If you’ve ever opened up a remote, a toy, or even a laptop, you’ve probably seen a green or blue board with lots of tiny parts on it. That’s a circuit board. And all those little parts? They each have an essential job.

Understanding what these parts are and what they do can help you fix electronics, build your own devices, or simply understand how things work. If you ever work with a PCB board manufacturer or one of the top PCB manufacturers, this knowledge will make things easier.

Let’s look at the parts of a circuit board in a simple, straightforward way.

What Is a PCB?

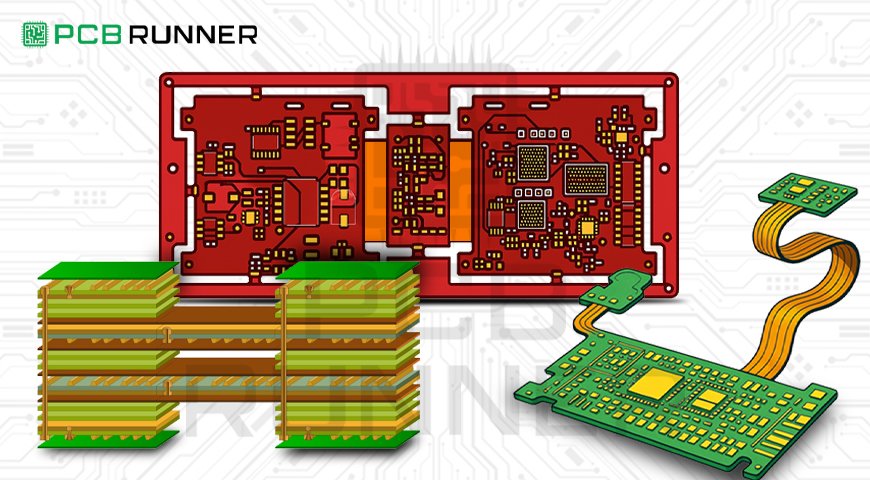

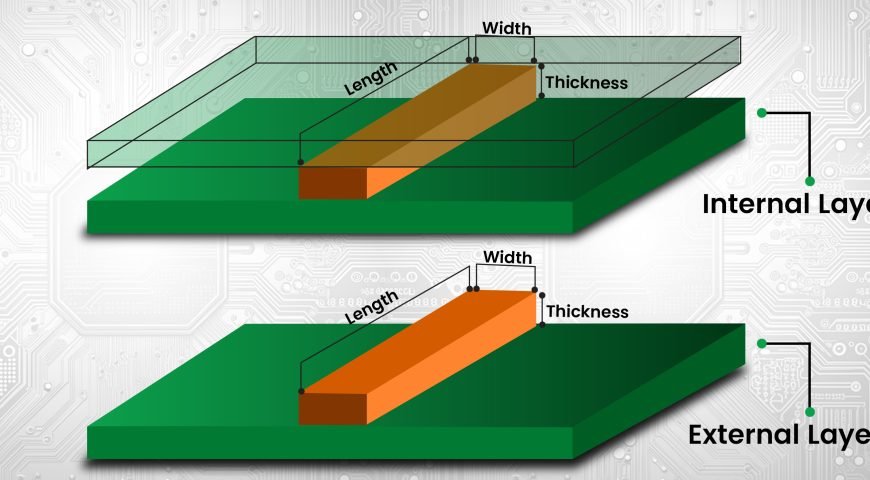

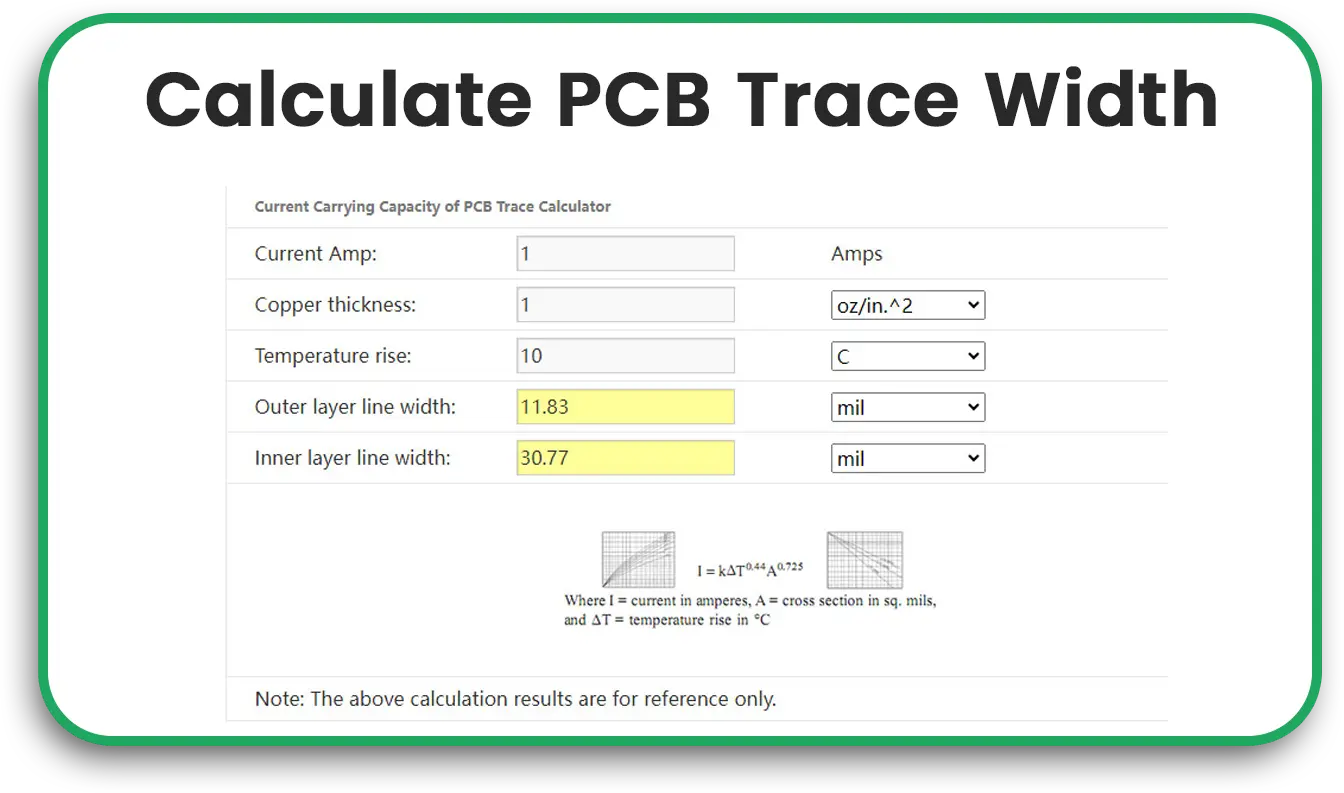

PCB stands for Printed Circuit Board. It holds the electronic parts in one place and connects them with copper lines. These copper lines carry electricity between the parts, kind of like roads.

