Any device with electronic components should significantly pay attention to the design and fabrication of printed circuit boards (PCBs) in order to achieve the desired results. Such devices have been steadily evolving and improving over time. The IPC functions as an international association with over 3000 member companies related to the design, manufacture and assembly of electronic equipment. Quality is not only ensured but also high outcomes are yielded from PCB prototypes using IPC circuit standards boards.

What Are IPC Standards?

The most essential function of IPC is to formulate internationally accepted standards that encapsulate all aspects of PCB designing, fabrication and assembly. These standards are incorporated without any alterations by different nations, as they help measure the defied quality and reliability as well as functionality levels of the APC products. By adhering to IPC standards, all players within the electronics industry, such as designers and fabricators, are operating with set expectations that guarantee contrived results.

Importance of IPC Standards

IPC standards guarantee that PCBs are fabricated to meet stipulated requirements which greatly enhances product reliability as well as performance, leading to improved Quality and Reliability. Some of the Industral benefits to adhering to set standards are consistency, communication efficiency, and overall ensuring that processes and products that were standardized will guarantee interoperability regardless of the fabricating company.

Cost Savings. IPC standards contribute to less expensive production due to lower errors and reduced needed rework.

Environmental Compliance. Many IPC standards emphasize the use of sustainable materials and processes, which is good for the environment.

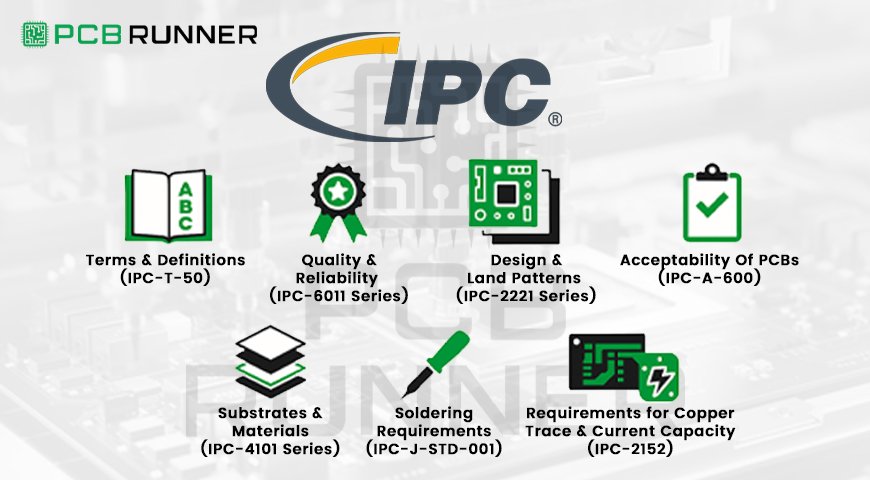

Important IPC Standards Regarding PCB Design And Fabrication

Some of the most important IPC standards and their relevance are given below.

1. Terms And Definitions (IPC-T-50)

This standard includes and explains all terms and definitions that are relevant to PCB design and manufacture for communication purposes within the industry.

2. Design And Land Patterns (IPC-2221 Series)

The IPC 2221 series provides general design requirements, including effective land pattern design for the most economical board layouts.

