The telecom world is changing fast. As 5G, IoT, and smart devices become part of daily life, the demand for better, faster, and more reliable telecom equipment is skyrocketing. But behind every smartphone, router, and cell tower is something you might not think about: the humble PCB. Printed circuit boards are the backbone of telecom technology, and how they’re made, and how quickly they move through the supply chain, can make or break your business. Let’s explore how smarter PCB manufacturing and supply chain strategies are powering growth in the telecom equipment market.

Why PCBs Matter in Telecom

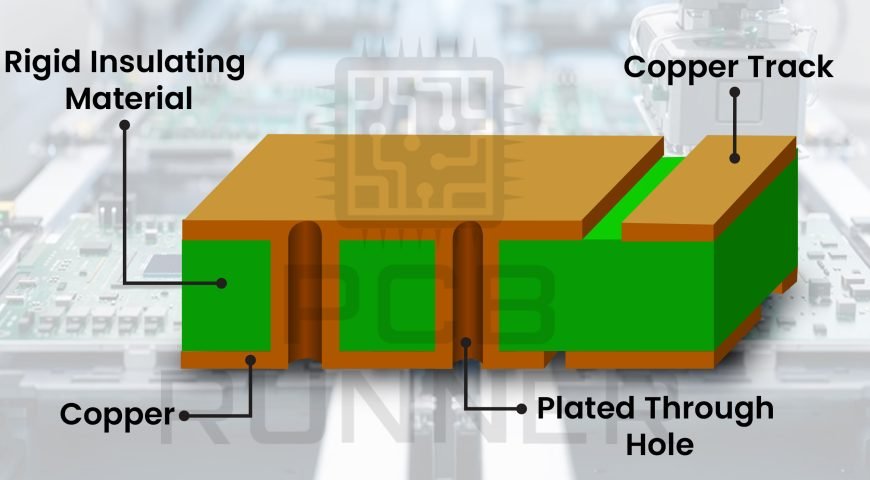

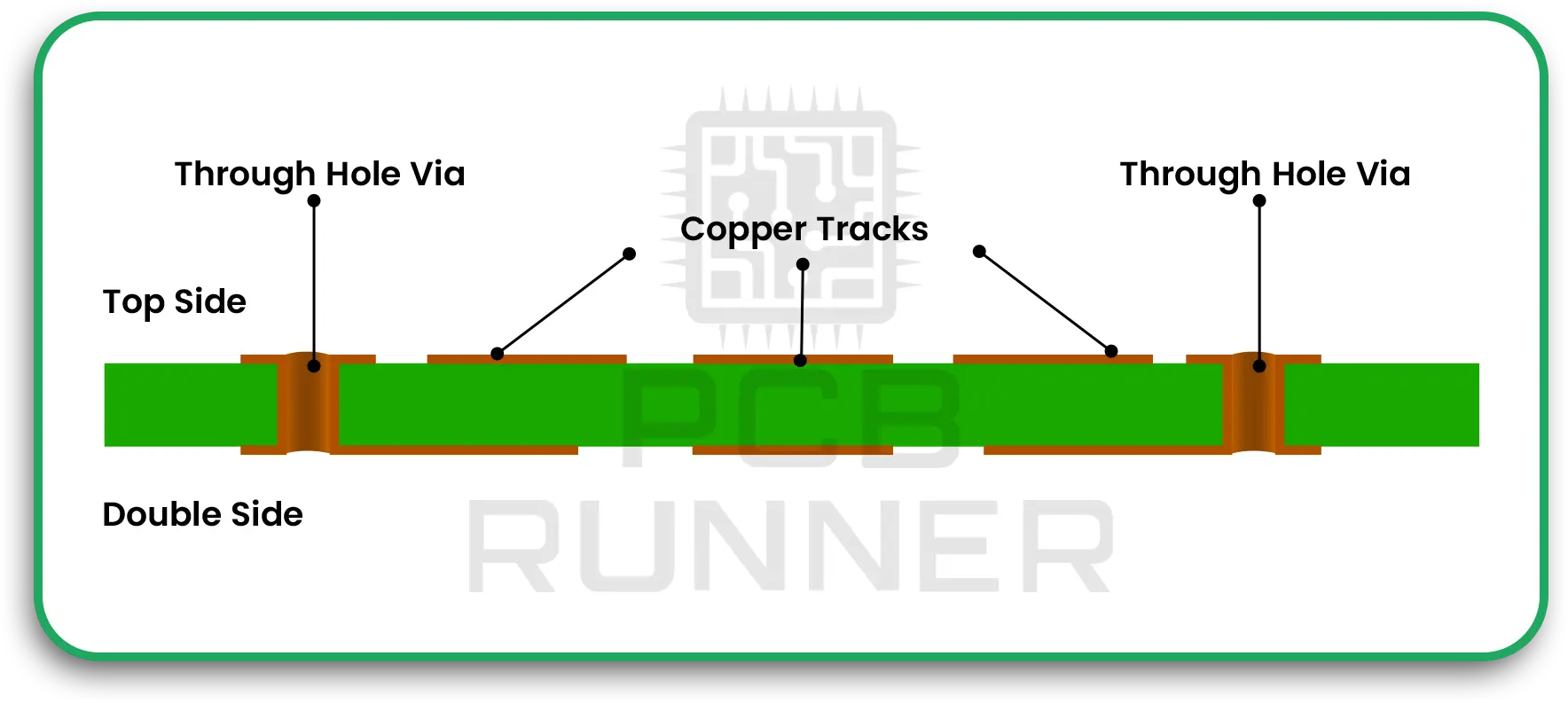

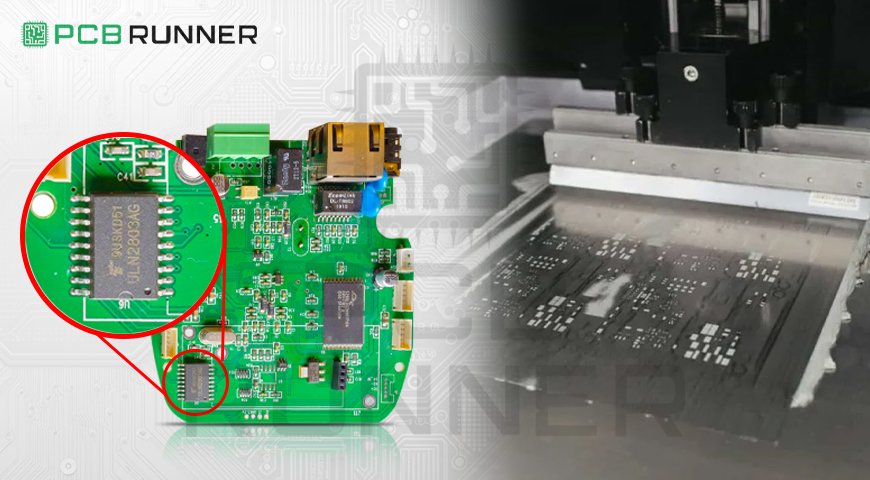

Every call, text, and video stream relies on a telecom pcb. These boards connect and control everything inside your devices, from antennas to processors. As telecom equipment gets more complex, the need for advanced PCB board components and custom PCB with components grows, too.