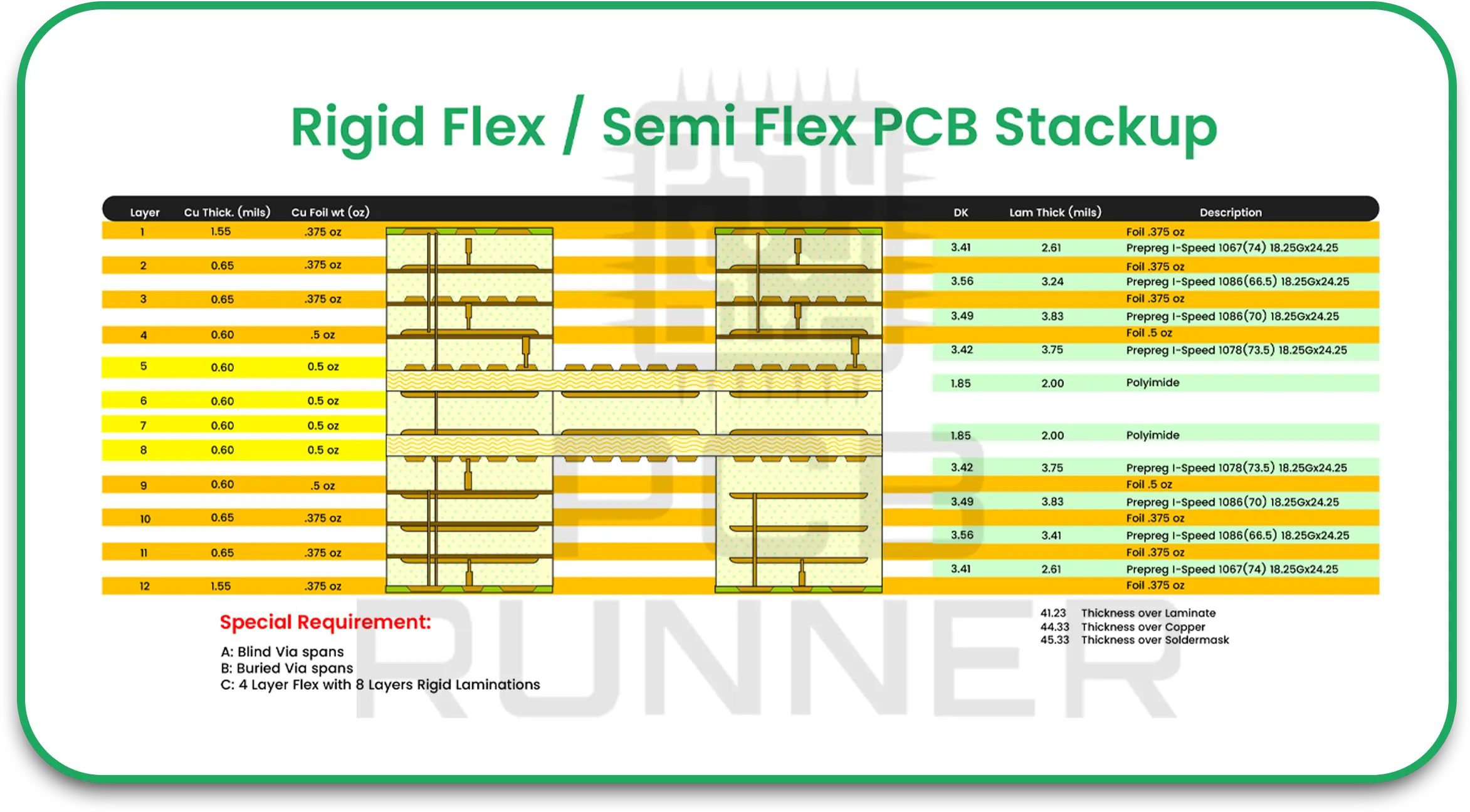

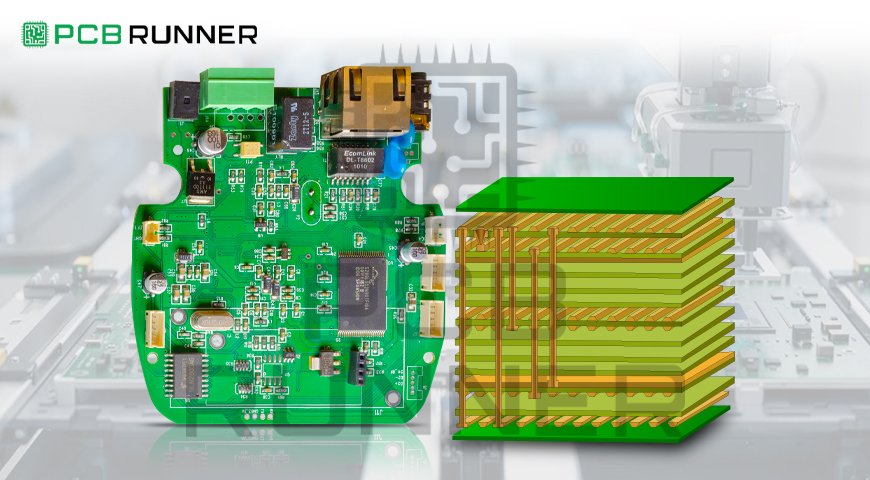

Some boards are simple, with just one layer. Others are complex, with many layers. These are called multilayer printed circuit boards. No matter the type, all PCBs have certain parts in common.

Why You Should Know the Parts

If you’re working with a PCB board manufacturer, identifying the parts correctly helps avoid mistakes. You can:

- Explain your design better

