conductive traces, resists corrosion, and stops solder bridging, the solder mask is a crucial component of a printed circuit board. Bare copper is frequently used as traces by PCB fabrication businesses, yet it is quickly oxidized, corroded, and destroyed. When exposed to aqueous solutions, such as water, bare copper traces will oxidize as well. Make sure a solder mask covers the copper in order to solder to bare copper effectively. If not, the copper will not be soldered to the solder. Additionally, flux should be used if you’re not soldering to bare copper and you’re not using a solder mask.

PCB Runner offers a variety of solder masks colors including LDI & LPI methods. Do reach out to our team for custom requirements quote, you can submit your Gerber files on https://www.pcbrunner.com/free-pcb-quote/ or do reach out to our team offline at engineering@pcbrunner.com or sales@pcbrunner.com for your current or upcoming projects needs.