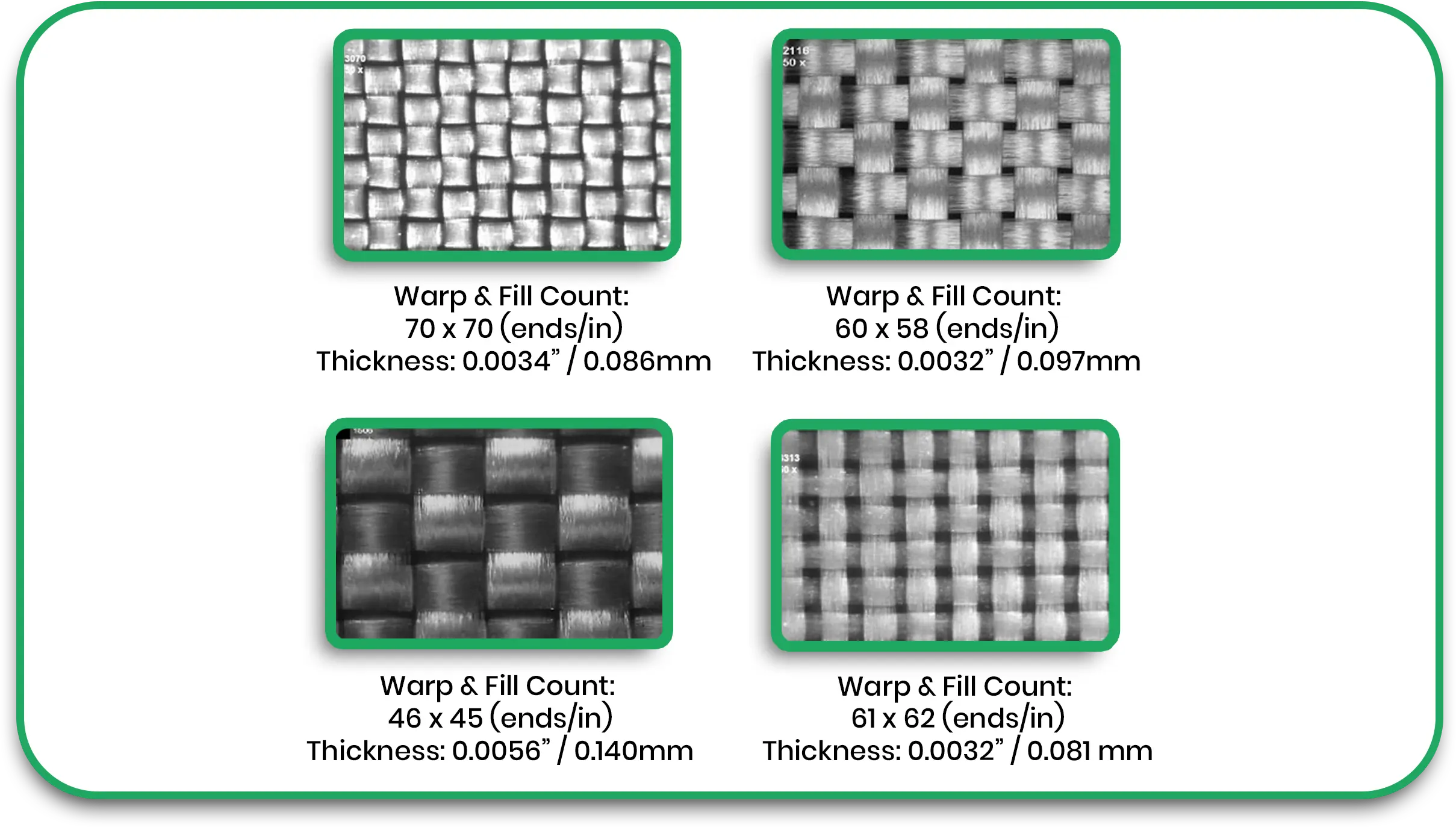

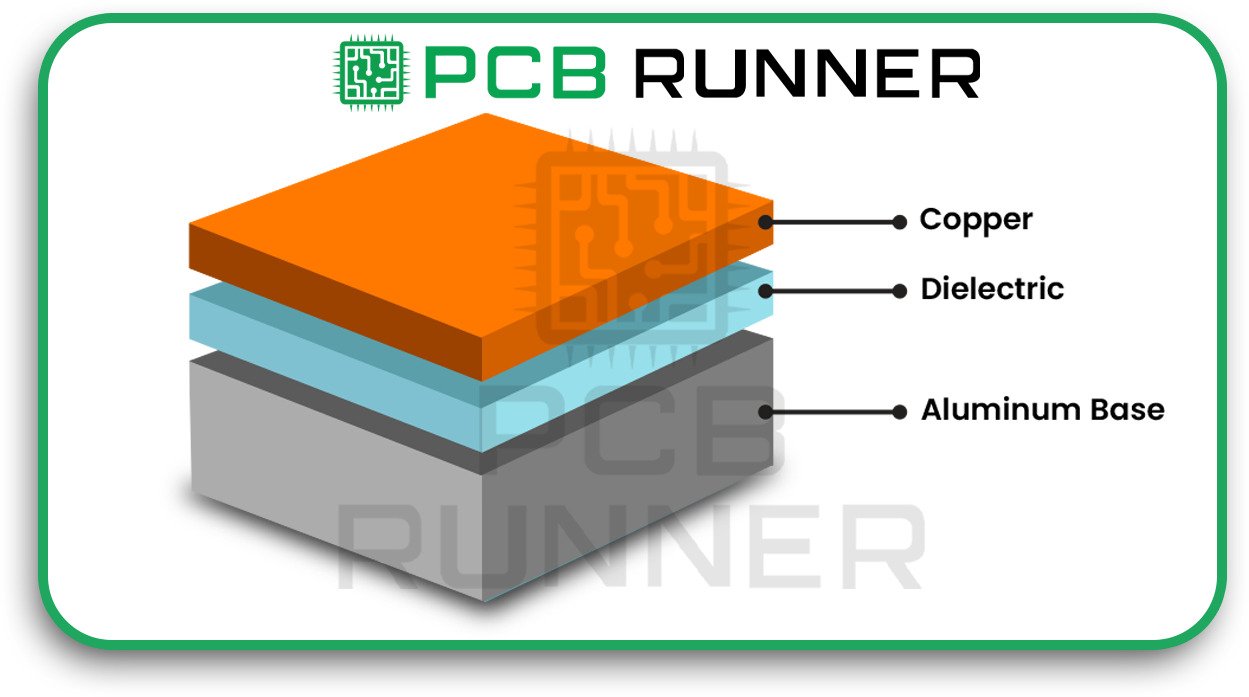

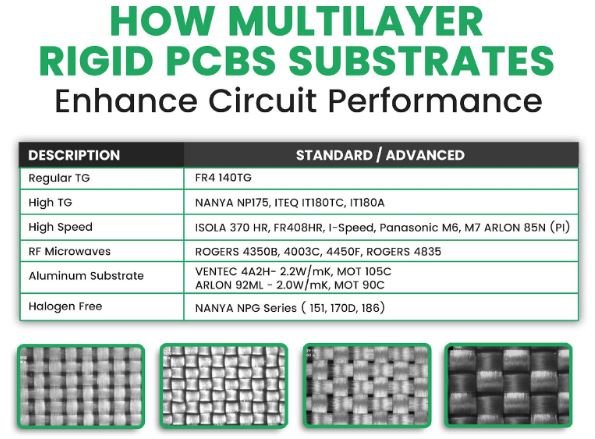

3. Substrates And Materials (IPC-4101 Series)

These standards describe the requirements for the PCB’s base materials and substrates, in selection for specific needs and criteria for different uses.

4. Quality And Reliability (IPC-6011 Series)

The rigid, flex, and rigid-flex boards have differing quality and reliability standards, and this overall standard sets criteria for those PCB types.

5. Acceptability Of PCBs (IPC-A-600)

This notably utilized standard intends to define the class of the PCB for its application and the acceptability requirements for completed boards.