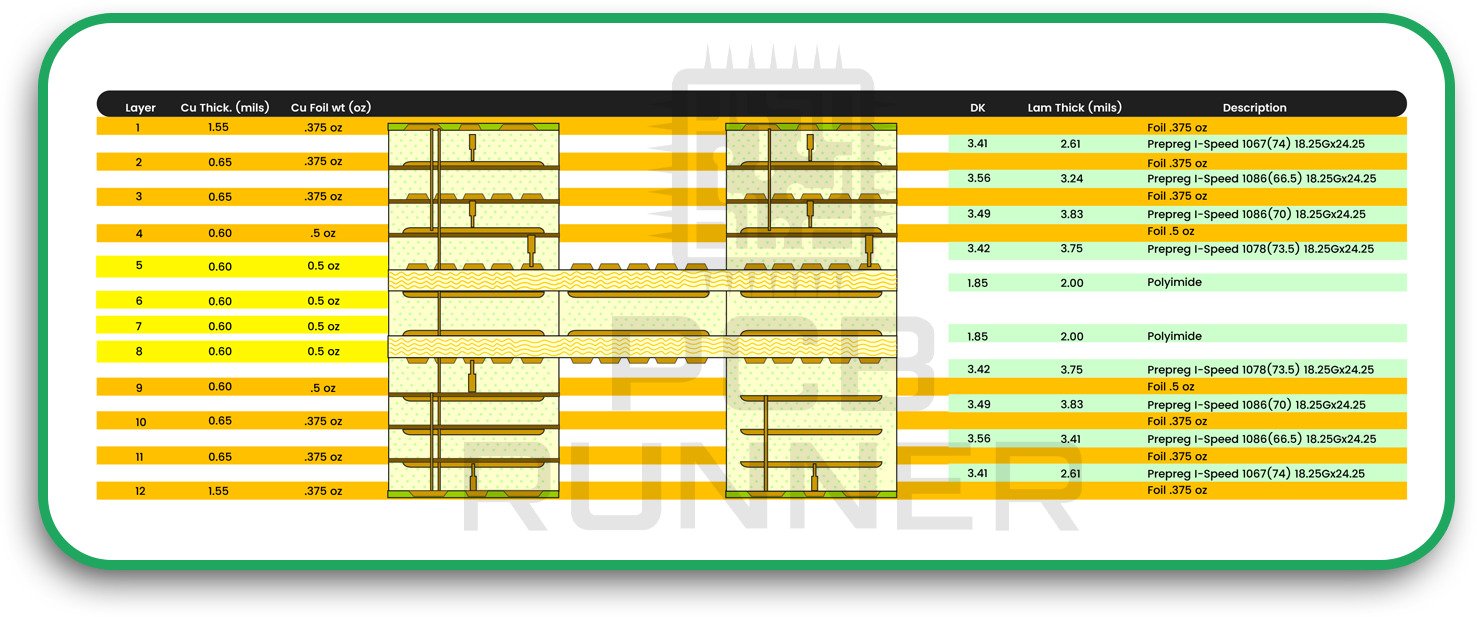

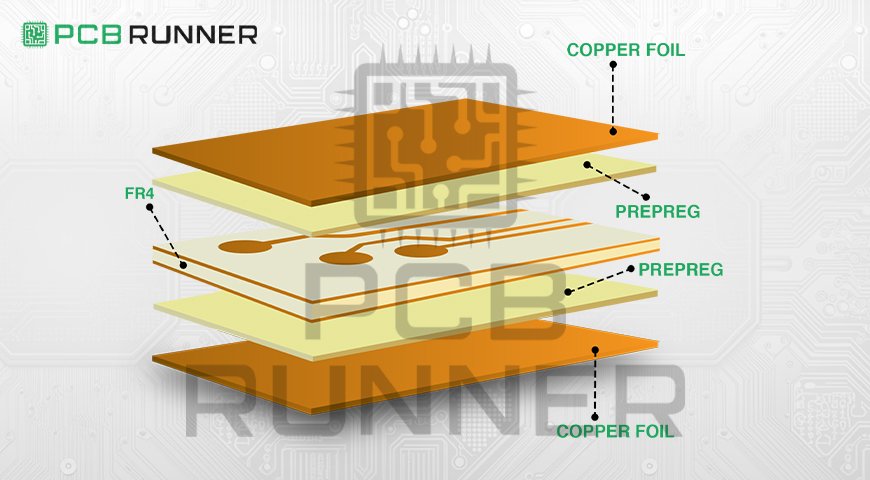

Today’s telecom PCB assembly isn’t just about putting parts on a board. It’s about building high-speed, high-frequency systems that can handle vast amounts of data. And with 5G rolling out worldwide, the bar is higher than ever.