- Catch errors early

- Save time during testing

- Pick the right parts

You also won’t feel lost when looking at a board made by PCB manufacturers.

Key Electronic Circuit Board Components

Here are the basic parts you’ll see on most PCBs:

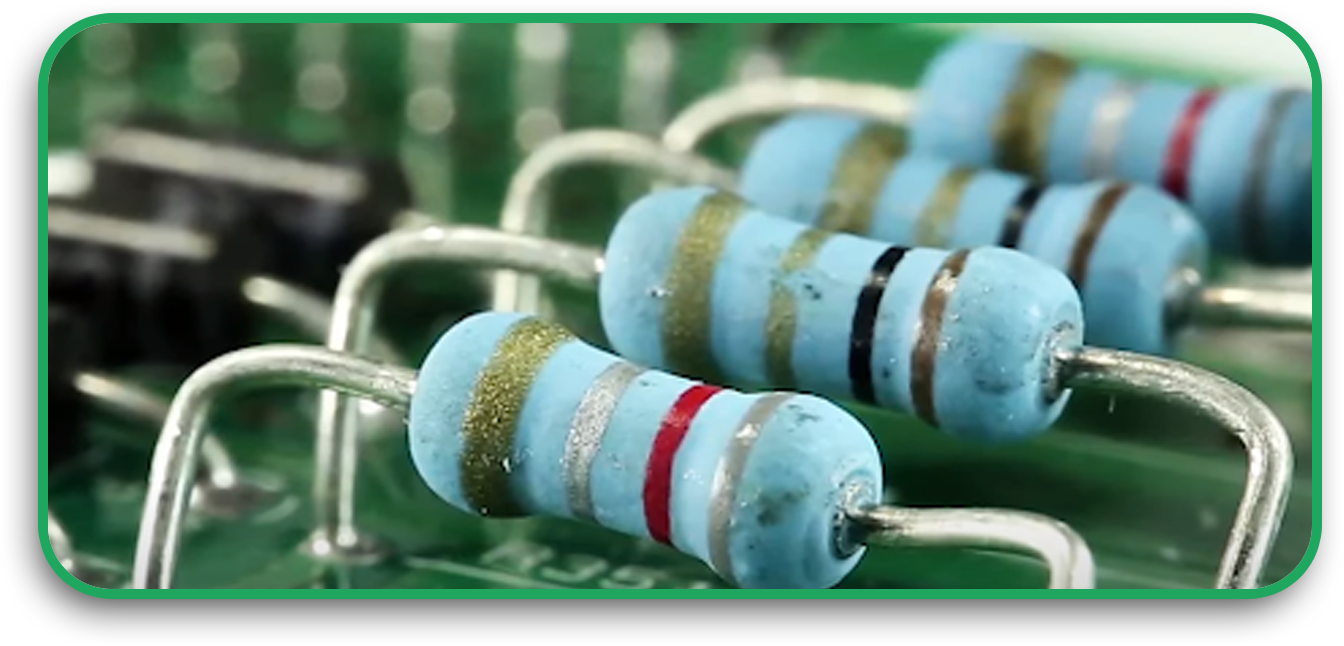

1. Resistors

- Control the amount of electrical current

- Look like tiny cylinders with coloured bands

- Often labelled with an “R” followed by a number (like R1, R2)