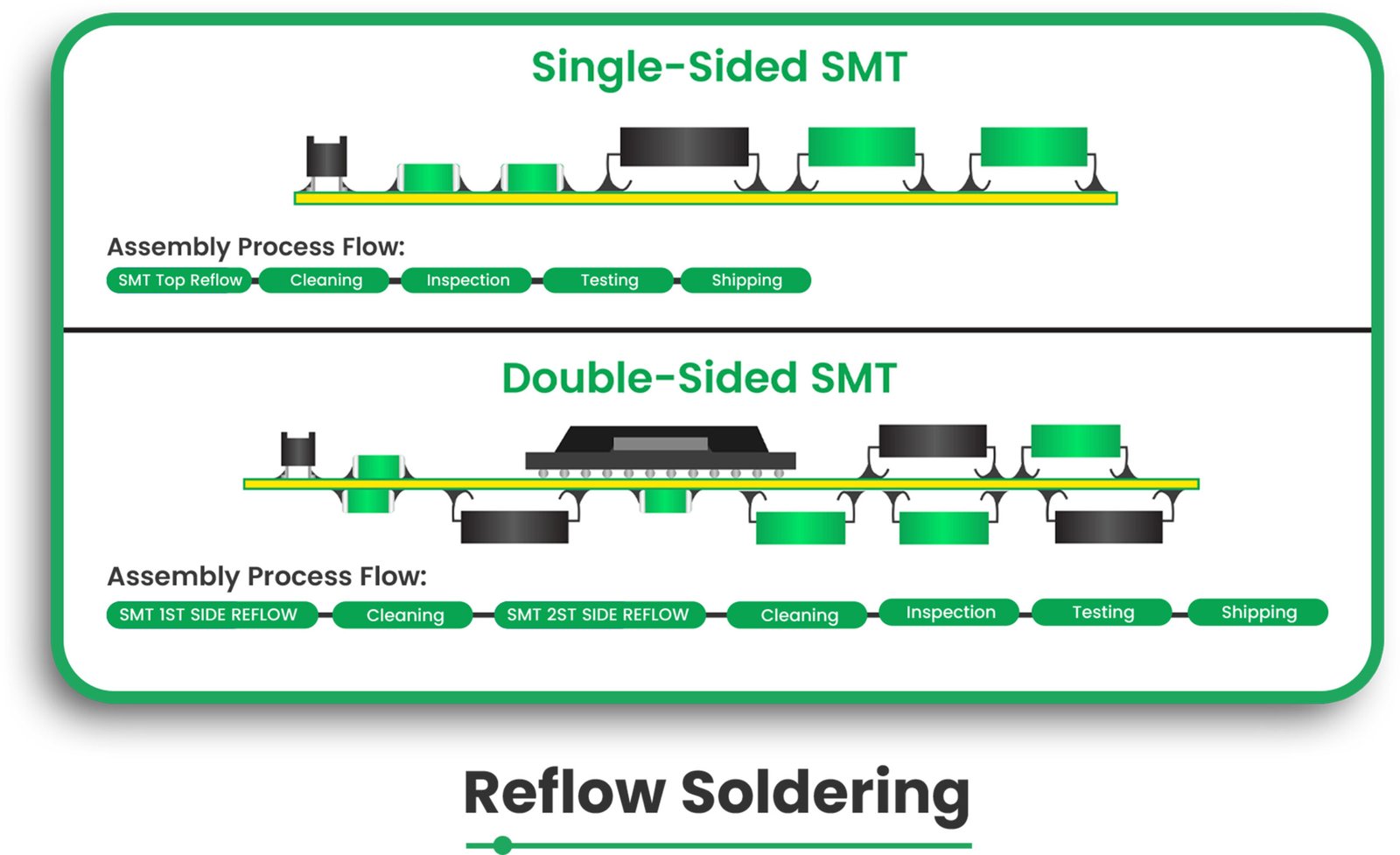

6. Soldering Requirements (IPC-J-STD-001)

This standard defines the requirements for soldered electronic assemblies in terms of materials, processes and workmanship.

7. Requirements for Copper Trace and Current Capacity (IPC-2152)

This document outlines the execution of a specific current capacity trace to a PCB design.

Use of IPC Standards in PCB Design and Prototyping

The application of IPC standards during the PCB prototype phase is critical to achieving the desired quality and performance in the final product. Manufacturers make IPC circuit board standards during design processes so that any evident flaws within the design can be resolved prior to manufacturing.