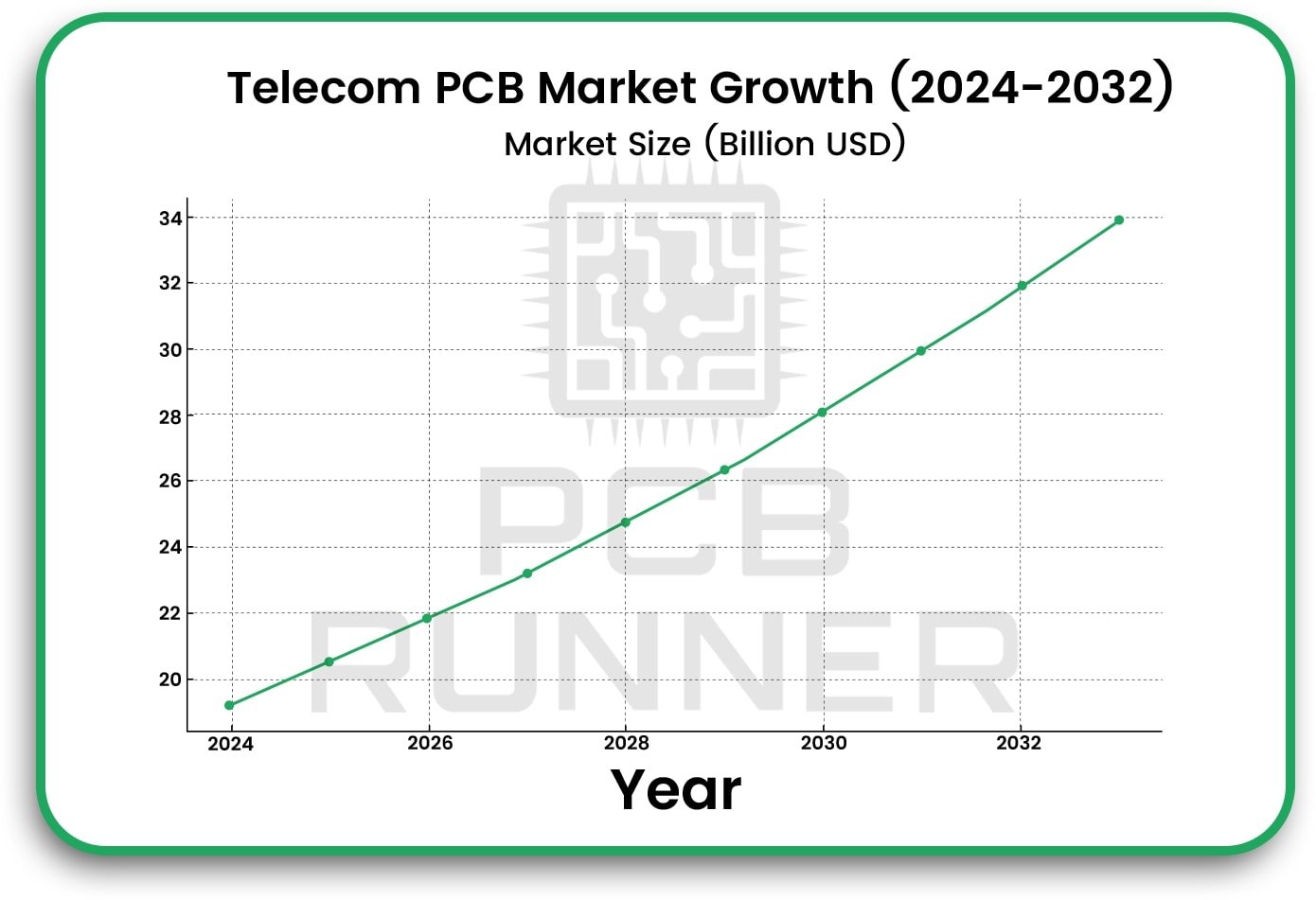

The Telecom Equipment Market: Growing Fast

The telecom equipment market is booming. According to recent reports, the telecommunications PCB market is set to grow from about $19.2 billion in 2024 to more than $32 billion by 2033, with a CAGR of 6.5%. That’s a big leap, driven by:

- The rollout of 5G networks

- More connected devices (think IoT, smart homes, and cars)

- The need for faster, more reliable data transfer

But growth brings challenges. Telecom companies need to deliver new products quickly, keep costs down, and make sure every device works perfectly. That’s where PCB manufacturing and supply chain efficiency come in.

PCB-Enabled Supply Chain Efficiencies: What Does It Mean?

When we talk about PCB-enabled supply chain efficiencies, we’re talking about every step from design to delivery. It’s about making sure your PCB production uk is fast, flexible, and ready to handle changes, without sacrificing quality.

Here’s how it works:

- Design for Manufacturability: Start with a PCB layout that’s easy to build and test. Fewer errors mean faster assembly and fewer delays.

- Local Production: Using PCB production, UK partners can cut shipping times and reduce the risk of global supply chain issues.

- Smart Sourcing: Work with suppliers who can deliver high-quality PCB component options quickly, even when demand spikes.

- Integrated Assembly: Choose partners who offer PCB printed circuit board assembly and telecom PCB assembly under one roof. This reduces hand-offs and speeds up delivery.

How PCB Supply Chain Efficiencies Accelerate Telecom Growth

Let’s break it down with real-world benefits:

1. Faster Time to Market

Telecom is a race. If you can launch your product before your competitors, you win more customers. Efficient PCB manufacture and assembly mean you can go from design to finished device in less time. That’s a significant edge in a crowded telecom marketing landscape.

2. Lower Costs

Every delay in the supply chain costs money. By streamlining pcb production uk and using fewer suppliers, you cut costs on shipping, storage, and rework. Plus, with local partners, you avoid the headaches of customs and long-distance logistics.

3. Better Quality and Fewer Failures

Mistakes in PCB board components or assembly can lead to device failures, and unhappy customers. Working with experienced telecom PCB assembly teams means fewer errors and more reliable products.