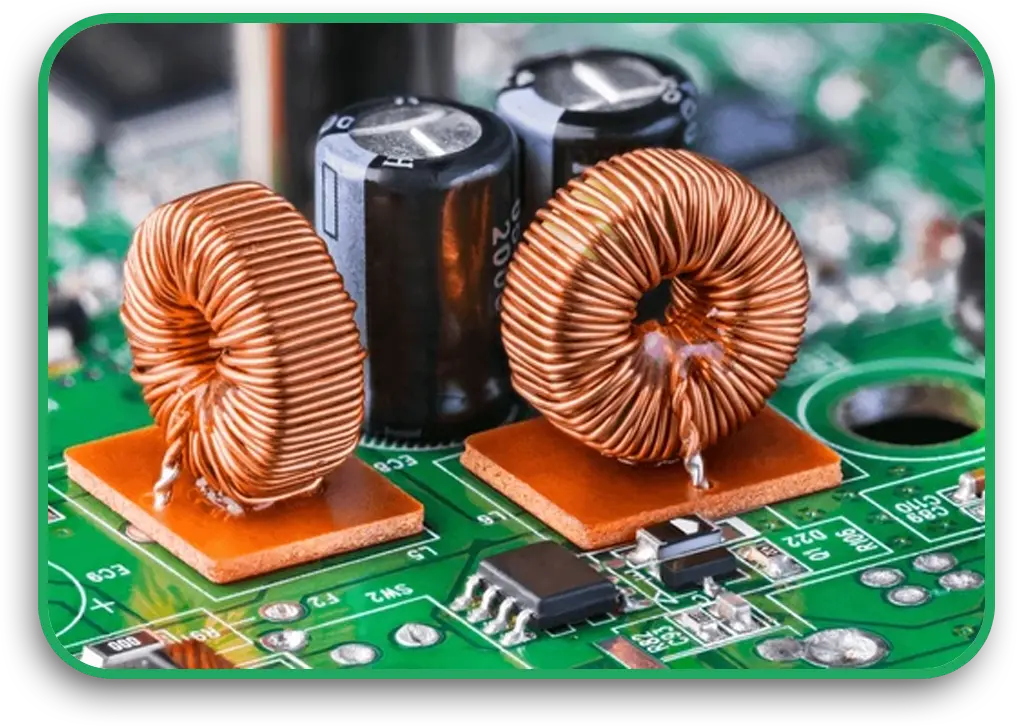

2. Capacitors

- Store and release energy quickly

- Look like small barrels or discs

- Labelled with a “C” and a number (C1, C2)

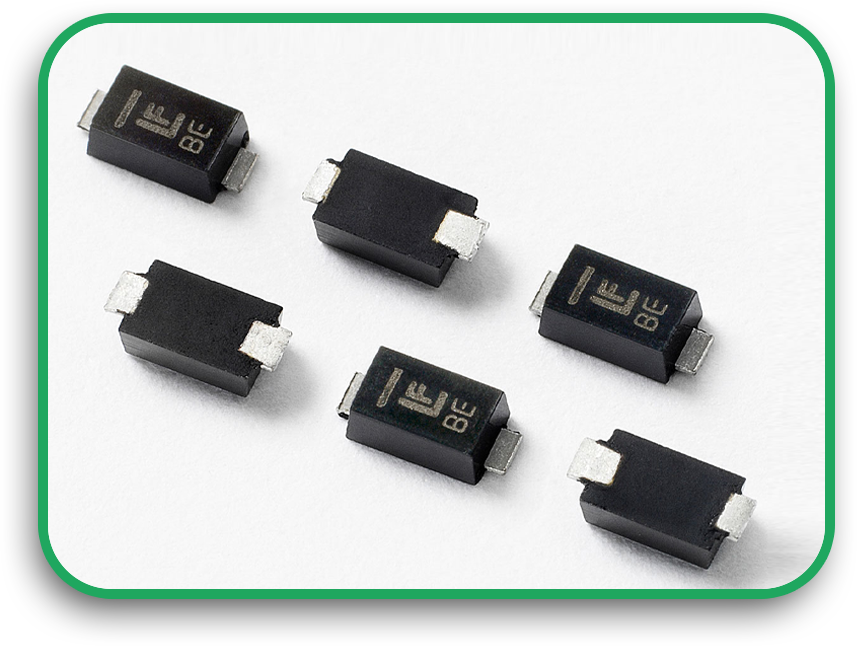

3. Diodes

- Let electricity flow one way only

- Look like small black cylinders with a silver stripe

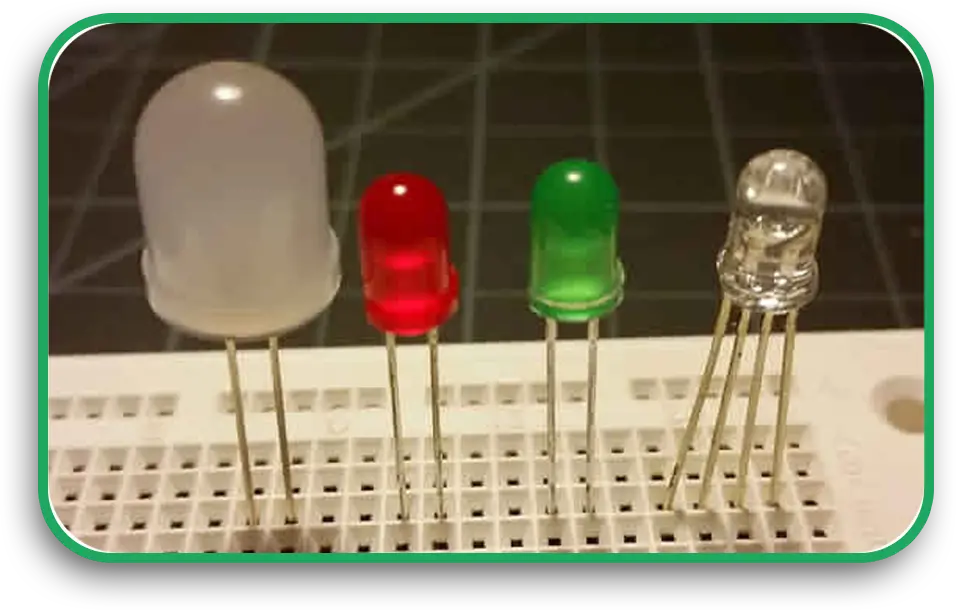

4. LEDs (Light Emitting Diodes)

- Small lights that glow when current flows

- Used as indicators (power on, charging, etc.)