Expert Insights: Progress of IPC-7351 Standards

A study published on ResearchGate suggests that the design and specification of the IPC-7351 standard are set to supersede the old IPC-SM-782 Surface Mount Design and Land Pattern Standards. IPC-7351 makes necessary changes with respect to design and requirements for assembly and testing, including metric specifications for component dimensions and land patterns, since there are differing geometry requirements based on a product’s use case.

The document includes guidance levels for three standard land pattern dimension levels:

Level A: Exceeds for most digital electronics requiring soldering.

Level B: Moderate balance for more compact electronics.

Level C: Less protrusion for minimum compact electro-mechanical assemblies.

Employing this system of levels makes it possible for manufacturers to customize electronic assemblies and components for optimum efficiency and reliability.

Analysis of Other Industry Comparisons

UL Standards

What separates UL standards from others is their focus on safety solely, which is in contrast with IPC circuit board standards that focus on both quality and reliability. It is a lot more integrated in its approach.

ISO Standards

ISO standards, like ISO 9001, focus on quality management systems without delving into specifics. These standards are too broad compared to IPC standards. Additionally, IPC standards focus on electronic assembly, which makes them ideal for the electronics sector.

Benefits of IPC Circuit Board Standards

1. Improved Product Performance and Quality

IPC standards take into account various operating conditions under which a PCB needs to function reliably. Therefore, Argus can maintain solid quality benchmarks.

2. Uniformity and Flexibility

Processes that are standardized reduce the chances of design errors and production inconsistencies.

3. Better Interaction

Collaboration between designers, manufacturers, and clients is more efficient due to shared standards and definitions.

4. Cheap Production

Rework and material waste have decreased, which, along with lean manufacturing, has made IPC standards cheaper to use.

5. Pro-Environmental

Many IPC circuit board standards define sustainable materials, which aids the use of pro-environmental practices.