4. Flexibility When You Need It

The telecom equipment market changes fast. Maybe a new standard comes out, or a customer wants a custom PCB with components you haven’t used before. With a smart, flexible supply chain, you can adapt quickly, without missing a beat.

Trends Driving PCB Innovation in Telecom

The printed circuit board industry is not standing still. Here’s what’s shaping the future of telecom pcb:

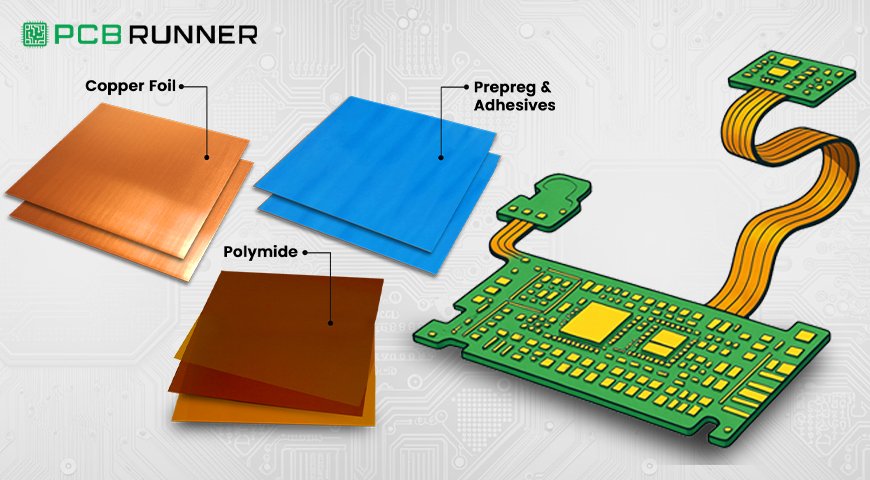

- Miniaturization: Devices are getting smaller, but expectations are getting bigger. Advanced PCB component choices and high-density layouts are the new normal1.

- High-Frequency Materials: 5G and beyond require PCBs that can handle higher speeds and more data4.

- Green Manufacturing: More companies are looking for eco-friendly pcb manufacture and recyclable materials1.

- Integrated Solutions: Telecom PCB assembly providers now offer everything from design to final testing, all in one place.

Actionable Tips for Telecom Companies

If you’re in the telecom business, here’s how you can use PCB-enabled supply chain efficiencies to your advantage:

- Work with local PCB production UK partners to cut lead times and improve communication.

- Choose assembly partners who specialize in telecom PCB assembly and understand your industry’s unique needs.

- Invest in design for manufacturability, get your engineers and PCB manufacturing teams talking early.

- Keep your supply chain flexible by having backup suppliers for key PCB component needs.

Monitor quality at every step, from incoming materials to final PCB printed circuit board assembly.

Final Thoughts

Telecom is all about speed, connection, and reliability. By focusing on PCB-enabled supply chain efficiencies, you can move faster, cut costs, and deliver the high-quality devices your customers expect. Whether you’re launching the next big thing in 5G or just looking to improve your current products, the right approach to PCB manufacture and assembly will help you stay ahead in the telecom equipment market.

Keep your supply chain smart, flexible, and focused on quality, and watch your business grow.

FAQs: Telecom PCBs and Supply Chain Efficiencies

1. Why is PCB manufacturing so important for telecom?

PCBs are the foundation of every telecom device. Fast, reliable manufacture means quicker launches and better products.

2. How does PCB production UK help with supply chain issues?

Local production cuts shipping times, avoids customs delays, and makes it easier to solve problems quickly.

3. What makes telecom PCB assembly different from other industries?

Telecom PCBs need to handle high speeds, lots of data, and demanding reliability standards. Assembly partners must have experience with these demands.

4. What are the key PCB board components in telecom devices?

Common components include processors, memory chips, power management ICs, and high-frequency connectors.

5. How can I make my supply chain more flexible?

Work with multiple suppliers, keep extra stock of critical PCB component parts and choose partners who can handle changes fast.

6. What’s the benefit of a custom pcb with components for telecom?

Custom PCBs allow you to design exactly what you need, improving device performance and reducing size.

7. How does supply chain efficiency impact telecom marketing?

Faster launches and better products help you stand out in the telecom marketing world, winning more customers.

8. What’s the outlook for the telecom equipment market?

With 5G, IoT, and smart devices growing fast, the telecom equipment market is set for strong growth in the next decade.