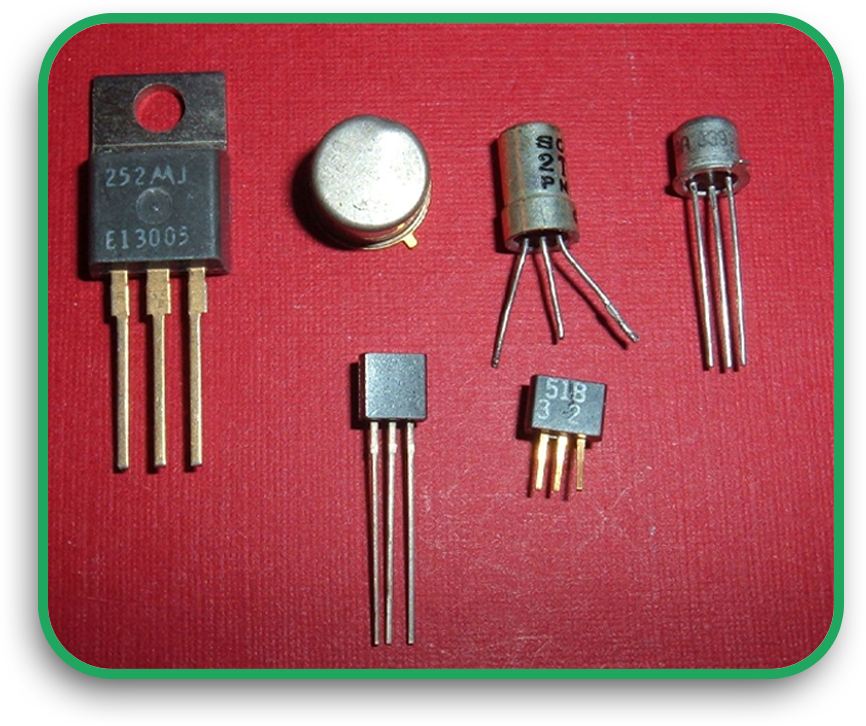

5. Transistors

- Control the flow of electricity like a switch

- It can also increase (amplify) signals

- Look like small black boxes with three legs

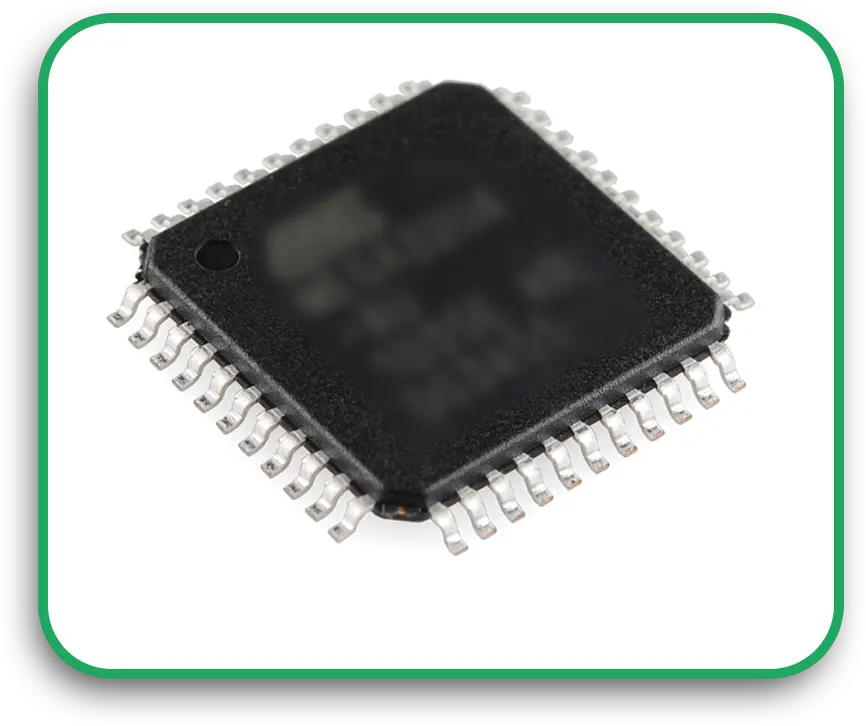

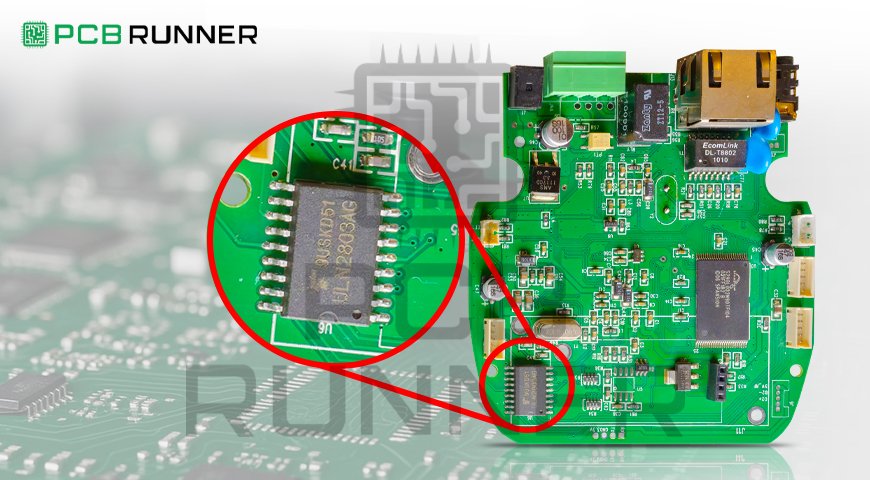

6. Integrated Circuits (ICs)

- Also called chips or microchips

- Do the real “thinking” or processing on the board

- Look like black rectangles with many legs

7. Connectors

- Allow the board to connect with power or other boards

- Look like plastic blocks with metal holes or pins

8. Inductors

- Store energy using a magnetic field

- Look like wire coils or small blocks

Learning to Identify Components

Want to learn component identification? Try these steps:

- Look at the shape and number of legs

- Find the label on the board (like R1, C3, U2)

- Use a magnifying glass to check small parts

- Search for part images online or in datasheets

If you’re using a board from a pcb board manufacturer, you can ask for a parts list. This list will tell you exactly what each piece is.

Understanding Circuit Board Parts

Each part plays a key role. If one fails, the whole board might stop working. That’s why pc board manufacturers take care when placing and testing each part.

Even on a multilayer printed circuit board, the same basic parts are used. But the connections can run through different layers, which you can’t always see from the top.

If you’re fixing or designing boards, knowing where the parts are and what they do will help you spot problems fast.

Talking to PCB Manufacturers

When you work with pcb manufacturers, clear communication matters. If you know the parts by name, it’s easier to:

- Choose replacements if a part is too expensive or slow to ship

- Avoid putting parts in the wrong place

- Test boards more accurately

Most PCB board manufacturers use files like a bill of materials (BOM) and layout diagrams. These show what parts go where.