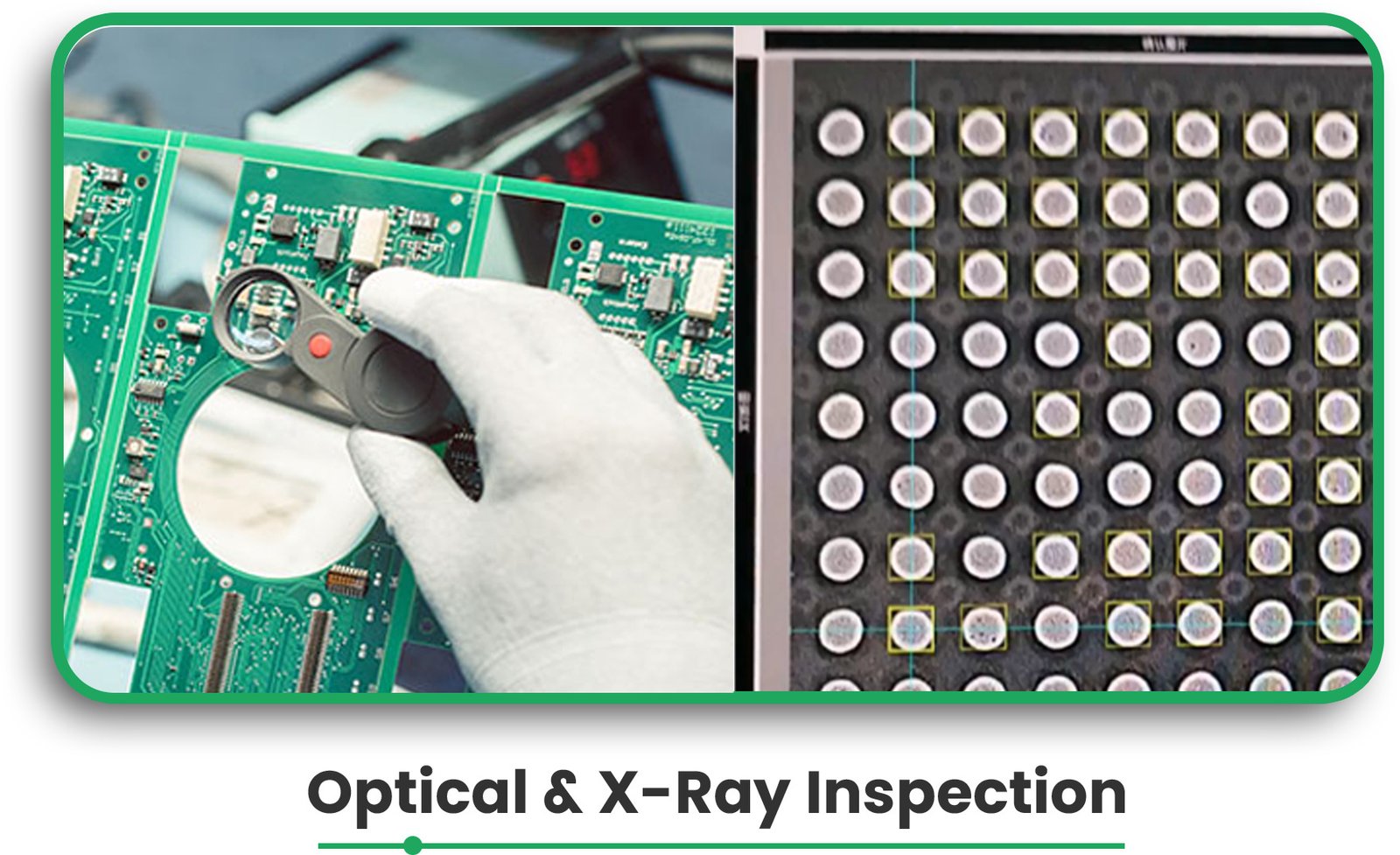

QAT and Quality Control Procedures Linked to IPC Standards

Electrical Tests

No particular assembly’s operational requirements are ignored, as the IPC standards set forth precise testing processes for all components of an assembly.