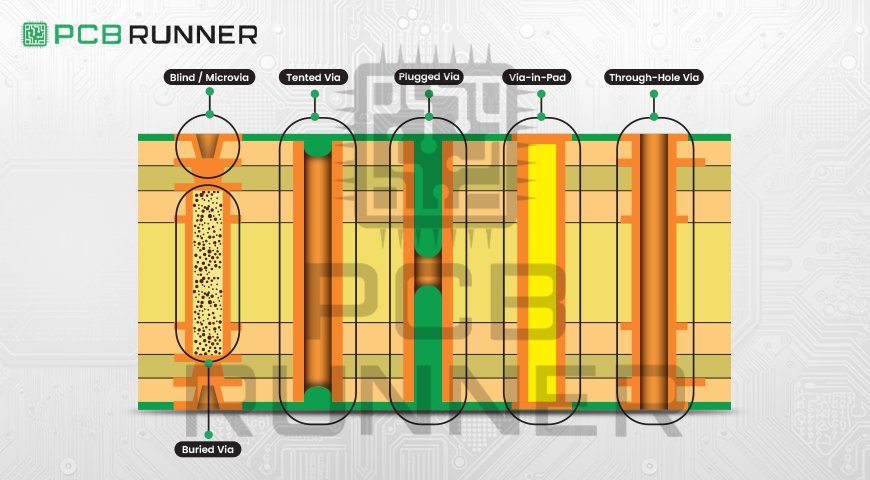

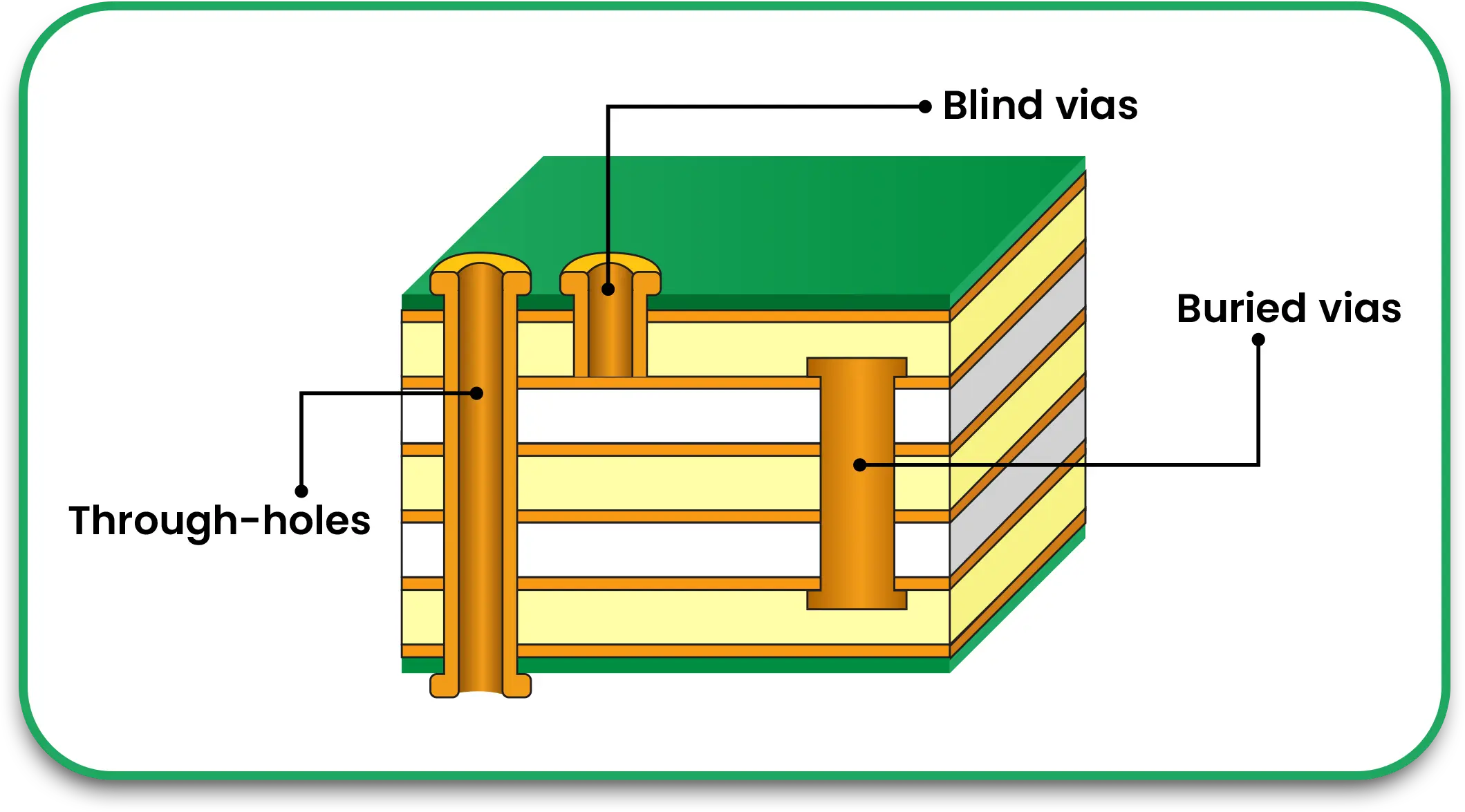

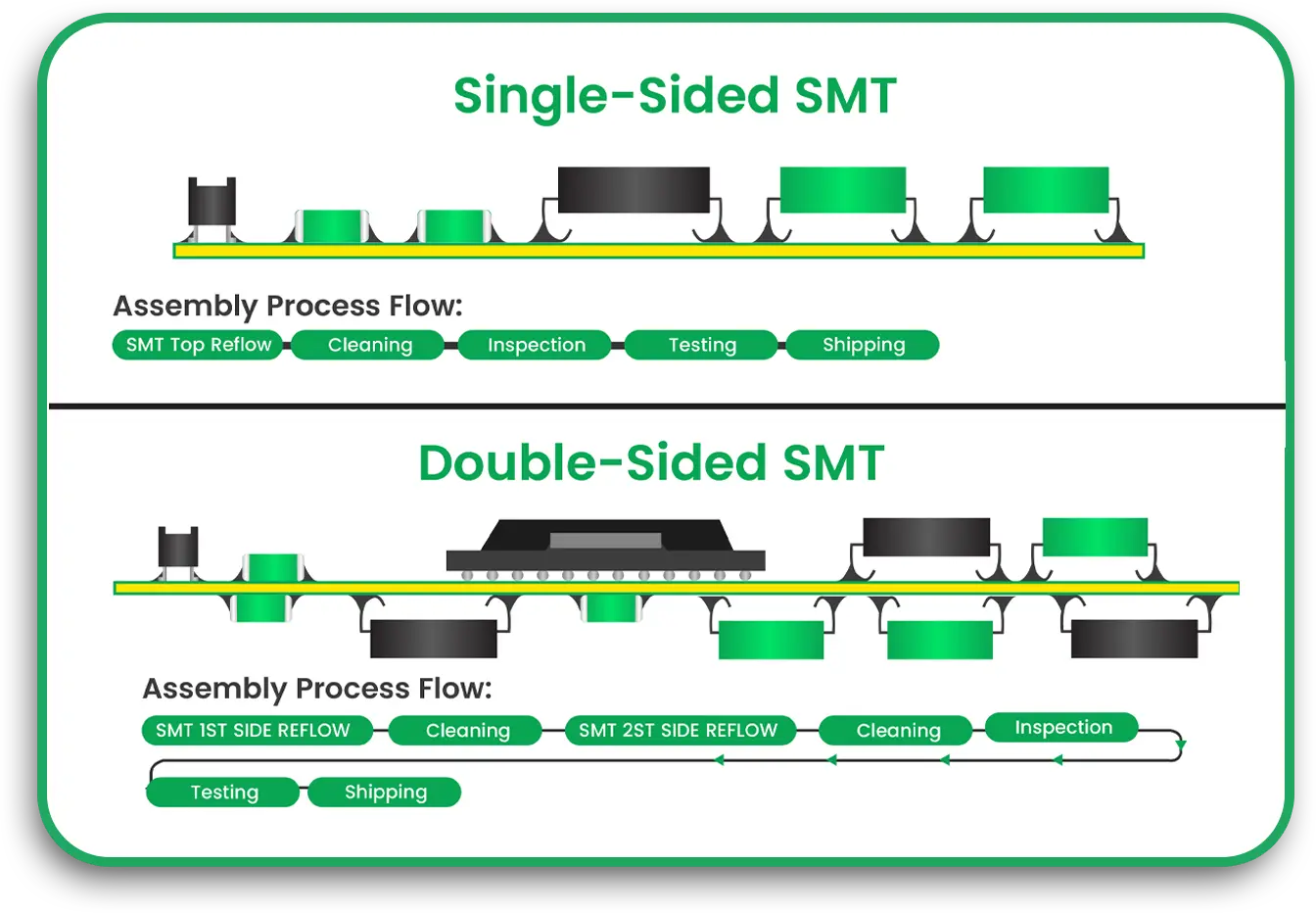

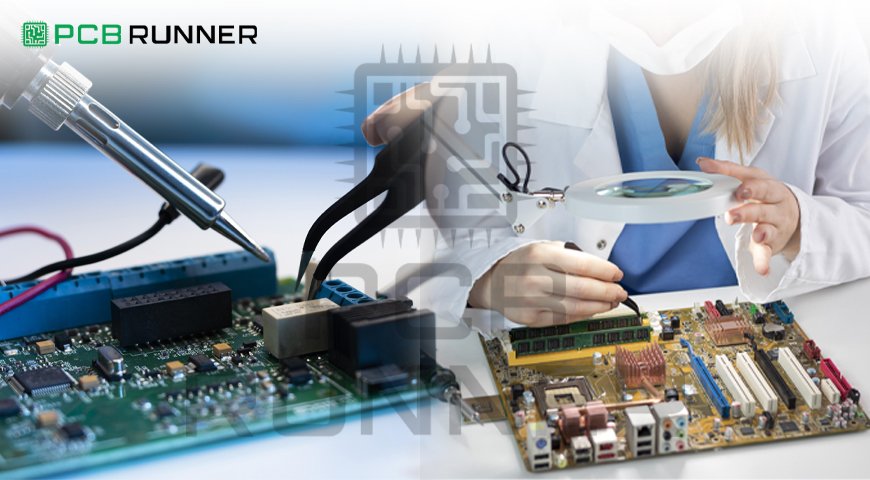

How PCB Components Are Assembled

Once the board is made, the parts are added. Some parts have legs that go through holes. These are called through-hole parts. Others sit flat on the surface. These are called surface-mount devices.

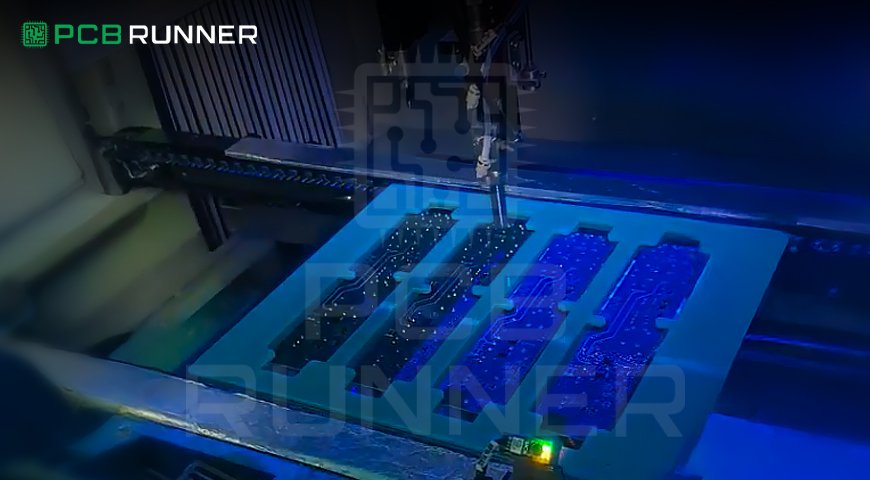

Most new boards use surface-mount parts. They’re smaller and cheaper. But they also need careful machines to place them right. That’s why choosing the right PCB manufacturers is essential.

When to Use Multilayer PCBs

Multilayer printed circuit boards are useful when your design is complex. For example:

- Phones

- Laptops

- Medical tools

They let you fit more connections in a small space. But they can also make tracing problems harder.

If you’re working with a PCB board manufacturer, ask them for a test report or an X-ray view of the inner layers.

Common Mistakes to Avoid

If you’re new to identifying circuit board parts, here are a few things to watch out for:

- Mixing up resistors and diodes

- Thinking all black chips are the same

- Skipping part labels

- Forgetting to check capacitor values

Even if a board looks simple, one missing part can stop everything. Always double-check.

Helpful Tools for Beginners

If you want to get better at component identification, try these:

- A digital multimeter (to measure resistance and voltage)

- A magnifier or microscope

- Free online PCB viewers

- Circuit board layout software

Some pc board manufacturers even provide test videos or 3D board previews. Ask for these if you’re ordering custom boards.

Final Thoughts

Knowing your electronic circuit board components gives you an edge. Whether you’re fixing a board, designing a new one, or working with a PCB board manufacturer, it helps to speak the same language.

Here’s a quick recap:

- Learn the shapes and jobs of each part

- Use part labels to guide your search

- Practice with real boards or kits

- Talk clearly with PCB manufacturers when designing or fixing

Start small, and don’t be afraid to ask questions. You’ll be surprised how fast you learn once you begin.

If you’re building your own design, choose experienced pc board manufacturers who understand your needs and can help you get the best results.

Need help with part sourcing or identifying parts on a damaged board? Reach out to a local PCB board manufacturer; many offer help for beginners.