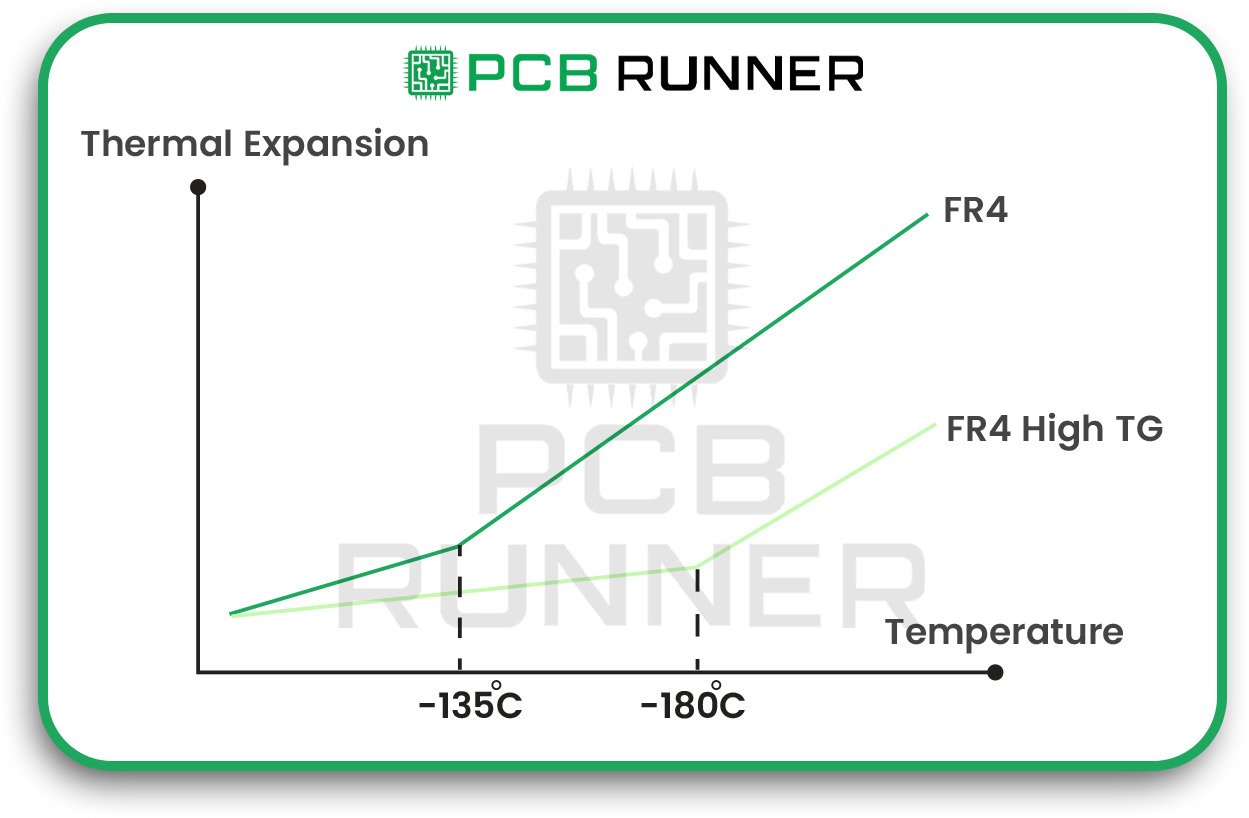

Environmental Tests

The endurance and thermal resistance of PCB products are tested under IPC standards for environmental testing.

Compliance with IPC Standards

Understanding the Standards

To comply with the IPC standards, one must have a deep comprehension of the IPC standards. This means mapping standards to specific PCB projects.

Implementation

Achieving compliance with IPC standards at all levels of PCB design and fabrication activities is fulfilled from the first step to the final test procedures.

Certification

IPC certification confirms a company’s commitment to quality and reliability, enhancing trust and credibility with partners and clients.

Conclusion

IPC standards drive the dynamism and quality of the PCB industry. From developing the scope of PCB prototypes to ensuring compliance at volume manufacturing, these standards make a tremendous impact on the development of high-quality, reliable and efficient electronics. Through the electronic design and production cycle, one needs to follow IPC standards for circuit boards to remain competitive in the business and deliver electronic products that the market needs.

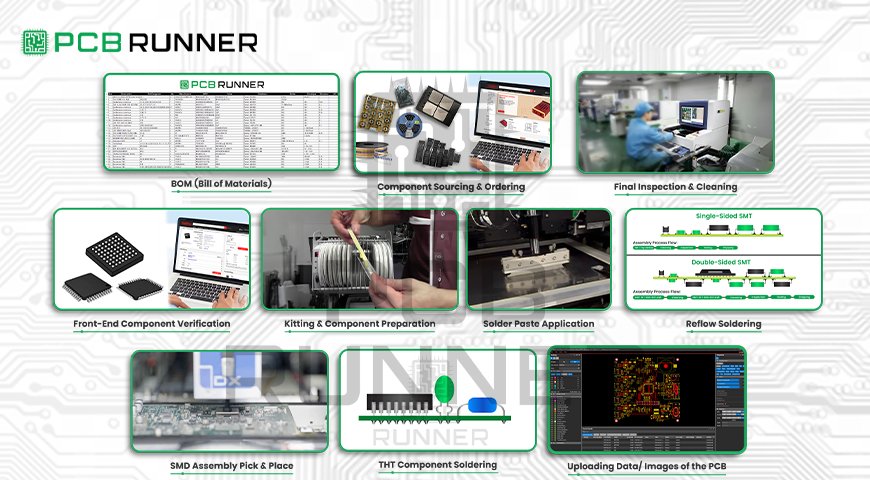

The electronics industry is being forced to adopt new standards because of increased competition and changing market dynamics. Embrace IPC standards with PCB Runners to ensure that new products developed will be reliable, efficient, and environmentally friendly.